Stressed-skin construction capable of implementing large area deformation

A large-area skinning technology, applied in the field of aircraft skinning, can solve problems such as limited deformability, increased resistance to skeleton deformation, and difficulty in co-deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

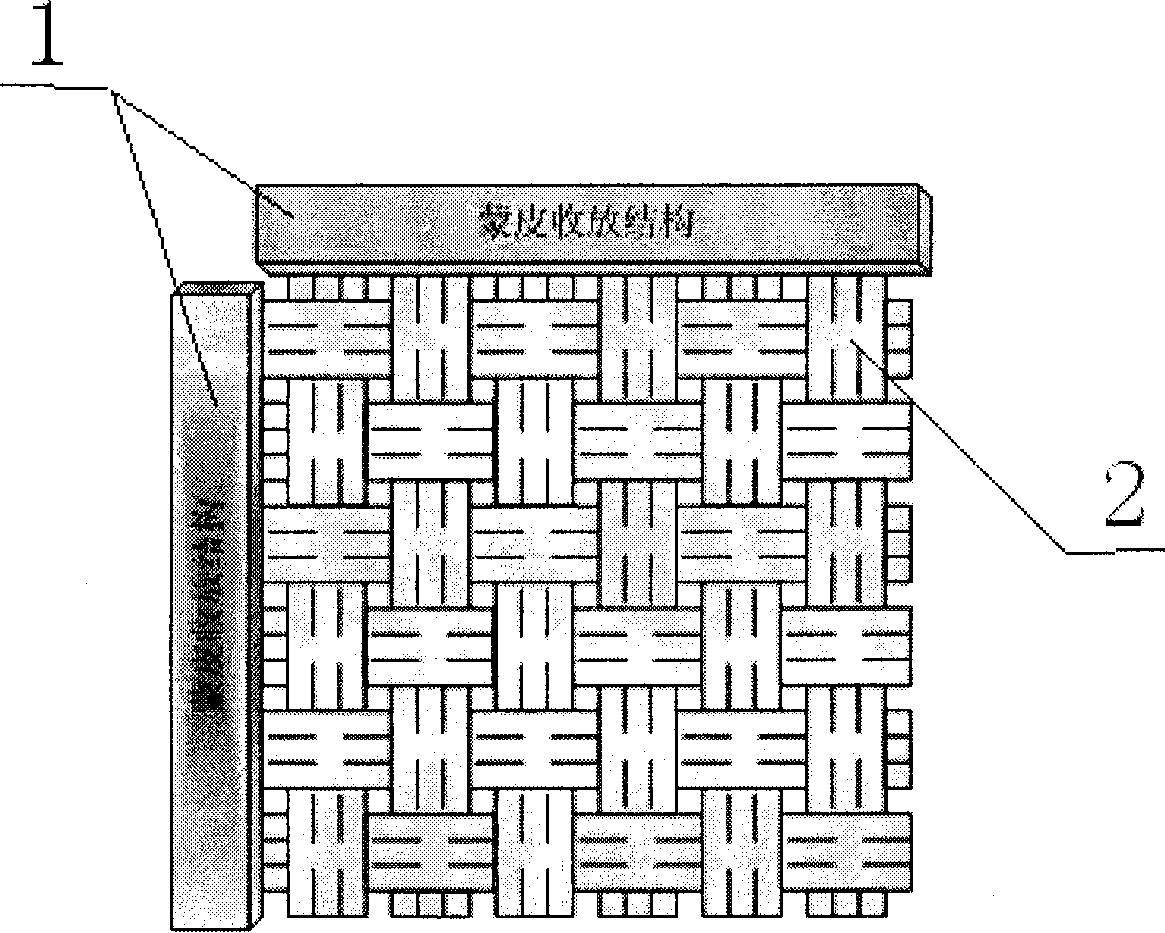

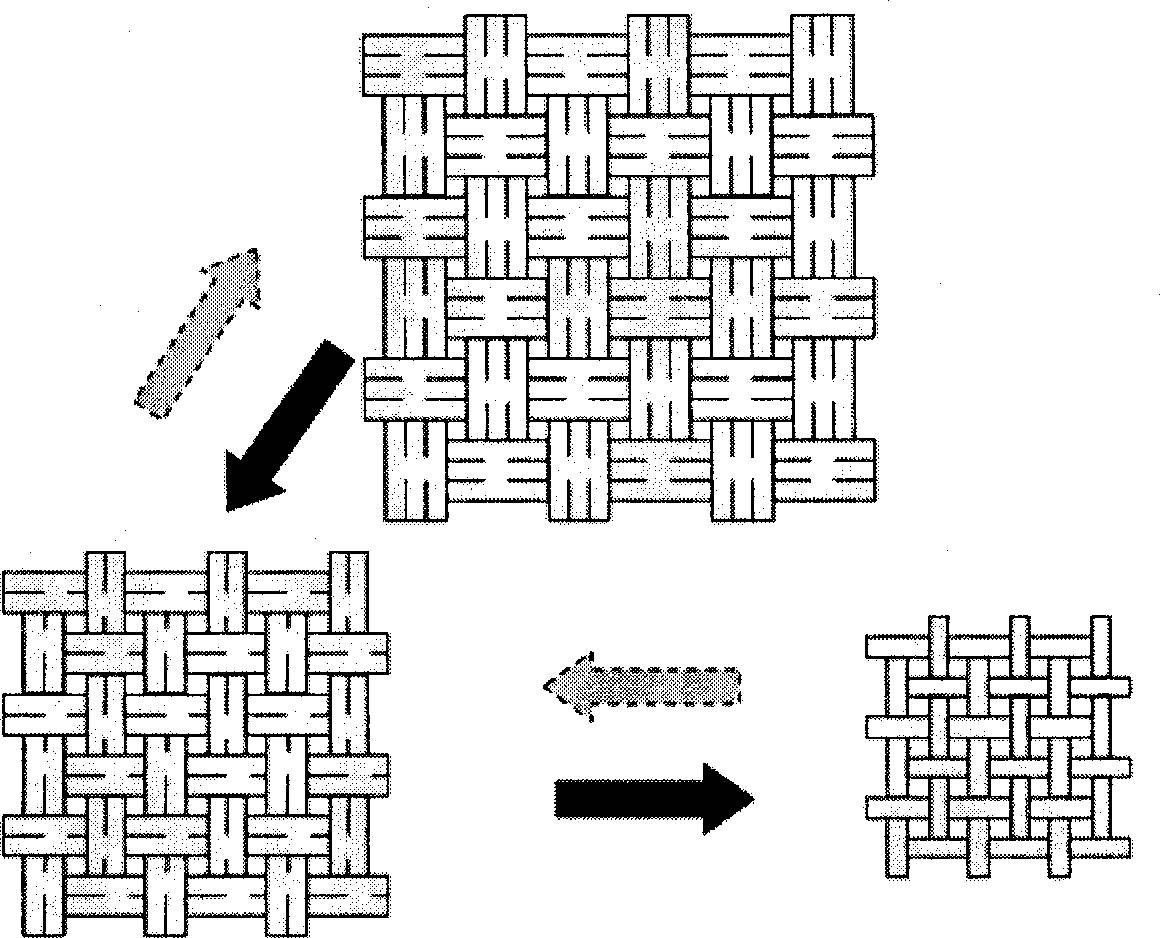

[0019] to combine figure 2 , the present embodiment is composed of skin overlapping structures 2 grid-like weaving, each skin overlapping structure 2 is close to no gap, and the side of the skin overlapping structure 2 is provided with a skin retractable structure 1. The