Quieter of pneumatic tool

A sound-absorbing device and pneumatic tool technology, which is applied in the direction of portable mobile devices, manufacturing tools, striking tools, etc., can solve the problems of large number of parts, deterioration and failure of sound-absorbing fiber bodies, troublesome material management and assembly, and achieve easy manufacturing and assembly , less types of parts, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

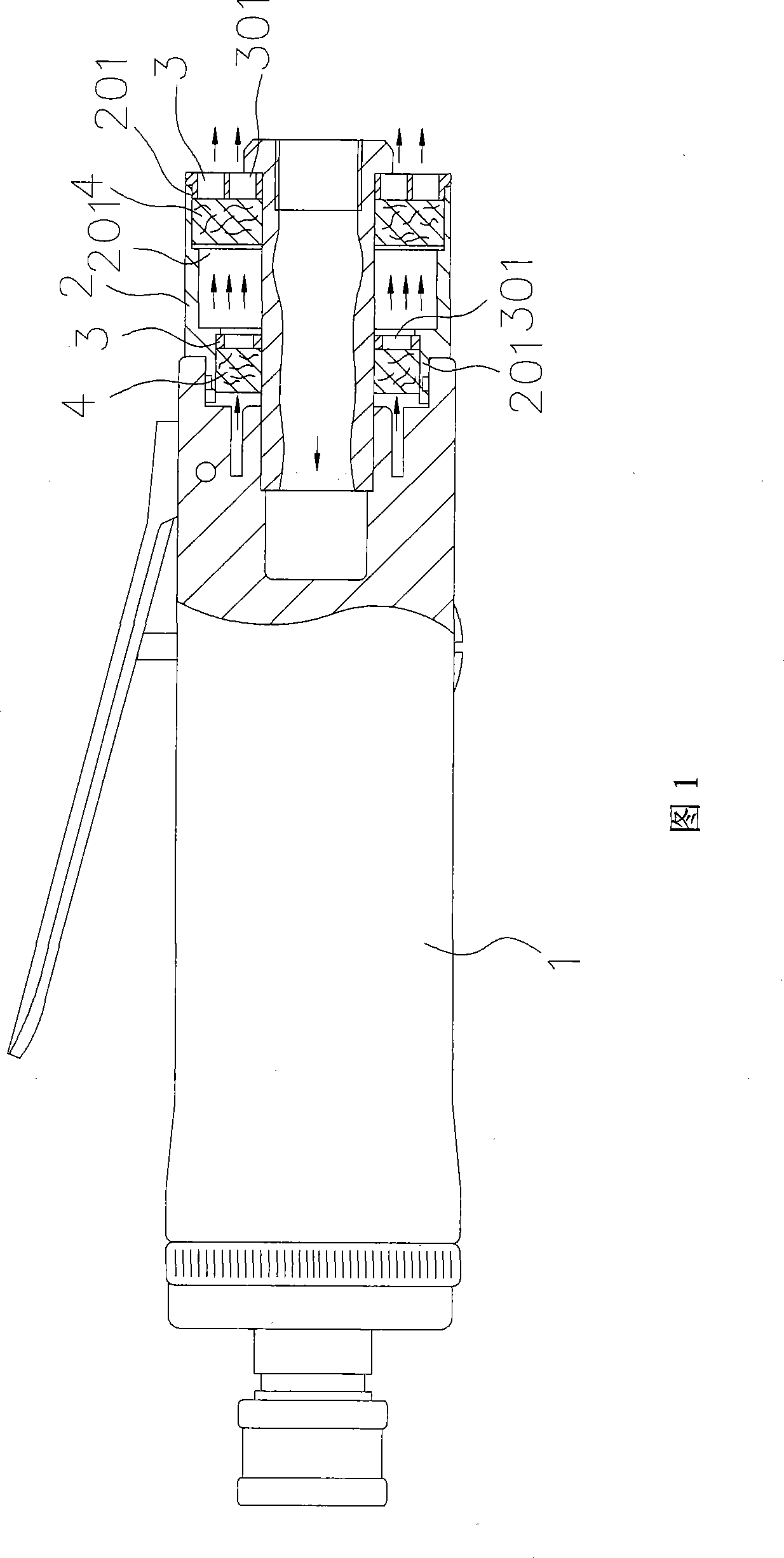

