Liquid-rationing valve

A technology of valves and liquids, which is applied in the direction of multi-way valves, valve devices, engine components, etc., can solve problems that need to be further improved, and achieve the effects of simple structure, high yield and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

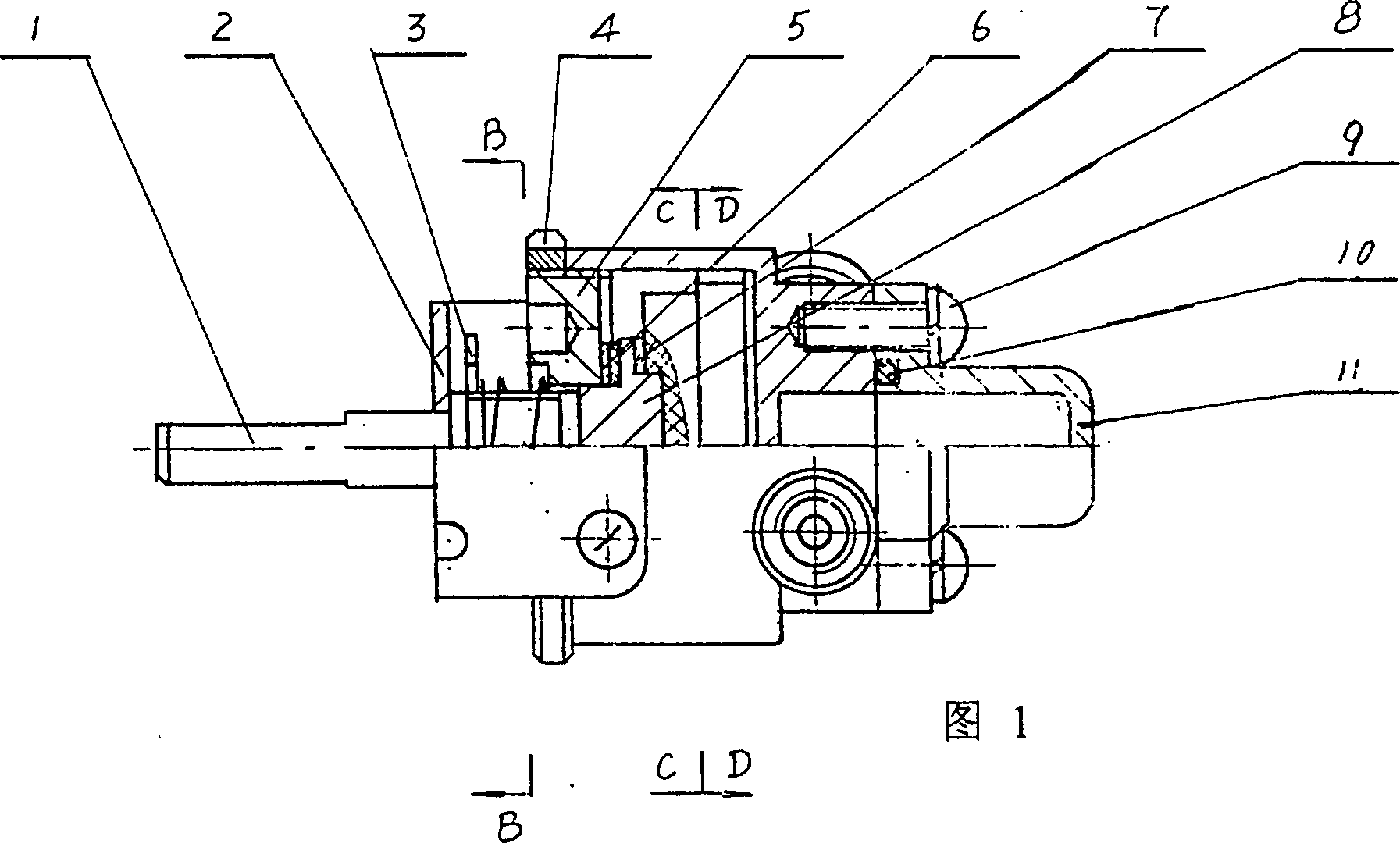

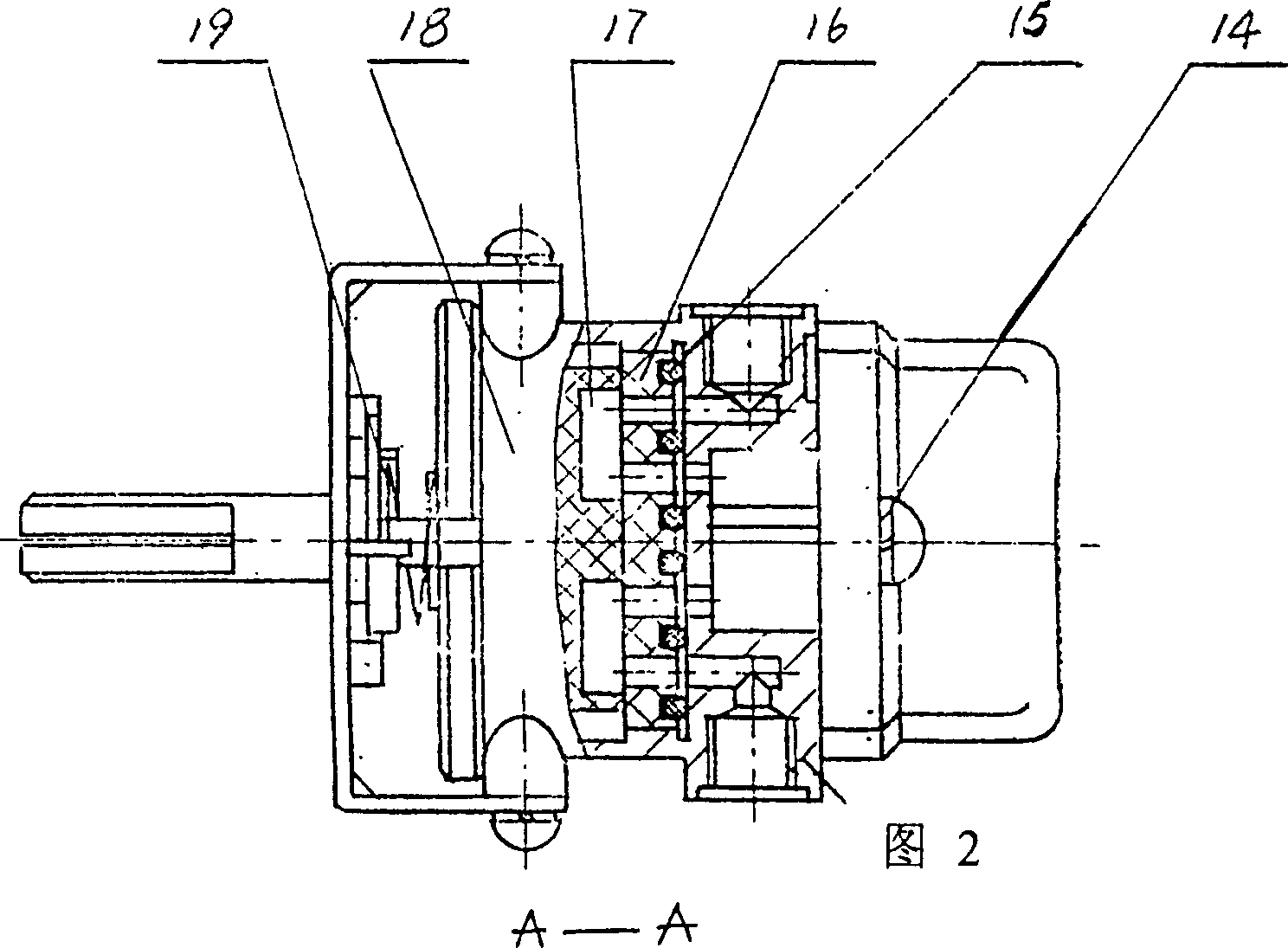

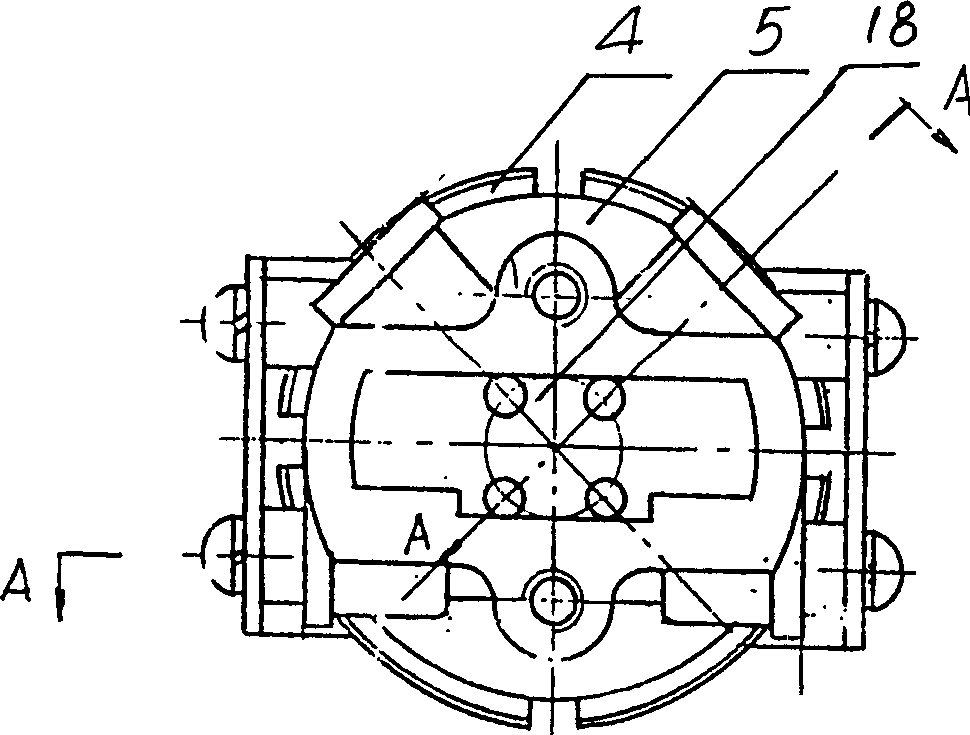

[0015] Fig. 1 is a schematic diagram of the front view of the present invention, and Fig. 2 is a schematic diagram of a cross-section of a liquid quantitative valve A-A, including a valve body 18, a quantitative cavity 11, a hole valve core 16 and a groove valve core 17, and one end of the valve body is a cylinder for placing the valve core hole, the other end is connected with the quantitative cavity, the hole spool 16 and the groove spool 17 are installed in the valve body 18, the quantitative cavity 11 can be connected on the valve body 18 by the bolt 9, the spring washer 14, in the quantitative cavity A quantitative chamber sealing ring 10 is arranged between the valve body and the valve body, so that quantitative chambers of different volumes can be easily replaced as required. Said groove valve core 17 has two communicating grooves I and II (referring t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap