adhesive composition

A composition and adhesive technology, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve problems such as equipment blockage, improve equipment blockage, improve antistatic properties, and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the copolymer is not particularly limited, and can be prepared by methods such as bulk polymerization, solution polymerization, emulsification polymerization or suspension polymerization commonly used in the art, preferably solution polymerization. In addition, when performing polymerization, generally used solvents, polymerization initiators, chain transfer agents for controlling molecular weight, and the like can be used.

[0040] The copolymer has a weight average molecular weight (in terms of polystyrene, Mw) measured by gel permeation chromatography (Gel permeation chromatography, GPC) of 5 to 2 million, preferably 400 to 2 million. When the weight-average molecular weight is less than 50,000, the cohesive force between the copolymers is low, which may cause problems in adhesion durability. When the weight-average molecular weight exceeds 2 million, in order to ensure Due to process nature, a large amount of diluent solvent may be required...

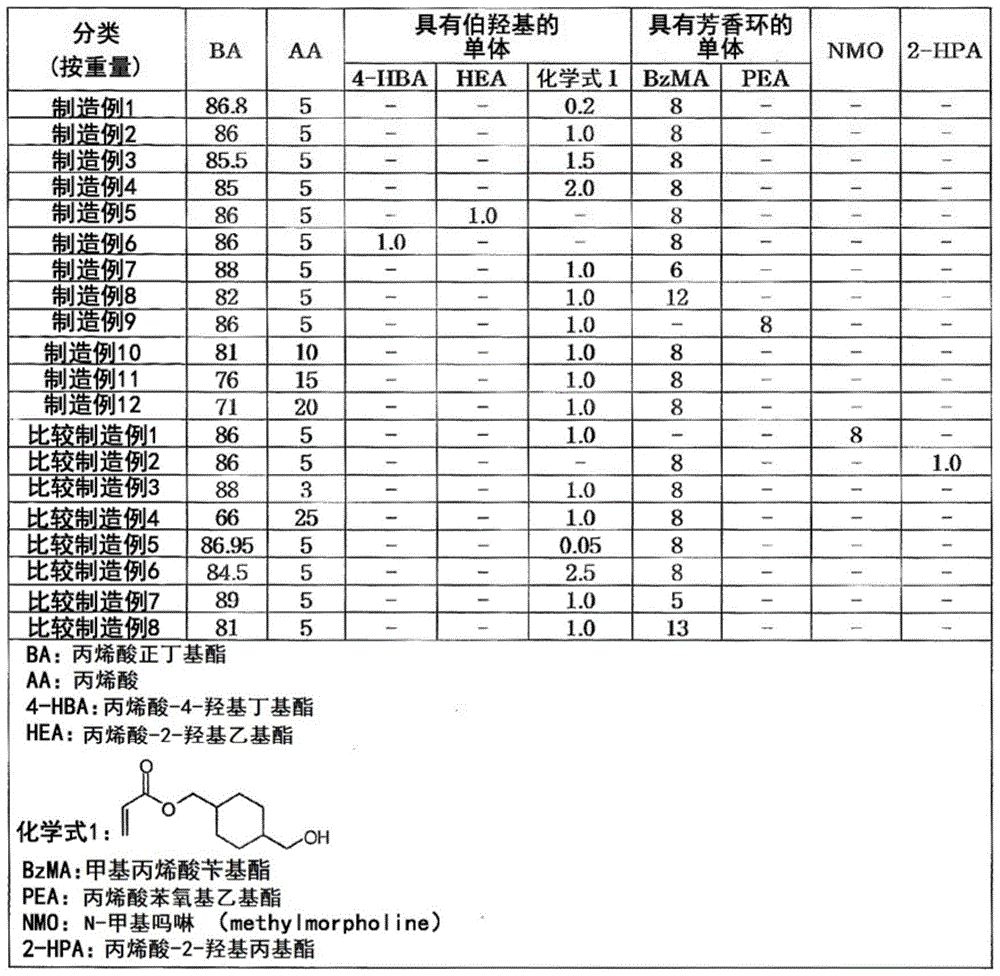

preparation example 1-12 and comparative preparation example 1-8

[0056] Into a 1 L reactor equipped with a cooling device so that nitrogen gas can be refluxed and the temperature can be easily adjusted, a monomer mixture composed of the composition in Table 1 below was added, and then 100 parts by weight of ethyl acetate as a solvent was added. ester. Next, nitrogen was purged for 1 hour to remove oxygen, and the temperature was maintained at 78°C thereafter. The above mixture was uniformly mixed, then, 0.03 parts by weight of azobisisobutyronitrile (AIBN) was added as a reaction initiator, and the reaction was carried out for 8 hours to prepare an acrylic copolymer having a weight average molecular weight of about 730,000.

[0057] [Table 1]

[0058]

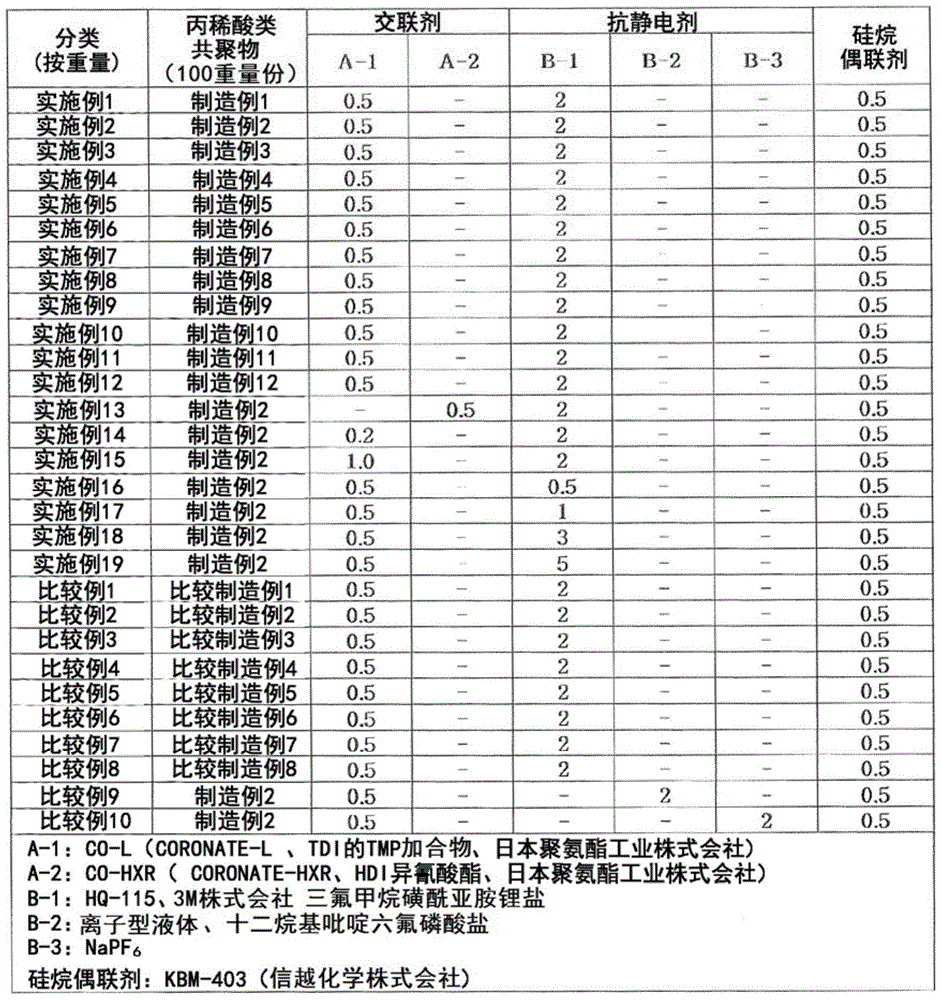

Embodiment 1-19 and comparative example 1-10

[0060] As shown in Table 2 below, after mixing the acrylic copolymer, ionic antistatic agent, crosslinking agent and silane coupling agent, dilute it with ethyl acetate to prepare an adhesive combination with a solid content concentration of 15%. things.

