Suspension type clothing transmission production line

A production line and hanging technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as troublesome and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing.

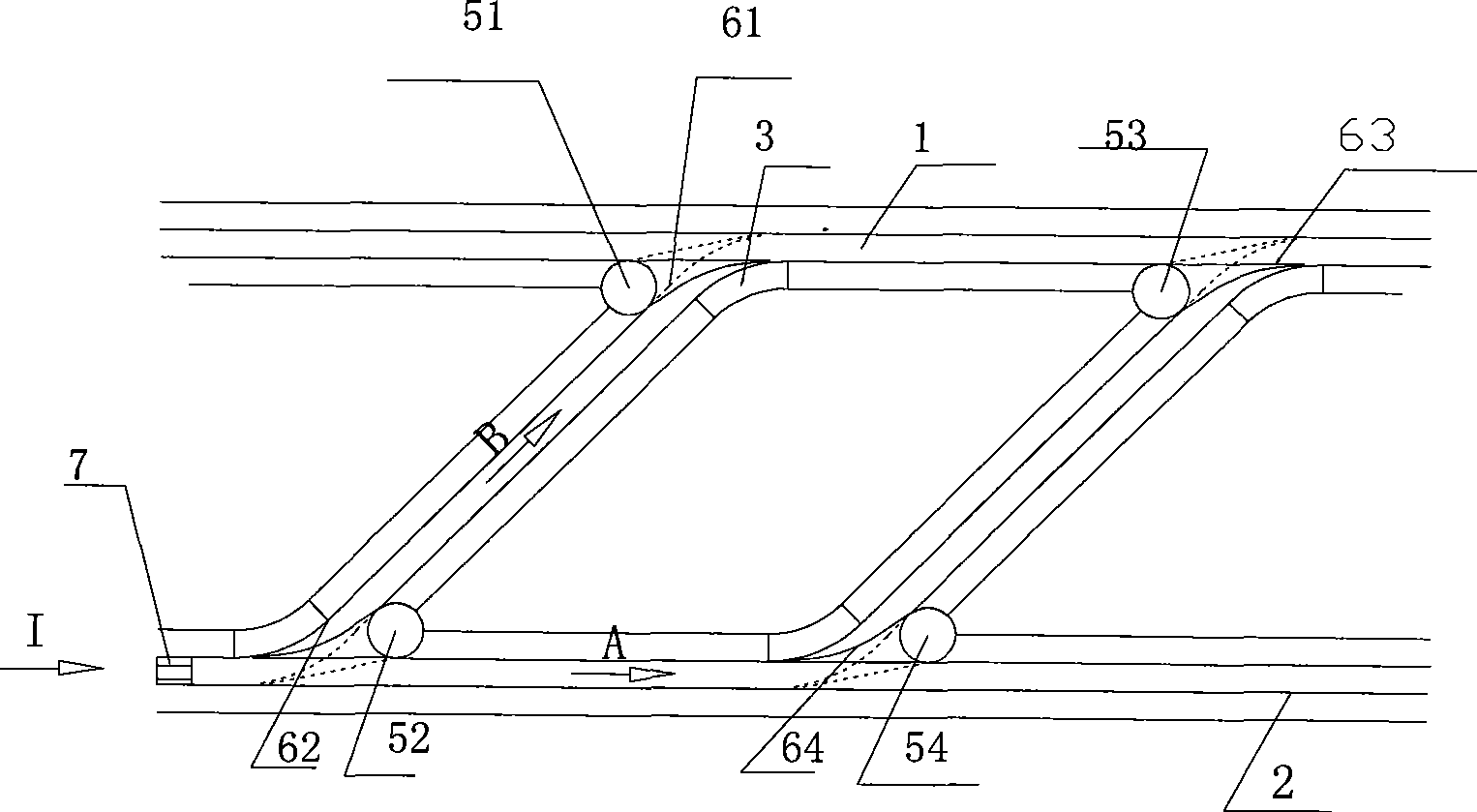

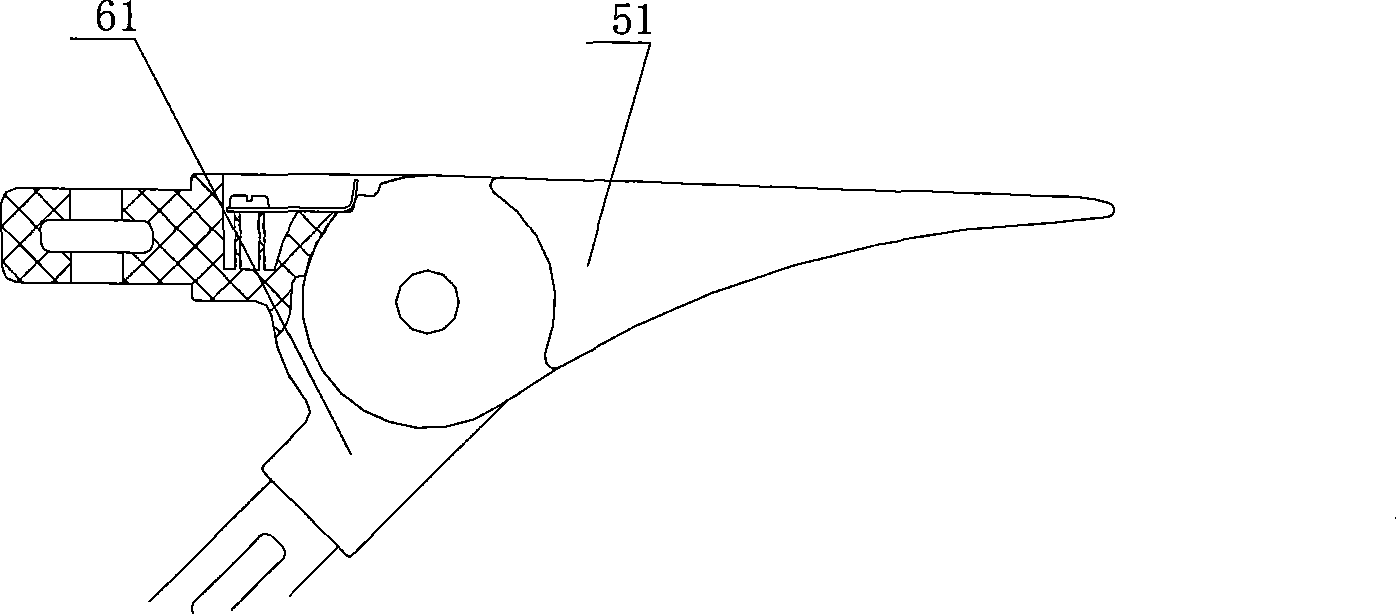

[0008] In order to solve the above-mentioned technical problems, a hanging type transmission production line of the present invention is composed of at least one station section, each station section is composed of rails 1, 2, curved rails 3, 4, and a conveyor 7, curved rails 3, 4 is the track connecting the tracks 1 and 2, which is fixed between the tracks 1 and 2, and the curved tracks 3 and 4 are arranged in a parallelogram to facilitate the transmission of the conveyor 7 on the tracks 1 and 2. The hanging transmission production line, Commutator seats 51, 52, 53, 54 and commutators 61, 62, 63, 64 movably connected to the two ends of the curved rails 3, 4 connected to the inner rails 1, 2 are respectively fixed, and the connection can be Pin connection, also can be hinge connection, adopt the suspension type transmission production line of this structure, it is easy to u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com