Welding device and welding method

A technology of welding equipment and welding method, which is applied in the direction of welding equipment, welding equipment, laser welding equipment, etc., and can solve the problems of reducing product yield, small area, volume or thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

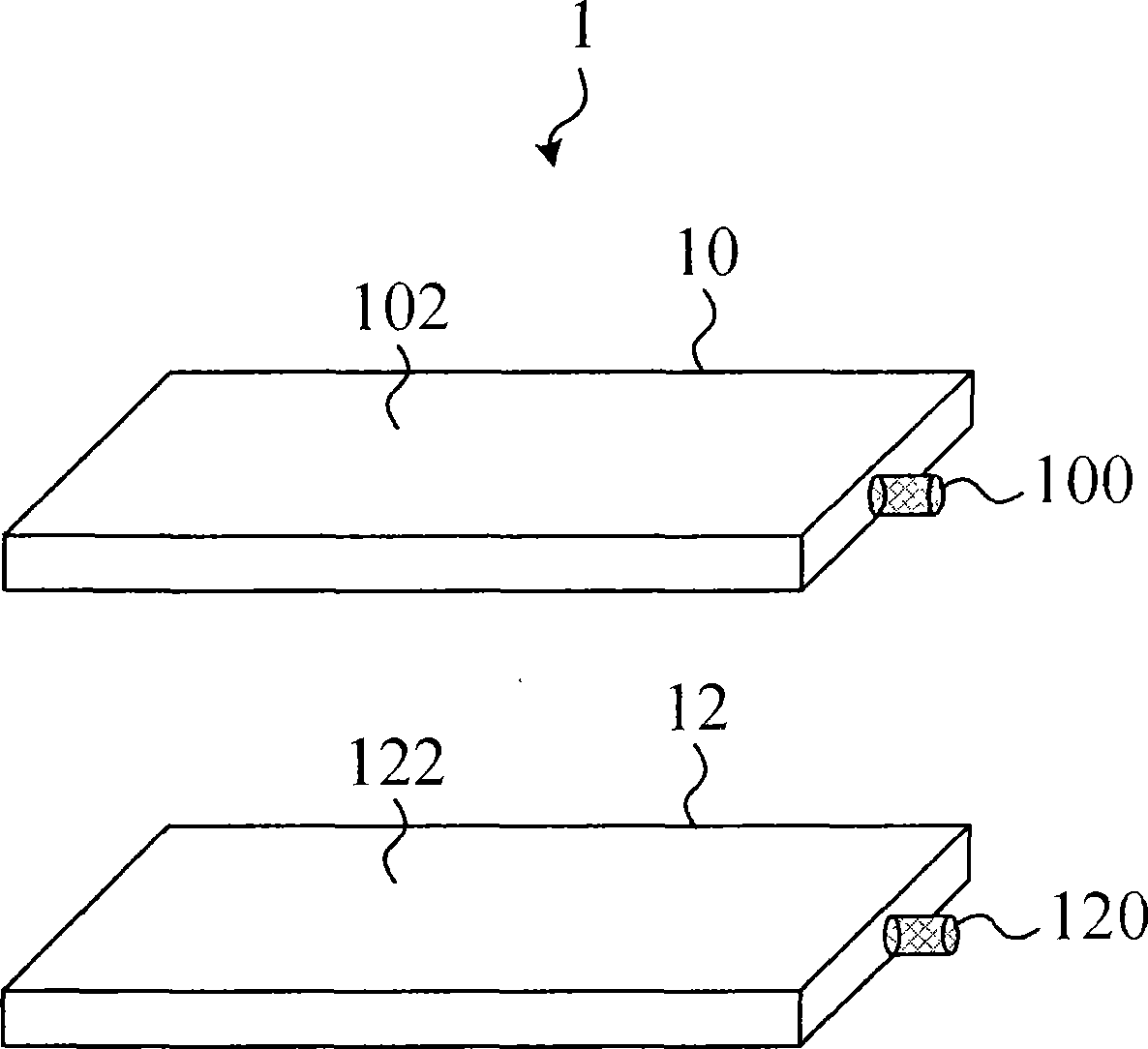

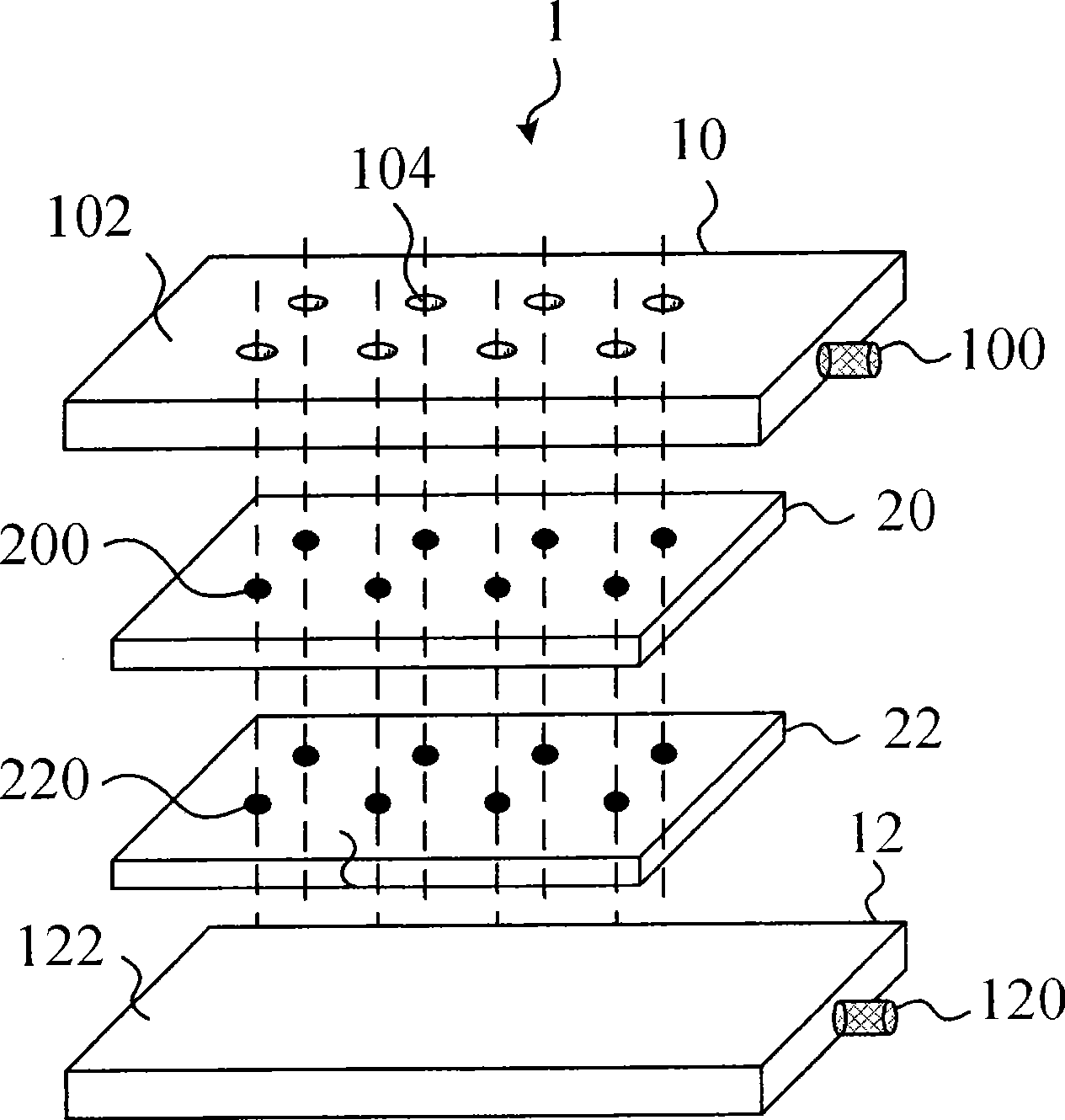

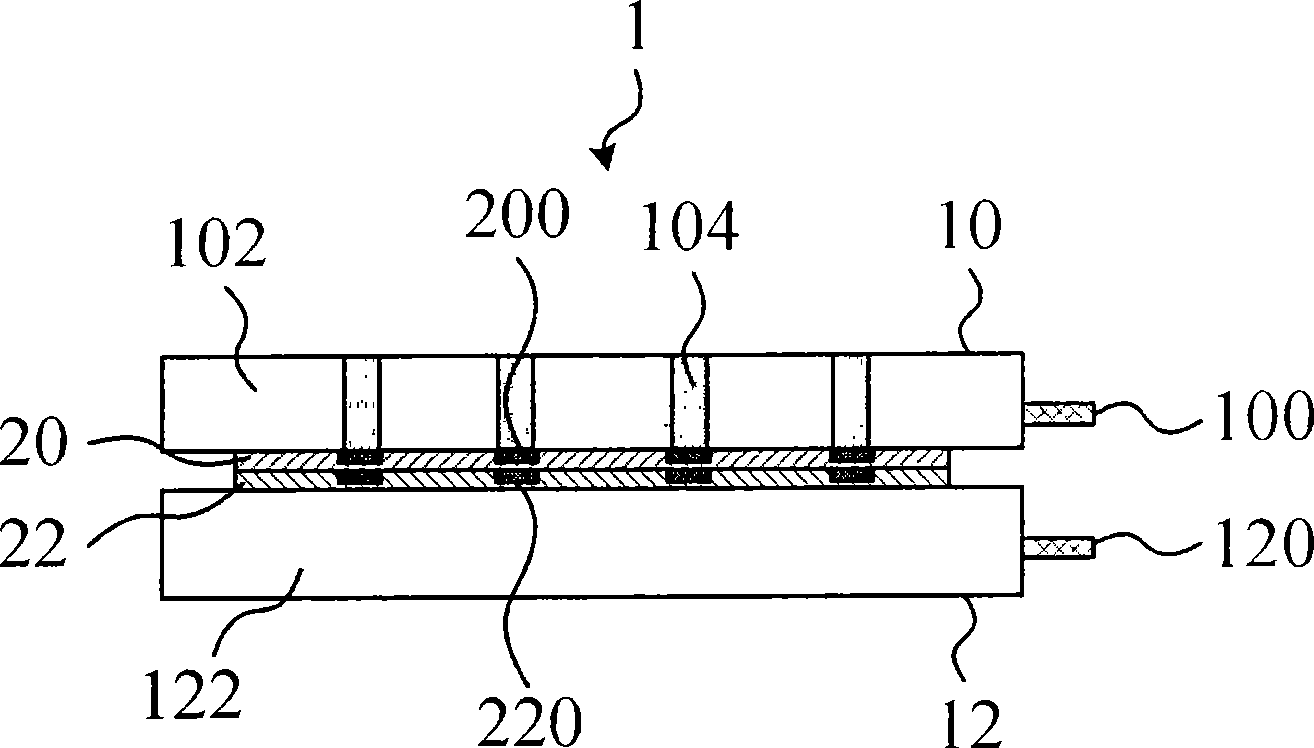

[0032] see figure 1 . figure 1 is a schematic diagram illustrating a welding device 1 according to a specific embodiment of the present invention. like figure 1 As shown, the welding equipment 1 includes a first temperature control device 10 and a second temperature control device 12 . The first temperature control device 10 further includes a first temperature controller 100 and a first body 102 , while the second temperature control device 12 further includes a second temperature controller 120 and a second body 122 . Wherein, the first temperature controller 100 maintains and provides a relatively low temperature to the first body 102 , and the second temperature controller 12 maintains and provides a relatively high temperature to the second body 122 . In practice, the relatively low temperature can reach, but is not limited to, 20 degrees Celsius. On the other hand, the relatively high temperature is up to, but not limited to, 80 degrees Celsius. Please note that in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com