Corn viscose blended yarn and preparing method thereof

A technology of blended yarn and viscose, which is applied in the direction of textiles, papermaking, yarn, etc. It can solve the problems that Modal yarn is easy to become hard, cool, and does not have clear evenness, etc., and achieves soft texture and clear evenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

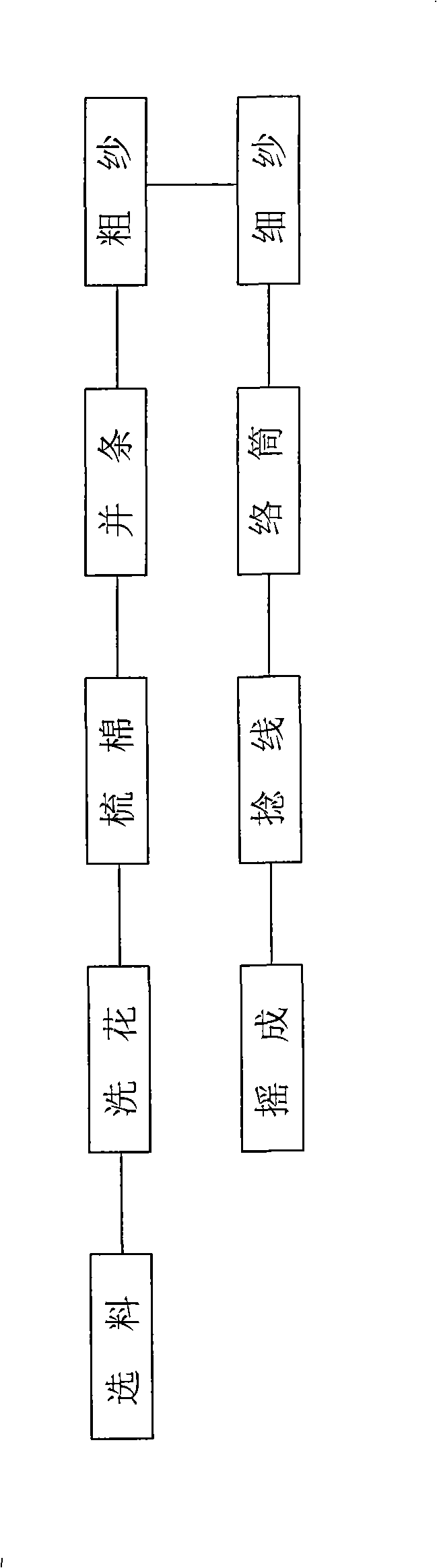

Method used

Image

Examples

Embodiment

[0015] Main ingredients: corn fiber and viscose. The weights are respectively: the weight ratio of corn fiber and viscose is 60:40, and the specification of the blended yarn is 18.2tex. The specific manufacturing steps are as follows: Mix the two main ingredients that have been weighed together and send them into the flower cleaning machine.

[0016] In the cleaning program, reduce the beating speed of the cleaning machine to 480rpm, and change the form of beating from blades to combing needles. After adjusting the machine, the two fibers are fully mixed in the cleaning machine, and then sent to the carding machine for carding . The key point of the cleaning process is to control the parameters of the above cleaning machines, so as to loosen and beat less fibers, so as to achieve the purpose of light combing and less shedding.

[0017] When carding, use the A186C model, chemical fiber bottom, and then set the main parameters of the carding machine as follows: cylinder speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com