Air pressure power multiplying cylinder

A double force cylinder and air cylinder technology, applied in the field of pneumatic double force cylinder, can solve the problems of large structure of force force mechanism, poor mechanical transmission effect, space limitation, etc., achieve smooth and fast movement, stable movement, and reduce air pressure power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

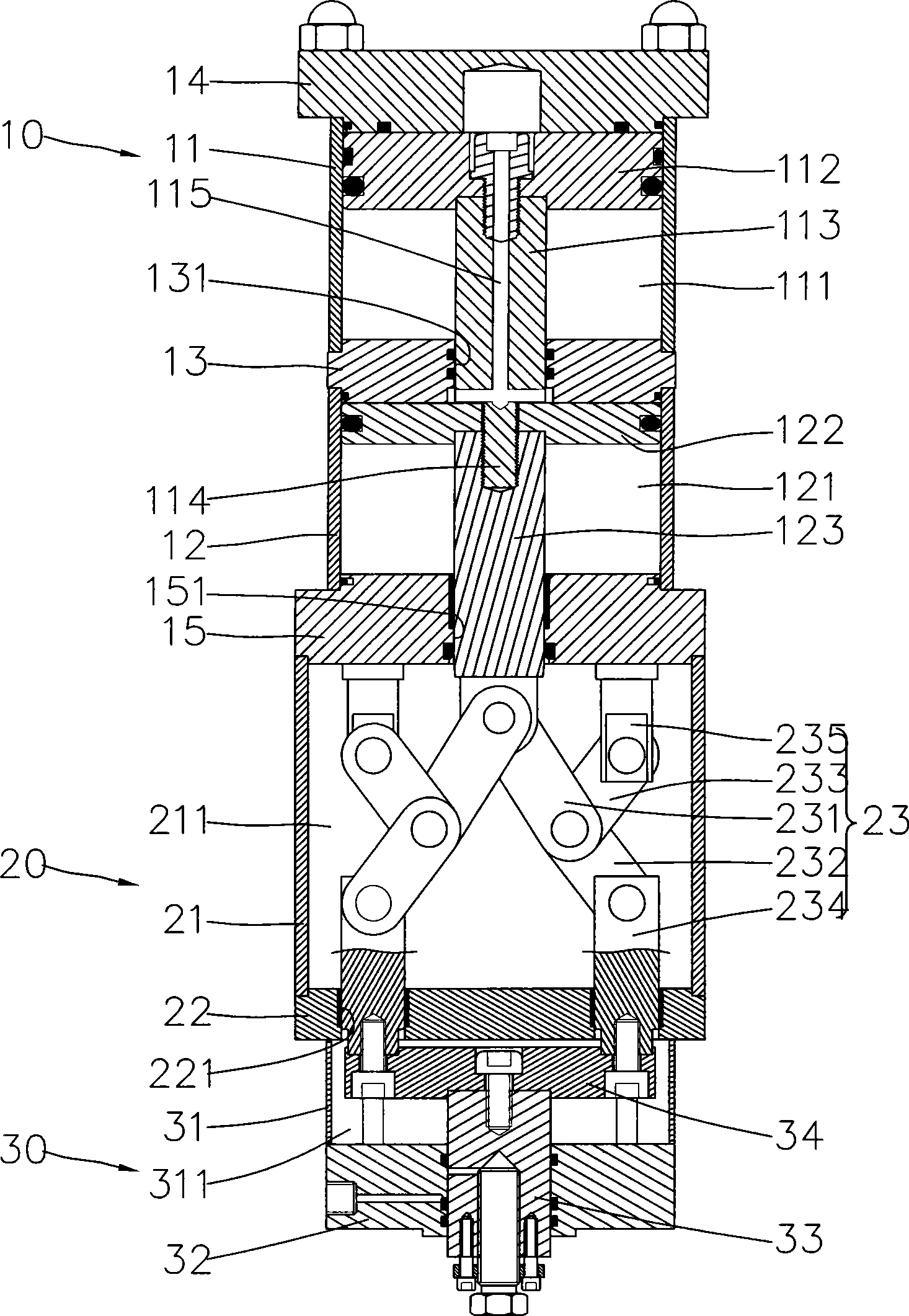

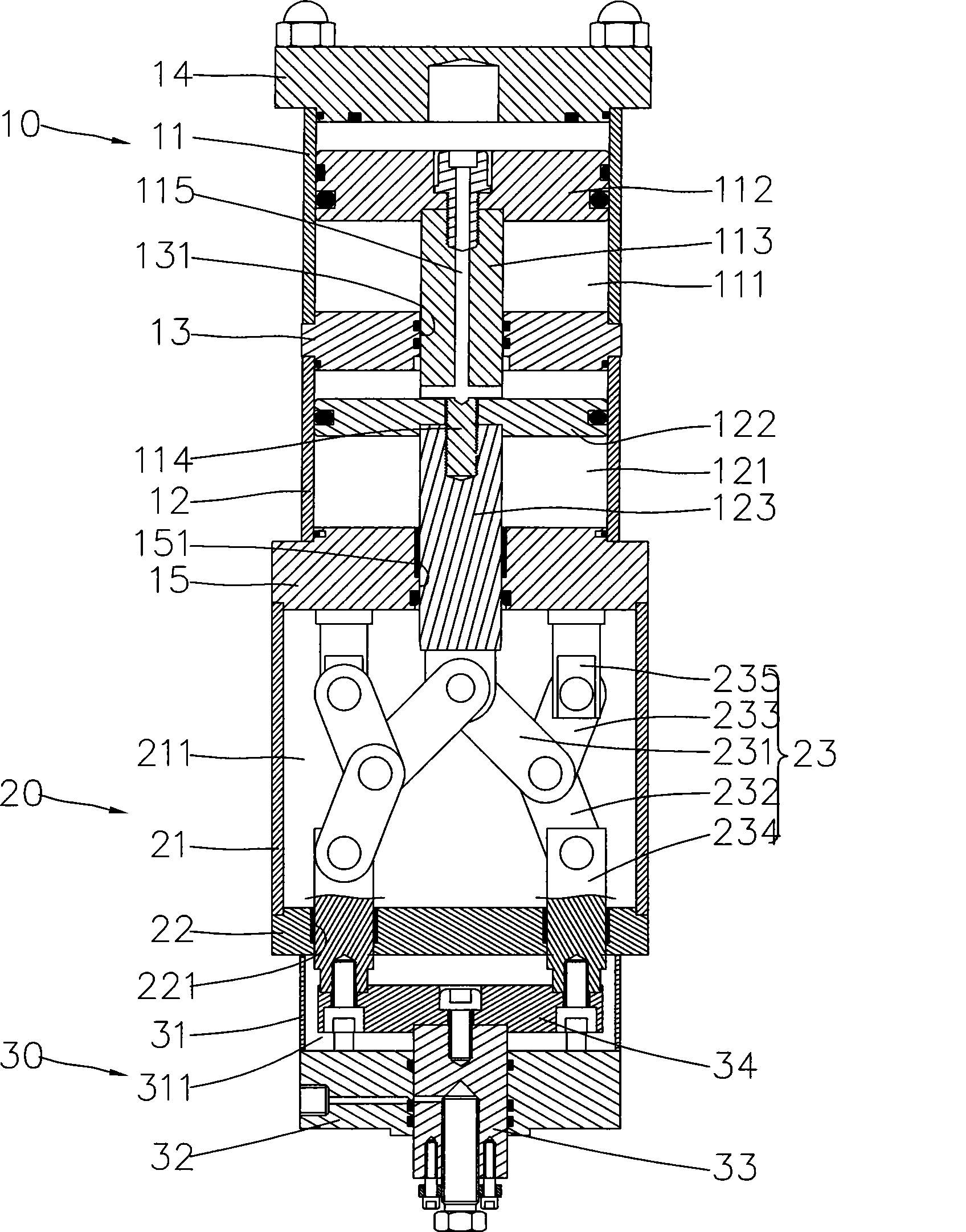

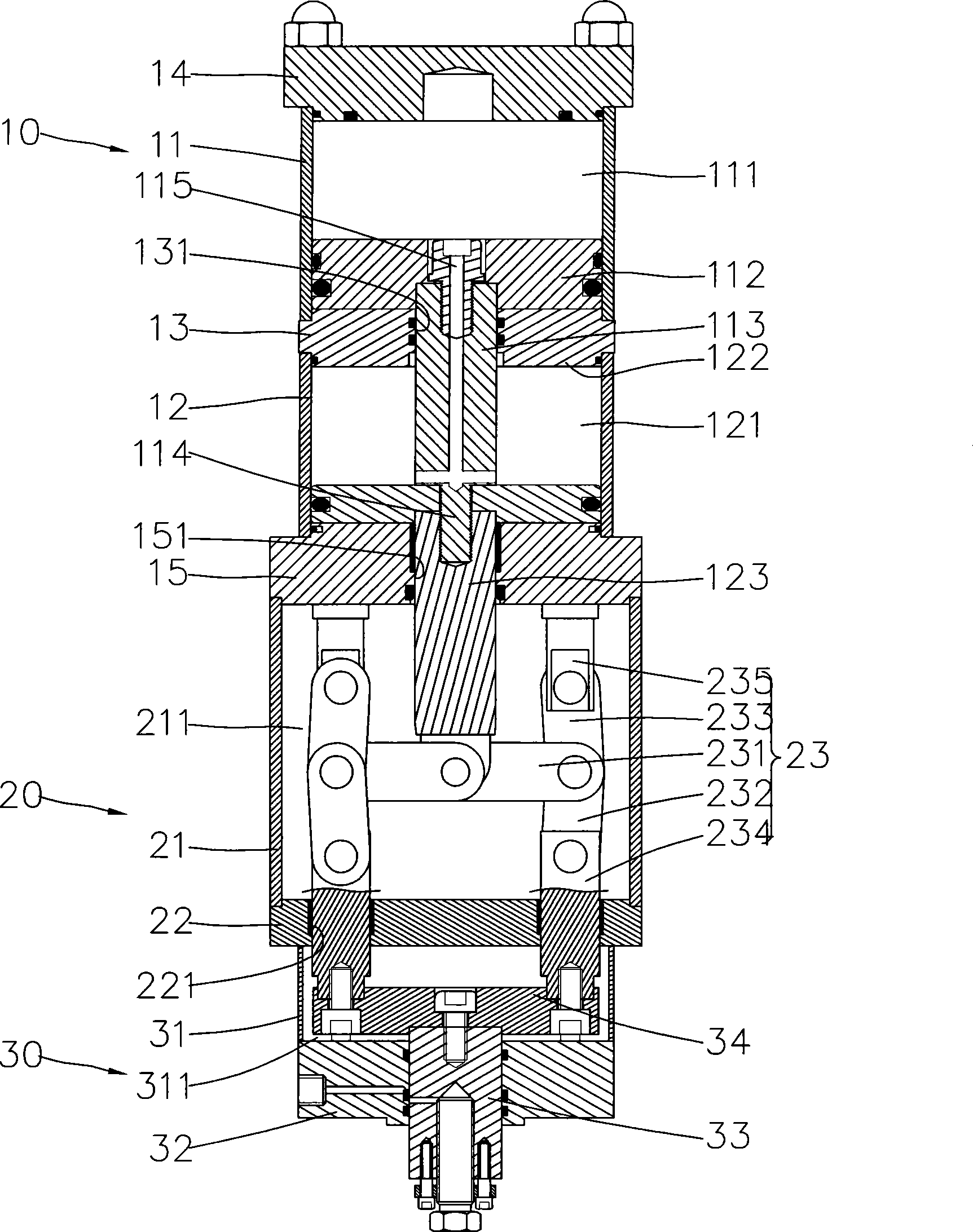

[0016] refer to figure 1 and figure 2 , the present invention includes a cylinder unit 10, a force multiplier unit 20 and an output unit 30; the force multiplier unit 20 is provided with a toggle mechanism to provide a multiplied output force. in:

[0017] The cylinder unit 10 includes a first cylinder block 11 and a second cylinder block 12 which are connected in series, and a central hole 131 is provided between the first cylinder block 11 and the second cylinder block 12. seat 13, so that an air chamber 111, 121 is formed between the two cylinder blocks 11, 12, respectively. The first cylinder 11 is equipped with a first piston 112 that can move in the air chamber 111, and the first piston 112 is screwed with a first piston rod 113 that extends through the hole 131 of the middle seat 13. . One end of the first piston rod 113 is formed with a joint portion 114 protruding into the air chamber 121 of the second cylinder 12 , and the first piston rod 113 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com