Extrusion type rubber roller for pump

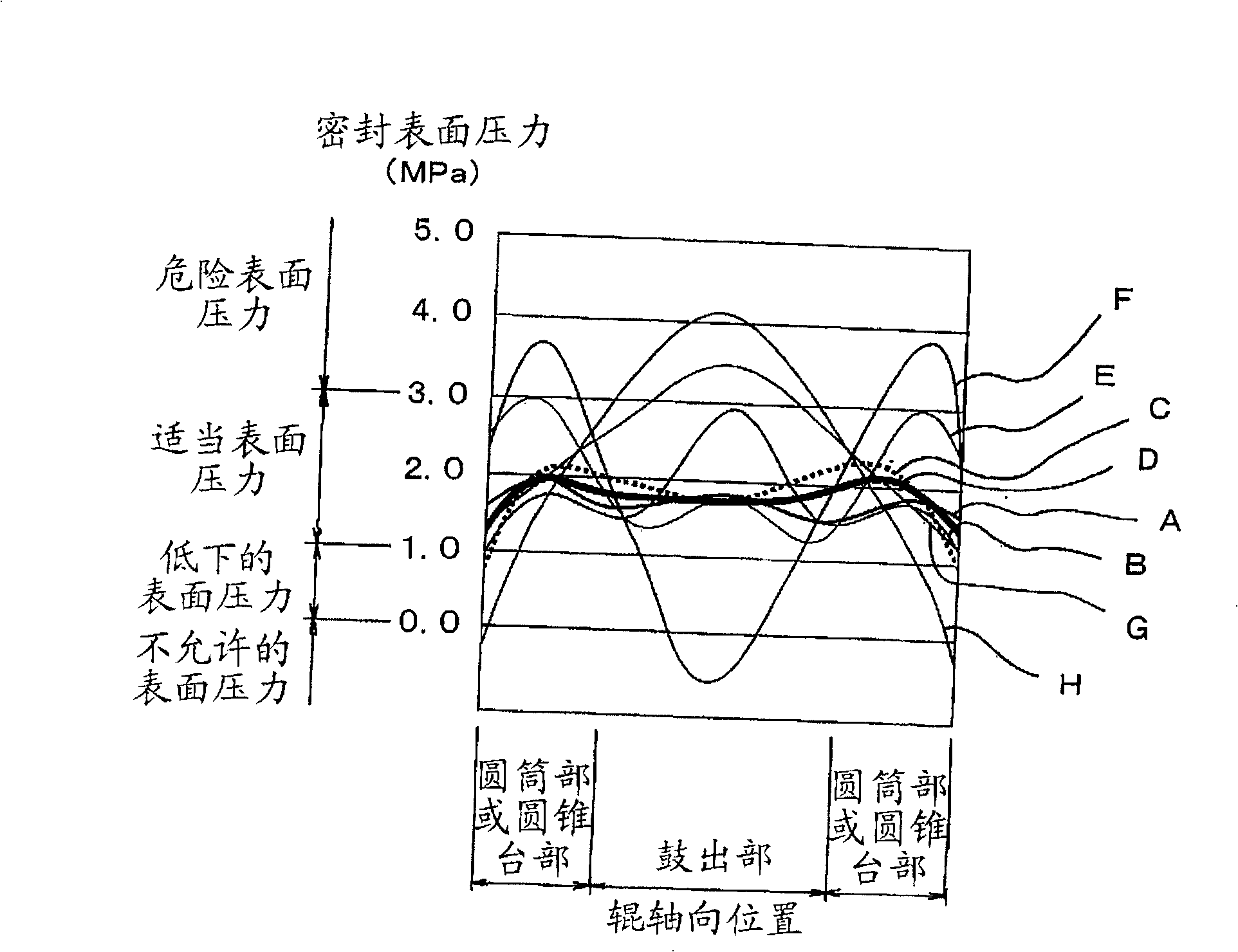

A rubber roller, extrusion technology, used in pumps, liquid variable capacity machinery, pumps with flexible working elements, etc., can solve the problem of not being able to seal both ends, improve recovery performance, stabilize sealing surface pressure, The effect of increasing the suction force of the fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