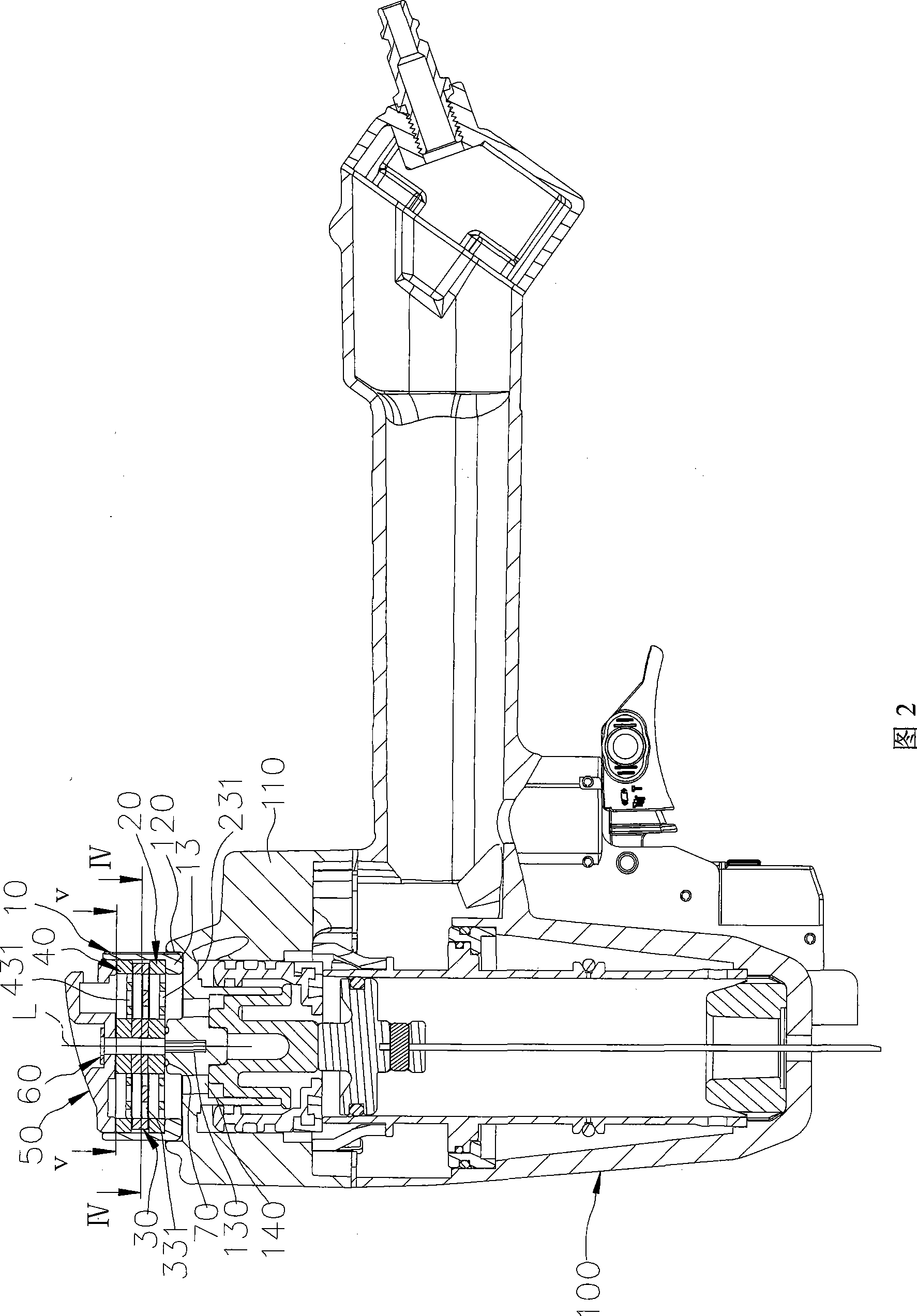

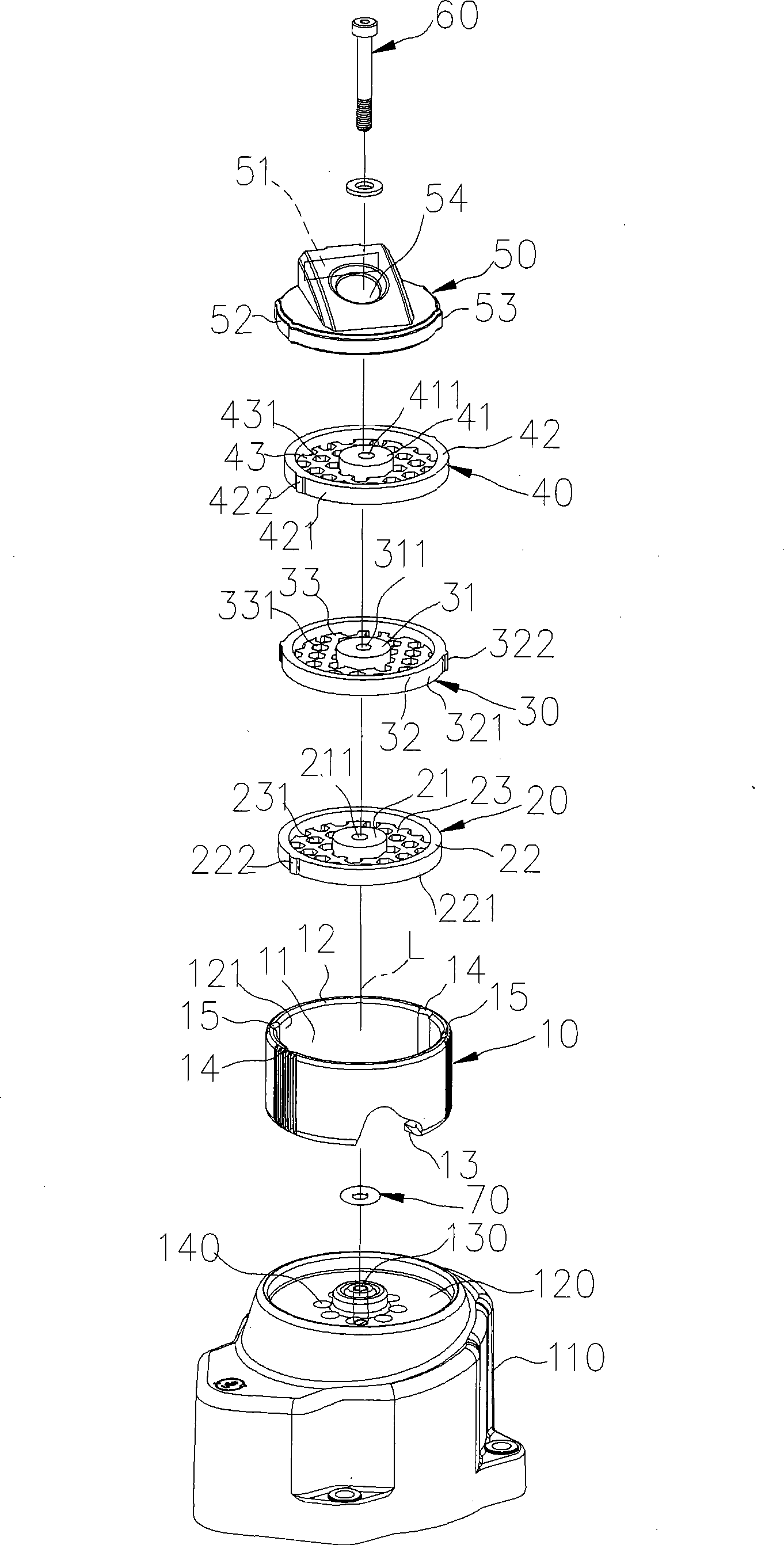

[0017] Figure 2 and image 3 As shown, the preferred embodiment of the noise reduction device of the air tool of the present invention, the air tool also includes a body 100 and a top cover 110 fixed on the body 100, the top cover 110 has a recessed top surface The recessed portion 120 , a screw hole 130 disposed in the recessed portion 120 , and a plurality of exhaust holes 140 arranged around the screw hole 130 . The noise reduction device is installed on the top cover 110 corresponding to the exhaust hole 140, and includes a housing 10, a first noise reduction sheet 20 installed inside the casing 10, and a first noise reduction sheet 20 stacked on the first noise reduction sheet. 20, a third sound-absorbing sheet 40 stacked on the second sound-absorbing sheet 30, a cover 50 sealed outside the third sound-absorbing sheet 40, and a cover 50 locked The locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com