Process and apparatus for continuously producing aromatic polycarbonate

A technology of polycarbonate and manufacturing methods, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical/physical chemical fixed reactors, etc., can solve problems such as switching losses and reduce quality degradation , the effect of reducing the switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

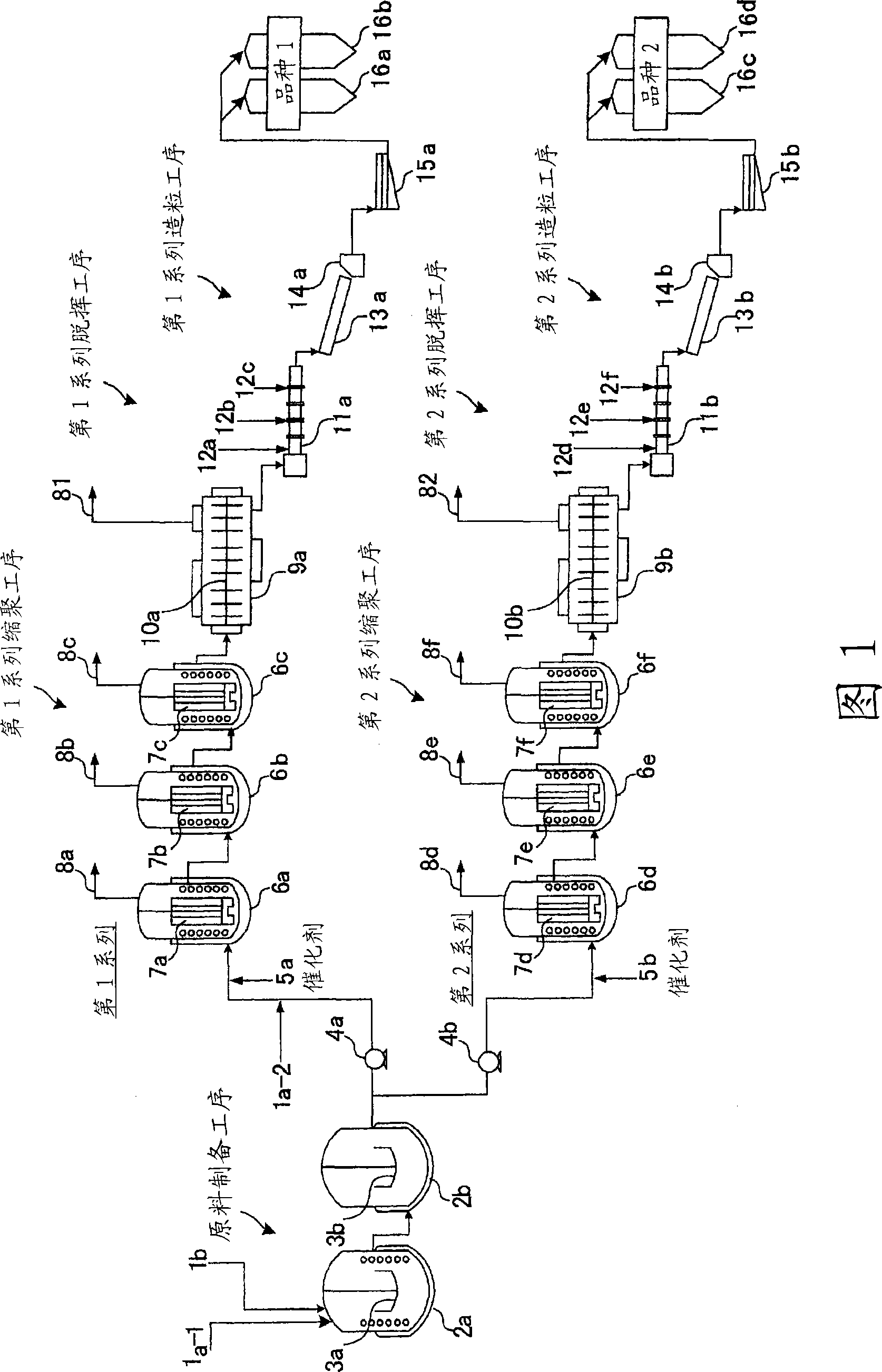

[0162] As shown in FIG. 1 , an aromatic polycarbonate was produced by an aromatic polycarbonate production apparatus having two series of polycondensation steps as follows.

[0163] (preparation of raw material solution)

[0164] The DPC melt prepared at 120°C under a nitrogen atmosphere and the BPA powder measured under a nitrogen atmosphere were supplied to the first raw material mixing tank 2a through the DPC supply port 1a-1 and the BPA supply port 1b, respectively. Utilize the micro-motion flowmeter and the weight feeder of weight loss compensation method to measure, so that the supply rate of DPC is 87.7 kg / hour, and the supply rate of BPA is 89.8 kg / hour (DPC / BPA molar ratio is 1.040). The first raw material mixing tank 2a is set at 140°C under normal pressure nitrogen atmosphere, and the inner volume of the first raw material mixing tank 2a is 0.4m 3, and it is equipped with an anchor type stirring impeller 3a. At this time, the transesterification catalyst does not ...