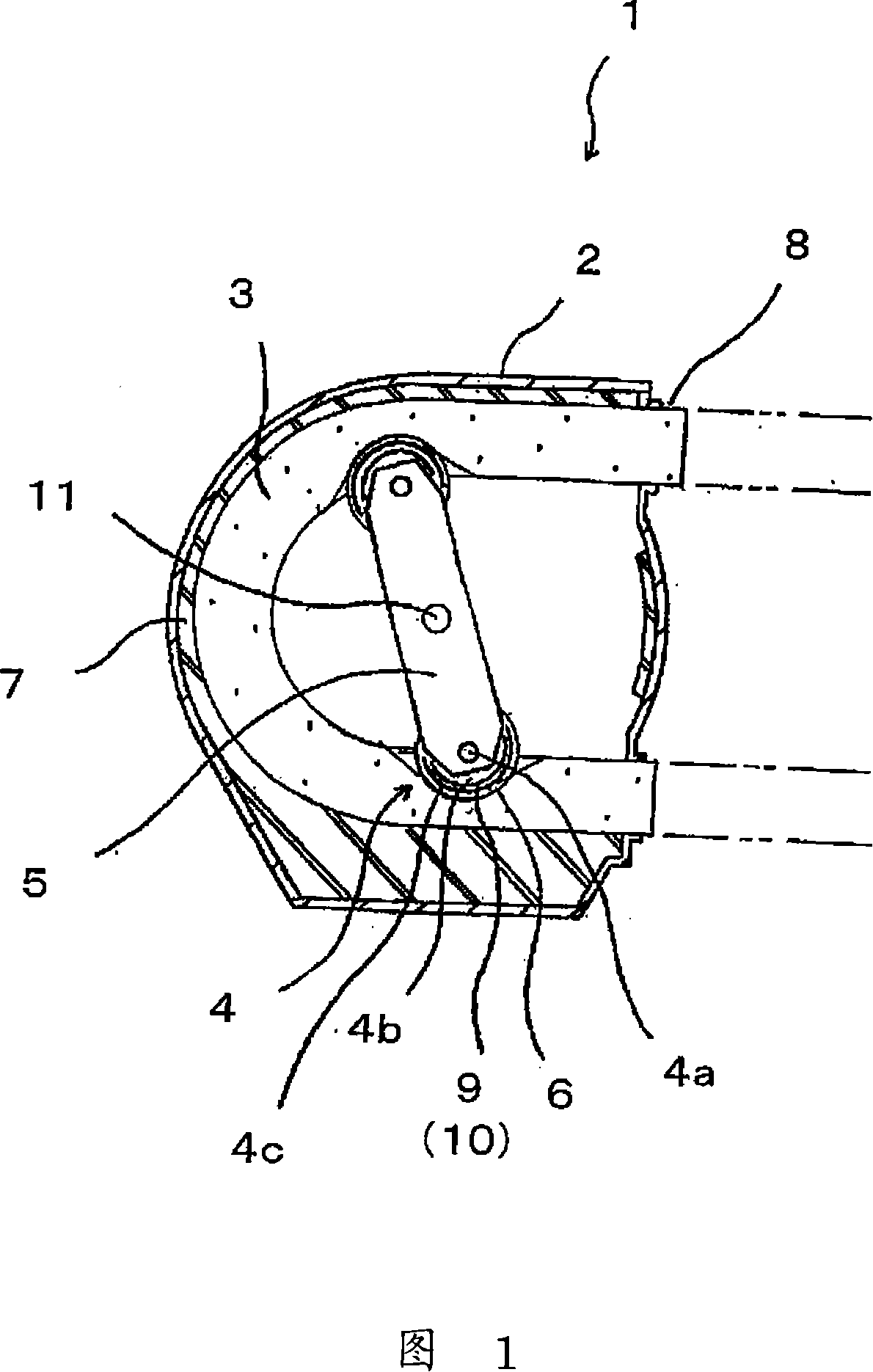

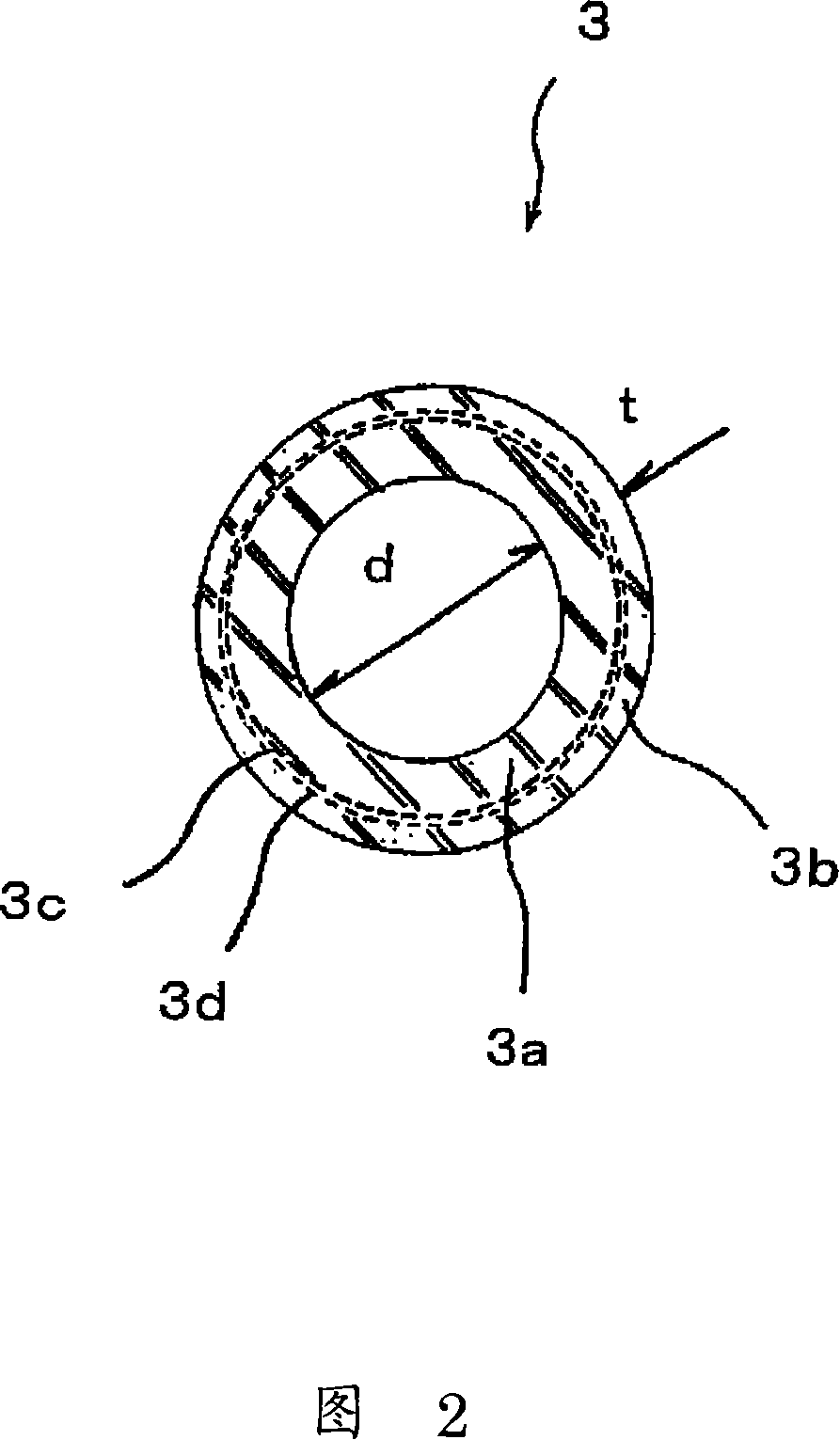

[0046] Hereinafter, the best mode for carrying out the squeeze pump rubber roller of the present invention will be described with reference to the drawings. figure 1 It is an overall sectional view of a squeeze pump having a rubber roller for a squeeze pump of the present invention. figure 2 is a cross-sectional view of the suction pipe. image 3 It is a cross-sectional view showing a state in which the suction pipe is pressed by a rubber roller whose both ends are cylindrical. Figure 4 It is a cross-sectional view showing a state in which the suction pipe is pressed by a rubber roller whose both ends are truncated cones.

[0047] Squeeze pump 1 is used to pressurize and convey fluids such as ready-mixed concrete, which has pump casing 2, suction pipe 3, rubber roller 4, and gyrator 5; The above-mentioned suction pipe 3 is bent along the inner peripheral surface of the pump casing 2 and installed in the pump casing 2; the above-mentioned rubber roller 4 is rolled to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com