Halogen-free flame-proof panlite composition

A polycarbonate resin, flame retardant technology, applied in the field of flame retardants, can solve the problem that halogen flame retardants cannot meet ECO environmental protection standards, and achieve the effects of free color performance, high flame retardancy, and reduced physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

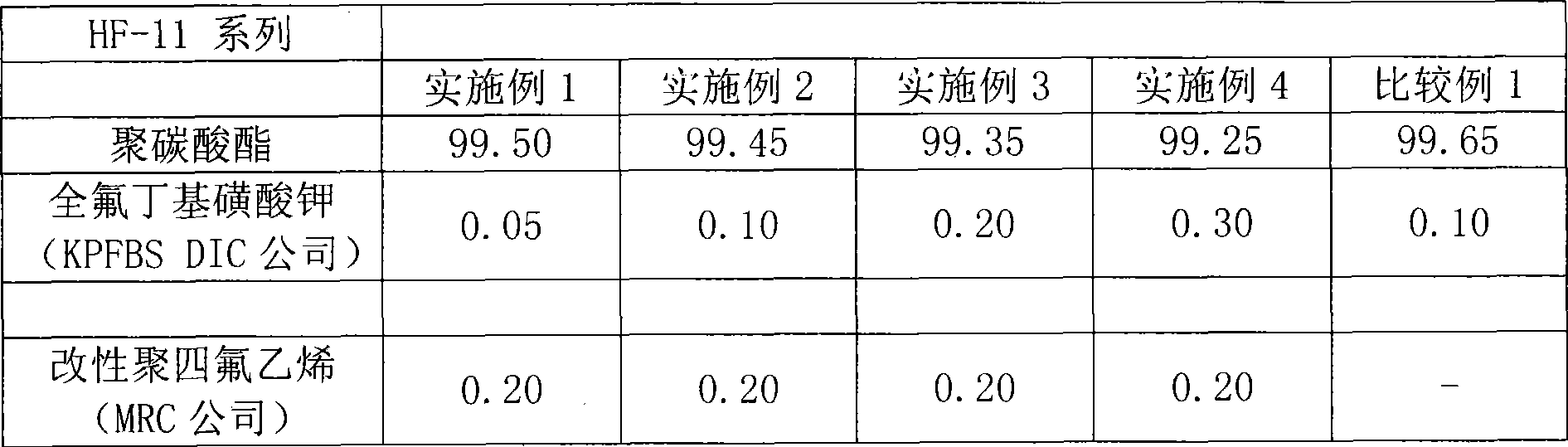

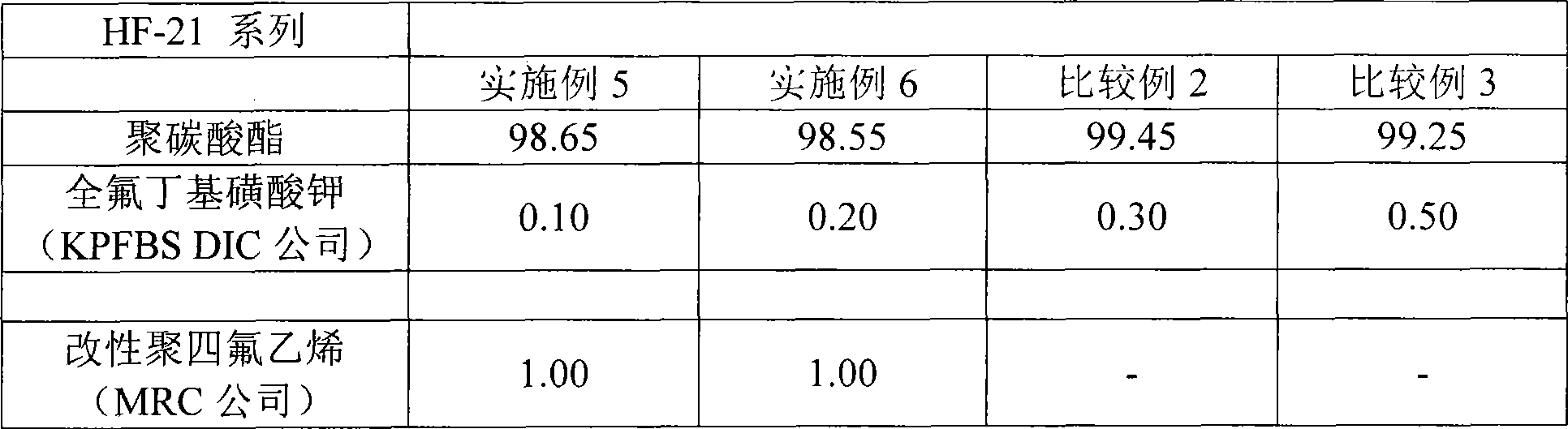

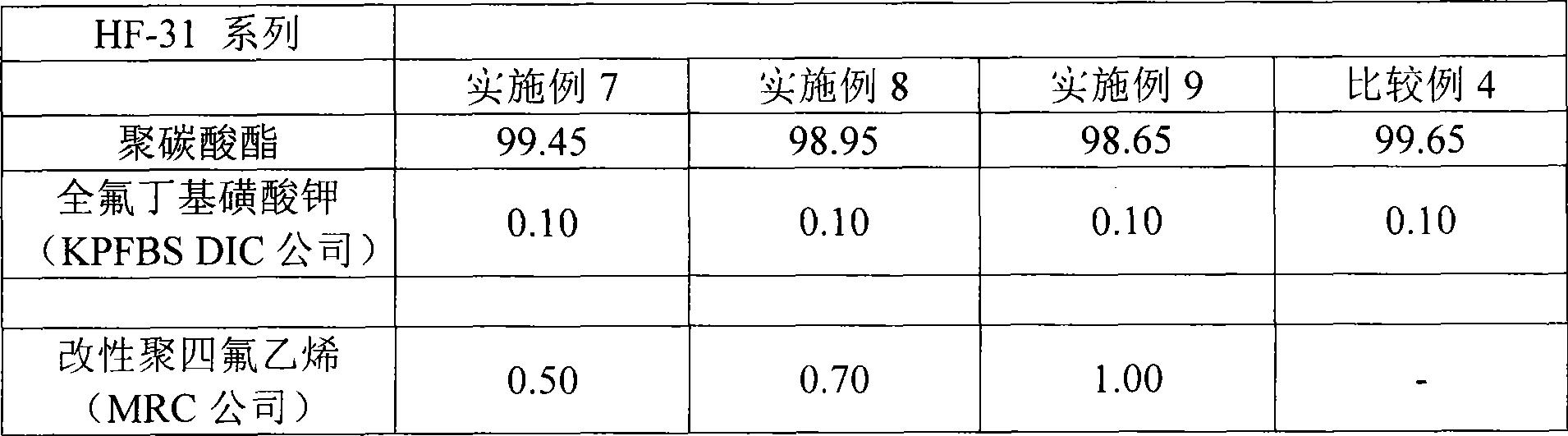

[0030] According to the composition and content ratio of Table 1 to Table 3, use a high-speed mixer (SuperMixer) to mix evenly, and use a program file (process file) to use a twin screw extruder (twin screw extruder) at a temperature of 250 to 290 ° C. out of the shape, and then cut into pellets (pellet). Granular (Pellet) samples are injection molded at a temperature of about 280-300°C, and fully conditioned at room temperature to produce test pieces. The physical properties of the test pieces were measured by the following methods, and the results are listed in Tables 1-3. In addition, known additives may be added as mentioned above, and the usage amount is 0.25 wt% relative to the total weight of the composition.

[0031] For the purpose of evaluating the flame retardancy of the above-mentioned test pieces, polycarbonate resin compositions were extruded according to different contents of potassium perfluorobutane sulfonate and acrylic modified polytetrafluoroethylene, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com