Leaking stoppage material of coal car and preparation thereof

A leak-stopping material and coal truck technology, applied in chemical instruments and methods, transportation and packaging, and other chemical processes, can solve problems such as high labor intensity, adverse consequences, and impact on user use, and achieve excellent mechanical properties and convenience The effect of on-site construction, good bonding and curing plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is a formula suitable for the plugging material used in summer.

[0037] Curing component:

[0038] Quick-setting cement 19.7wt%

[0039] Lime 10.0wt%

[0040] Polyacrylamide powder 0.3wt%;

[0041] Plugging skeleton components:

[0042] Coal powder 65.0wt%

[0043] Talc 5.0wt%;

[0044] The amount of the adhesive is then determined according to the ratio of the total solid amount of the above curing component and the plugging skeleton component: the amount of the adhesive = 55%: 45%;

[0045] The composition of described adhesive component is:

[0046] Carboxymethylcellulose 6.0wt%

[0047] Polyvinyl alcohol 2.0wt%

[0048] Water-Alcohol 92.0wt%

Embodiment 2

[0050] This embodiment is a formula suitable for the plugging material used in spring.

[0051] Curing component:

[0052] Quick-setting cement 25.0wt%

[0053] Lime 10.0wt%

[0054] Plugging skeleton components:

[0055] Coal powder 60.0wt%

[0056] Talc 5.0wt%;

[0057] The amount of the adhesive is then determined according to the ratio of the total solid amount of the above curing component and the plugging skeleton component: the amount of the adhesive = 55%: 45%;

[0058] The composition of described adhesive component is:

[0059] Carboxymethylcellulose 6.0wt%

[0060] Polyacrylamide 0.3wt%

[0061] Polyvinyl alcohol 1.0wt%

[0062] Water-Alcohol 92.7wt%

Embodiment 3

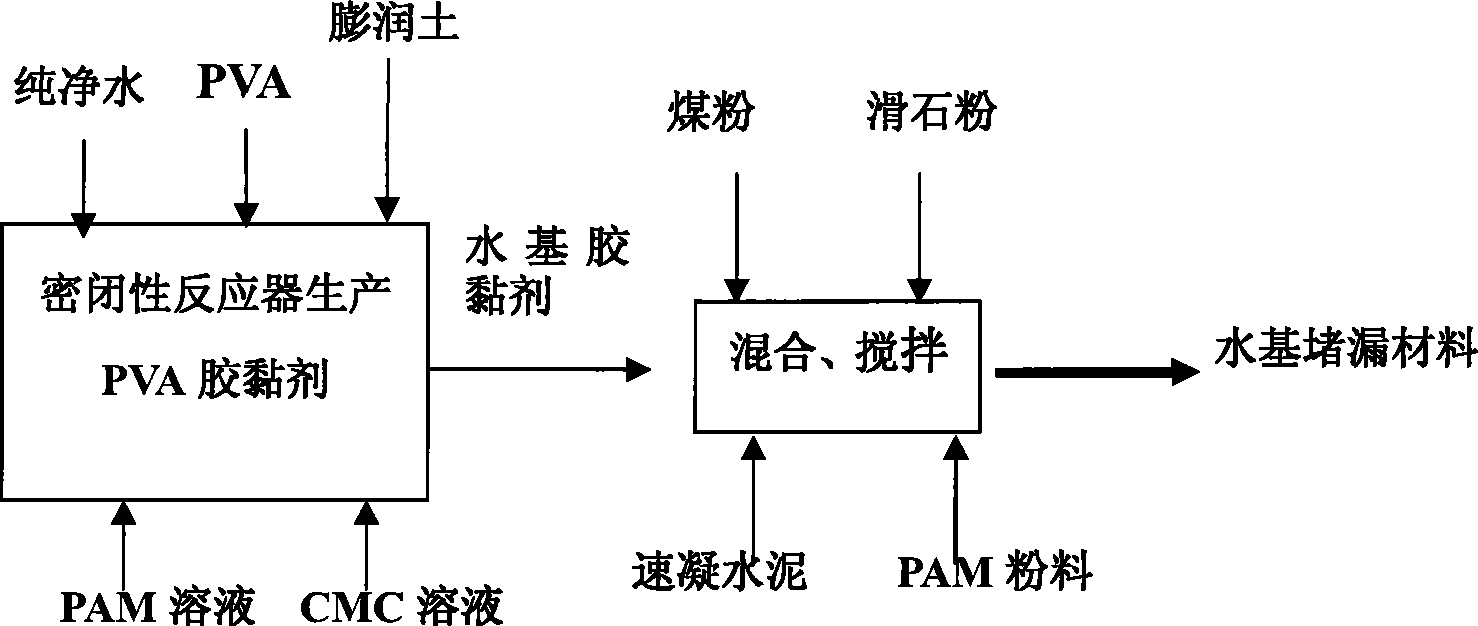

[0064] This example is for reference figure 1 A specific embodiment of preparing adhesive:

[0065] (1) Preparation of polyacrylamide-organic bentonite emulsion: first dissolve polyacrylamide in water to make a 2% solution, then add bentonite and stir evenly to form a white emulsion.

[0066] (2) Preparation of adhesive: add pure water to the reactor, heat to boiling, add polyvinyl alcohol while stirring, wait for the polyvinyl alcohol to dissolve, add carboxymethyl cellulose and alcohol, keep below 85°C to continue the reaction To form a transparent solution, add polyacrylamide-organic bentonite emulsion, stir evenly, cool down and discharge to obtain an adhesive. The conversion ratio of each component is

[0067] Solid carboxymethyl cellulose 6.0wt%

[0068] Solid polyacrylamide 0.3wt%

[0069] Solid polyvinyl alcohol 1.0wt%

[0070] Water-Alcohol 92.7wt%

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com