Organic light emitting device and method for manufacturing the same

一种有机发光器件、有机的技术,应用在电固体器件、电致发光光源、光源等方向,能够解决注入的电流量增加等问题,达到简化工艺、提高制备效率、缩短制备时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

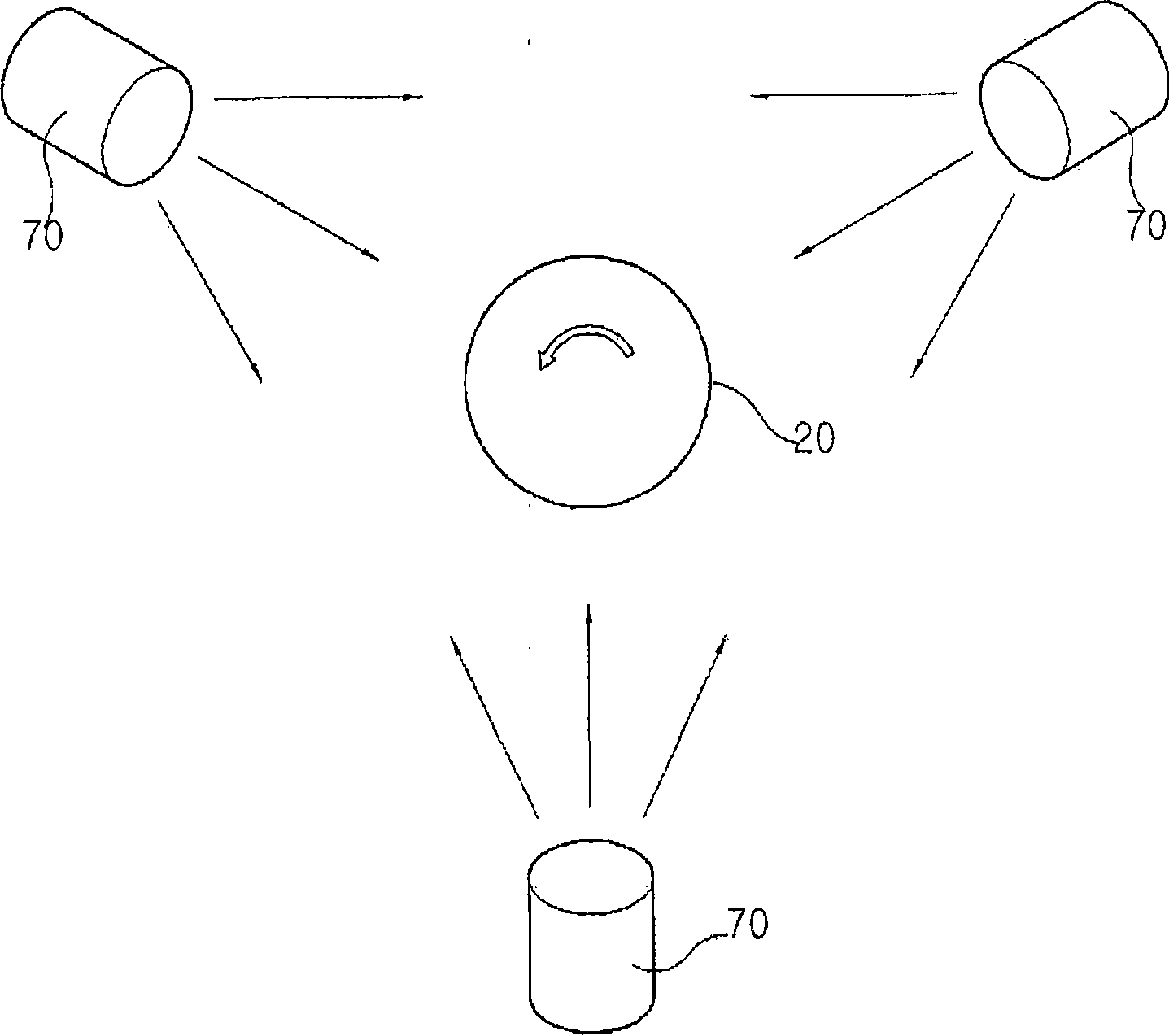

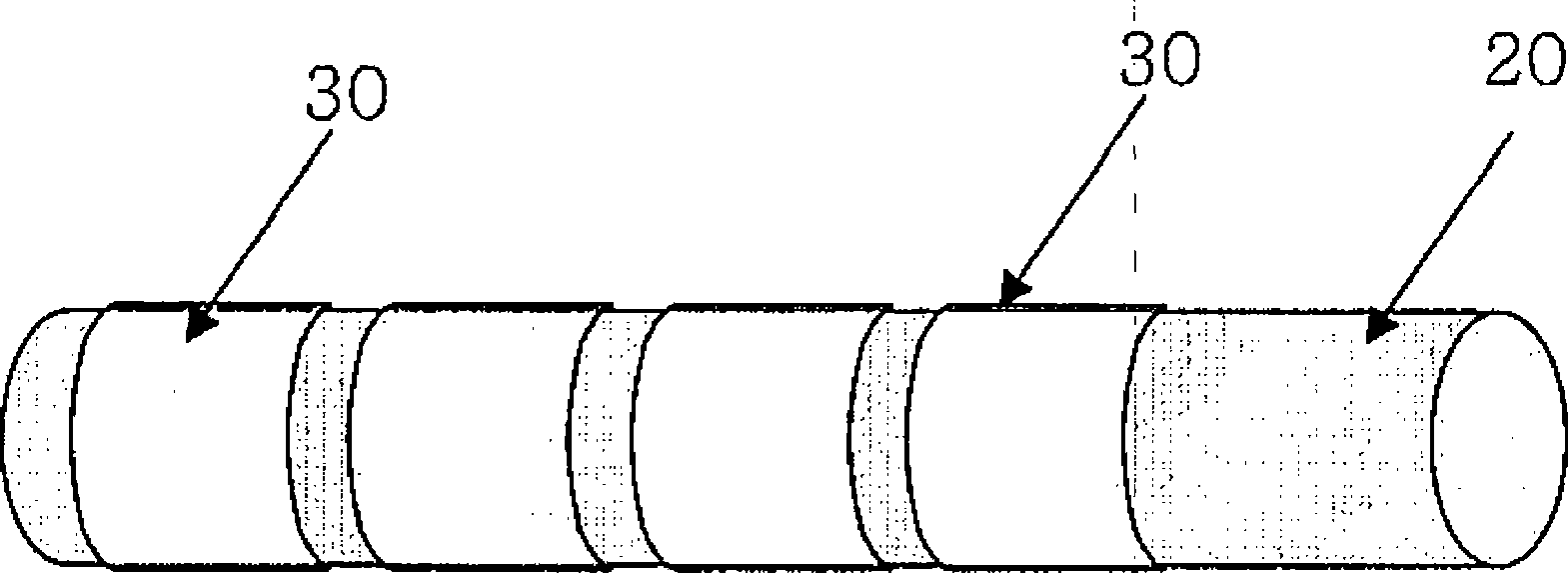

[0040] According to another embodiment of the present invention, a method for preparing an organic light-emitting device, the method includes the following steps: (a) preparing a base rod; forming a plurality of first electrodes; (c) forming a plurality of organic layers on the circumferential surfaces of the plurality of first electrodes at predetermined intervals along the longitudinal direction of the base rod; and (d) forming a plurality of organic layers at predetermined intervals along the longitudinal direction of the base rod; A plurality of second electrodes are formed on the circumferential surface of each organic layer, so that the second electrode of each organic light emitting unit is in contact with the first electrode of each organic light emitting unit adjacent to the first electrode of each organic light emitting unit, A plurality of organic light emitting units including the first electrode, the organic layer, and the second electrode formed on the organic lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com