Gear drive synchronous overturning type bogie and control method thereof

A gear transmission and flipping technology, which is applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve problems such as high cost and error-prone, and achieve the effect of ensuring stability, ensuring accuracy, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0025] A gear transmission synchronous overturning trolley, the composition of which includes:

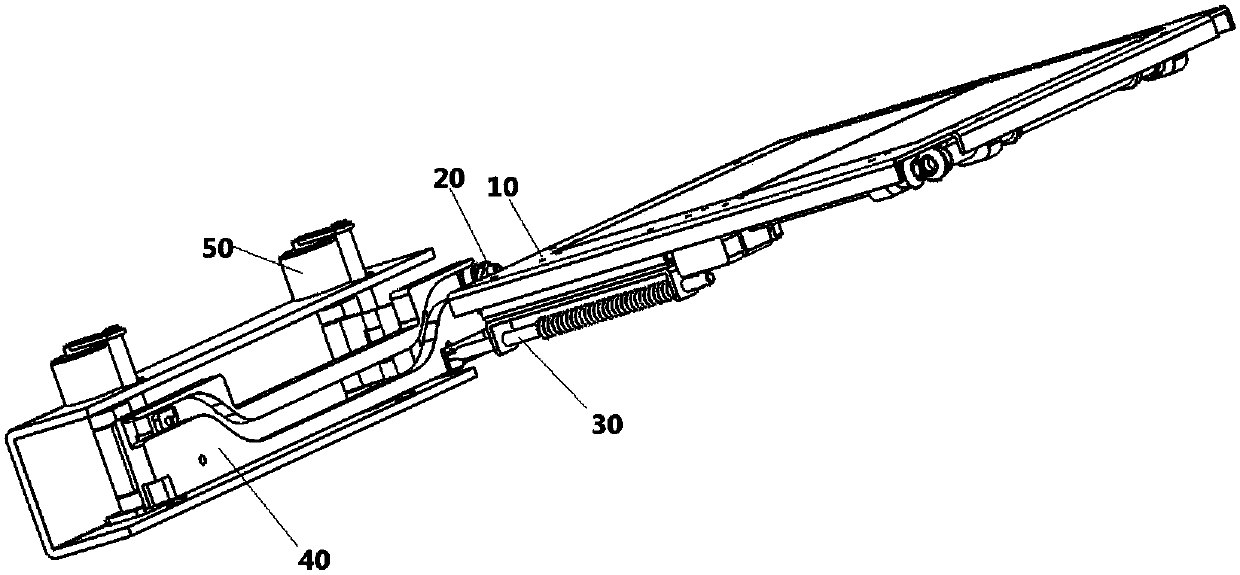

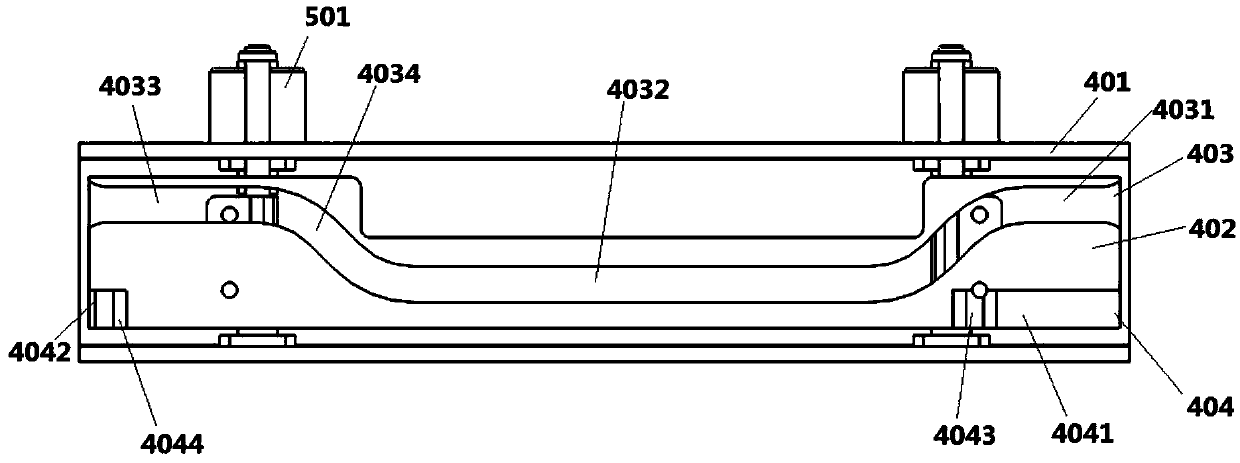

[0026] The trolley main body 10, the overturning control mechanism 20, the advancing lock mechanism 30 and the control track mechanism 40.

