Pen and manufacturing method therefor

A manufacturing method and pen holder technology, which is applied in the repair of pen holders, ballpoint pens, ink pens, etc., can solve the problems of poor pen feel, non-environmental protection, and easy damage, and achieve the effects of strong environmental protection, low cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

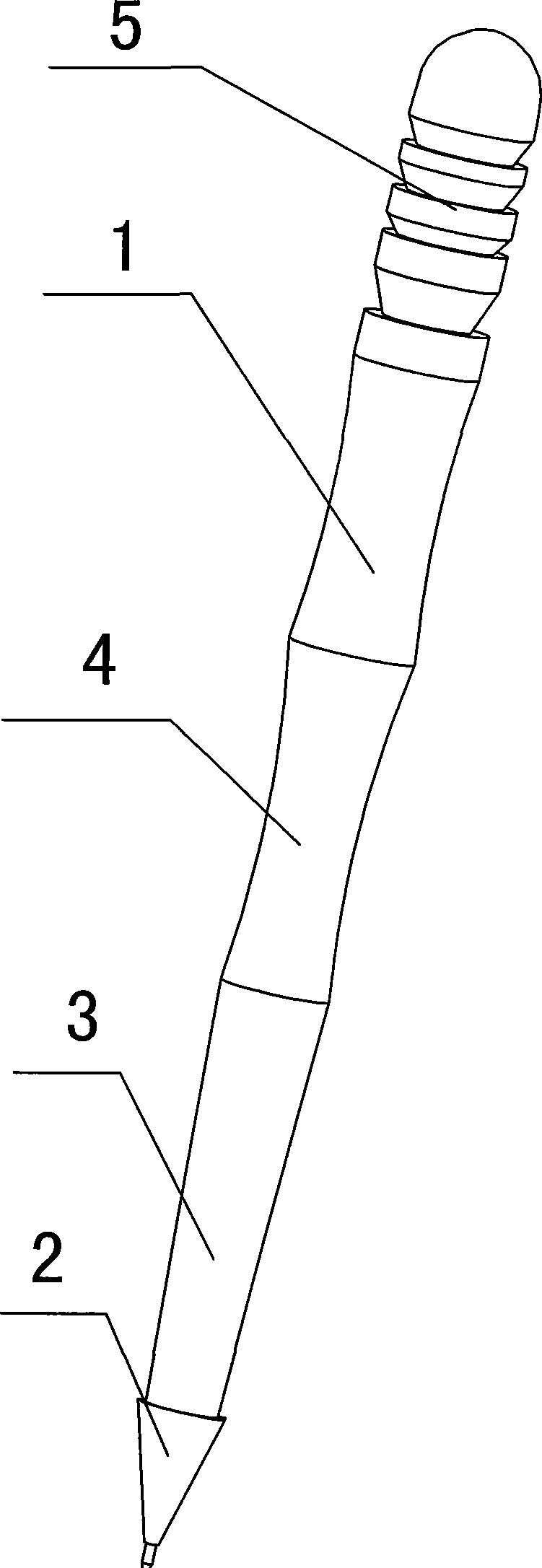

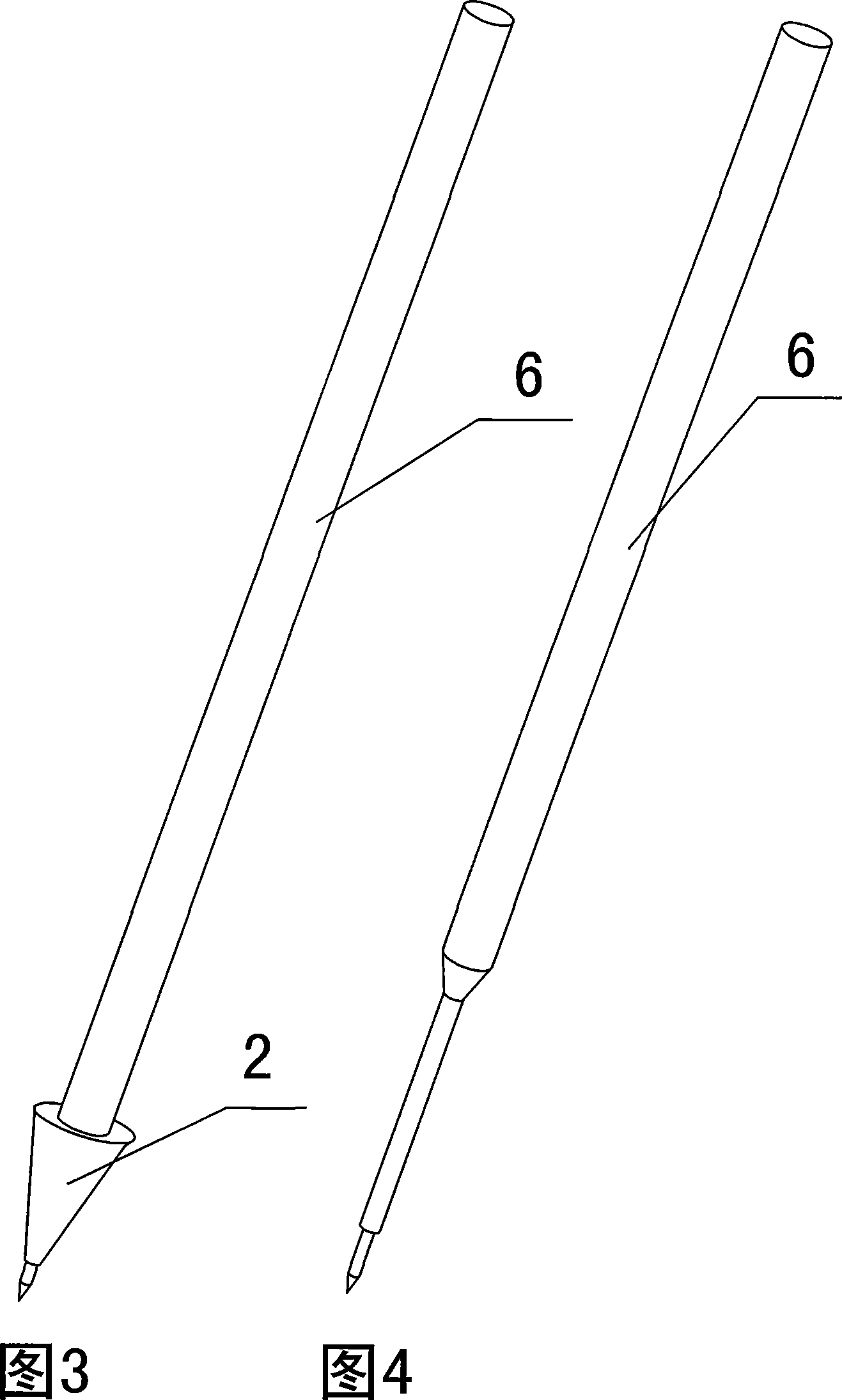

Embodiment 1

[0049] Embodiment 1: the pen core bottom type. In this embodiment, a pen center hole is drilled in the middle of the pen holder 1, and the pen center hole is a blind hole, and its opening is at the front end 3 of the pen holder, and the rear end of the pen holder is sealed. The refill used in the present embodiment is a special refill, the front end of the refill is a bullet-shaped nib 2, and the rear end is a cylindrical pen tube 6 for ink storage. Pen oil or ink is housed in the pen tube 6. In this embodiment, Among them, the pen core is inserted in the pen holder 1, and the diameter of the pen core hole in the middle of the pen holder 1 matches the diameter of the pen core, so that the pen core will not come out when inserted into the pen core hole. Since the core of the pen and the pen holder 1 are connected by plugging, in this embodiment, the section of the nib 2 at the front end of the core of the pen is elliptical, and the minor axis of the ellipse is the same as the s...

Embodiment 2

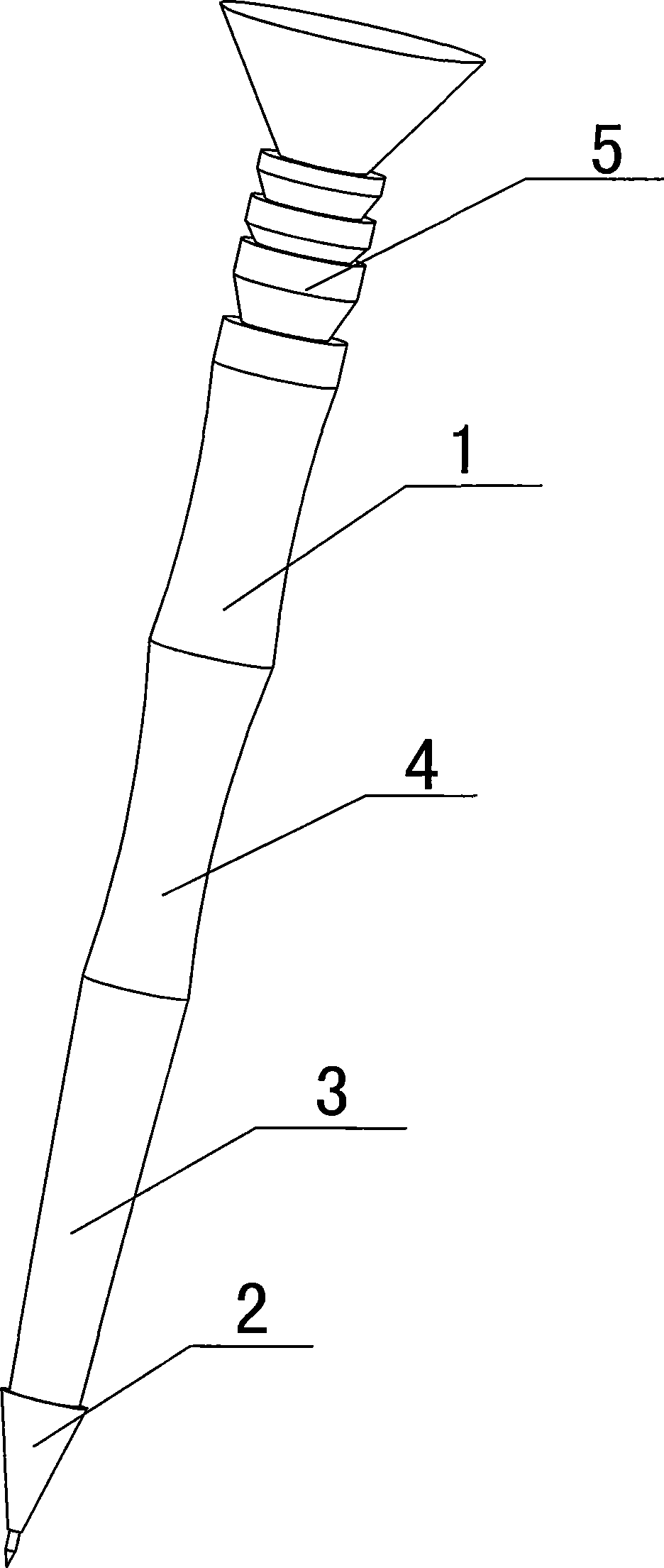

[0050]Embodiment two: the top-mounted type of refill. In this embodiment, a pen center hole is drilled in the middle of the pen holder 1, and the pen center hole runs through the pen holder 1. The front end 3 of the pen holder is made into a bullet-shaped nib 2 during manufacture, and the nib 2 and the pen holder 1 are integrated. In this embodiment, the diameter of the pen core hole near the front end of the pen holder is smaller, and the diameter of the pen core hole near the rear end of the pen holder is larger in a stepped shape. The inside of the core hole is provided with an internal thread near the rear end of the penholder, and a rear nib 7 is installed at the internal thread, and an external thread is provided on the rear nib 7, and the rear nib 7 is connected with the penholder 1 by threads. The refill used in this embodiment is a special refill that matches the shape of the refill hole in the penholder 1 . After the pen core is inserted into the pen core hole, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com