Bead ring locking mechanism of tire vulcanizer

A technology of tire vulcanization and wire ring, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of looseness and insufficient tightening of positioning screws 53, and achieve the effect of simple replacement and reliable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

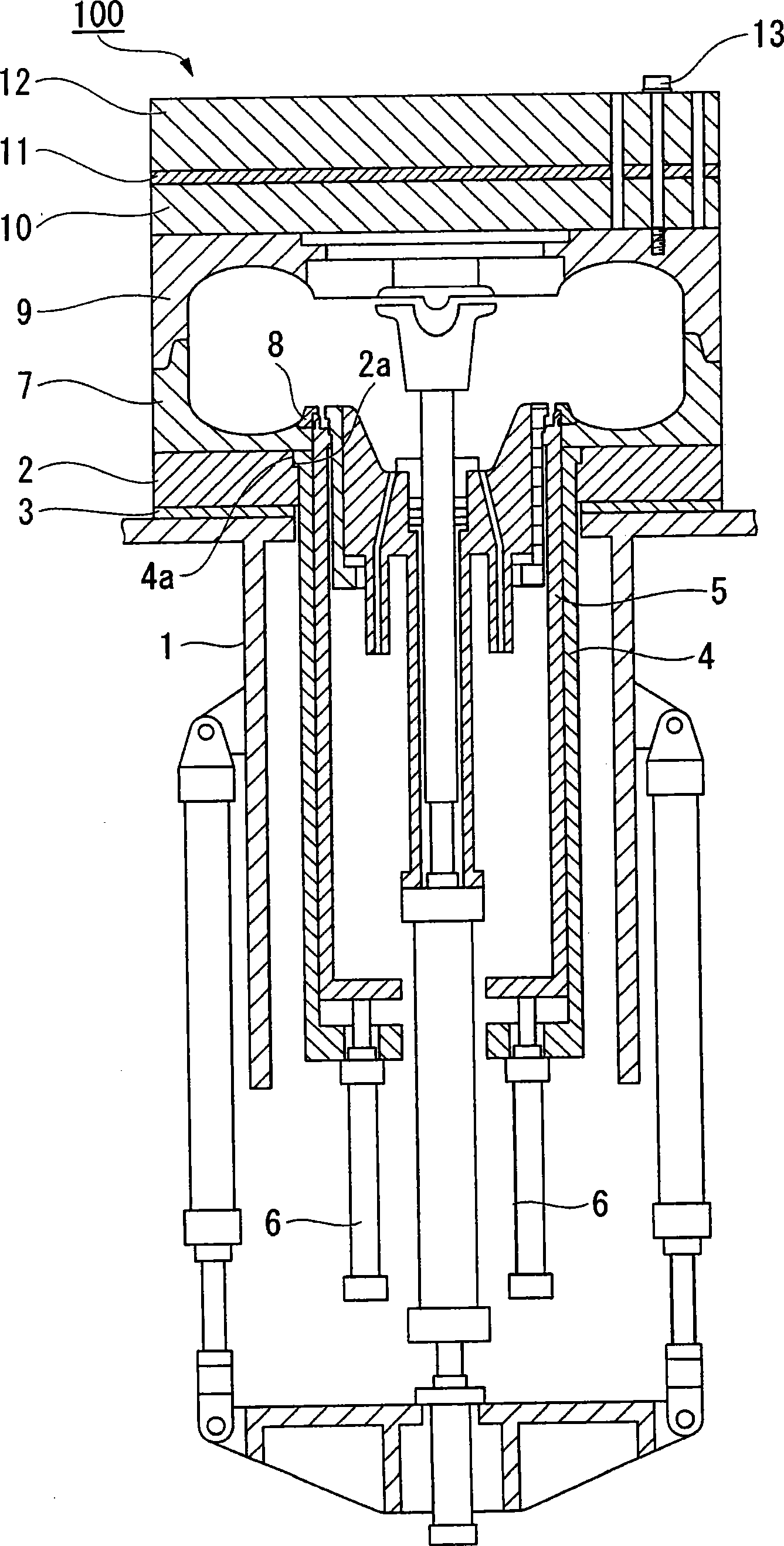

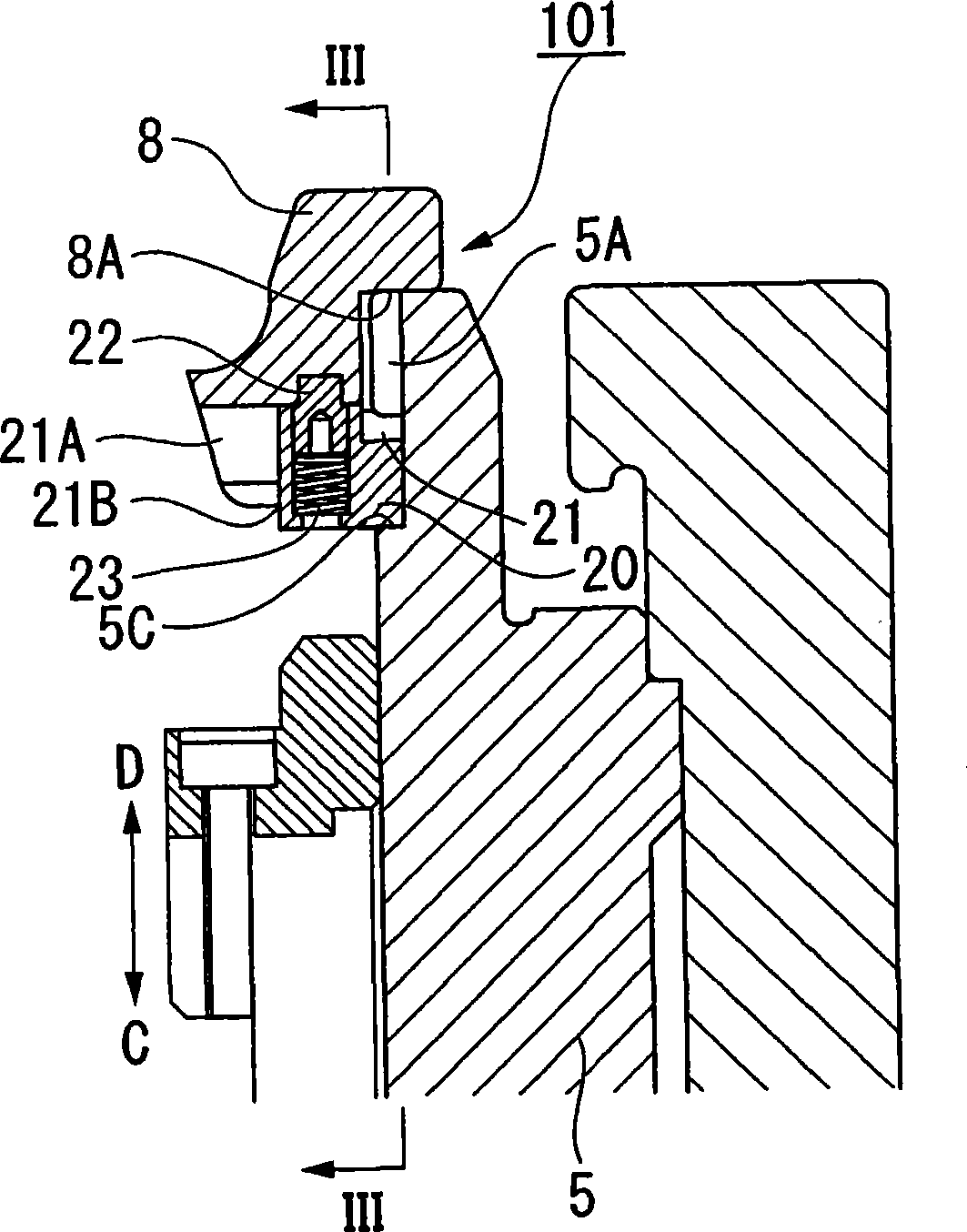

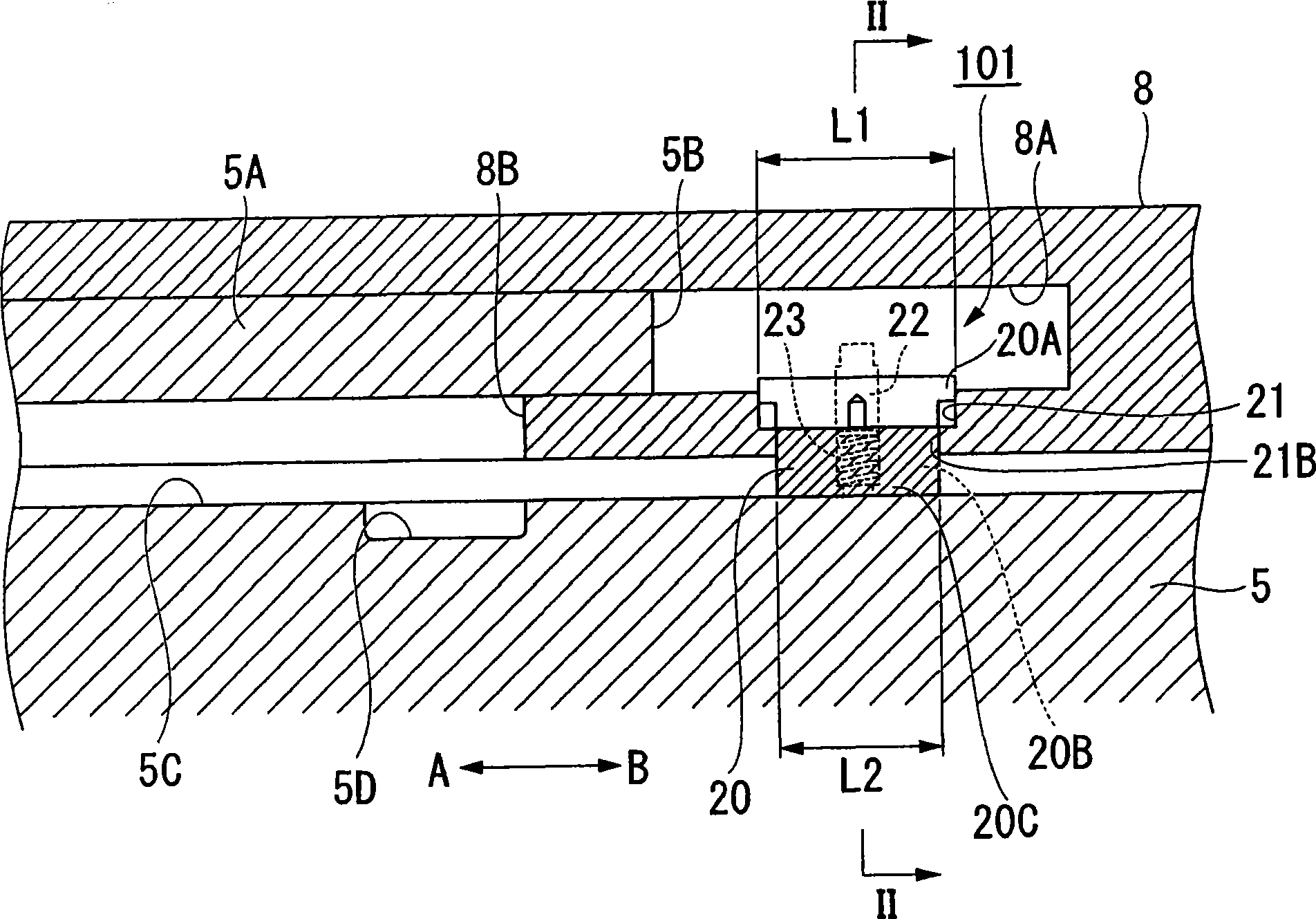

[0030] Below, according to Figure 1 to Figure 6 Embodiments of the present invention will be described.

[0031] figure 1 It is a front sectional view showing the whole of the vulcanizing machine 100 . A lower deck 2 is fixed to the upper surface of the base 1 with bolts (not shown) via a heat insulator 3 . In addition, a central mechanism outer cylinder 4 is arranged at the center of the base 1 , and its upper end is inserted into the center hole of the lower deck 2 , and the upper flange 4 a is engaged with the upper inner surface 2 a of the lower deck 2 . In addition, a cylindrical elevator 5 is slidably inserted into the inner peripheral surface of the center mechanism outer cylinder 4 . The elevator 5 is raised and lowered by a cylinder 6 disposed under the center mechanism outer cylinder 4 .

[0032] A lower mold 7 is provided on the lower platen 2 . A lower traveler 8 functioning as a part of the die is engaged with the inner periphery of the lower die 7 . The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com