Process and equipment for welding sealing thin-wall metal tube using laser technique

A welding sealing and laser technology technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of unreachable impact resistance, unsatisfactory welding quality and yield, and reducing the mechanical strength of metal pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

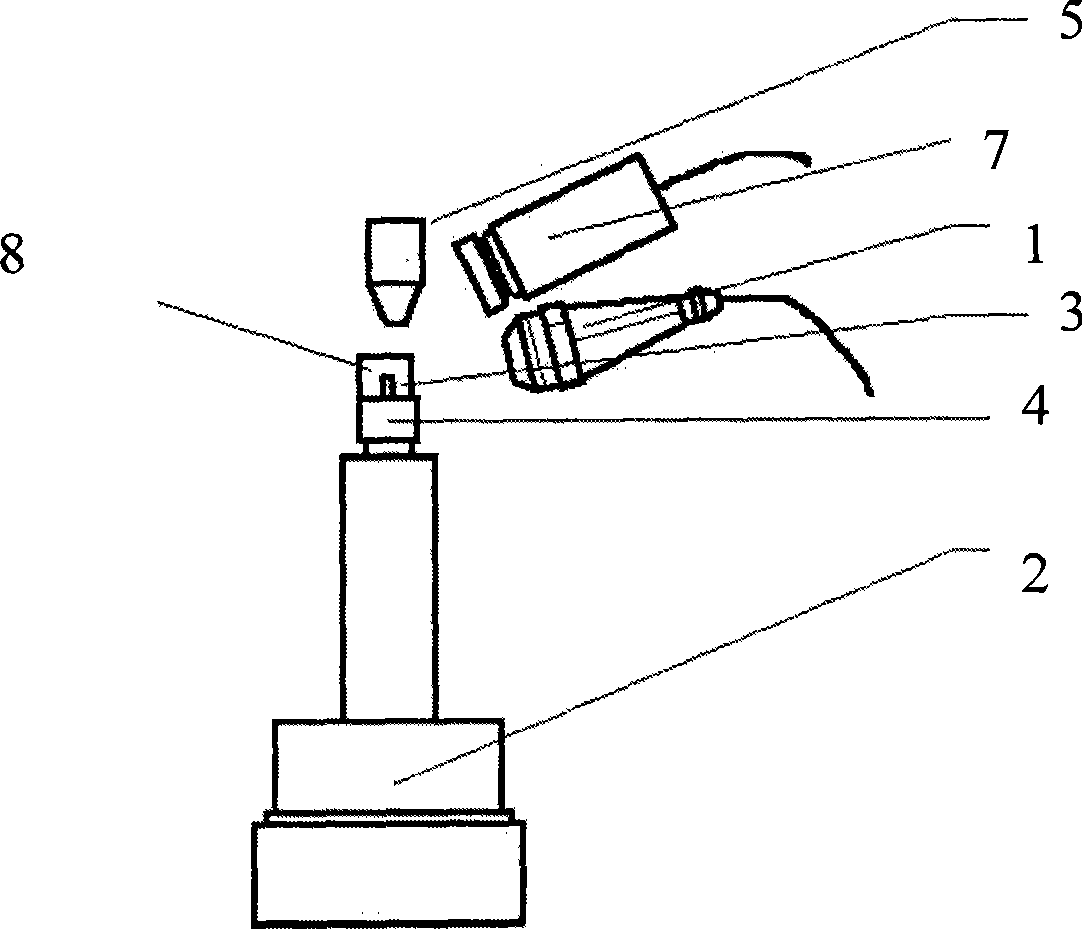

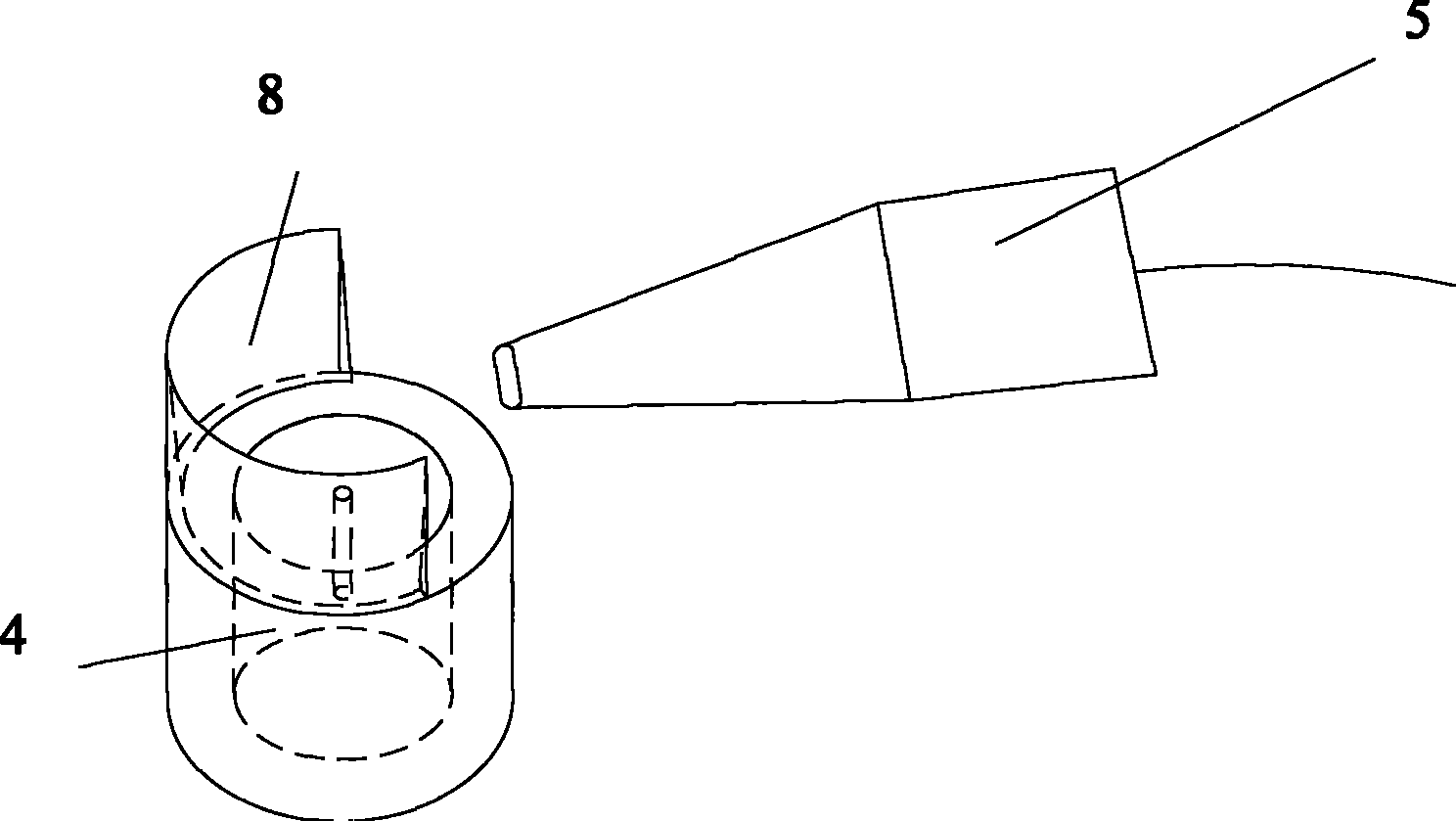

[0049] In this example, a titanium tube with a diameter of 0.8 mm and a wall thickness of 0.05 mm and a laser spot with a diameter of 0.8 mm are taken as an example. The specific welding and sealing process is as follows:

[0050] 1. Place the titanium tube 3 to be welded and sealed on the fixture 4 of the electric workbench 2;

[0051] 2. Adjust the light output energy of the laser welding machine to 2±0.1J, and the light output frequency to 6 times per second, so that it can just make the titanium tube in a molten state under the protection of an argon atmosphere, and quickly solidify on the backlight surface;

[0052] 3. Adjust the flow rate of argon to 0.2M 3 / h (cubic meter per hour), the gas pressure is adjusted to 200Kpa (kpa) by the pressure regulating valve, and the protective gas nozzle 5 is adjusted to control the flow direction, so that the molten titanium tube 3 during the whole welding process will not be oxidized or nitriding;

[0053] 4. Translate the electri...

Embodiment 2

[0062] In this example, a titanium tube with a diameter of 1.2 mm, a wall thickness of 0.05 mm and a laser spot diameter of 0.8 mm is taken as an example. The specific welding and sealing process is as follows:

[0063] 1. Adjust the light output energy of the laser welding machine to 2.2±0.1J, and the light output frequency to 8 times per second, so that it can just make the titanium tube in a molten state under the protection of an argon atmosphere, and quickly solidify on the backlight surface;

[0064] 2. Place the titanium tube 3 to be welded and sealed on the fixture 4 of the electric workbench 2;

[0065] 3. Adjust the flow rate of argon to 0.3M 3 / h, the pressure is 200Kpa, and the protective gas nozzle 5 is adjusted to control the flow direction, so that the molten titanium tube 3 will not be oxidized or nitrided during the entire welding process;

[0066] 4. Translate the electric workbench 2 so that the top welding spot of the titanium tube 3 is just at the focal p...

Embodiment 3

[0075] In this example, a titanium tube with a diameter of 1.2 mm and a wall thickness of 0.08 mm and a laser spot with a diameter of 0.8 mm are taken as an example. The specific welding and sealing process is as follows:

[0076] 1. Adjust the flow rate of argon to 0.1M 3 / h, the pressure is 200KPa, and the protective gas nozzle 5 is adjusted to control the flow direction, so that the molten titanium tube 3 will not be oxidized or nitrided during the whole welding process;

[0077] 2. Adjust the light output energy of the laser welding machine to 2.5±0.1J, and the light output frequency to 8 times per second, so that it can just make the titanium tube in a molten state under the protection of an argon atmosphere, and quickly solidify on the backlight surface;

[0078] 3. Place the titanium tube 3 to be welded and sealed on the fixture 4 of the electric workbench 2;

[0079] 4. Translate the electric workbench 2 so that the top welding spot of the titanium tube 3 is just at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com