Lead sealing structure of ammeter

A technology of lead seals and electric meters, which is applied to seals, stamps, instruments, etc., can solve the problems of low production efficiency, increased cost, and high cost, and achieve the effects of high production efficiency, guaranteed safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

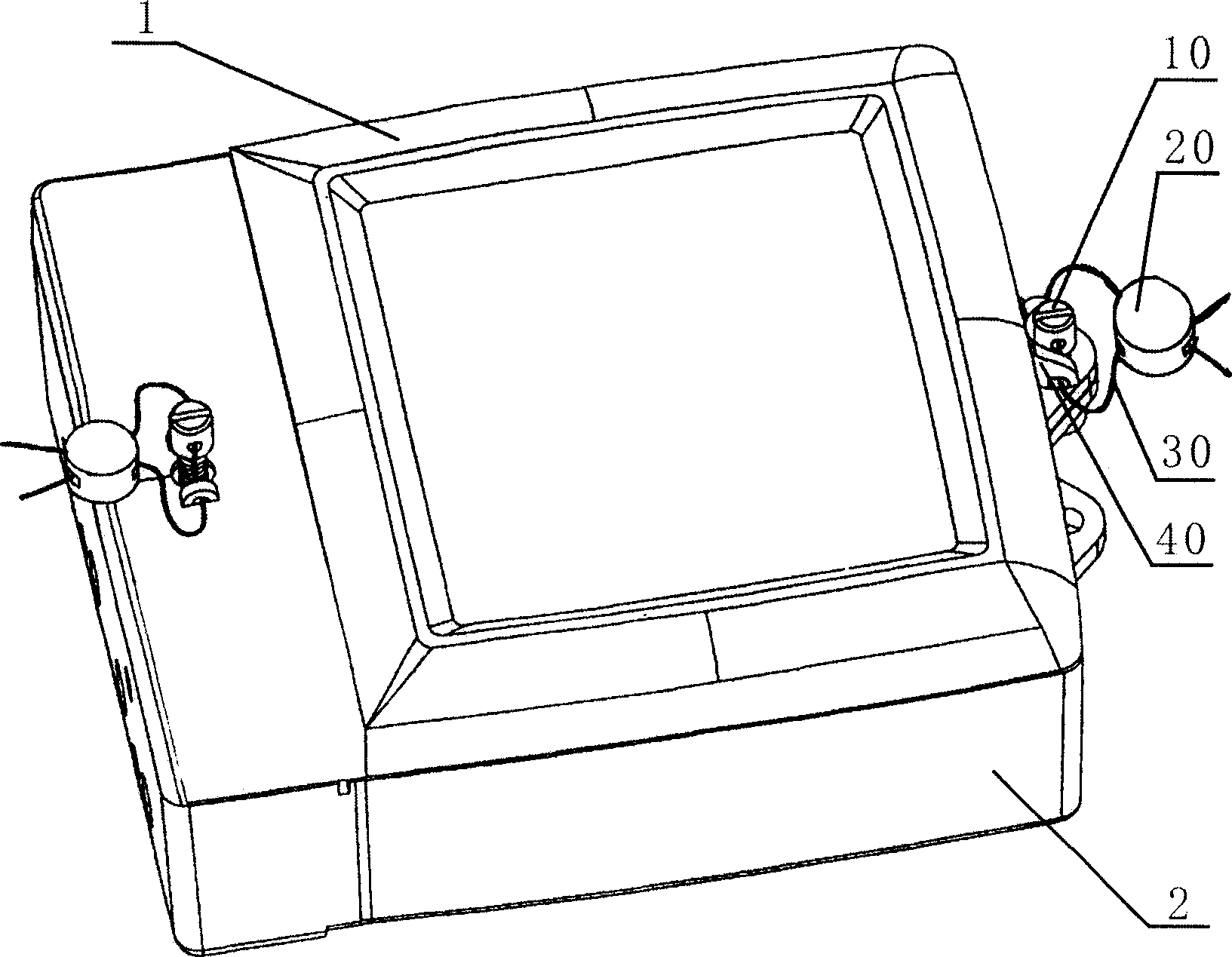

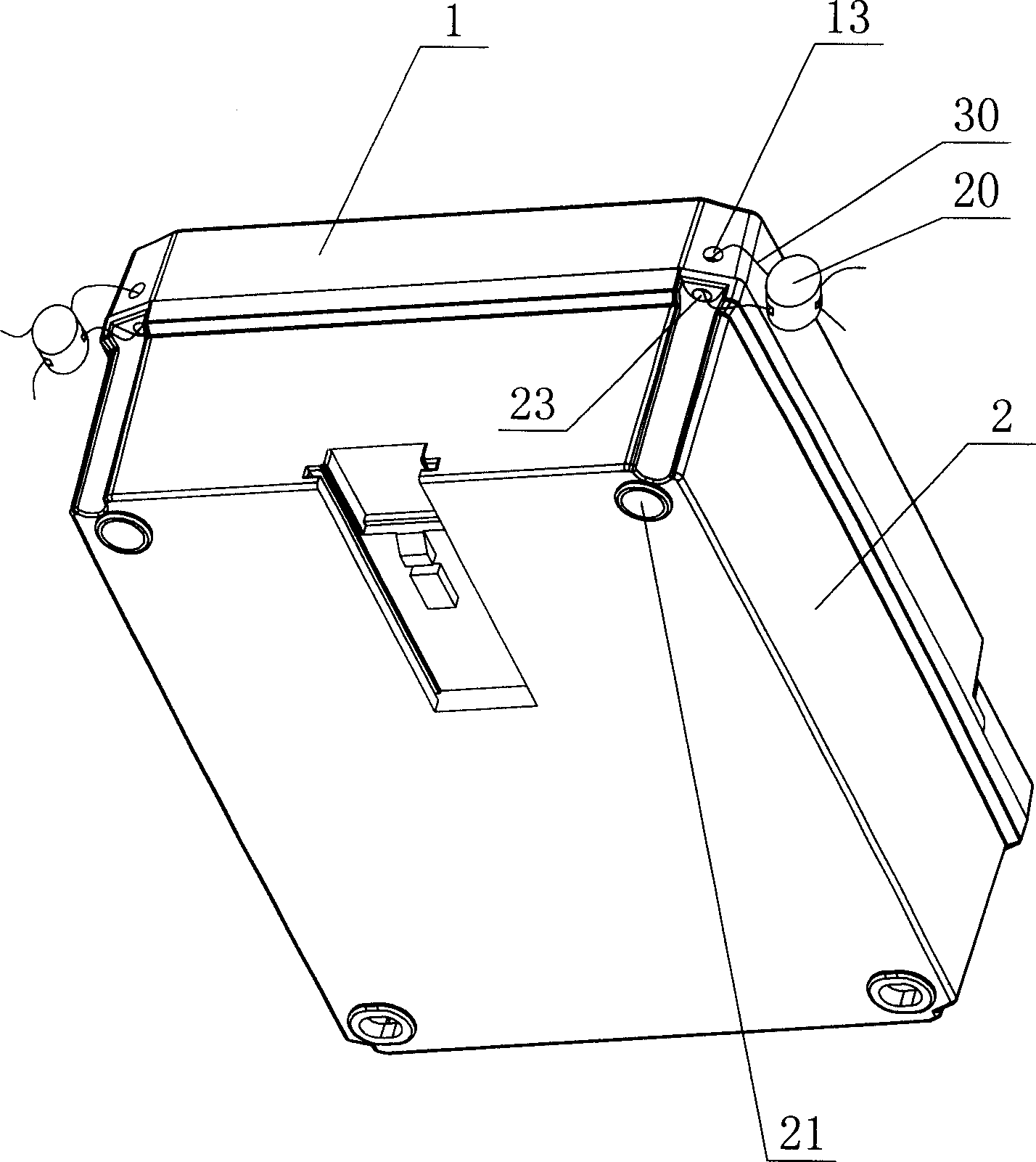

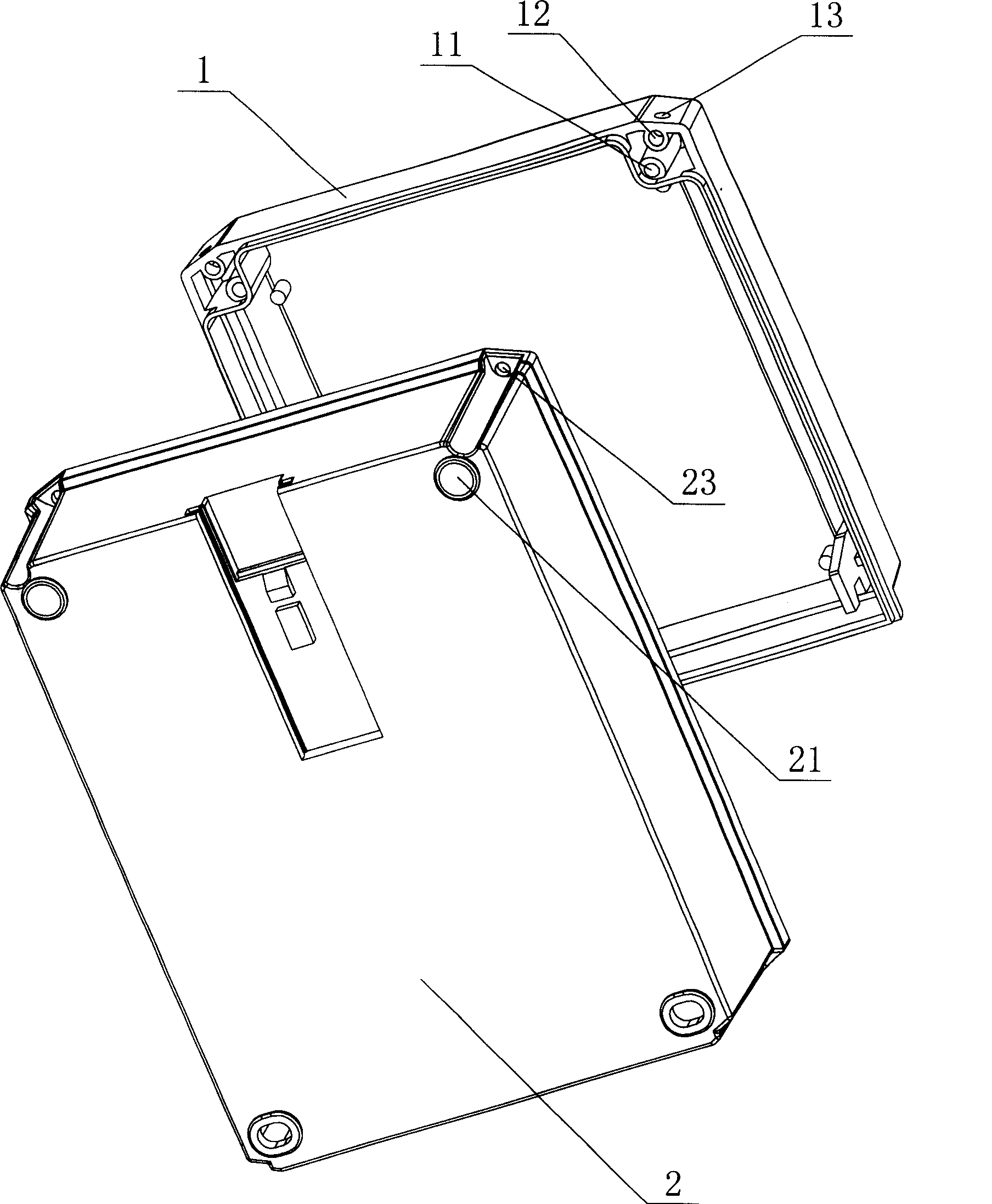

[0010] Such as Figure 2 ~ Figure 4 As shown, the electric meter of the present invention includes a loam cake 1 and a base 2, and the loam cake 1 is fixedly connected to the base 2, and the lead sealing structure of the electric meter includes a lead seal block 20, a lead seal line 30, a self-tapping screw, the upper cover 1 is provided with a screw post 11, a wire hole 12, and an I thread hole 13, and the wire hole 12 communicates with the I thread hole 13, and the base 2 is provided with a nail-holding groove 21. II threading hole 23, the II threading hole 23 is located next to the nail-holding groove 21, the tail of the nail-holding groove 21 is provided with a screw hole 22, the position of the screw post 11 and the screw hole 22 Compatible, the position of the thread passing hole 12 is compatible with the II threading hole 23, the self-tapping screw is located in the nail receiving groove 21 and passes through the screw hole 22 and connects with the screw column 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com