Method for constructing water injection well

A technology of water injection wells and high-pressure water guns, applied in buildings, waterway systems, water supply devices, etc., can solve problems such as incomplete filtration of rainwater, pollution of groundwater layers, and small filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

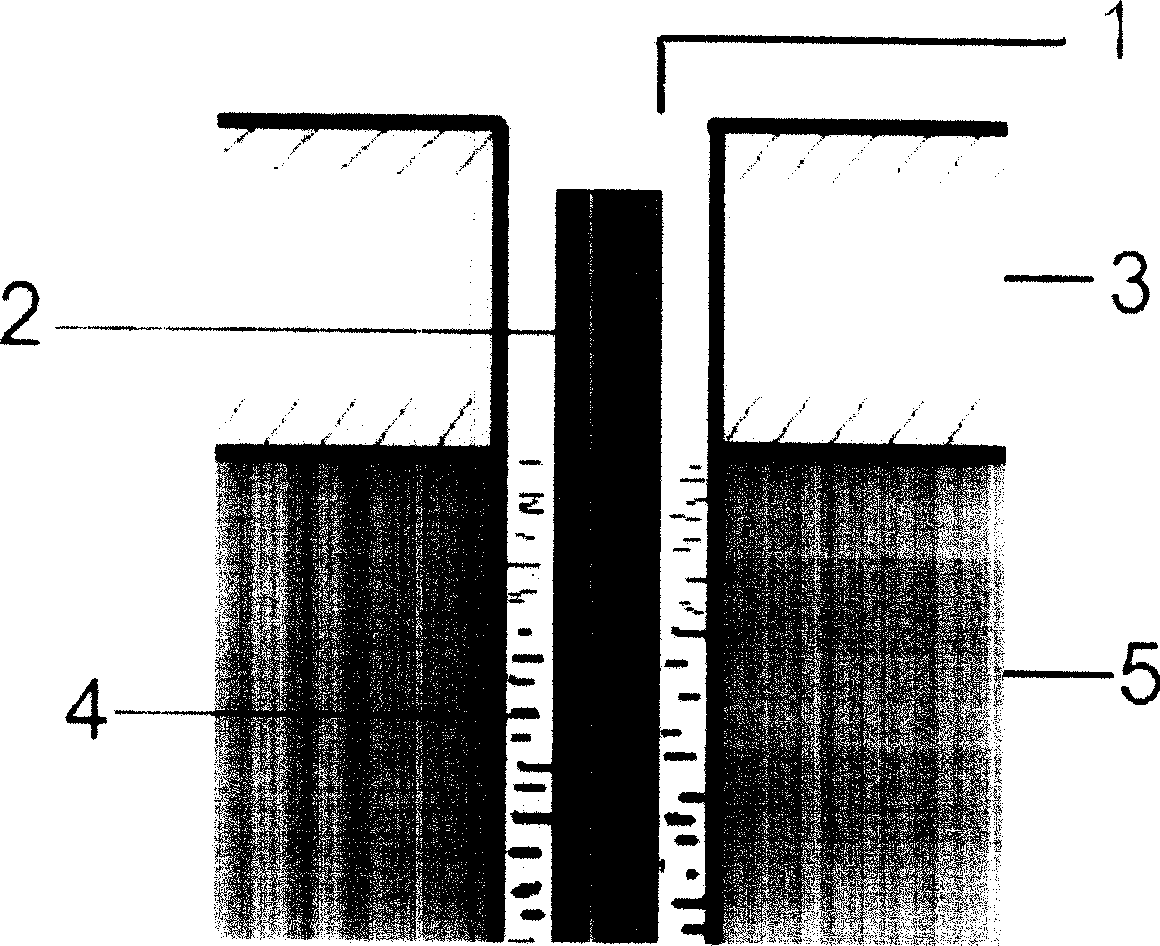

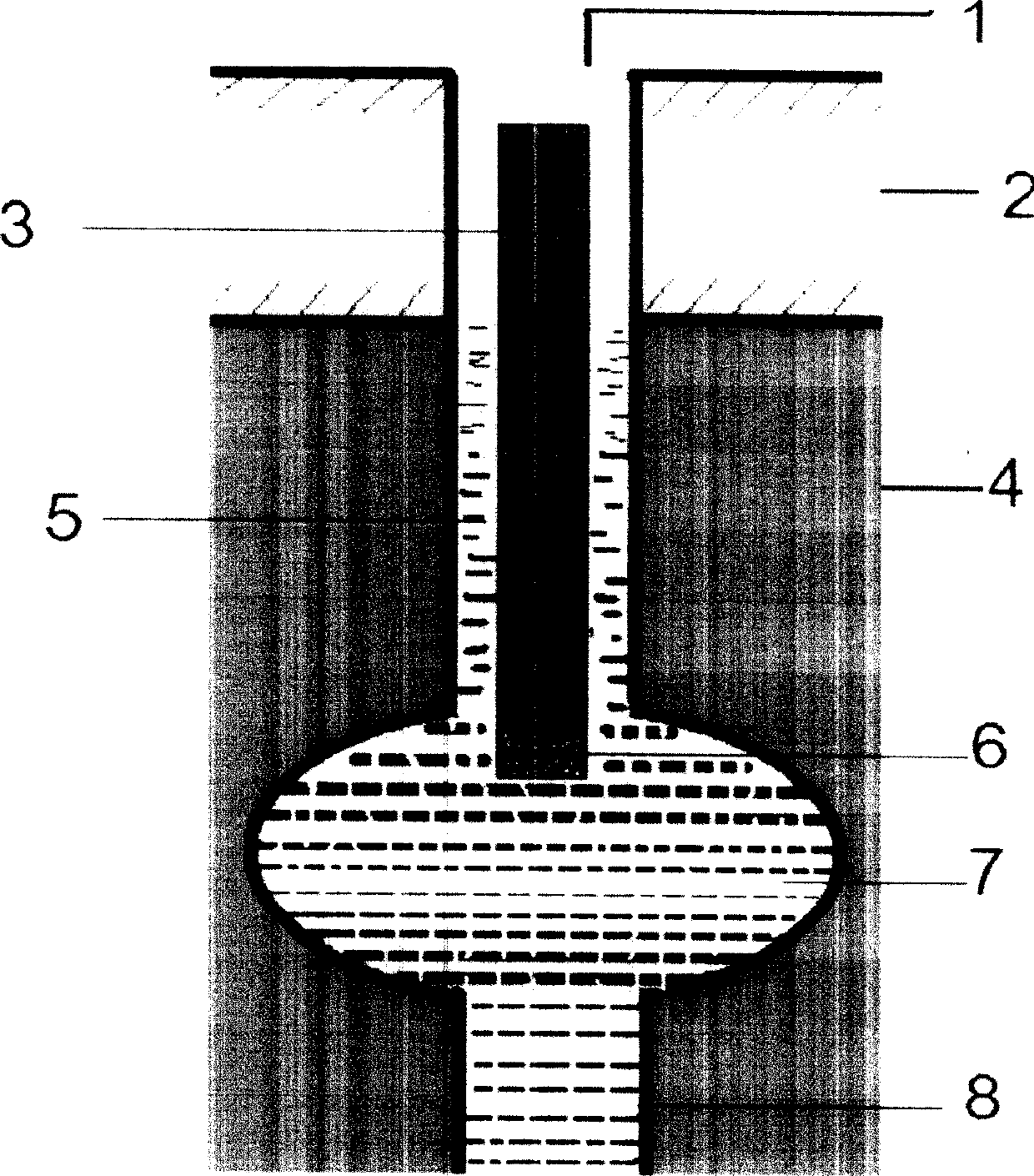

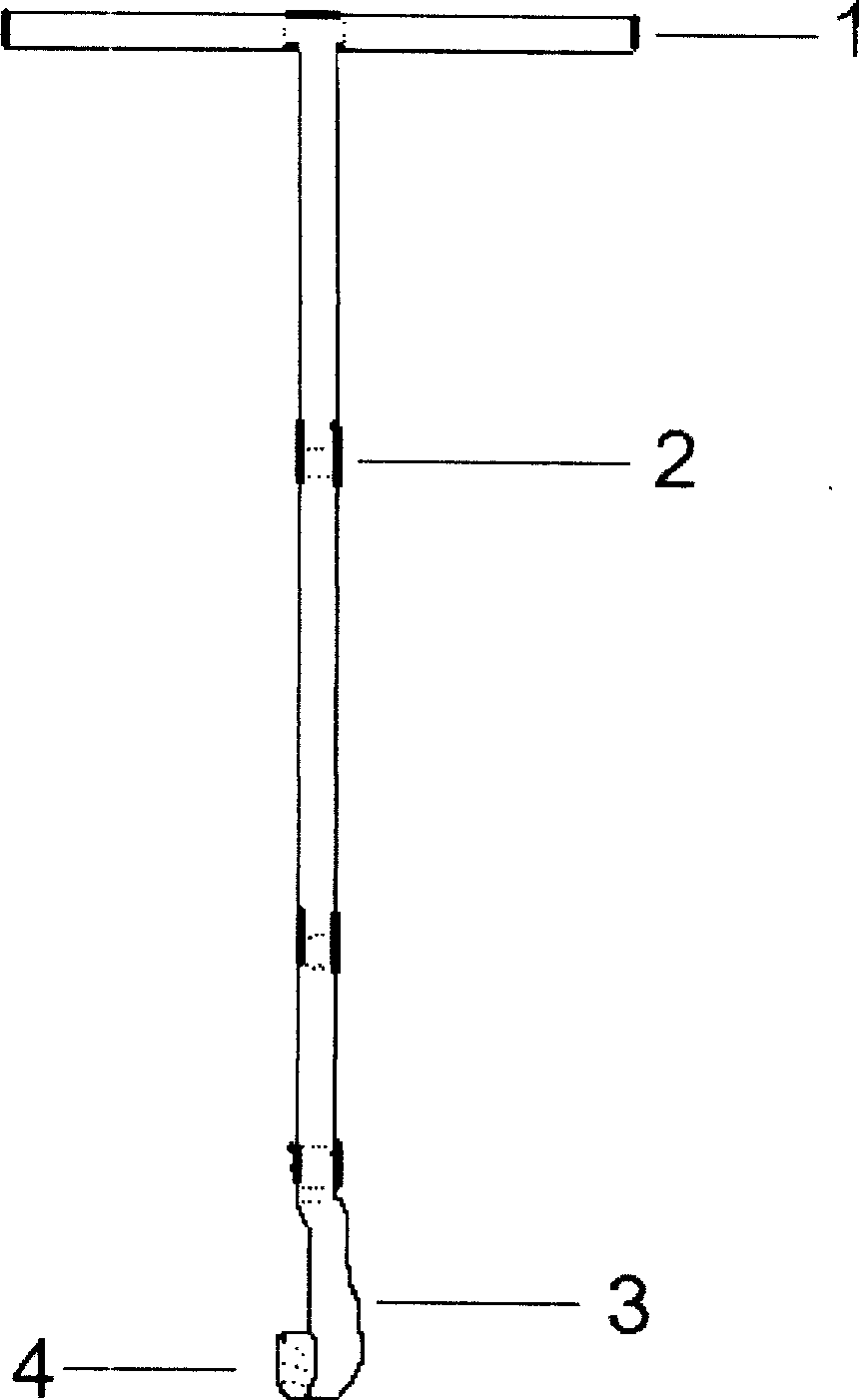

[0014] In a certain place in Haidian District, Beijing, a 500-caliber well with a depth of 18 meters was drilled using the water method, and the well was washed. Use a high-pressure water gun consisting of a 13-meter-long, 1-inch steel pipe and a nozzle, and use a pump with a lift of 50 meters and a displacement of 3 cubic meters per hour to supply water to expand the position at a depth of 12 to 12.5 meters. Divide into three times, put water in the first two times, fill 0.5 meters and 1.8 meters respectively. The third time the amount of water was too small, so it was not released, 13.5 meters. Start to add filter material, the specifications of quartz sand and the amount of material to be added in order are as follows: 20-40 mm per bag (one bag weighs about 50 kg), 10-20 mm per bag, 5-10 mm per bag, 2-5 mm One bag completes the base layer, 12.5 meters. After that, 1 bag of 1-2 mm, 2 bags of 2-5 mm, 2 bags of 5-10 mm, 4 bags of 10-20 mm, and 4 bags of 20-40 mm (17 bags in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com