Adhesive, coal car leaking stoppage material containing the same, and preparation thereof

A plugging material and adhesive technology, which is applied in the field of coal truck plugging materials and its preparation, can solve the problems of high labor intensity, adverse consequences, and many manpower, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

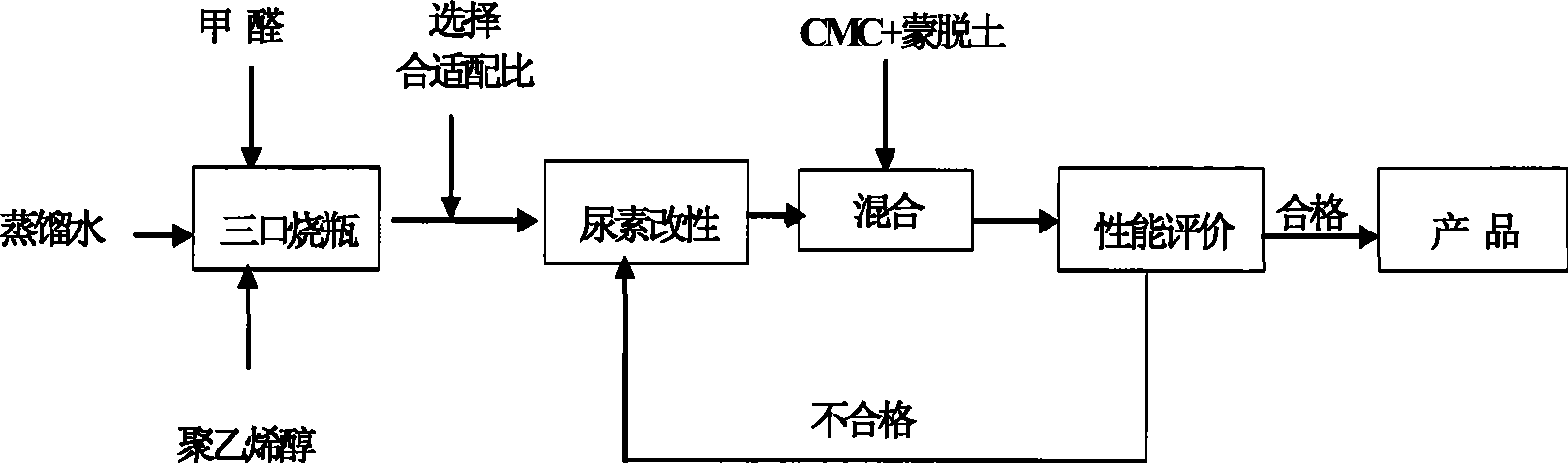

[0049] refer to figure 1 The schematic process to prepare M-PVF adhesive

[0050] (1) Add 100ml of water into the reaction kettle, raise the temperature to 70°C, and start the agitator;

[0051] (2) Add polyvinyl alcohol at one time, continue to heat up to 85-95 ° C, and keep the temperature until the polyvinyl alcohol is completely dissolved;

[0052] (3) After the polyvinyl alcohol is completely dissolved, cool down to 78°C, add hydrochloric acid catalyst, adjust the pH value to 1.5-2.5, then raise the temperature to 78-92°C, and continue stirring for 10 minutes;

[0053] (4) Lower the temperature to 80°C, add all the formaldehyde in a thin stream, raise the temperature to 78-92°C while stirring, and stir for 10 minutes; open the reaction kettle at 78-90°C, stop stirring and observe, and make it in a static state Continue the reaction at low temperature until the reactant starts to appear milky white and dehydrated, then continue to start the agitator and lower the tempera...

