Selection and service life assessment method for automobile speed variator bearing

An automotive transmission and transmission technology, which is applied in mechanical bearing testing, transmission parts, belts/chains/gears, etc., can solve the problems of inability to adapt to the rapid development and reliability design of automotive products, complex analysis process, and low calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

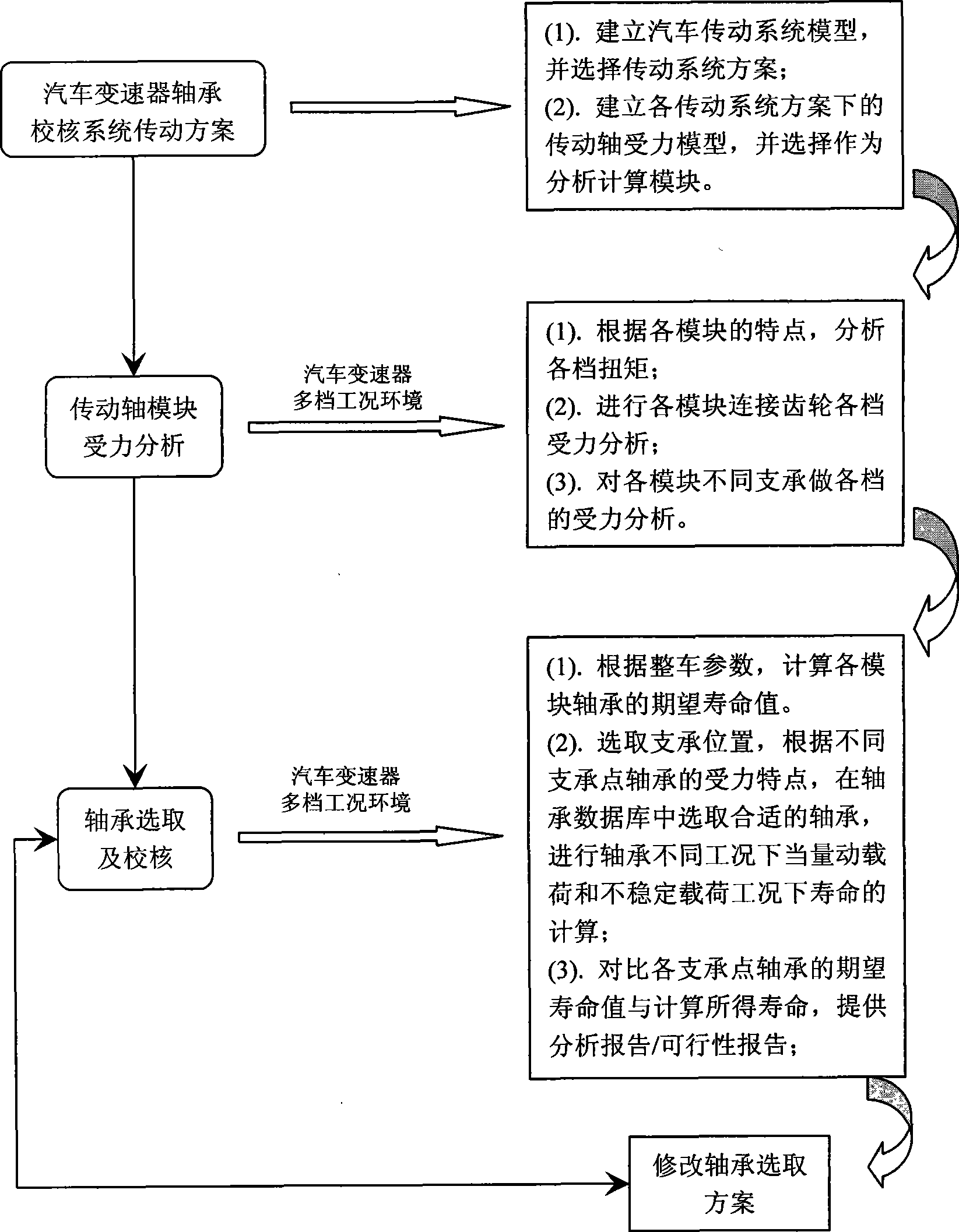

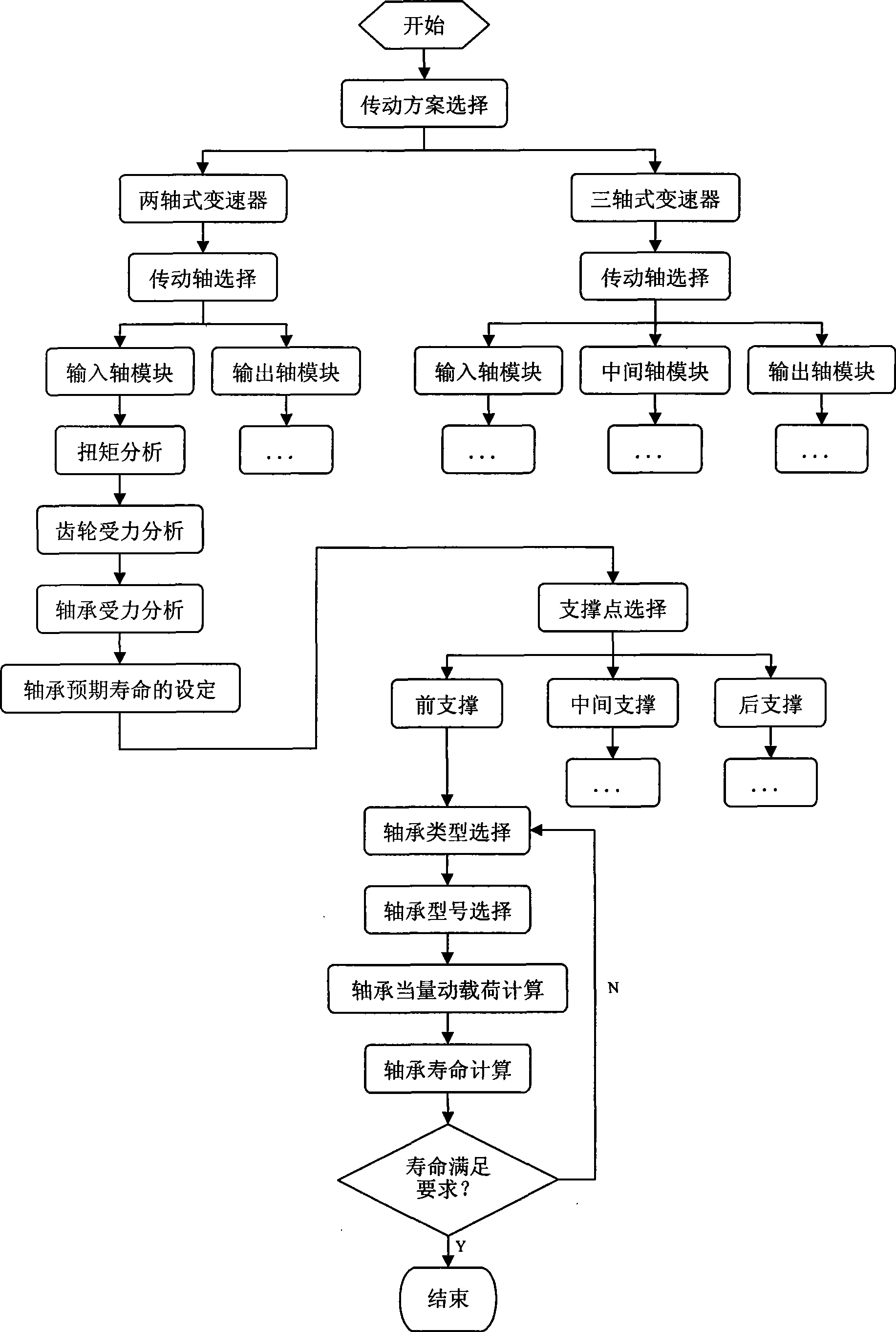

[0023] The matching and life evaluation method of the automobile transmission bearing provided by the embodiment of the present invention are as follows: figure 1 Shown:

[0024] (1) On the basis of the common structure, working gear, and support position of the automobile transmission, with the support shaft of the transmission as the basic unit, the force model and analysis and calculation module of the support shaft under each transmission system scheme are established; Independent, can be combined according to design needs.

[0025] (2) Based on Web technology, under the development environment of Microsoft Visual Studio 2005.NET, using ASP.NET technology combined with C# language, five modules are constructed by using the newly added server control Wizard in ASP.NET 2.0.

[0026] (3) According to the design requirements, select the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com