Mechanical locking differential lockout mechanism

A locking mechanism, locking clutch technology, applied in mechanical equipment, differential transmission, transmission and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

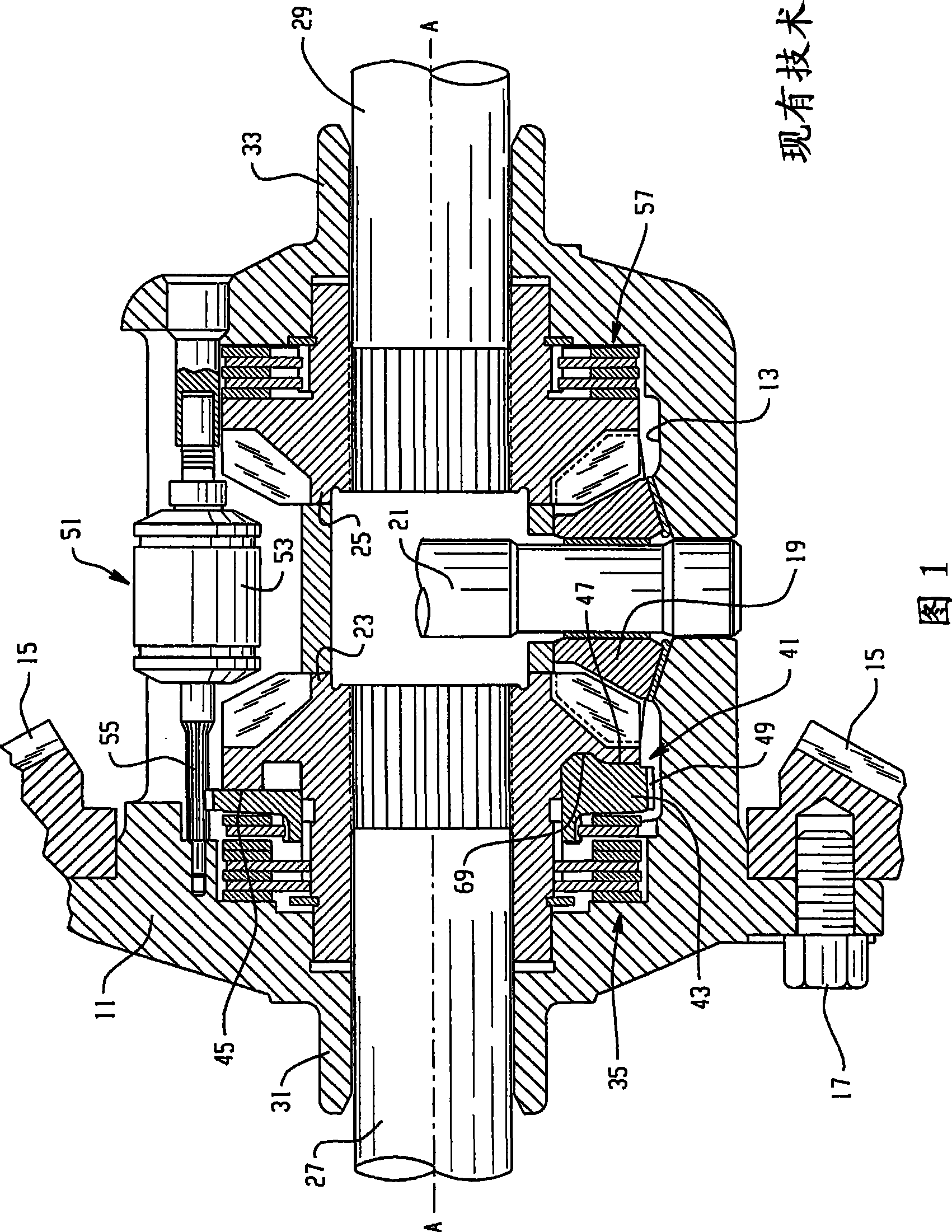

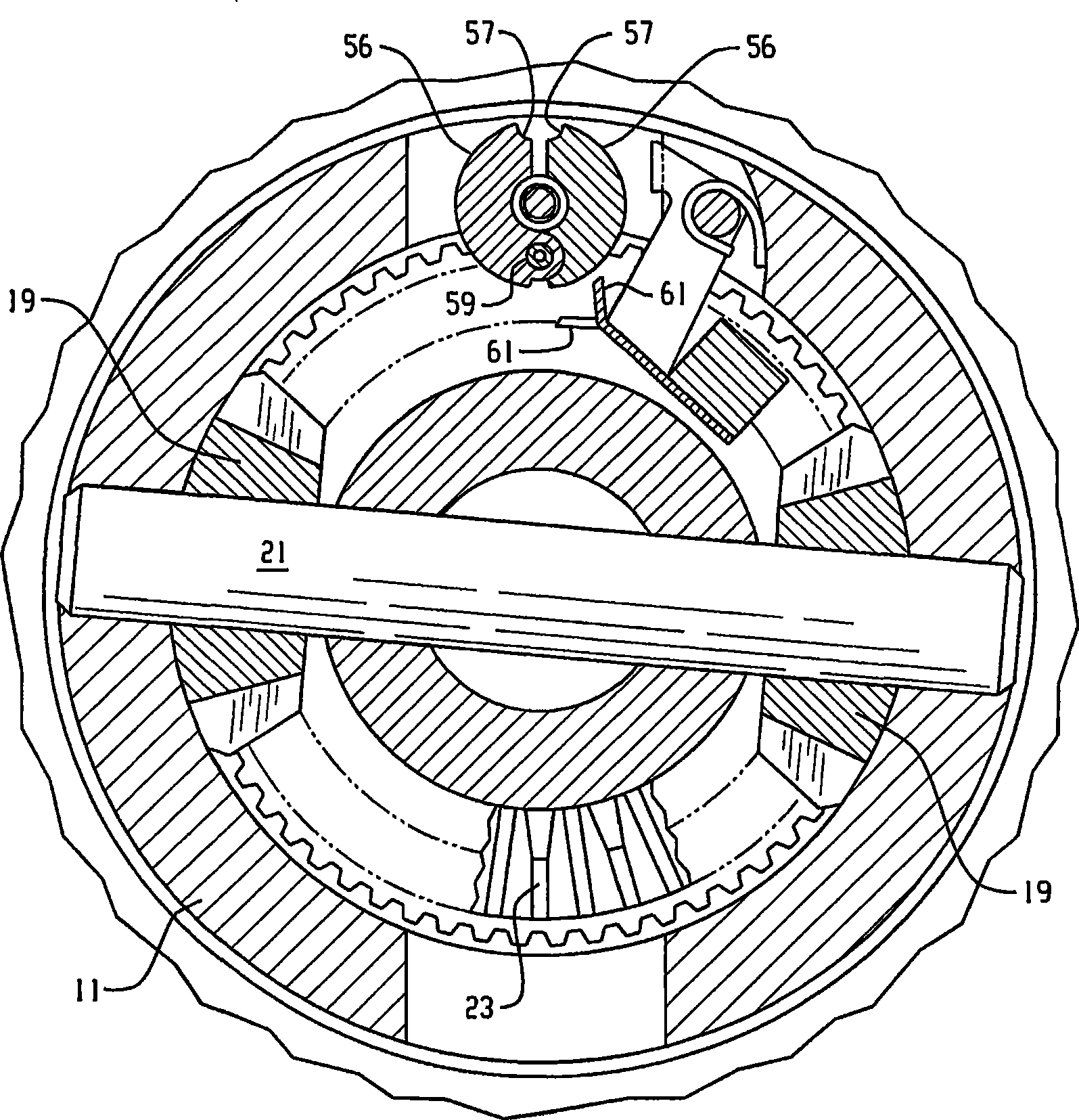

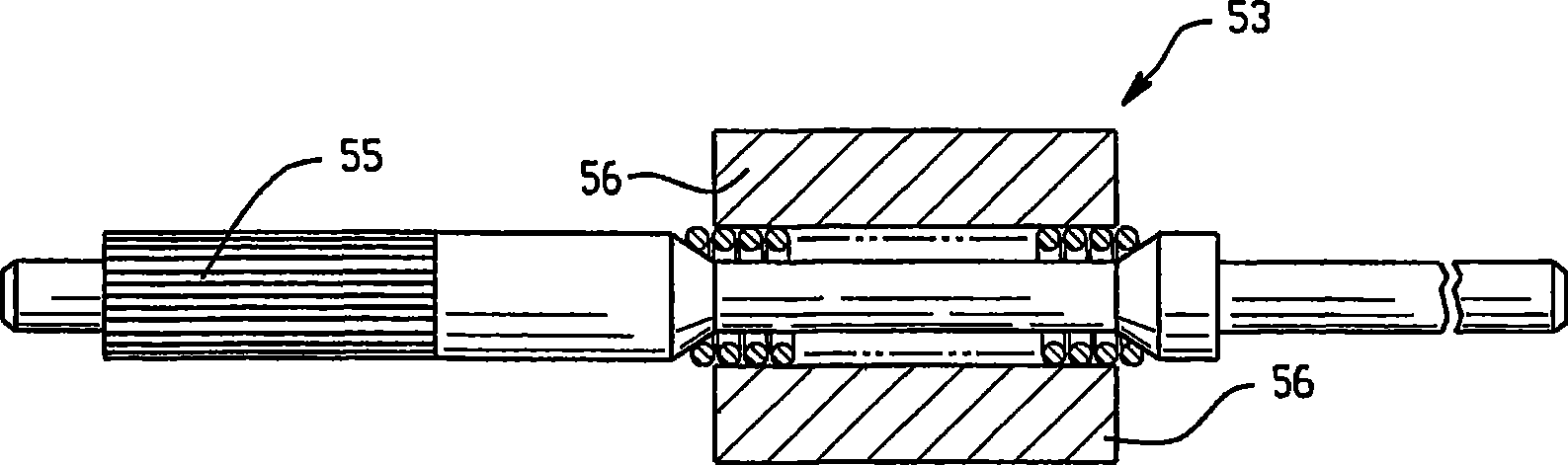

[0032] Referring now to the drawings, these drawings are not intended to limit the invention. BRIEF DESCRIPTION OF THE DRAWINGS Figure 1 is an axial cross-section of a locking differential gear mechanism in which the present invention may be advantageously employed. The general construction and operation of the locking differential shown in FIG. 1 is well known to those skilled in the art and has been depicted and described in more detail in the above incorporated patents. The differential gear mechanism shown in FIG. 1 ("Prior Art") comprises a gear housing 11 internally defining a gear cavity generally indicated at 13 . Torque is typically input to the locking differential through input gear 15 (only partially shown in FIG. 1 ). An input gear 15 (also referred to as a "ring gear") is intended to mesh with an input pinion (not shown in FIG. 1 ) that receives input drive torque from the vehicle driveline. The input gear 15 may be attached to the gear housing 11 by a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com