Method for reclaiming and recycling waste nickel-cadmium battery

A nickel-cadmium battery and production method technology, applied in chemical instruments and methods, battery recycling, cadmium compounds, etc., can solve the problems of high production cost and high risk of secondary pollution, and achieve the effect of retaining usability

Inactive Publication Date: 2010-11-10

SOUTHEAST UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main disadvantage of this method is high production cost and high risk of secondary pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

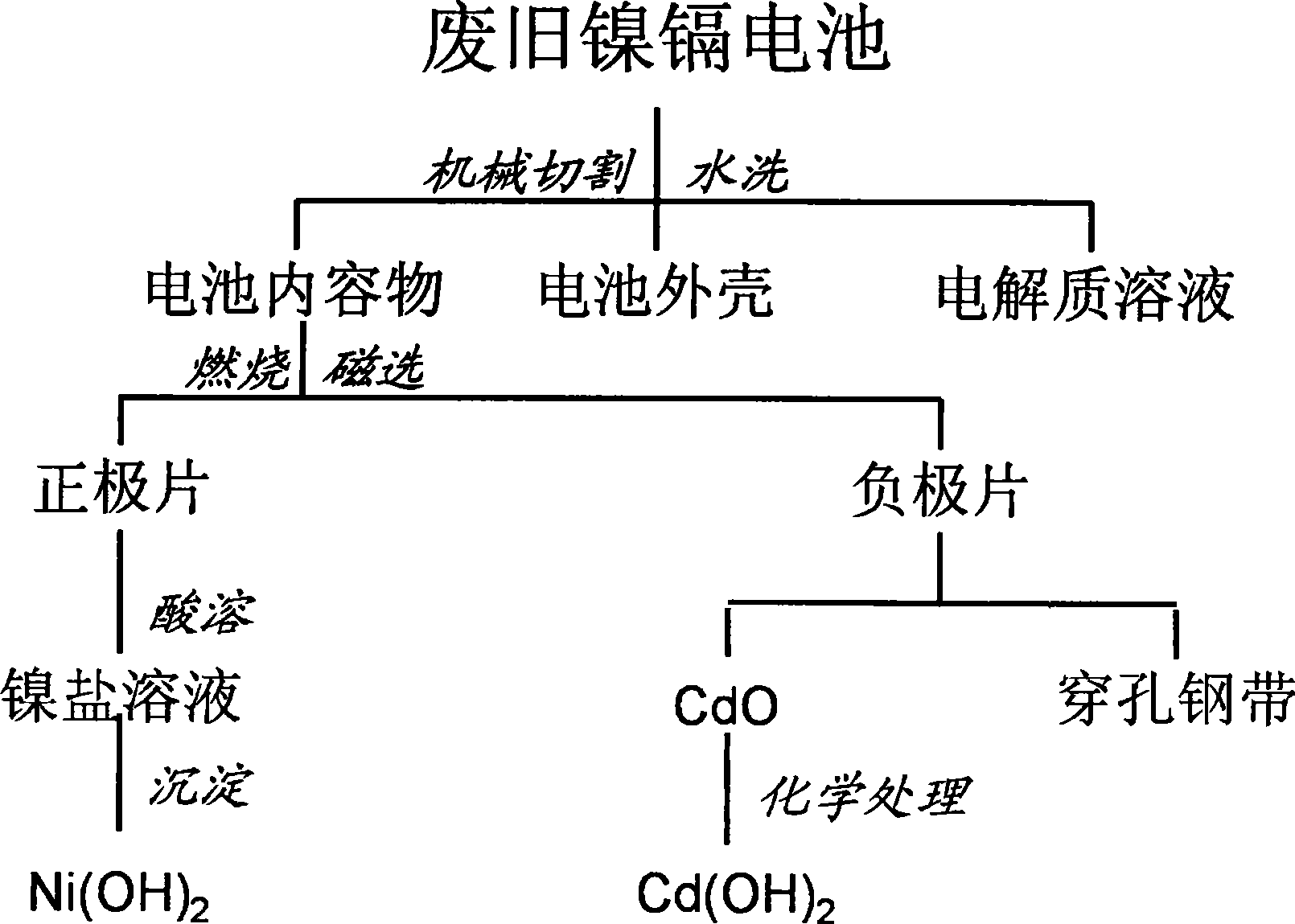

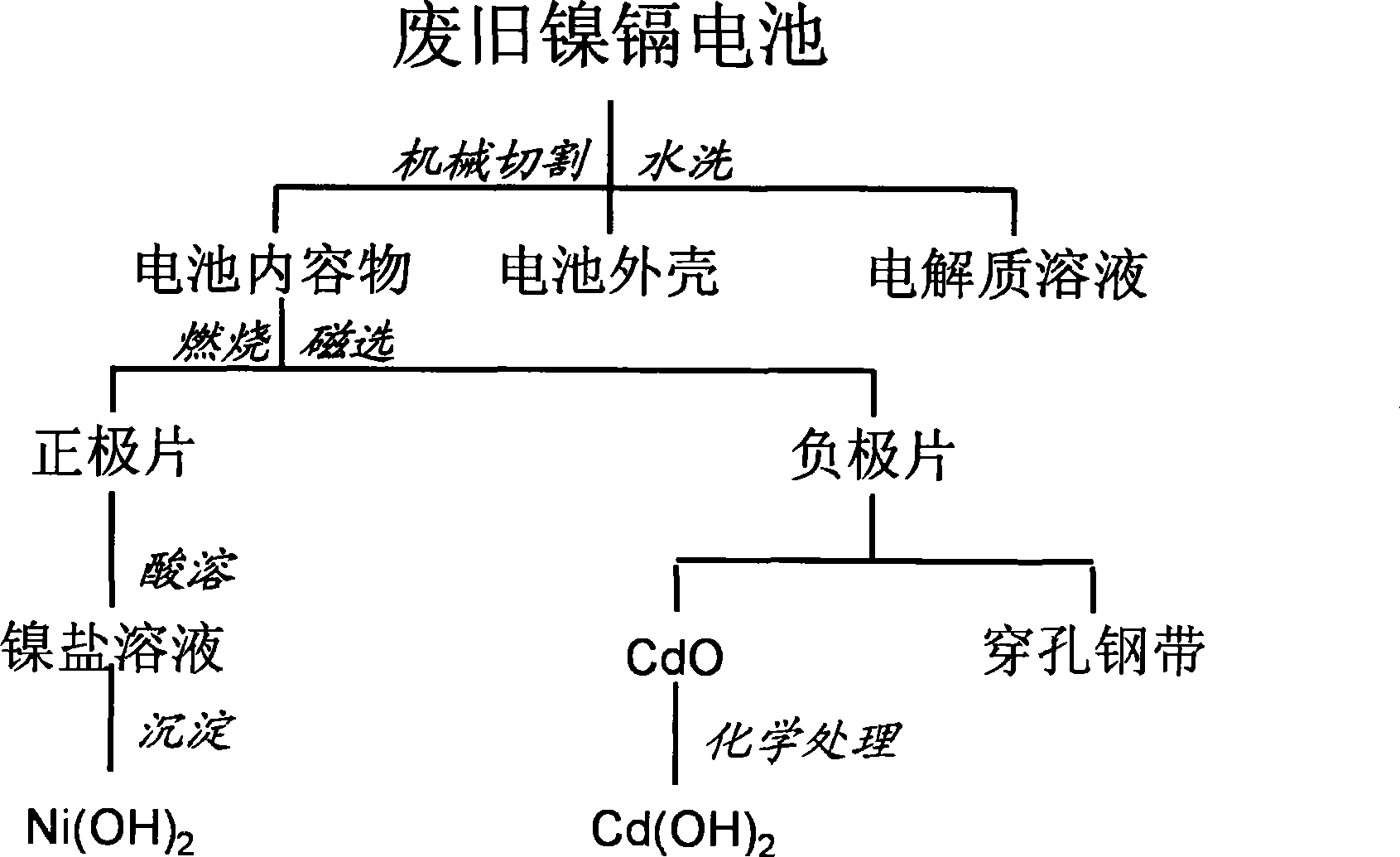

The invention provides a resource recycling production method of waste nickel cadmium batteries, relating to a physical separation method for the various components of the waste nickel cadmium battery, including a shell, an electrolyte, a positive plate, a negative electrode material and a negative electrode electricity collecting body perforated steel ribbon, and a recycling scheme of a pure electrode material obtained by separation; and the method provides a low-cost way for resource recycling production of the waste nickel cadmium battery. Concretely, all the components of the waste nickelcadmium battery are separated by the physical method at first, then the obtained positive plate and negative electrode powder are chemically treated to prepare new positive electrode material Ni(OH)2and negative electrode material Cd(OH)2 of the nickel cadmium battery, and then the commercialized nickel cadmium battery production line is used for producing new nickel cadmium batteries.

Description

A kind of recycling production method of waste nickel-cadmium battery technical field The present invention relates to a physical separation method for various components of waste nickel-cadmium batteries, including shell, electrolyte, positive electrode material, negative electrode material, current collector perforated steel strip, and the separated positive electrode material and negative electrode material. The reuse scheme provides a low-cost route for the recycling of waste nickel-cadmium batteries and the recycling production of nickel-cadmium batteries. Background technique Nickel-cadmium (Ni-Cd) battery, also known as nickel-cadmium battery, is a fairly mature secondary battery. It has the characteristics of long service life, high output power, and short charging time, and is currently mainly used in the power tool industry. Driven by strong market demand, my country has become the world's largest producer of nickel-cadmium batteries, with an annual output of 1 ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M10/54B09B3/00C01G53/04C01G11/00

CPCY02E60/12Y02W30/84

Inventor 雷立旭曹磊唐琛明

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com