Shaft sealing structure for handle of rack lock

A shaft sealing and handle technology, which is applied in the sealing structure field of cabinet locks, can solve the problems of poor sealing of the gap between the handle shaft and the lock body, lower waterproof and dustproof level, and poor waterproof performance, so as to achieve small wear of the sealing ring, Increased reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

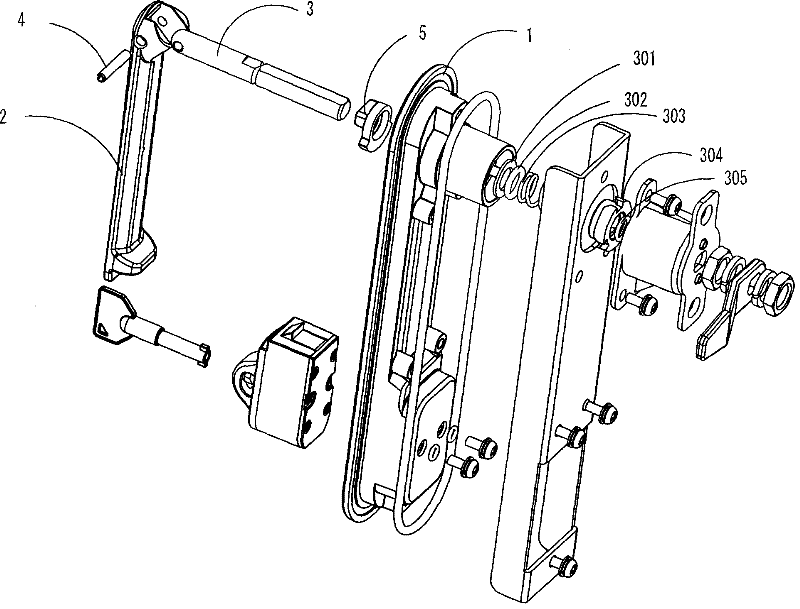

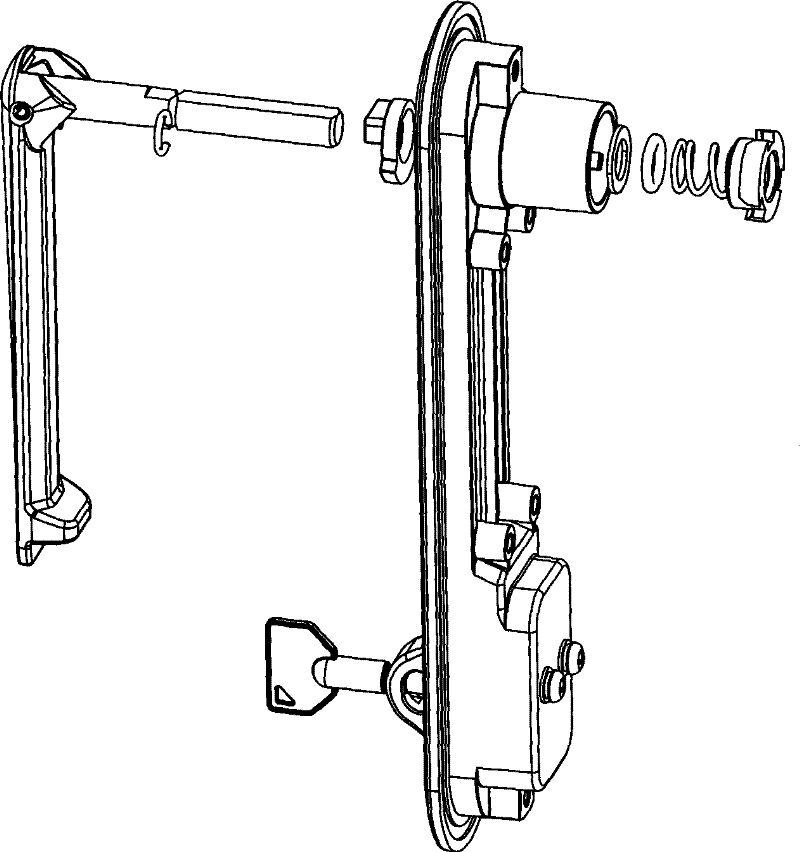

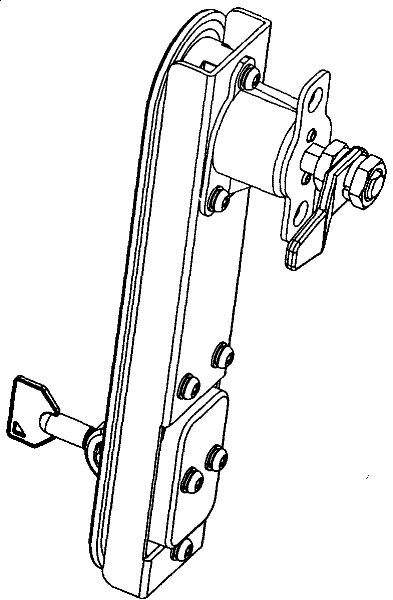

[0029] Such as Figure 1a , Figure 1b , Figure 2a , Figure 2b Shown is the first embodiment of the present invention, for the sake of clarity, Figure 1b , Figure 2b Part of the lock body is removed, and the cabinet lock handle shaft sealing structure includes lock body 1, handle 2 and handle shaft 3, handle 2 and handle shaft 3 are hinged through pin 4, and handle shaft 3 passes through lock body 1 The shaft installation hole 102 on the top is installed on the lock body 1, and the handle shaft 3 is driven by the handle 2 to rotate to realize the opening and locking of the cabinet. A handle shaft lifting mechanism is provided between the handle 2 and the handle shaft 3 to When closing the lock, press the handle 2 and lift the handle shaft 3. After the handle shaft 3 passes through the installation hole on the lock body 1, there is a seal ring 301 on it, and the corresponding seal ring part on the lock body is provided with a tapered seal ring Groove 101 is used to acco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap