Connector for coaxial cable

A coaxial cable and connector technology, applied in the direction of conductive connection, connection, two-component connection device, etc., can solve the problems of cumbersome crimping operation, and achieve the effect of easy crimping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

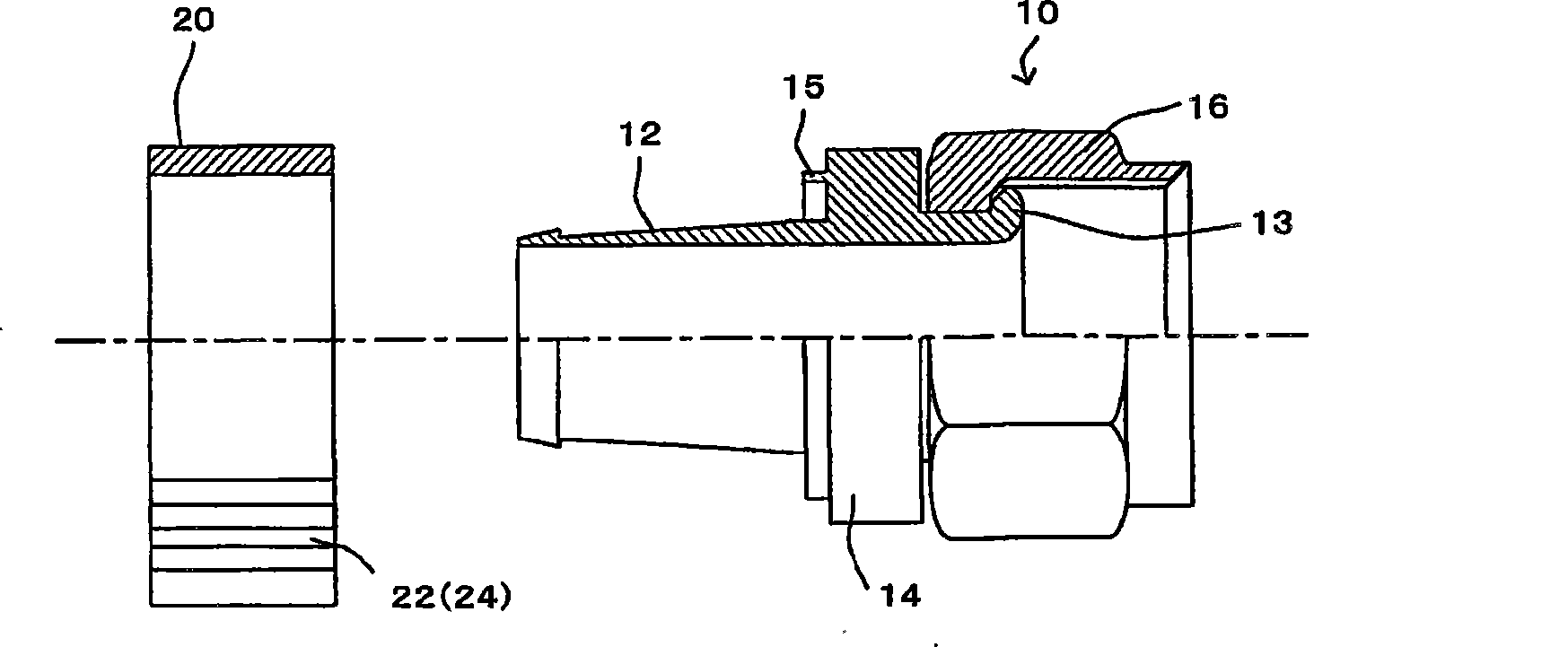

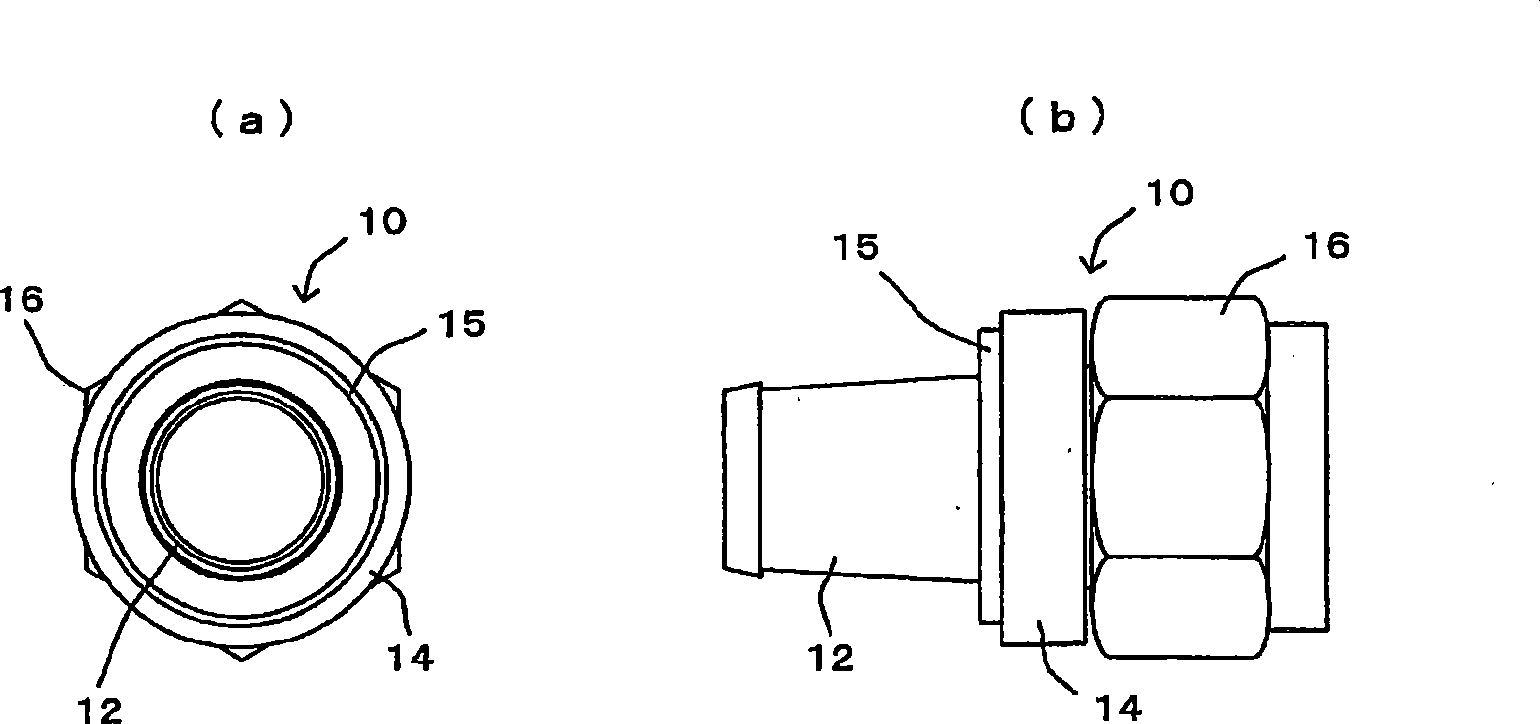

[0073] figure 1 is a partial cross-sectional view showing the composition of a coaxial cable connector (hereinafter simply referred to as a connector) according to an embodiment of the present invention. figure 2 (a) and (b) are shown figure 1 Explanatory drawing of the appearance of the connector body shown. exist figure 1 In , the part above the dot-dash line along the central axis of the connector shows the section of the connector, while the part below the dot-dash line shows the appearance of the connector. figure 2 (a) is an end view of the connector body seen from the side mounted on the coaxial cable. figure 2 (b) is a side view of the connector body.

[0074] The connector of the present invention is used to connect a coaxial cable to a connection object such as an F-type relay and an F-type antenna terminal. Such as figure 1 shown, withFigure 15 Like the conventional connectors shown in (a) to (e), the connector of the present invention includes a connec...

Embodiment approach 1

[0085] (Variation 1: see Figure 4 (a) and (b))

[0086] For example, in the above embodiments, the annular protrusion 15 suitable for fitting with the inner surface of the locking ring 20 protrudes from the flange portion 14 of the connector body 10 . However, for example, as Figure 4 As shown in (a) and (b), several protrusions 17 (three in the figure) may be arranged at the flange portion 14 of the connector body 10 to fit with the inner surface of the locking ring 20 . In this way also, the same effects as those of the above-described embodiment can be obtained. If several protrusions 17 protrude from the flange portion 14 , the size and quantity of the protrusions 17 can be appropriately set according to the size and weight of the fixing ring 20 , so as to fix the locking ring 20 .

[0087] In addition if Figure 4 As shown in (a) and (b), if the knurling is formed on the outer surface of the fitting portion 16 of the connector body 10, slippage that occurs when the ...

