Crimped casing for electric transmission and distribution wire

A technology for crimping sleeves and power transmission and distribution lines. It is applied in the direction of connection where permanent deformation works. It can solve the problems of loose, corroded, and disconnected connecting wires, and can ensure straightness, low resistance, and low temperature rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

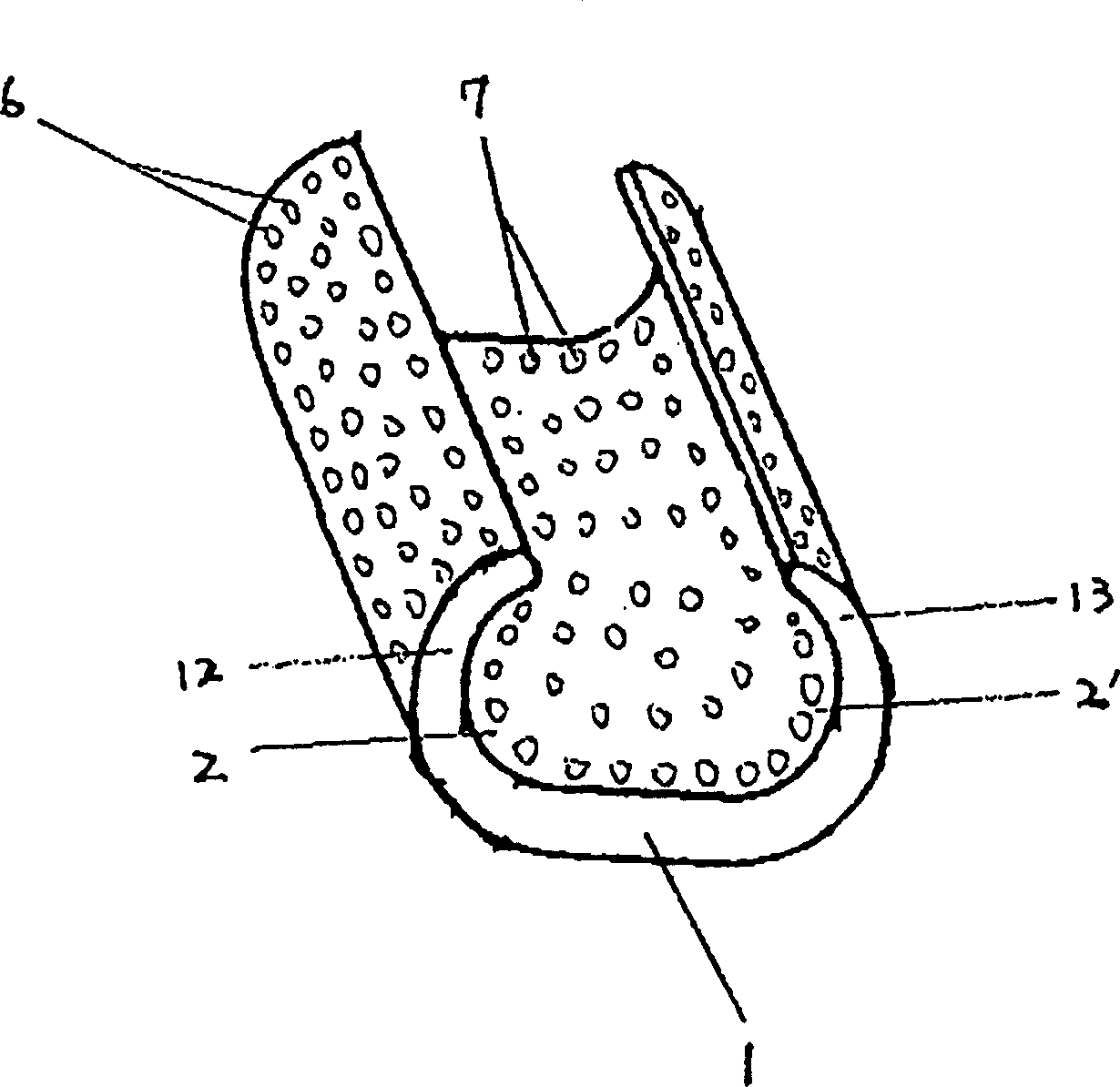

[0154] Embodiment one, such as figure 1 As shown, a crimping sleeve for transmission and distribution lines of the present invention is composed of a columnar base 1 with a C-shaped cross section, and the two ends of the base 1 are two wire grooves 2, 2' that are in contact with the electric wires. , the two grooves 2, 2' are surrounded by two upper and lower C-shaped hooks 12, 13 approximately in the shape of semicircular arcs, and the grooves 2, 2' at both ends are in the shape of through holes. The inner surface of the base body 1 is respectively provided with locking protrusions 7 which are randomly distributed in a point shape, and the outer surface of the base body 1 is respectively provided with locking recesses 6 which are randomly distributed in a point shape. The shape is approximately hemispherical; the shape of the locking cavity 6 is approximately hemispherical; the locking cavity 6 is 5 pieces / cm 2 distribution, the locking protrusions 7 are 5 pieces / cm 2 distr...

