Ring rolling mill and ring rolling method

A ring rolling mill, one-party technology, applied in the direction of metal rolling, metal rolling, etc., can solve the problems of inability to differentiate and incomprehensible differences, and achieve the effect of processing and high-efficiency processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

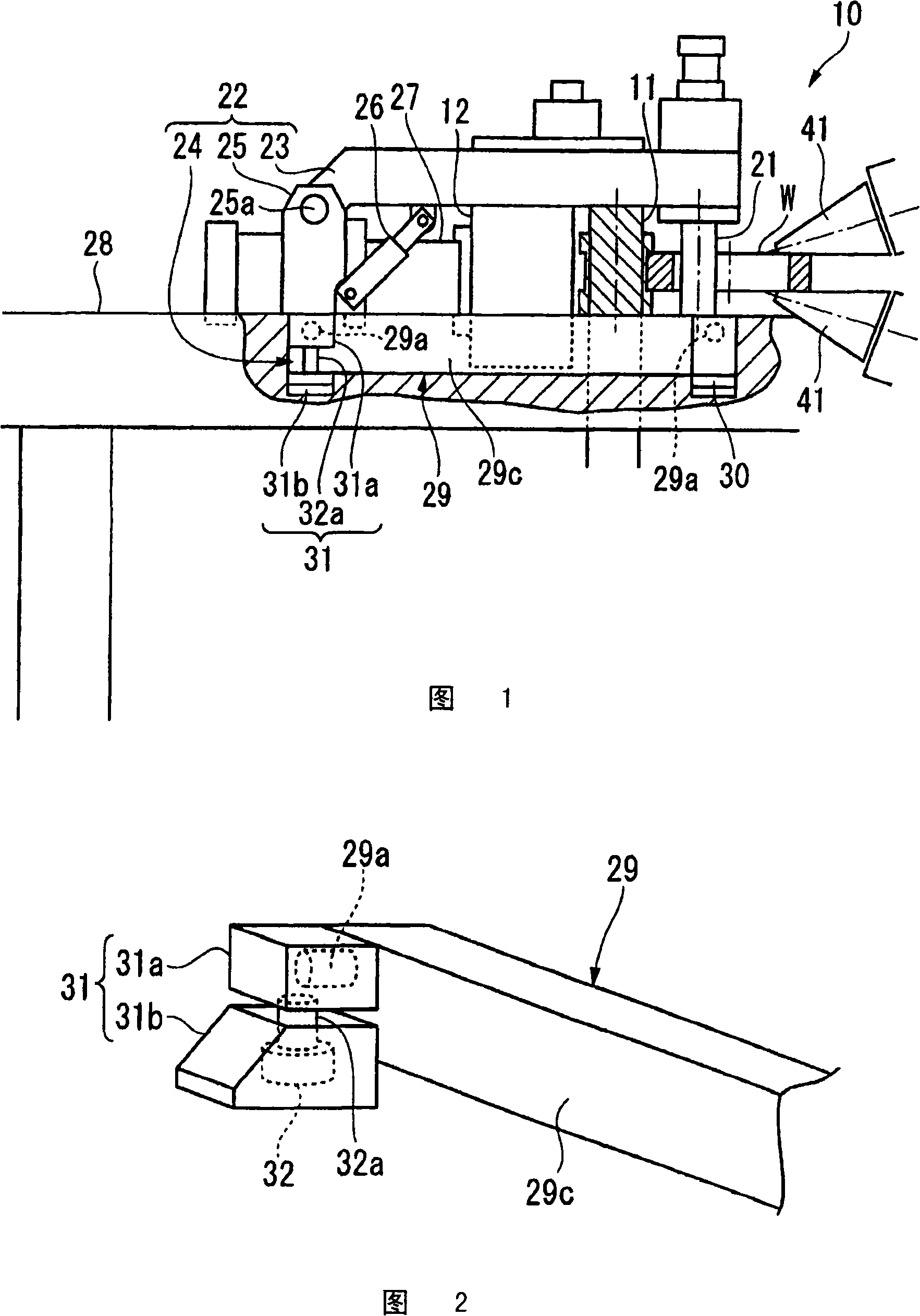

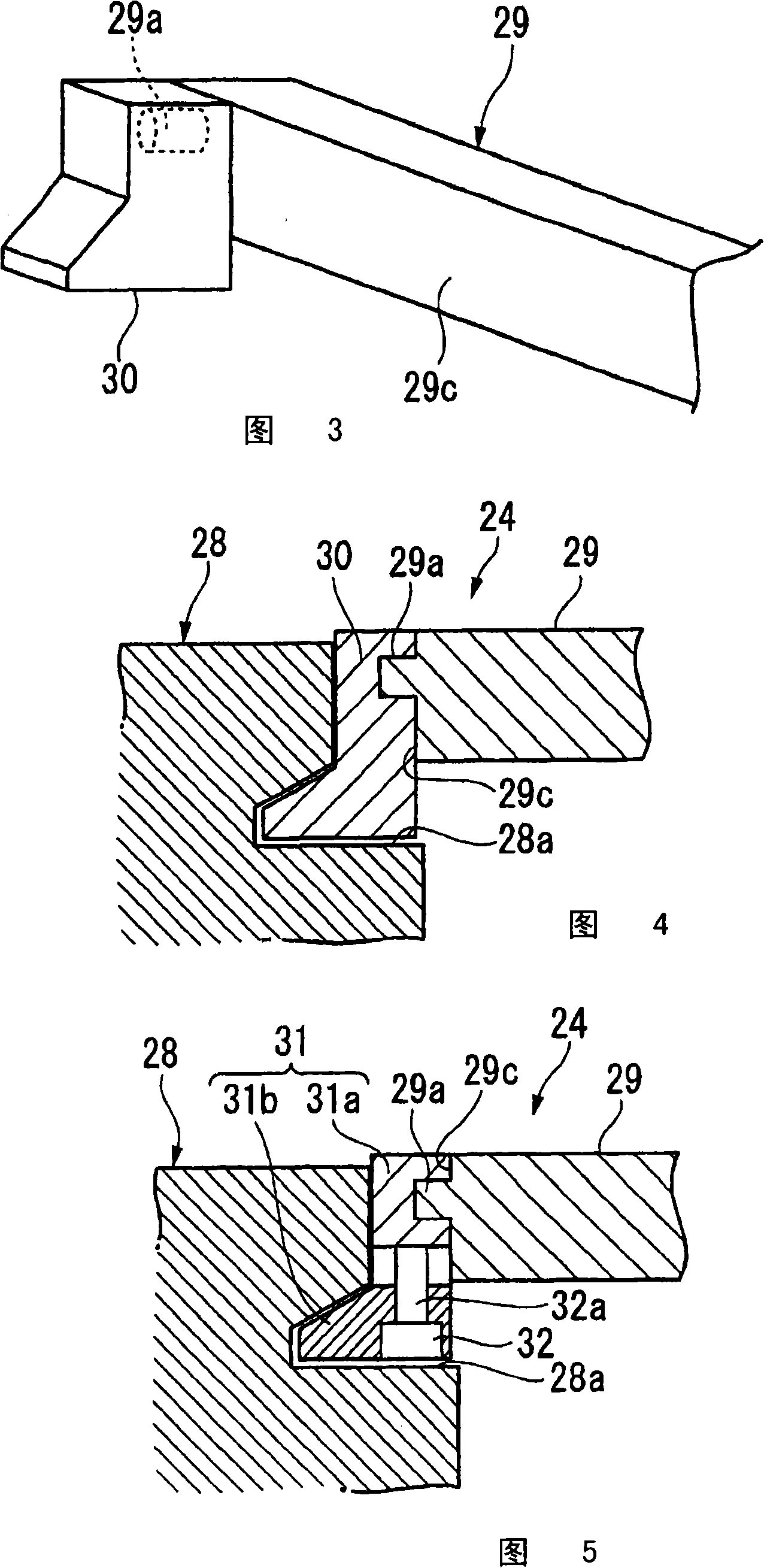

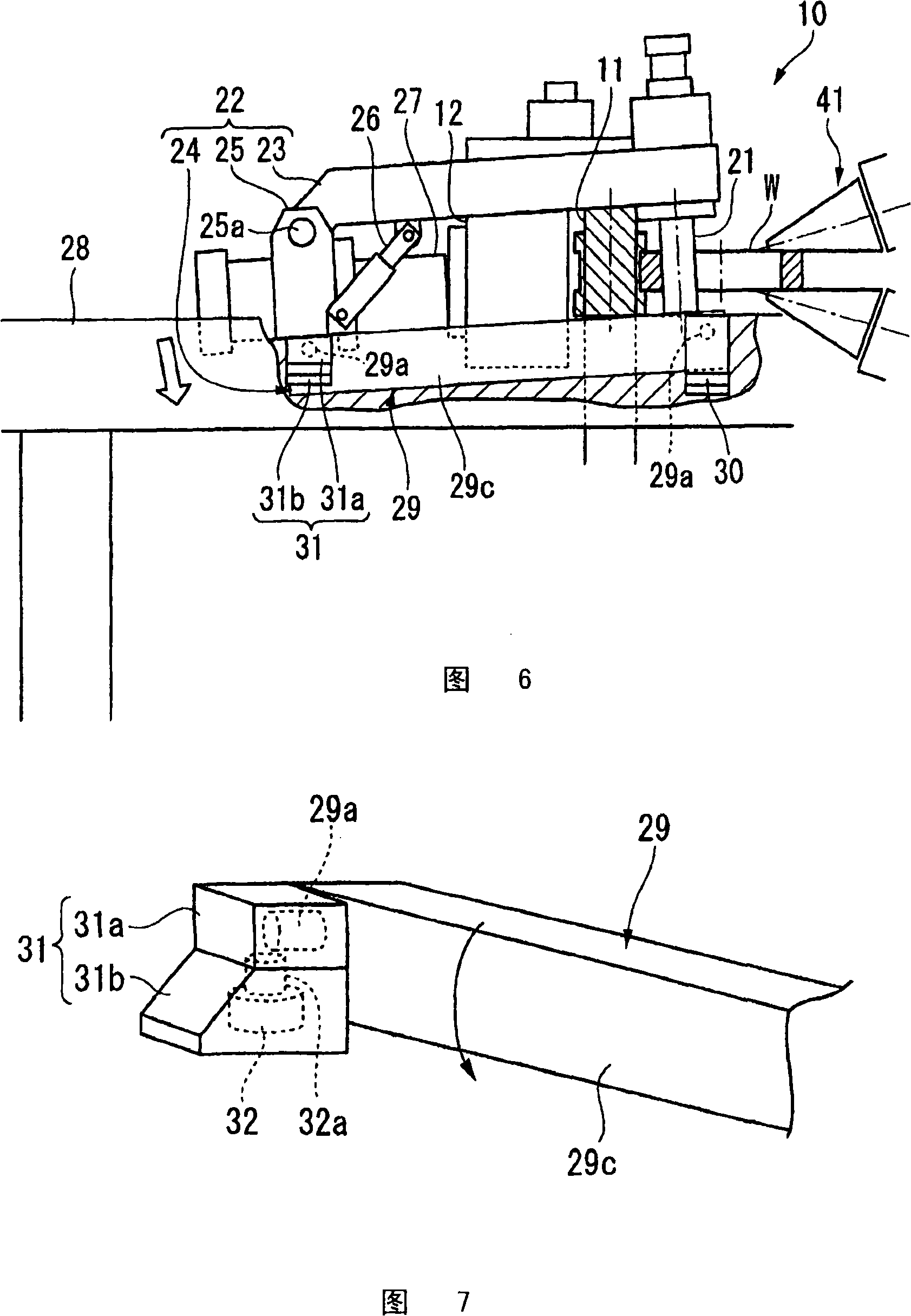

[0082] First, referring to FIGS. 1 to 10C , a first embodiment of the present invention will be described as follows. As shown in FIG. 1 , a ring rolling mill 10 according to this embodiment has a main roll 11 and a mandrel 21 which are provided so as to be close to or apart from each other. And, in a state where the peripheral portion of the annular body W is clamped in its radial direction between the outer peripheral surface of the main roll 11 that is rotationally driven about its axis and the outer peripheral surface of the mandrel 21 that is rotatable about its axis, While rotating the annular body W in the circumferential direction, the above-mentioned peripheral portion is radially rolled.

[0083] Also, the annular body W is formed by blank forging a molten ingot and then forming a through hole in the ingot.

[0084] At a position opposite to the main roll 11 and the mandrel 21 across the axis of the annular body W, a pair of axial rollers 41 sandwiching the annular ...

no. 2 approach

[0112] Below, side reference Figure 11A ~ Figure 15 A second embodiment of the present invention will be described as follows. In addition, in the following description, differences from the above-mentioned first embodiment will be mainly described, and the description of other points will be omitted as the same configuration as the above-mentioned first embodiment.

[0113] In the above-mentioned first embodiment, the mandrel 21 is tilted by rotating the entire movable frame 22 vertically and vertically, but in the ring rolling mill 110 of this embodiment, only the upper frame 23 (hereinafter referred to as the upper side frame 123) in parallel in the horizontal direction to tilt the mandrel 21, this point is particularly different.

[0114] Such as Figure 11A As shown, the ring rolling mill 110 of this embodiment has a tilting stand 122 as the mandrel tilting support mechanism of the present invention.

[0115] The tilt frame 122 has: a pair of upper frames 123 extendin...

no. 3 approach

[0137] Next, while referring to Figure 16 ~ Figure 18 A third embodiment of the present invention will be described as follows. In addition, in the following description, differences from the above-mentioned second embodiment will be mainly described, and the description of other points will be omitted as the same configuration as the above-mentioned second embodiment.

[0138] In the ring rolling mill 210 of the present embodiment, members corresponding to the upper stands 123 (hereinafter, This is particularly different in that the mandrel 21 is tilted by extending and contracting in the horizontal direction (referred to as the upper frame 223 ).

[0139] Such as Figure 16 As shown, the ring rolling mill 210 of this embodiment has: a pair of middle stands 225 as bases respectively fixed at fixed positions on each lower stand 124; A shaft body 271 parallel to the axis line CL5 parallel to the horizontal axes CL1 and CL2 ;

[0140] Each upper frame 223 has: a fixed side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com