Embodiment approach 2

[0089] (Variation 2: see Figure 5 (a), (b) and (c))

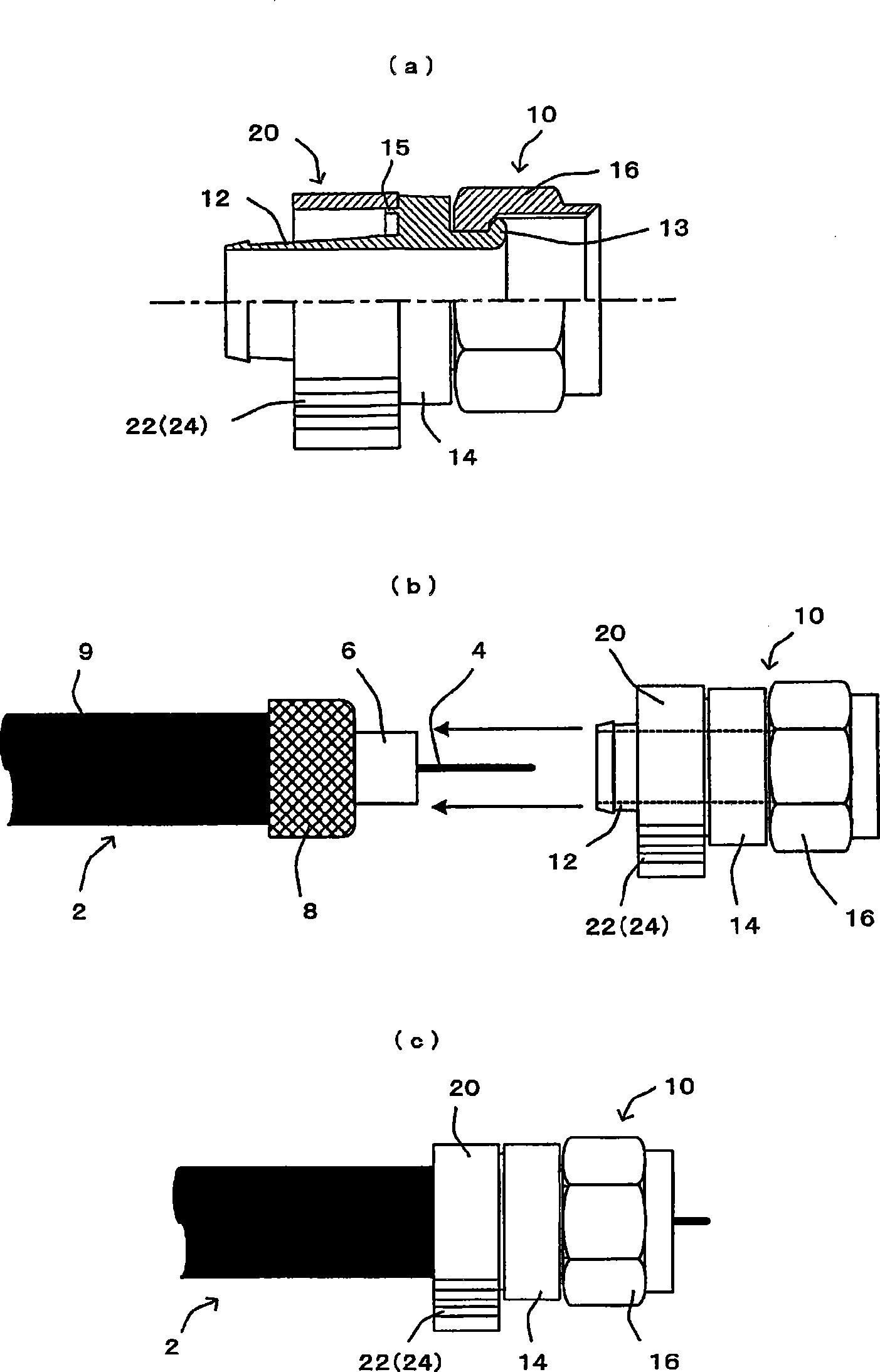

[0090] For example, if Figure 5 (a) to (c), in the case where the connecting body 10 is provided with an annular skirt 18 from the outer peripheral edge of the flange portion 14 toward the opposite side of the fitting portion 16 to surround the end of the coaxial cable, it is possible to The inner diameter of the skirt 18 (or the outer diameter of the locking ring 20 ) is set so that the locking ring 20 can be directly fitted to the inner surface of the skirt 18 .

[0091] However in this case, as Figure 5 As shown in (a) to (c), when the crimping protrusions 20, 24 protrude from the locking ring 20, a part of the skirt 18, which is the annular protrusion protruding from the flange part 14, must be notched. , so that when the locking ring 20 is engaged with the skirt 18, the crimping protrusions 20, 24 protruding from the locking ring 20 can reach outside the ring of the skirt 18, and can be clamped with pliers or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com