Embodiment 2

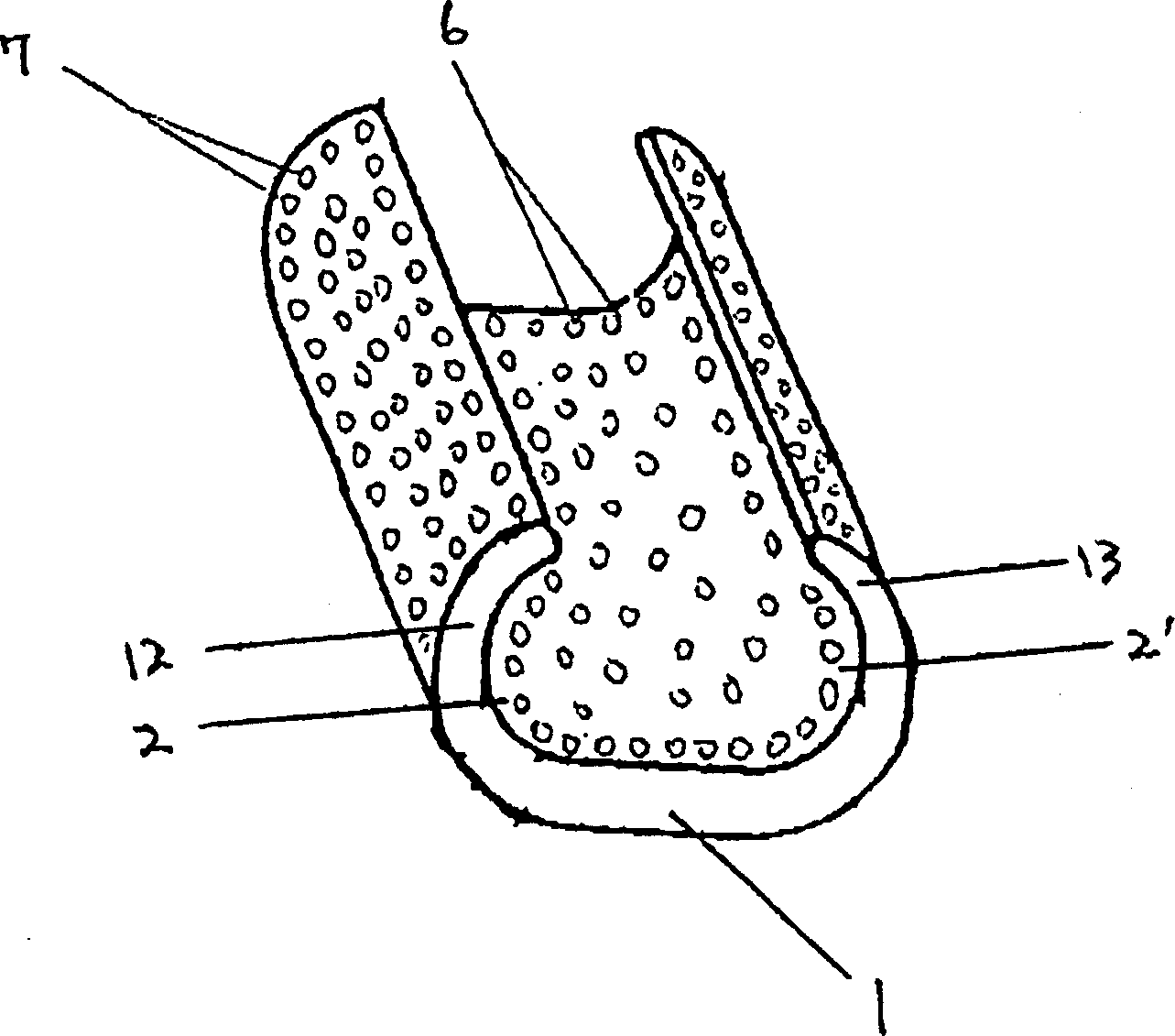

[0156] Embodiment two, such as figure 2 As shown, the difference between this embodiment and the previous embodiment is that the locking protrusion 7 is provided on the outer surface of the base 1 , and the locking recess 6 is provided on the inner surface of the base 1 . At the beginning of crimping, the recesses on the inner surface will be closed early, which is beneficial to improve the compressive stress on the inner surface of the cable clamp and help the bending of the hook part of the cable clamp; the locking protrusion on the outer surface improves the strength and helps the clamp The tail end of the hook fits the wire, which is conducive to crimping and close contact with the wire, so that the wire clip can effectively cover the wire in the shape of a wire diameter, and the wire clip is approximately cylindrical. When the locking protrusions and locking recesses are distributed in a point shape, the recesses and protrusions have the same effect.

