A High-precision Reference Voltage Source Circuit Using Quadratic Positive Temperature Coefficient Compensation

A reference voltage source and positive temperature coefficient technology, which is applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve problems such as unusable, application site restrictions, etc., to improve range, reduce power consumption, and avoid voltage clamping The effect of the use of the amplifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

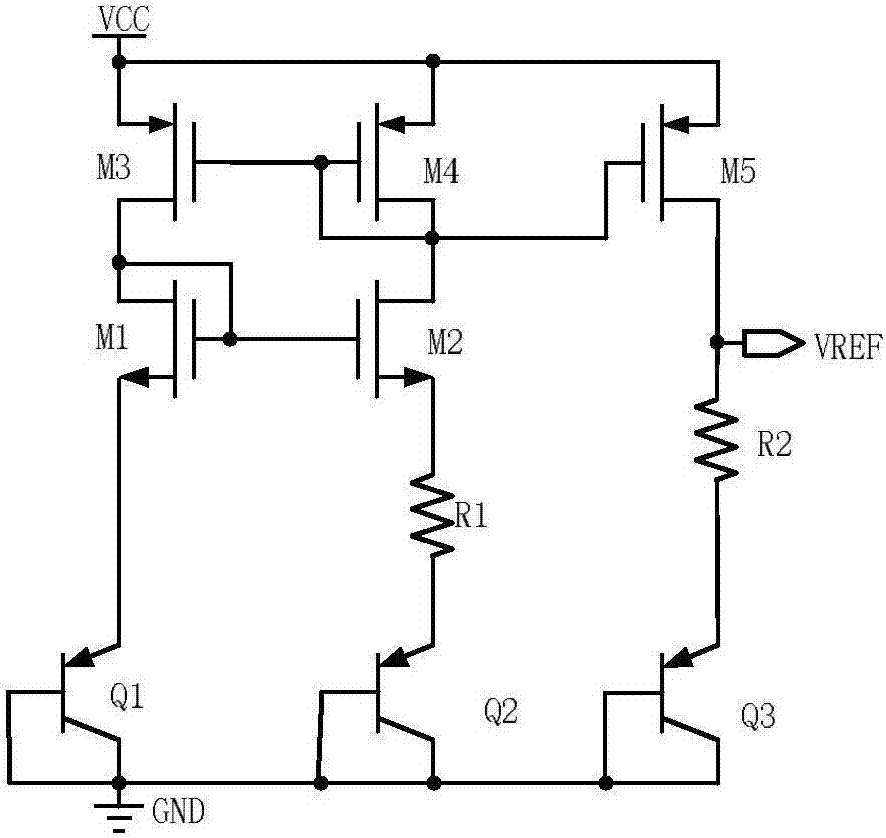

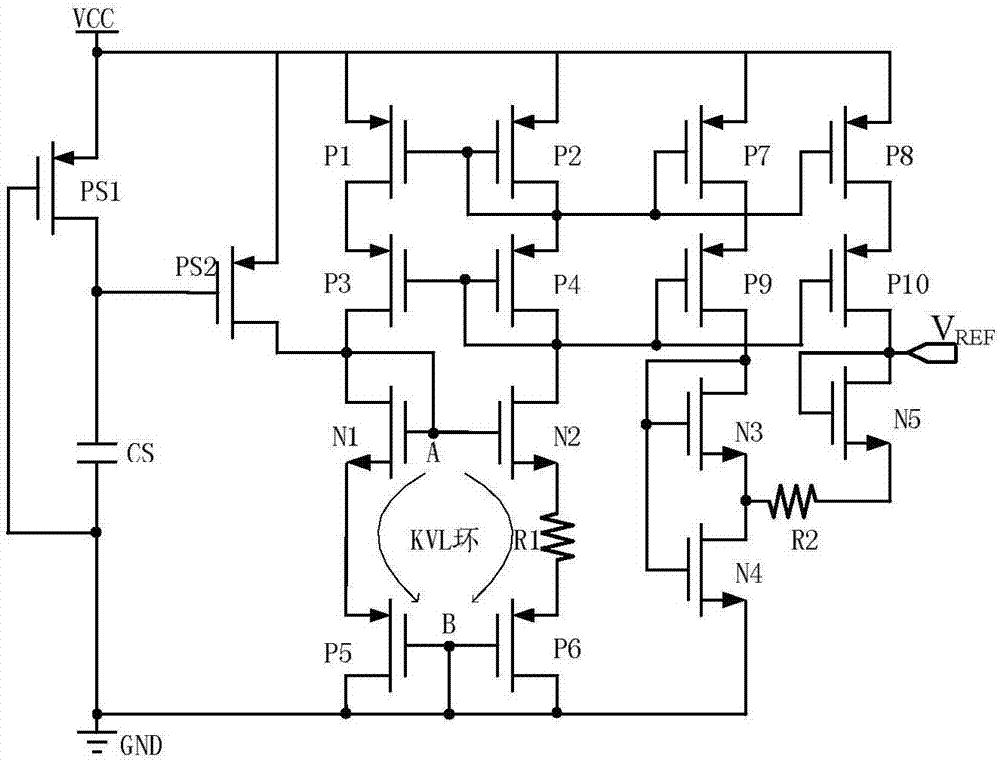

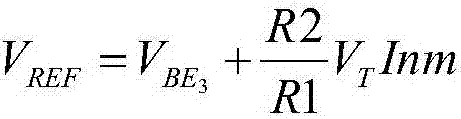

[0037] like figure 2 As shown, a high-precision reference voltage source circuit, the reference voltage source circuit includes a start-up circuit, a PTAT current generating circuit and a reference voltage generating circuit that are electrically connected in sequence;

[0038] The start-up circuit is used to generate a start-up signal for the start of the circuit, so that the entire PTAT current generation circuit and the reference voltage generation circuit are completely turned on, and then the start-up circuit is closed by itself;

[0039] The PTAT current generating circuit is used for generating a reference current proportional to the temperature;

[0040] The reference voltage generating circuit: used to generate a temperature-independent high-precision reference voltage.

[0041] In the specific implementation process, the PTAT current generating circuit includes a current mirror composed of two pairs of PMOS transistors P1, P2 and P3, P4 in a cascode structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com