Source container of a VPE reactor

A container and reactive gas technology, which is applied in the directions from chemical reactive gas, chemical instruments and methods, gaseous chemical plating, etc., can solve the problems of source conversion efficiency change and inconstancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

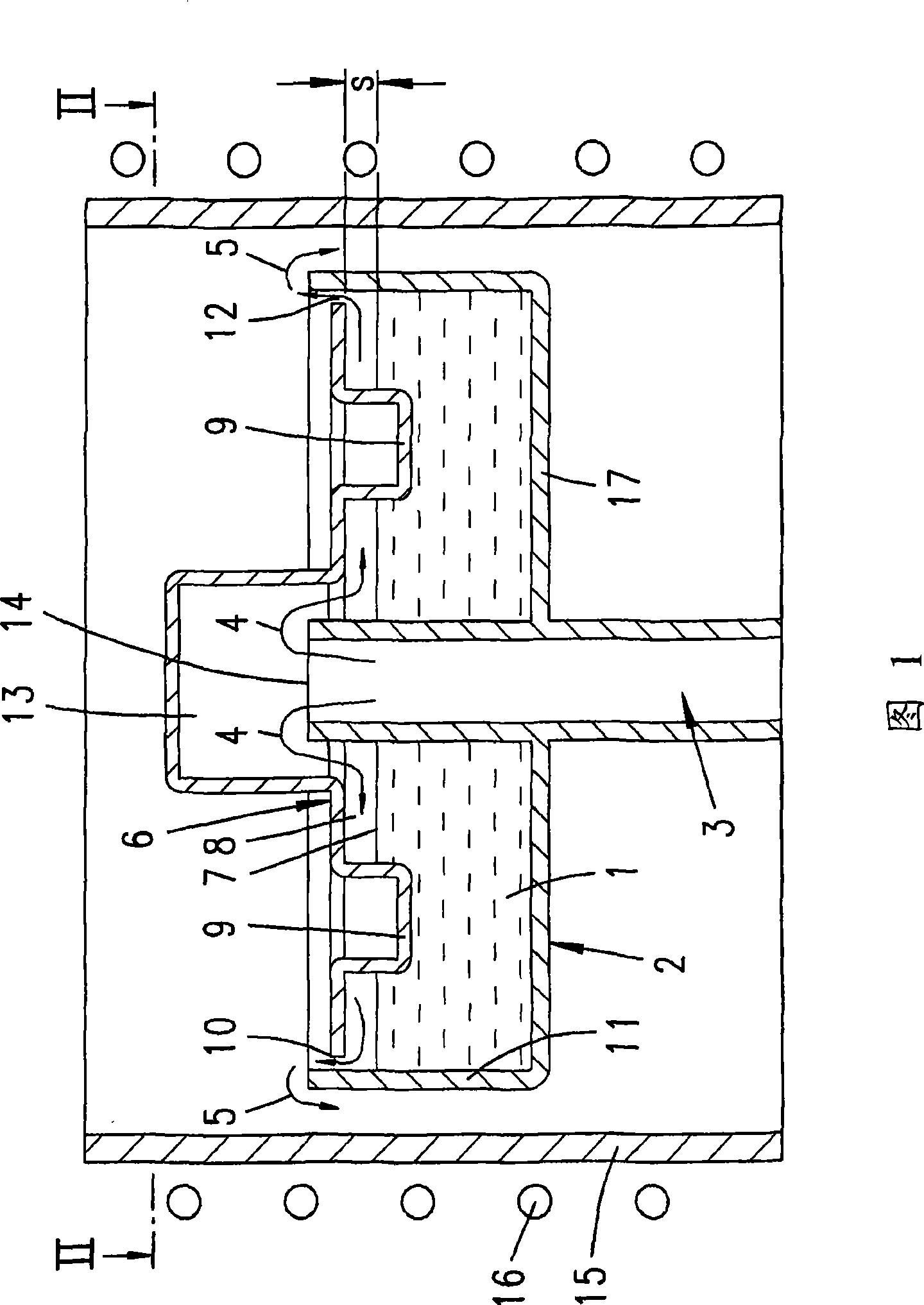

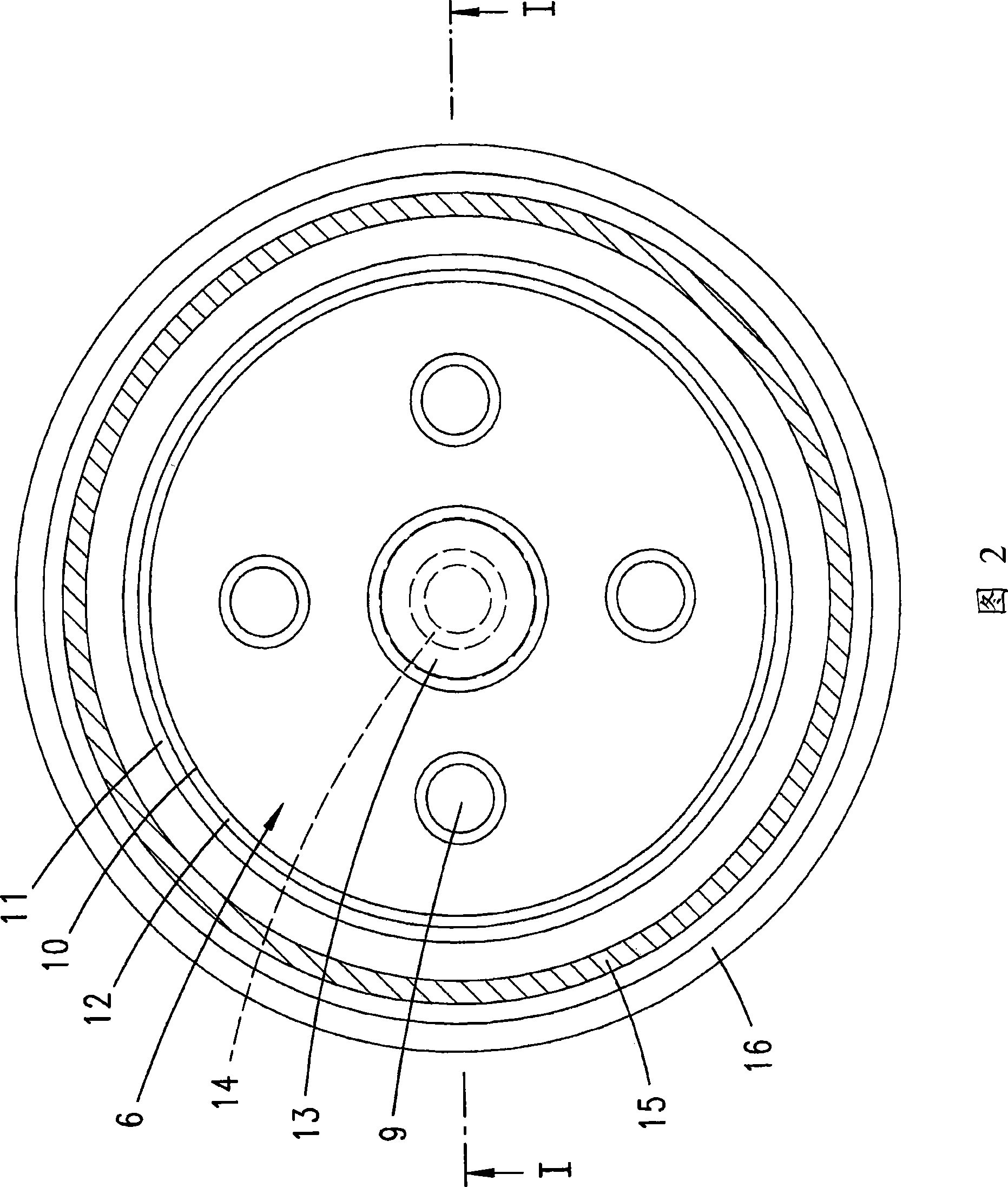

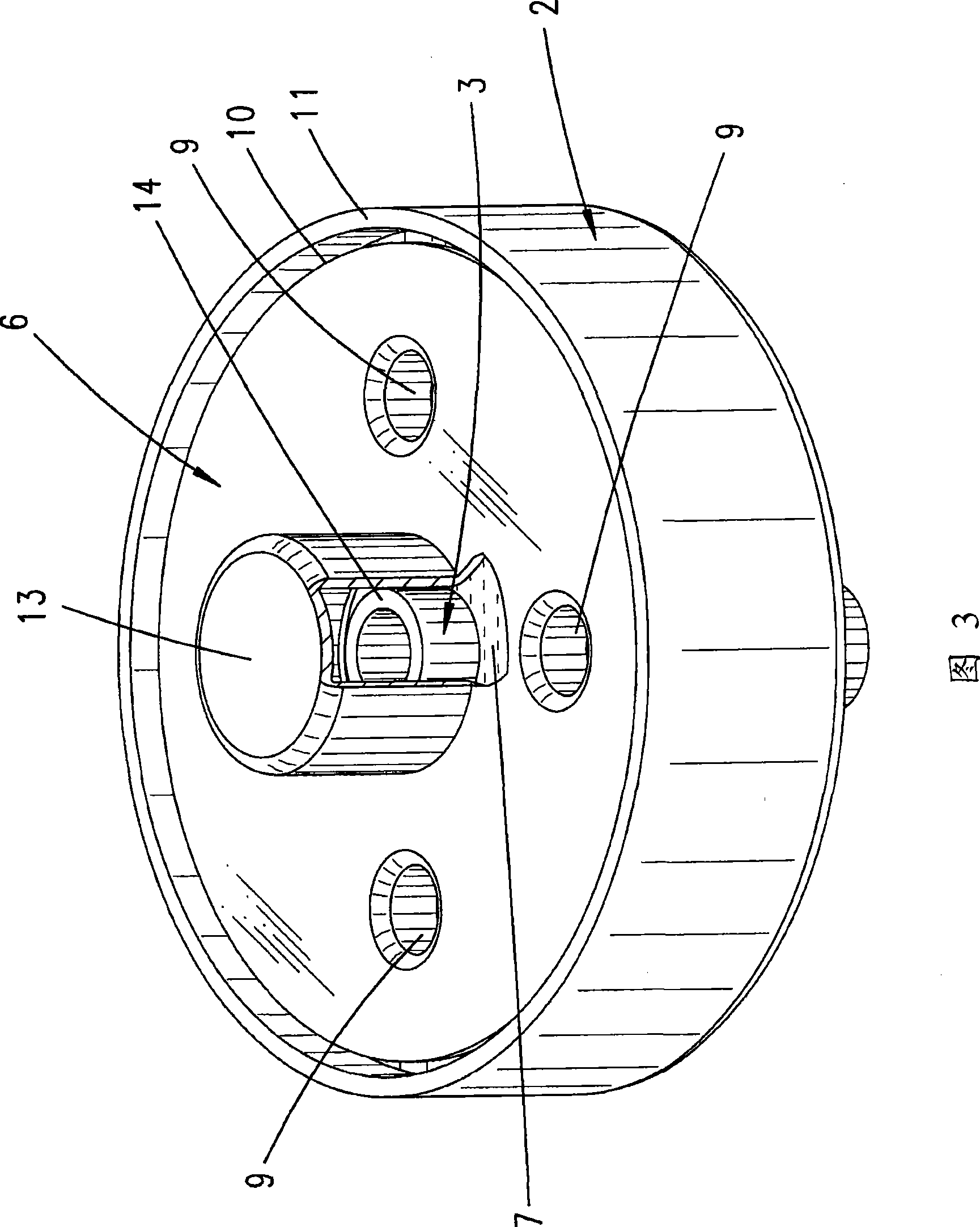

[0021] The VPE reactor represented in Figure 4 is a horizontal reactor, since the process chamber 21 extends in the horizontal direction. The floor of the substantially circular process chamber 21 forms a base 23 . The soleplate is heated from below by means of resistive heaters 25 . Other types of heating are also possible; in particular, RF heating may be employed. On a disk-shaped bottom plate 23, there are a large number of substrates 22. The substrate 22 is arranged around the center of the base 23 in a circular arrangement.

[0022] Above the base 23 is a process chamber ceiling 24 . It extends parallel to the bottom plate 23 and has an opening in the center. The opening is located outside the area on the base 23 where the substrate 22 is placed. Above this circular opening in the process chamber ceiling 24 is the source region. The source region includes ducts extending in a vertical direction. The duct forms the wall 15 of the source region. The tube is closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com