Embodiment 3

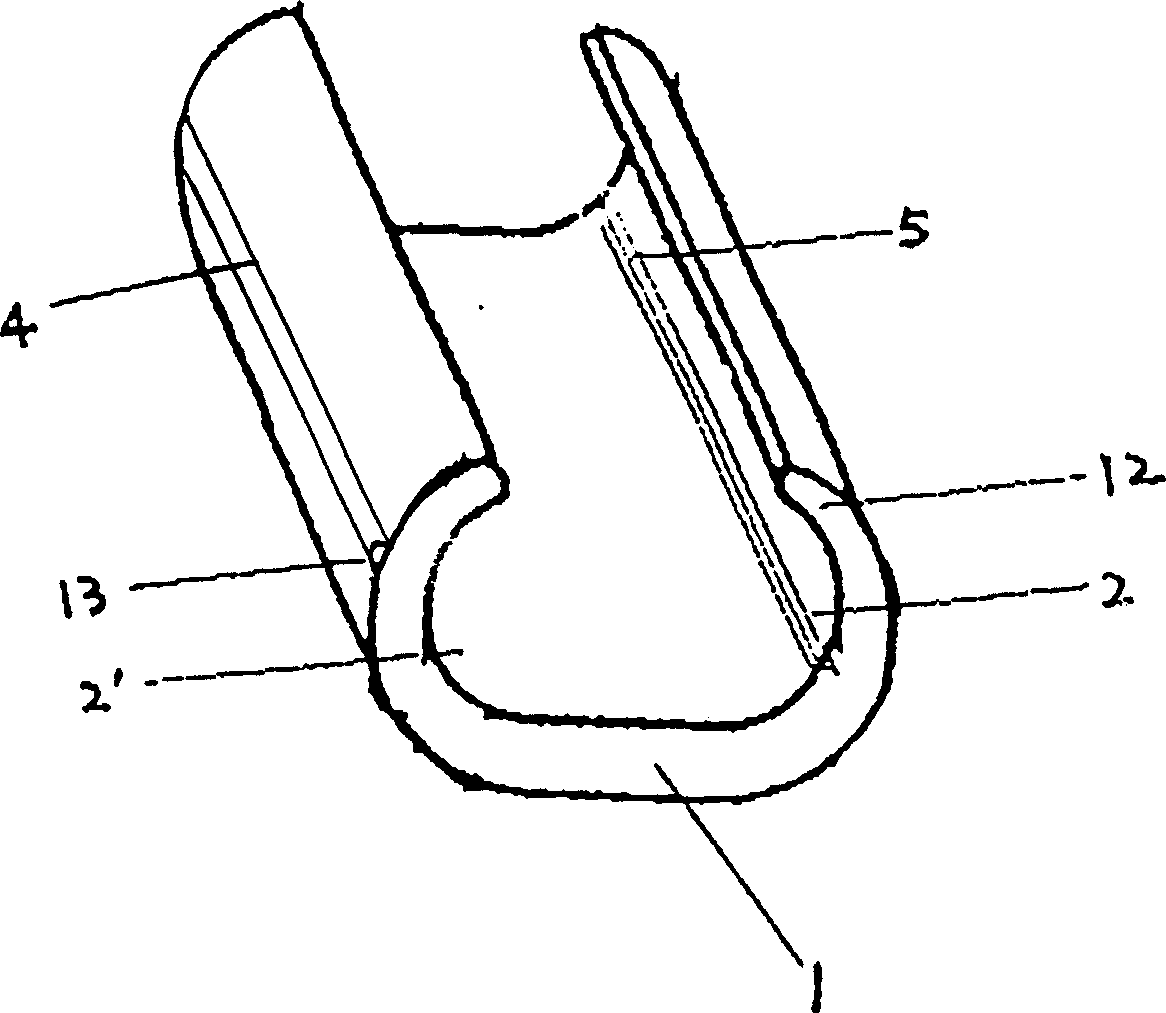

[0157] Embodiment three, such as Figure 3A , 3B , 3C, and 3D, a crimping sleeve for transmission and distribution lines of the present invention, the sleeve is composed of a columnar base 1 with a C-shaped cross section, and the two ends of the base 1 are two wires that are in contact with the wires. Grooves 2, 2', the two grooves 2, 2' are surrounded by hooks 12, 13 of upper and lower semicircular arcs of a C shape, and the grooves 2, 2' are in the shape of through holes; A locking rod 4 and a locking groove 5 are also provided on the surface of the base body.

[0158] Such as Figure 3A As shown, the shape of the locking rod 4 is a semi-cylindrical shape parallel to the length of the wire clamp; the shape of the locking groove 5 is a straight groove with a V-shaped cross section and parallel to the length direction of the wire clamp; the locking rod 4 is set At the apex of the outer surface of the hook portion 13 surrounding the line groove 2 ′, the locking groove 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com