[0027] A blanking chute is provided on the table of the main body 10 of the trolley, and a flap 101 for opening and closing the blanking chute is provided in the blanking chute. in the tank;

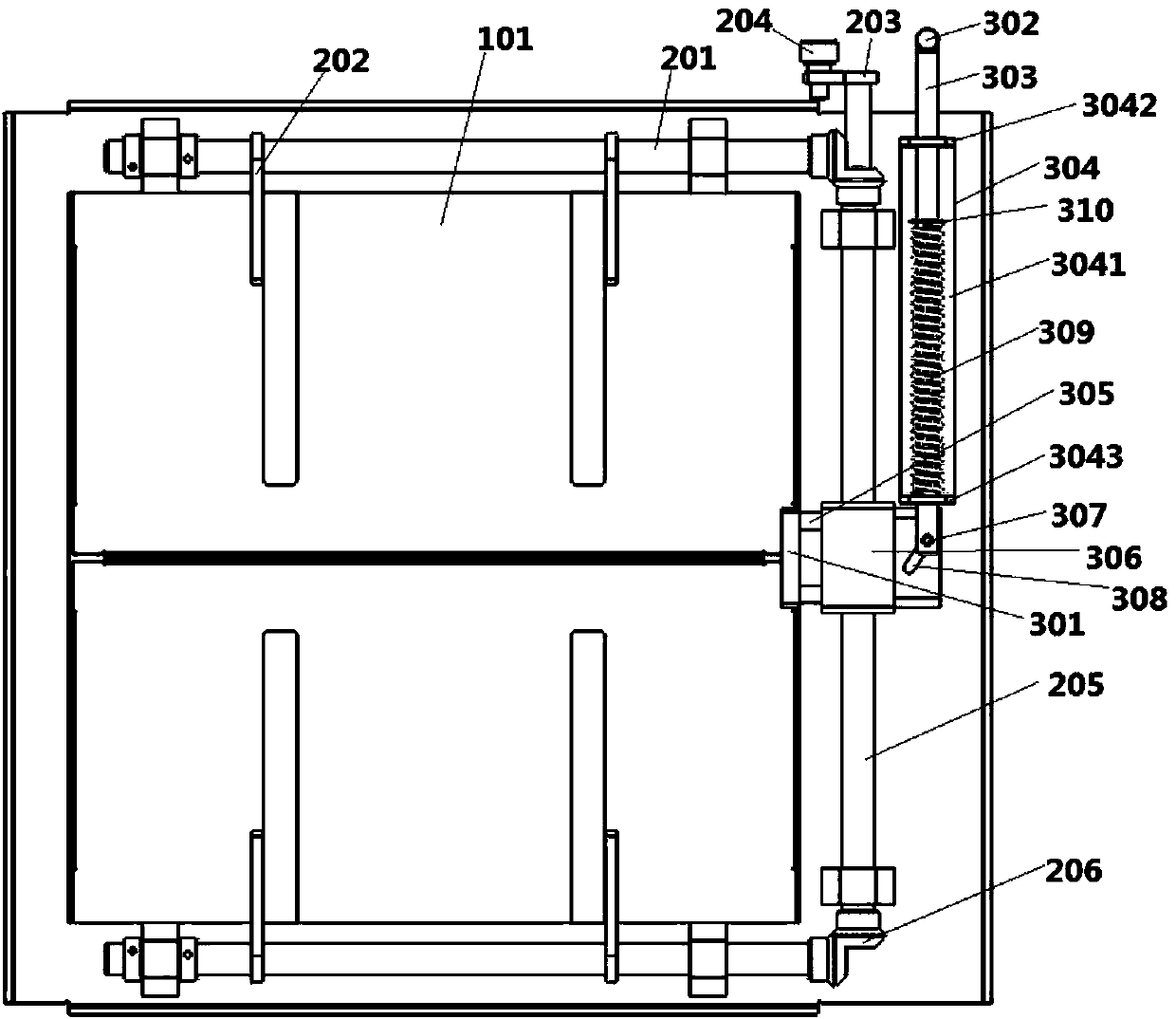

[0028] The turning control mechanism 20 includes a rotating shaft 201, a support rod 202, a drive shaft 205, and a rocker arm 203. The rotating shaft 201 is provided with two, which are respectively arranged near the hinged end on one side of the turning plate 101, and the extension direction of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com