[0061] [Table 2]

[0062]

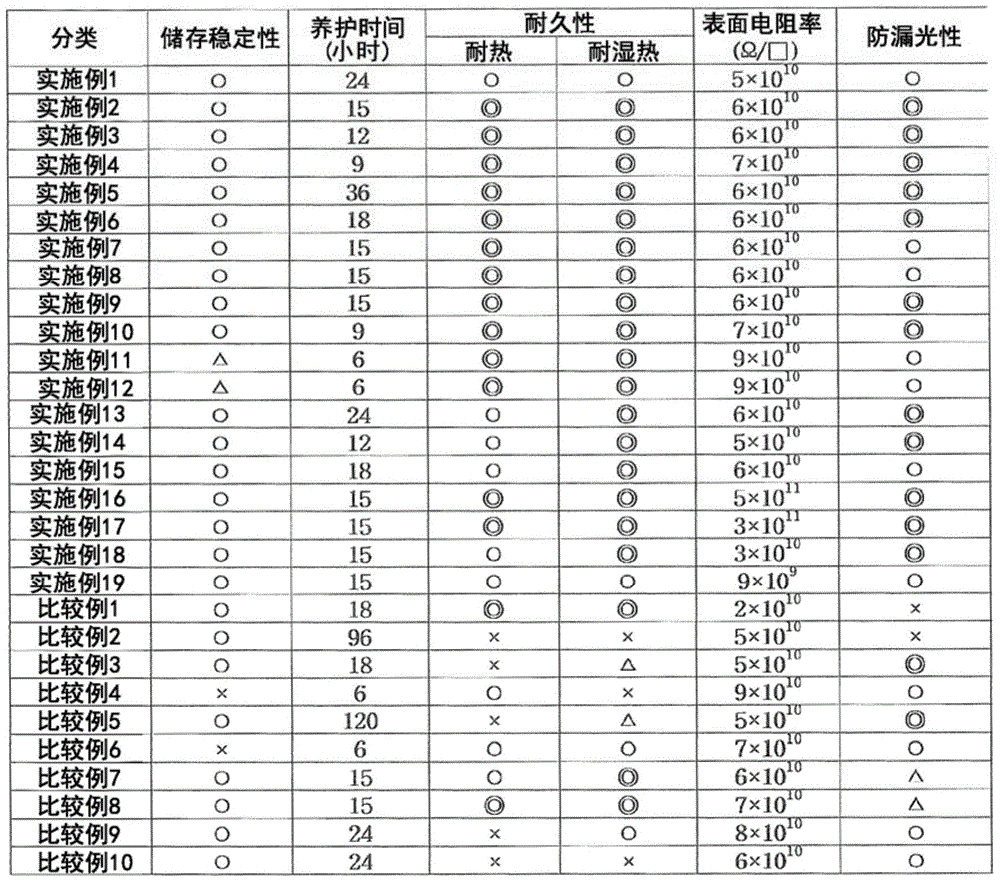

[0063]The adhesive composition prepared in the above manner was coated on a release film coated with a silicon release agent in a thickness of 25 μm, and dried at 100° C. for 1 minute to form an adhesive bond. Floor. In addition, a release film was further laminated on the adhesive layer to prepare an adhesive sheet.

[0064] After the release film of the prepared pressure-sensitive adhesive sheet was peeled off, the pressure-sensitive adhesive layer prepared above was laminated on an iodine-based polarizer having a thickness of 185 μm by adhesion processing to prepare an adhesive-attached polarizing plate. The prepared polarizing plate was stored at 23° C. and 60% RH for 20 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com