Device for the treatment of packaging foils

A technology of packaging and packaging equipment, used in packaging, thin material handling, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

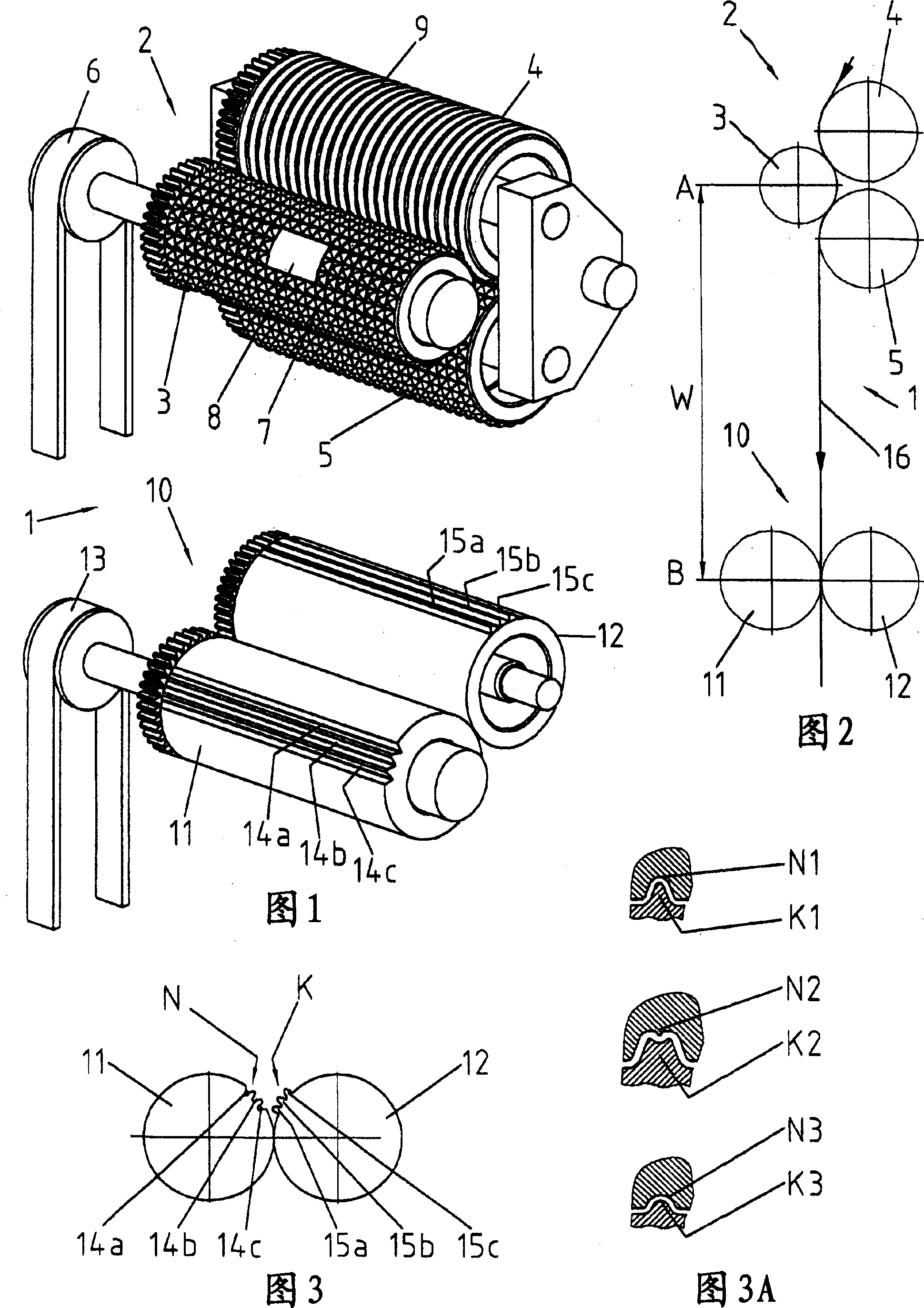

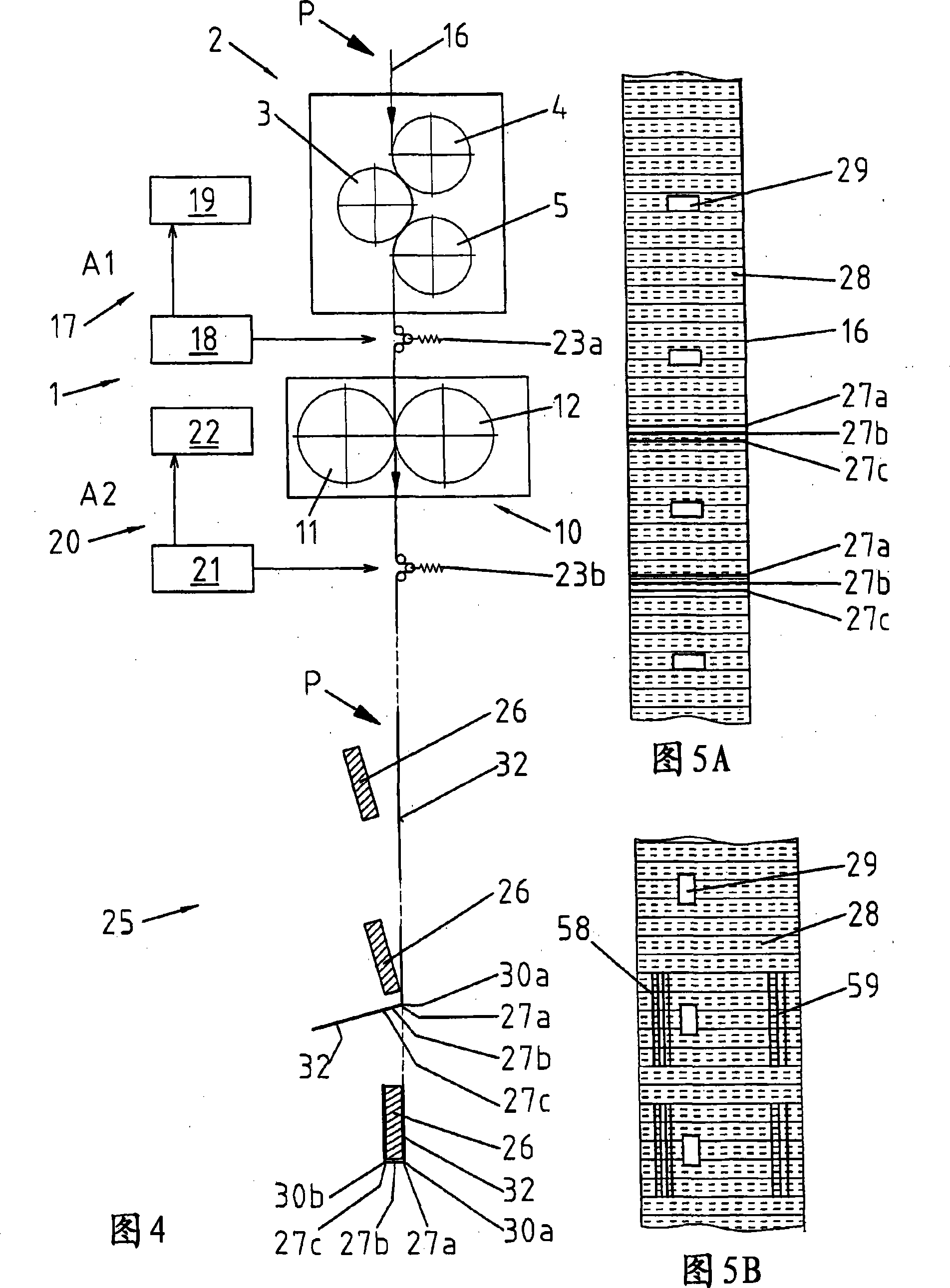

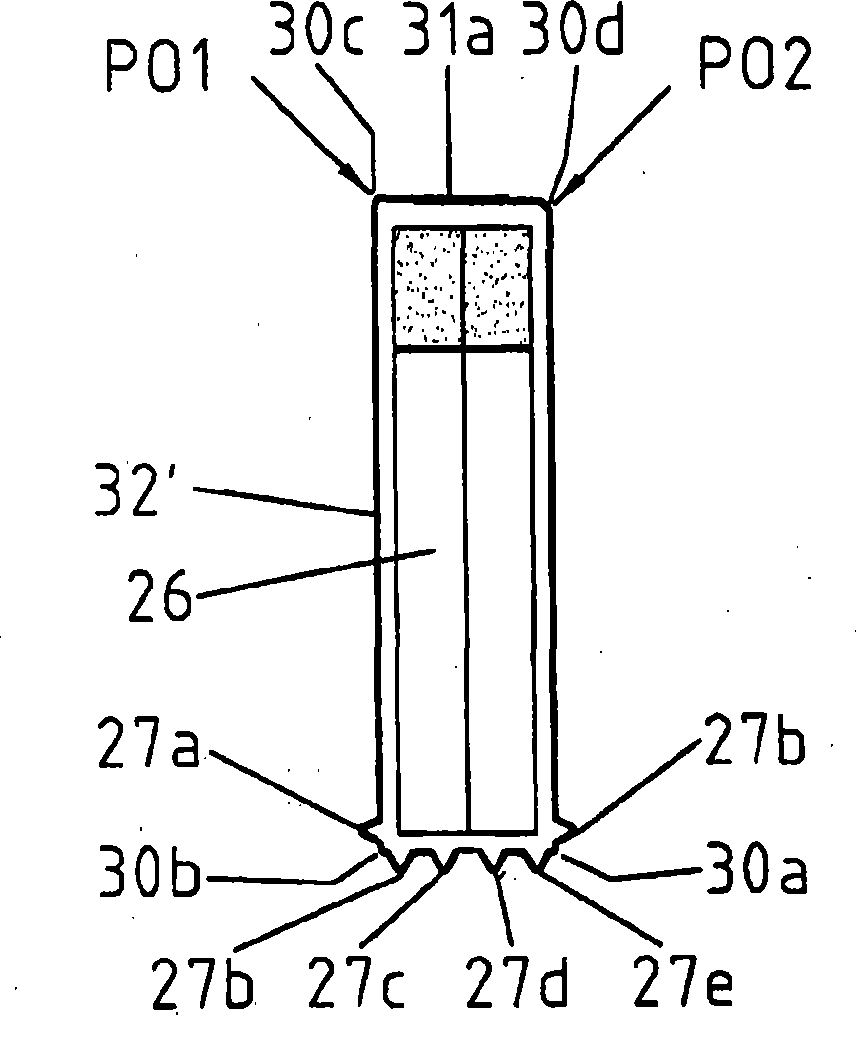

[0035] The device 1 for preparing a packaging foil for subsequent packaging treatment comprises a first embossing unit 2 and a second embossing unit 10 . The first embossing unit 2 comprises three embossing rolls 3 , 4 , 5 , the embossing roll 3 being driven by a drive 6 . The shape and structure of the embossing rollers 3, 4, 5 are known per se and have been disclosed in the various patent specifications and in the references cited in the introduction. The driven embossing roll 3 has a surface structure comprising toothed embossing structures 7 arranged in an axially and recurring homogeneous grid pattern and by means of which a gloss finish is obtained. This surface structure is called a basic grid. More specifically, the embossed structure 7 can be pyramidal, truncated pyramidal or conical in shape with different sections. In the pyramidal embossed structure 7, the embossed structure has a parallelogram cross-sectional shape.

[0036] Furthermore, on the surface of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com