Vertical self-priming pump valve-free self-antisiphoning device

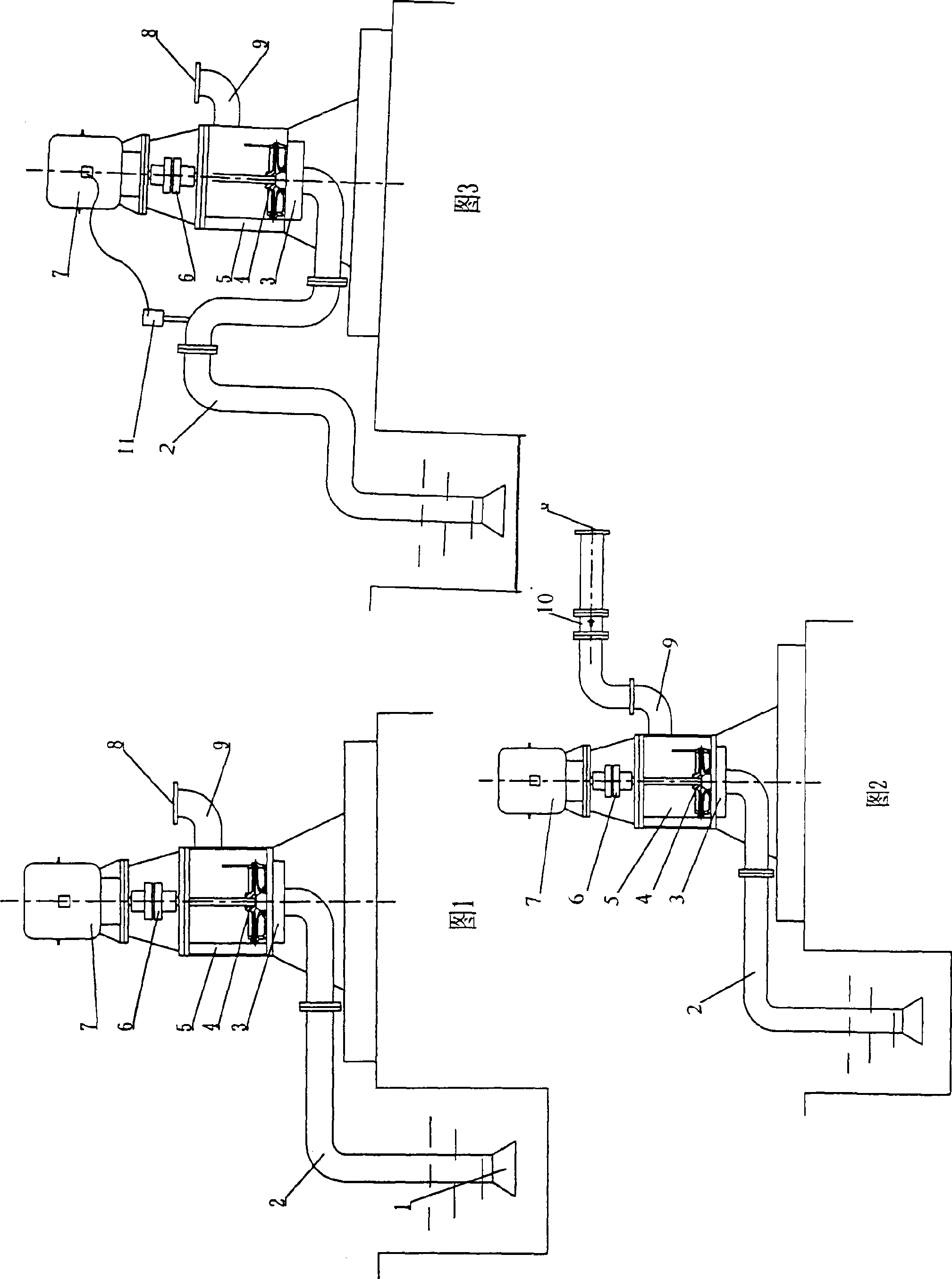

A self-priming pump and anti-siphon technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problems of electromagnetic coil burnout, wear, and inapplicability of air valves. Achieve the effects of reducing maintenance costs, reducing production costs, and simplifying product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

