Metallic phase automatic grinding and polishing device

A polishing machine and automatic technology, which is applied in the direction of grinding/polishing equipment, grinding machine parts, grinding machines, etc., can solve the problems of sample grinding deviation and grinding amount difficult to control accurately, so as to improve the grinding accuracy and reduce the Clearance, the effect of improving the lifting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

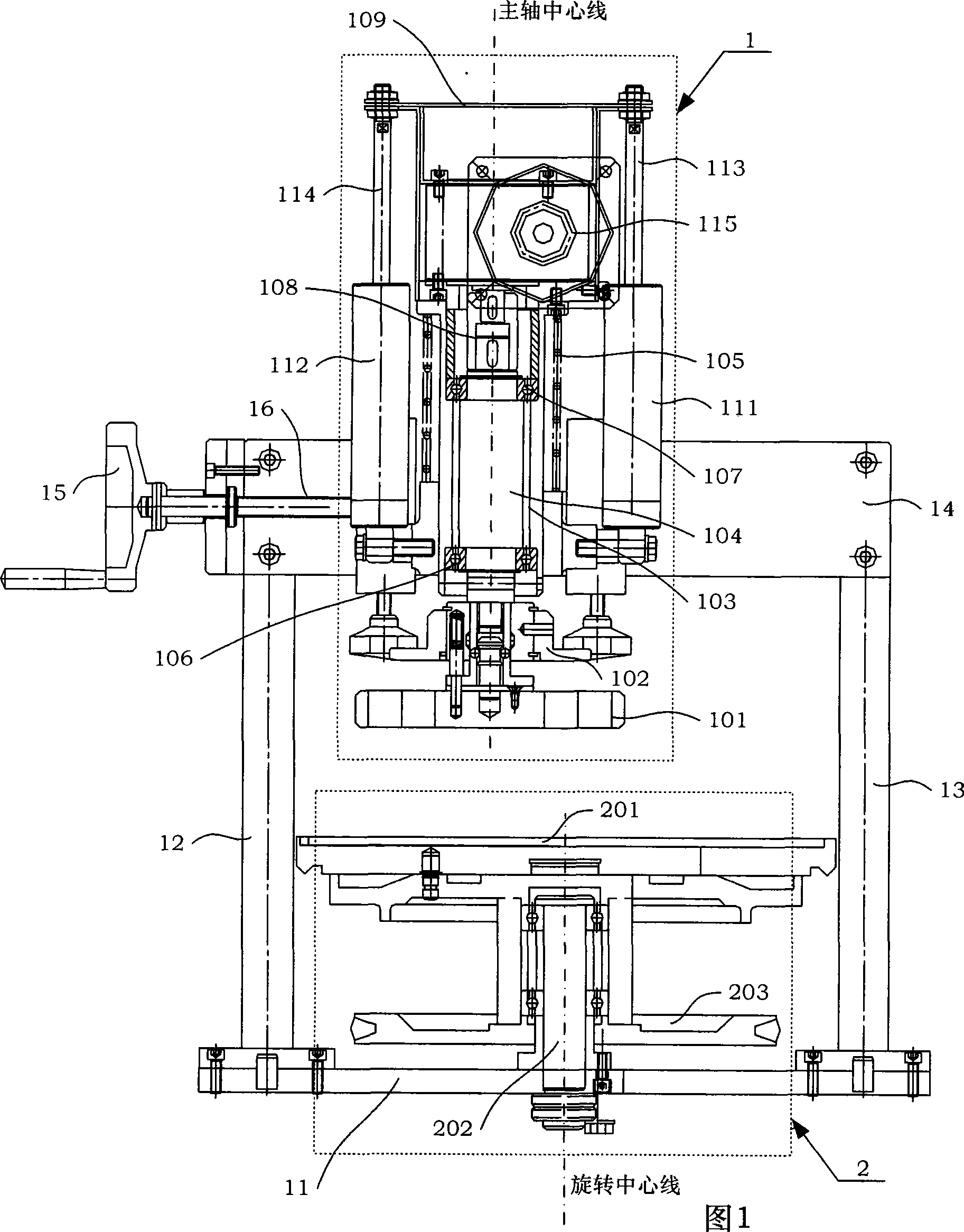

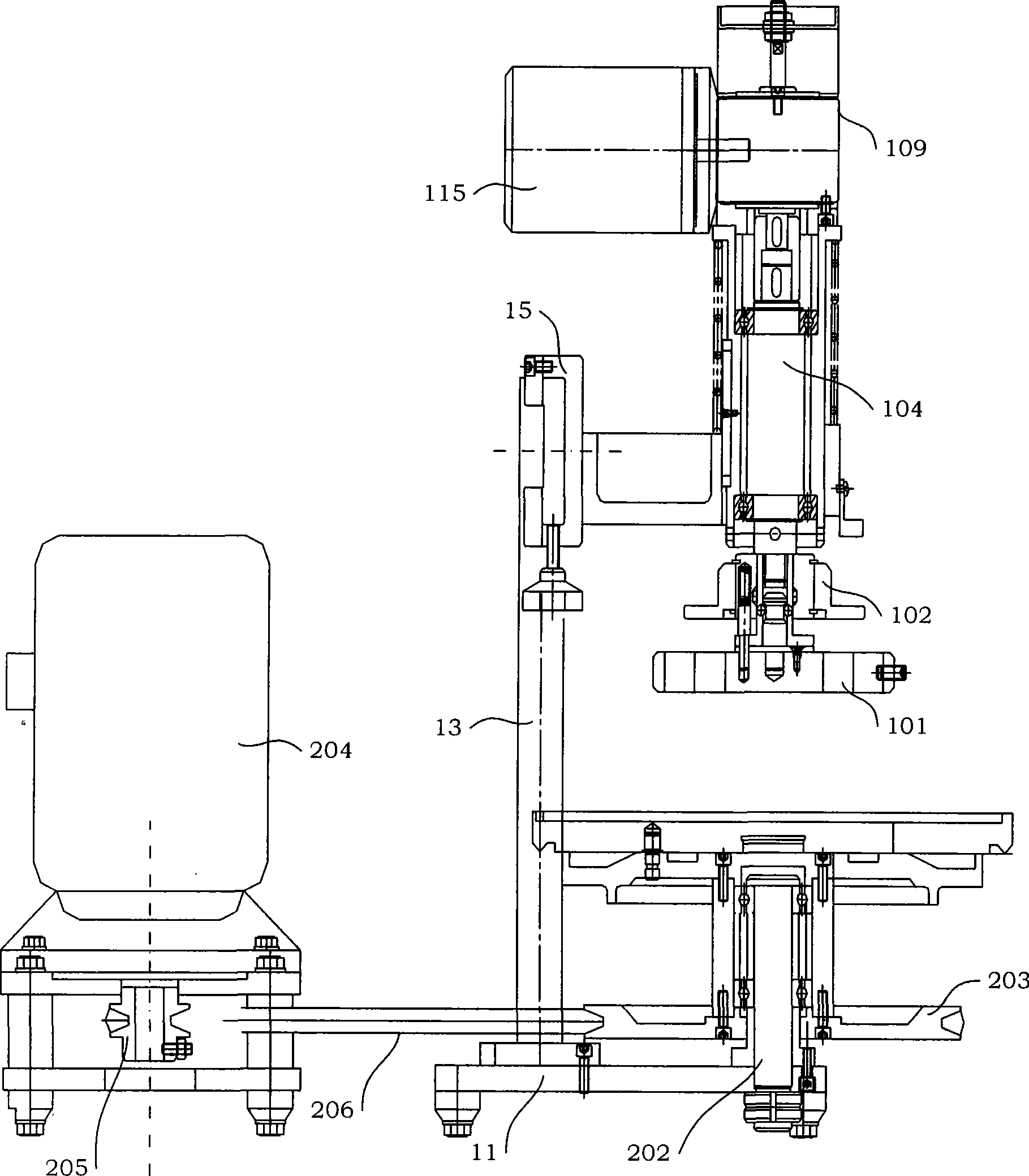

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The invention is a metallographic automatic grinding and polishing machine capable of performing surface grinding and polishing treatment on high-hardness metals such as aluminum alloy, titanium aluminum alloy, and niobium-silicon alloy. The metallographic automatic grinding and polishing machine includes an electric control unit, a hydraulic unit, The cooling water unit, the polishing main shaft unit, and the rotating grinding disc unit, and the polishing main shaft unit and the rotating grinding disc unit are of a separate structure.

[0022] In the present invention, the electrical control unit is controlled by PLC (programmable logic controller), has a good man-machine interface, and can grind and polish different kinds of metals or alloys. With the function of stepless speed regulation, it can adapt to materials with different hardness. Lubricant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com