Light steel structure house with outdoor corridor bottom girder

A technology for light steel structures and houses, which is applied in building structure and construction, etc., can solve the problems that the structure of light steel houses cannot be beautiful and practical, the floor space of corridor columns increases, and the joints between beams, columns and corridors are complicated. The effect of improving safety and stability, simplifying beam-column joints, and short on-site construction period

Inactive Publication Date: 2010-12-01

官木喜

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, this method of on-site welding requires power supply at the installation site, which poses a potential safety hazard; in addition, it is difficult for this outdoor corridor with stairs to be integrated with the light steel house structure, and its strength is poor. , increasing the column of the corridor will increase the floor area to a certain extent, and it is impossible to make the structure of the light steel house beautiful and practical.

In addition, due to the many types of work required for on-site installation and construction, the joints between beams, columns and corridors are complicated, the construction process is many, and the cost is also high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

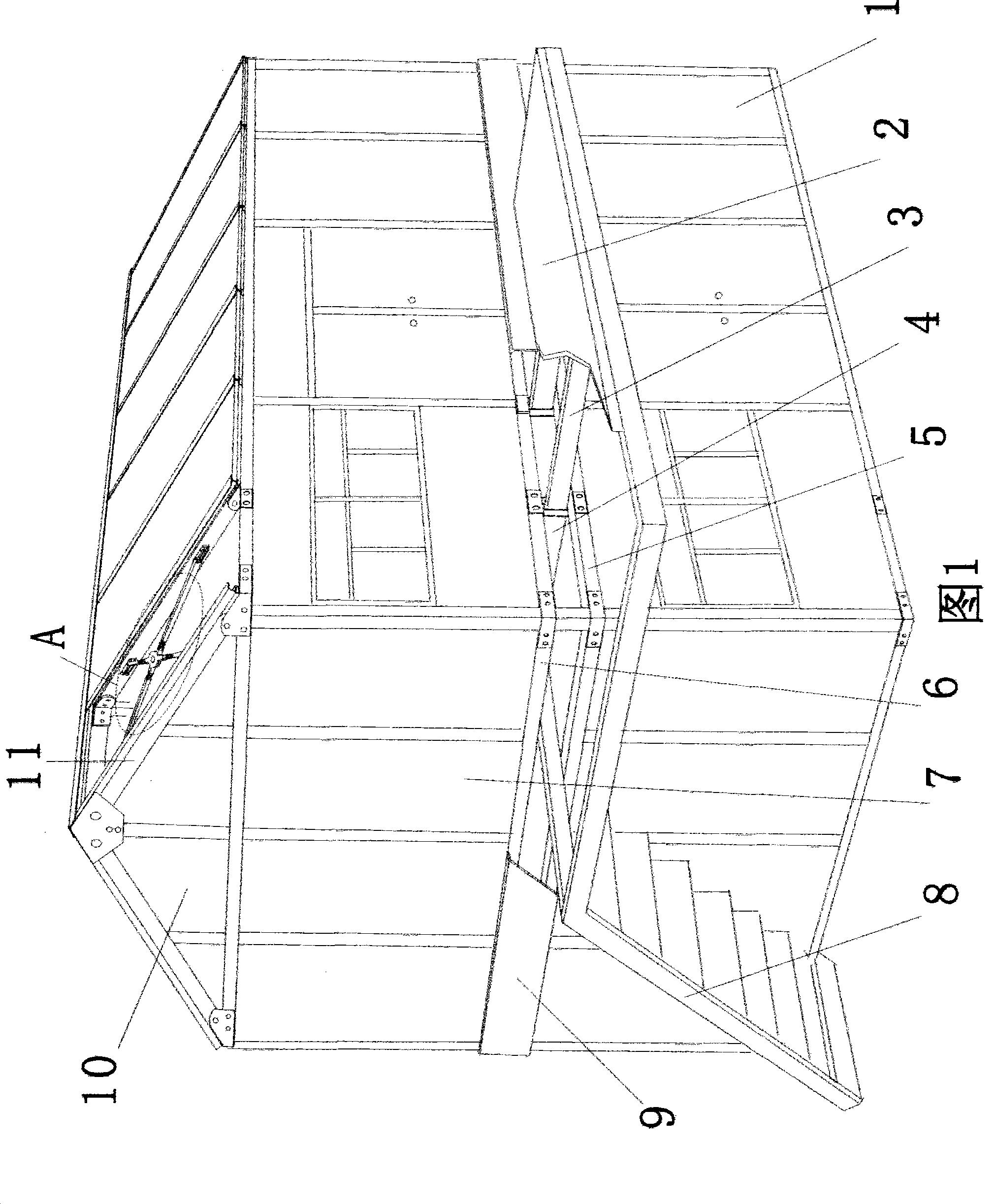

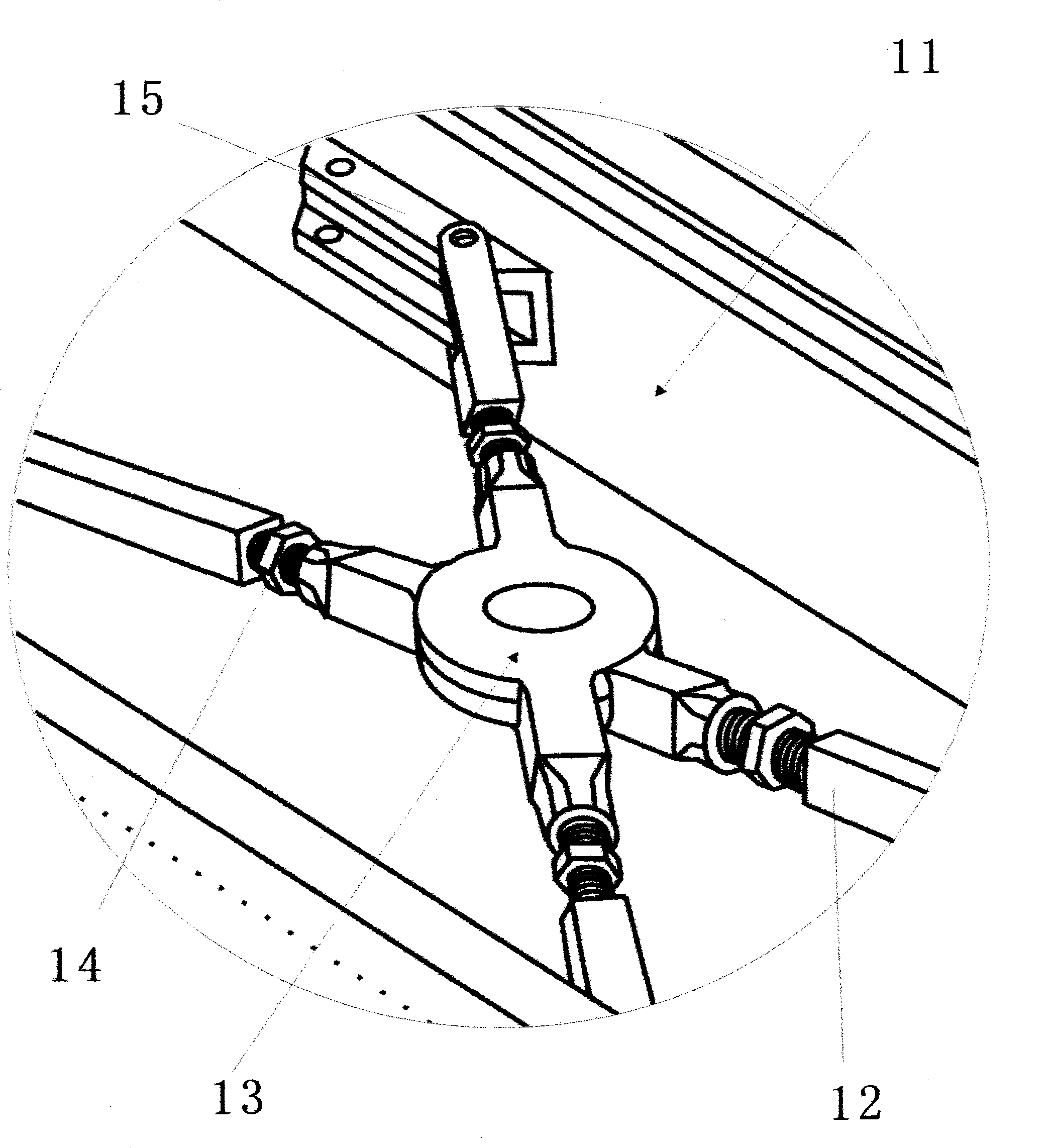

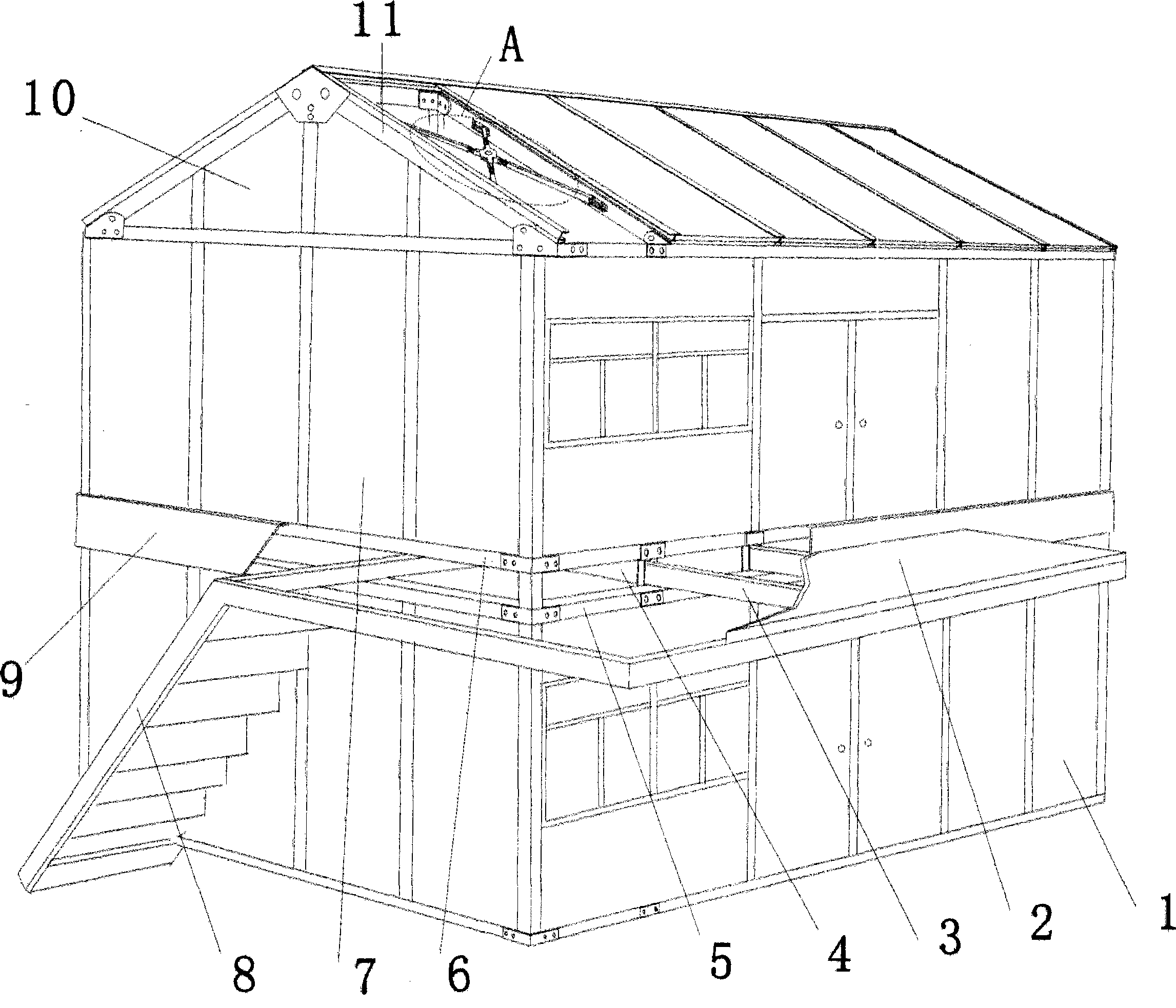

The invention relates to a light steel structural house with an outdoor corridor mudsill, which comprises a lower house structure and an upper house structure, and adopts the technical key points that a hollow metal section supporting layer is arranged between the lower house structure and the upper house structure, an outward extending part of a metal section in the supporting layer is the outdoor corridor mudsill, and auxiliaries for manufacturing an outdoor corridor are fixedly connected to the outdoor corridor mudsill in turn. When the outdoor corridor is installed, corridor upright postsare saved and the outdoor corridor forms an integral structure with the light steel house, so not only safety and stability are greatly improved, but also occupied space is saved, and installation ofa balcony and an outdoor air conditioner is convenient. For southern houses, an air passage of the hollow metal section supporting layer can adjust air circulation on the upper floor and the lower floor. The house simplifies beam and column nodes, and has the advantages of less construction process and convenient and quick installation. The house also has the advantages of simple and reasonable structure, safety and reliability, short site operation period, convenience and practicality, wide application range, and the like.

Description

A light steel structure house with an outdoor corridor bottom beam technical field The invention belongs to the technical field of civil or industrial buildings, and in particular relates to a light steel structure house with an outdoor corridor bottom beam which adopts standard parts for on-site assembly, has occupancy function and is easy to disassemble. Background technique With the continuous development and progress of human society, in order to reduce the harm caused to human beings by natural disasters such as earthquakes and fires, the majority of scientific and technological personnel have been working hard to continuously improve and perfect the houses on which human beings depend. The emergence of light steel structure houses is a concrete manifestation of reducing the damage caused to people by natural disasters such as earthquakes and fires. For two-story or more light-steel structure houses, when installing outdoor corridors, most of them use on-site welding ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04B1/343E04B1/24

Inventor 官木喜

Owner 官木喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com