Embodiment 2

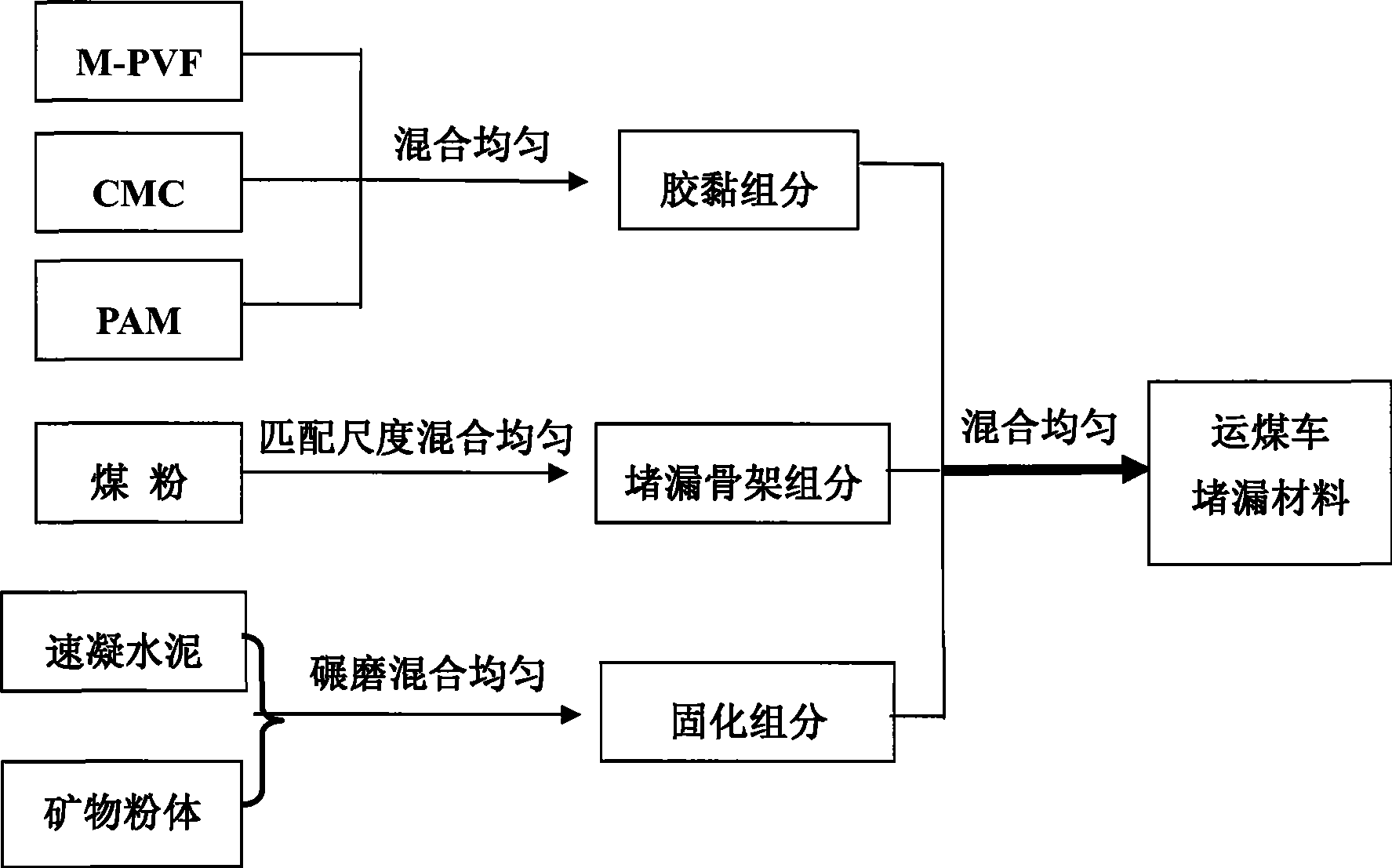

[0060] refer to figure 2 The illustrated process prepares the plugging material for the coal truck.

[0061] (1) determine each component and its weight percentage in the plugging material;

[0062] When determining the amount of components, first determine the amount of solid matter, that is, the plugging skeleton and the components of the curing agent, and the weight percentage of the amount is:

[0063] Quick-setting cement (Qinling Cement Plant MSR type) 19.7wt%

[0064] Lime 14.0wt%

[0065] Polyacrylamide powder 0.3wt%

[0067] Carboxymethylcellulose 3.0wt%

[0068] Talc 3.0wt%

[0069] Determine the amount of adhesive in the ratio of the above-mentioned solid dosage:adhesive dosage=55:45.

[0070] (2) Coal powder, talcum powder and carboxymethyl cellulose powder are mixed evenly in proportion, and recorded as A component;

[0071] (3) Mix quick-setting cement, lime, and polyacrylamide powder evenly in proportion, and record it as com...

Embodiment 3

[0075] refer to figure 2 The illustrated process prepares the plugging material for the coal truck.

[0076] (1) determine each component and its weight percentage in the plugging material;

[0077] When determining the amount of components, first determine the amount of solid matter, that is, the plugging skeleton and the components of the curing agent, and the weight percentage of the amount is:

[0078] Quick-setting cement 24.7wt%

[0079] Lime 9.0wt%

[0080] Polyacrylamide 0.3wt%

[0081] Coal powder 60.0wt%

[0082] Carboxymethylcellulose 3.0wt%

[0083] Talc 3.0wt%

[0084] Determine the amount of adhesive in the ratio of the above-mentioned solid dosage:adhesive dosage=55:45.

[0085] (2) Mix the coal powder, talc powder and CMC powder evenly in proportion, and record it as component A;

[0086] (3) Mix quick-setting cement, lime, and PAM powder evenly in proportion, and record it as component B;

[0087] (4) Compulsorily stir and mix the A component and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com