Fixed contact tap switch with rotating bearing structure

A technology of rotating bearings and tap changers, which is applied to the shape/structure of contact surfaces, transformers, electrical components, etc. It can solve the problems of unobvious hand feel and large switching torque, and achieve brisk rotation, small torque, and small connection resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

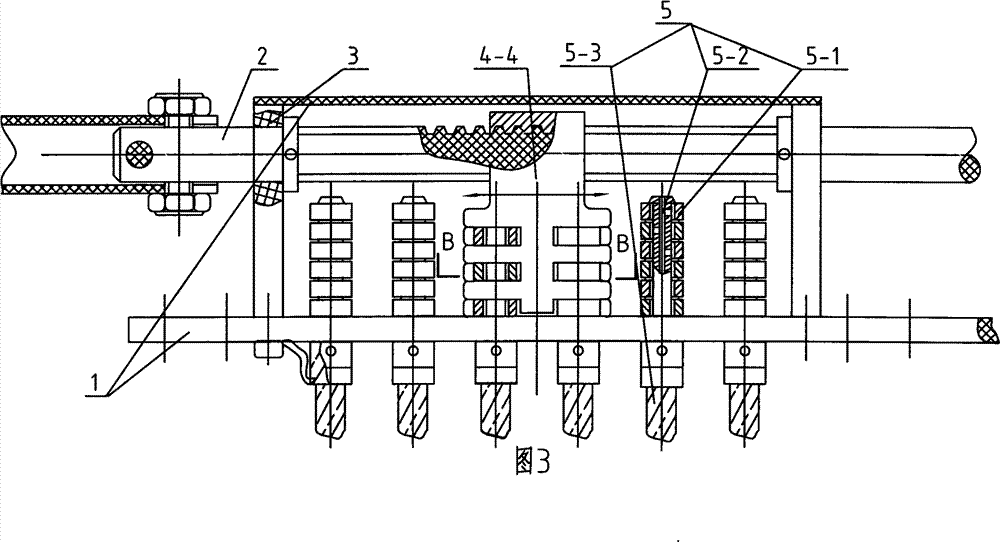

[0019] Two embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

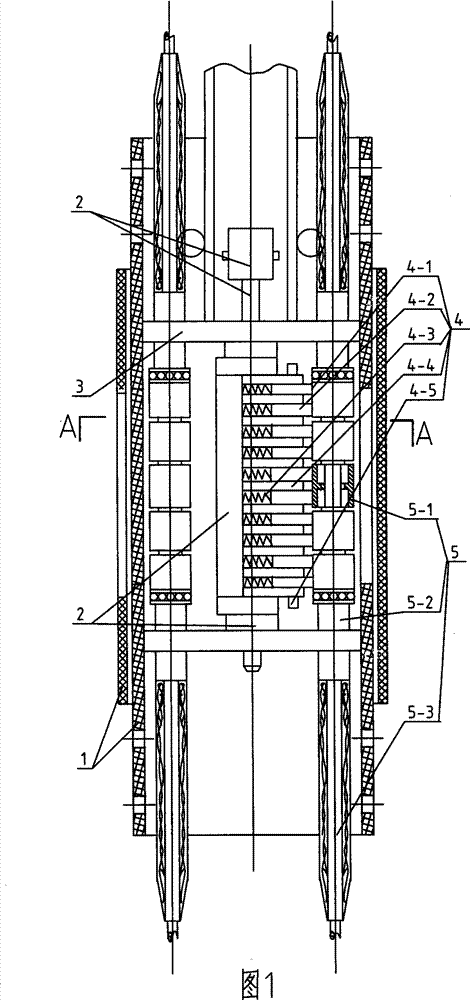

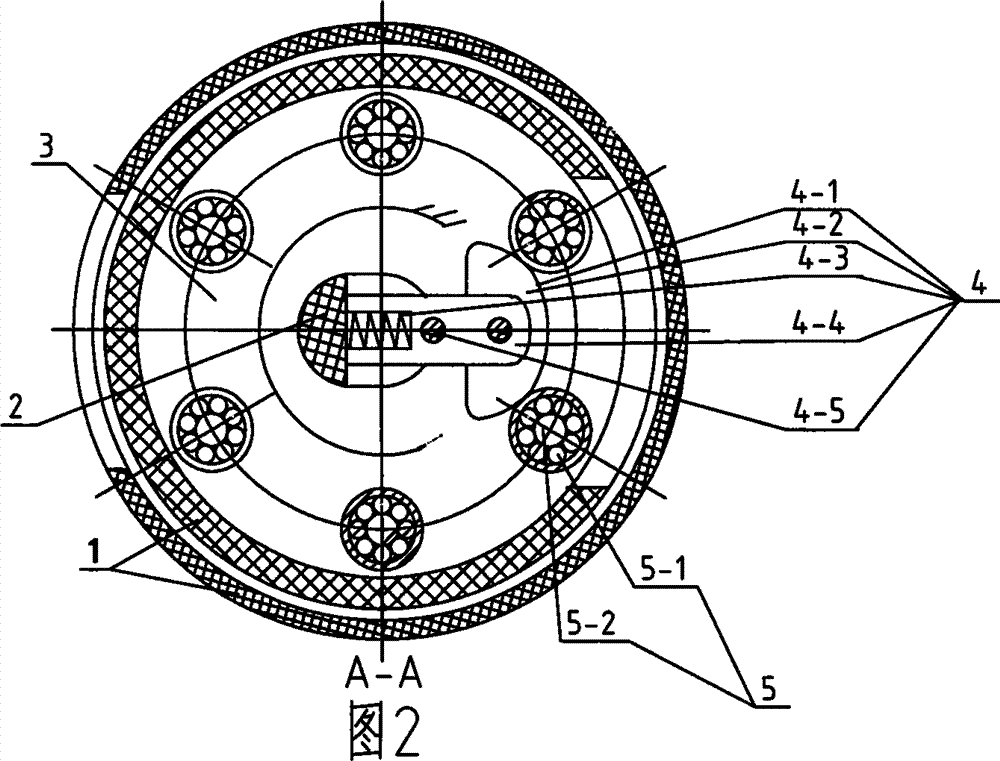

[0020] The first example is figure 1 and figure 2 As shown, it is a single-phase drum-shaped tube switch with a fixed contact of a rotating bearing structure. The reason why it is called a drum-shaped tube type is because the appearance looks like a drum-shaped switch, and its internal structure is in the form of a tube-shaped switch. However, it doesn't matter whether it integrates the drum shape, the tube shape or even the cage shape. The most important thing is that it has the patented feature of the fixed contact of the rotating bearing structure.

[0021] The main structure of this embodiment is as follows: 1 is an outer insulator, which is composed of two layers of insulating cylinders; 2 is a transmission shaft, which is composed of a shaft head that rotates on the axis line at both ends and a bow-shaped shaft in the middle section; 3 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com