skin overlapping structure is composed of a single skin overlapping, which is a multi-layer slideway structure and makes the multi-layer flexible skin completely overlap into one layer; the skin retractable structure is that the skin can be rolled in and out of the retractable structure, including rollers and the skin storage compartment, the skin overlapping structure connects the rollers.

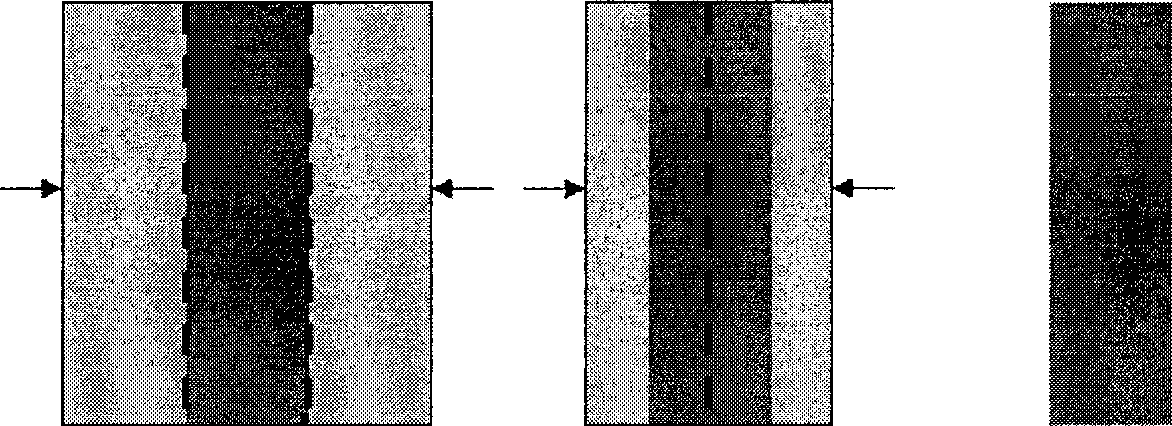

[0020] In this embodiment, in order to realize large-area deformation, a braided structure is used to realize it. When the wing area needs to change greatly, this change is often in two direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com