Solid-liquid separation device

A solid-liquid separation and separation part technology, applied in the field of solid-liquid separation devices, can solve problems such as shortening the life of the movable plate, and achieve the effect of inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of the present invention will be described with reference to the drawings, and the aforementioned conventional disadvantages will be more specifically described with reference to the drawings.

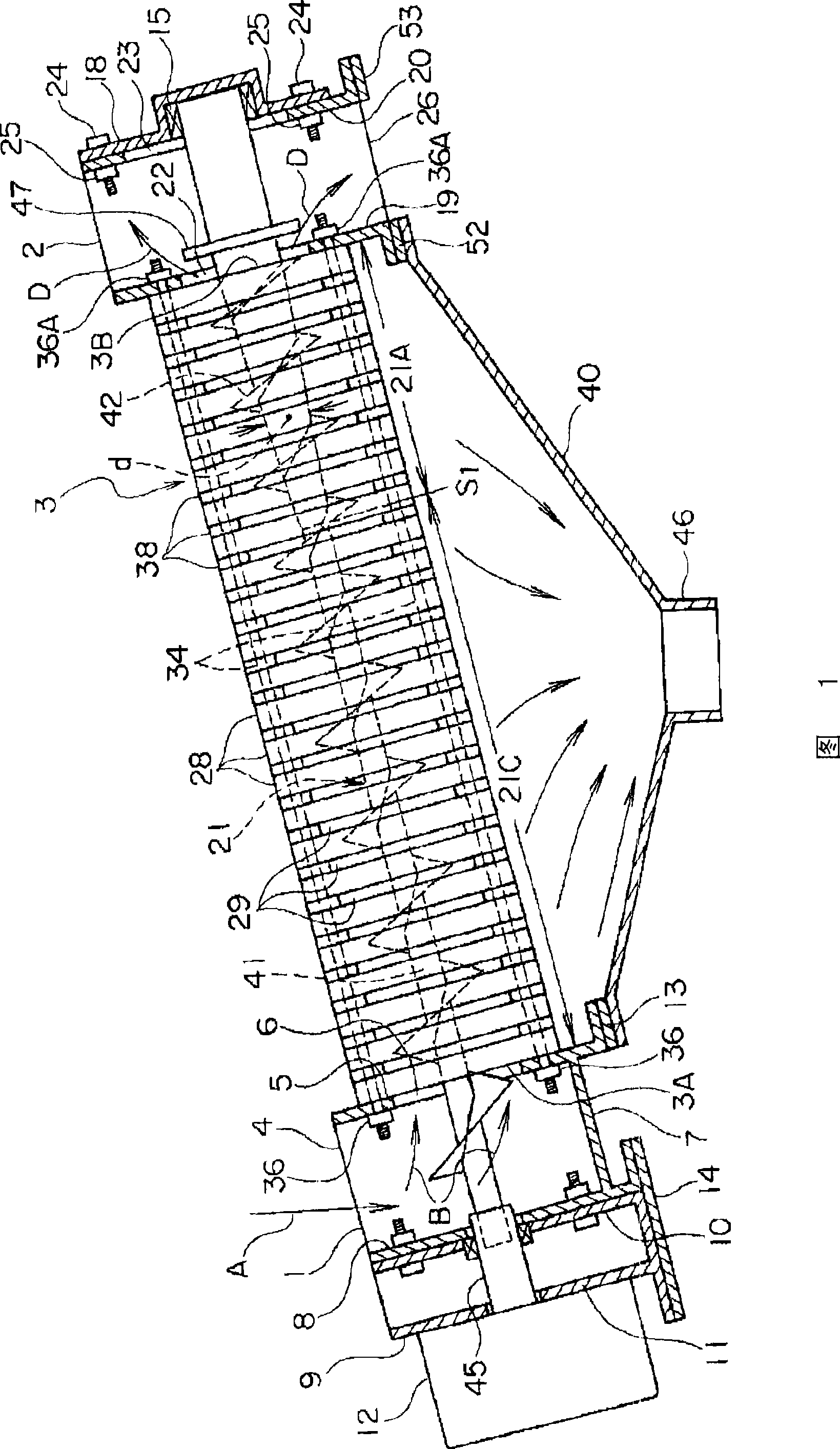

[0067] Fig. 1 is a sectional front view showing an example of a solid-liquid separator. This solid-liquid separator can also separate solid components and liquid components from various treatment objects containing oil and other liquids other than water. Here, the case of dehydrating sludge containing a large amount of water will be described.

[0068] The solid-liquid separation device shown in FIG. 1 has an inlet member 1, an outlet member 2, and a solid-liquid separator 3 disposed therebetween. The inlet member 1 is formed in the shape of a rectangular box with an upper opening, and constitutes an inflow port 4 through which sludge flows through the upper opening. Reference numeral 7 denotes the bottom wall of the inlet part 1 . In addition, an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com