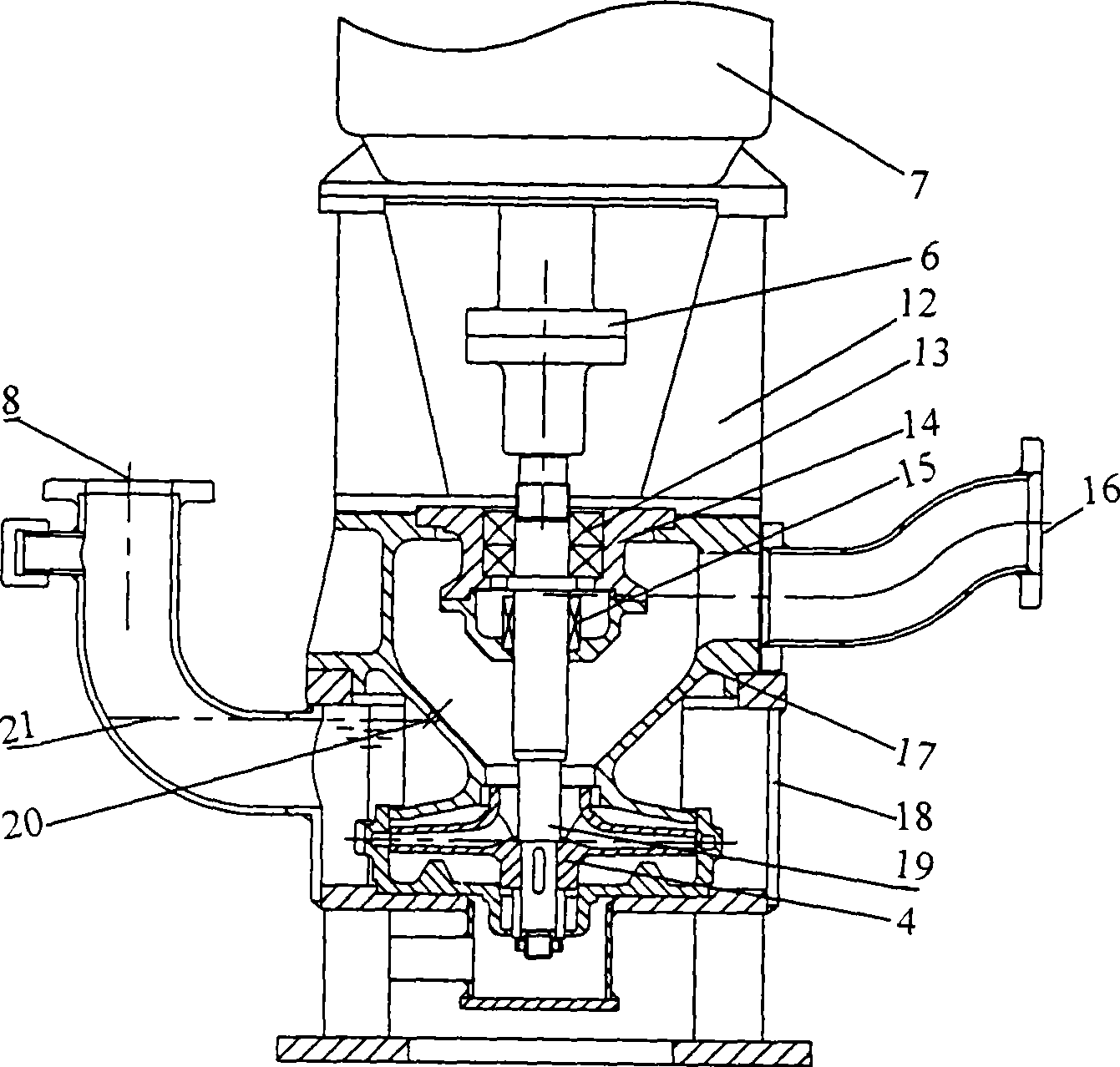

[0015] Control attached Figure 4 , its structure includes motor base 12, bearing 13, bearing housing 14, mechanical seal 15, inlet nozzle 16, water inlet chamber 17, pressure outlet chamber 18, rotating shaft 19, air inlet 20, basic liquid level 21, outlet Liquid port 8, coupling chamber 6, motor 7, impeller 4, wherein motor base 12 is motor 7, motor 7 is connected to coupling chamber 6, bearing 13 is on bearing housing 14, mechanical seal 15 is on rotating shaft 19, impeller 4 It is located at the bottom of the pump discharge chamber 18, the liquid inlet 8 is located at the top of the discharge chamber 18, and the liquid outlet 8 is located in the middle of the impeller 4 and the liquid inlet nozzle 16. The water inlet chamber 17 of the pump and the water outlet chamber An air inlet 20 is drilled on the part wall that is separated, that is, at a position near the basic liquid level 21 horizontal plane.

[0016] In the prior art, when the pump is out of service, the liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com