Embodiment 2

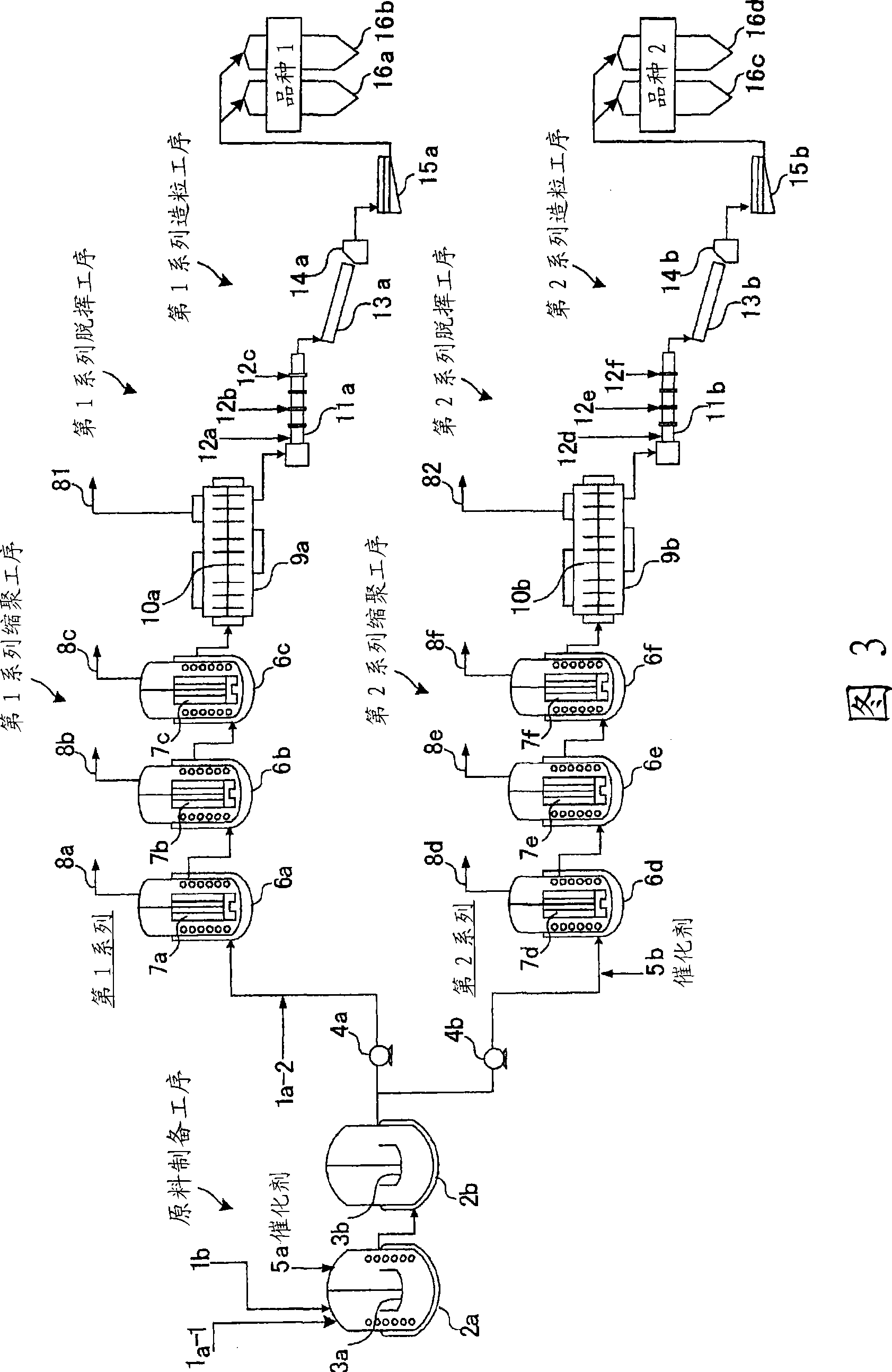

[0252] An example of producing an aromatic polycarbonate through two or more series of polycondensation steps after the raw material preparation step by additionally adding diester carbonate filtered through a filter will be described.

[0253] Fig. 4 is a diagram showing an example of an aromatic polycarbonate production apparatus in which a diester carbonate filtered through a filter is supplemented after the raw material preparation process. The specifications of each machine are the same as those of the raw material preparation process, the first series and the second series in the aromatic polycarbonate production apparatus used in Example 1, and the same symbols are used.

[0254] As shown in Fig. 4, the DPC melt prepared at 120°C under a nitrogen atmosphere was passed through a SUS316L filter 1f with an absolute filtration accuracy of 0.5 μm, and then passed through the DPC supply port 1a provided in the middle of the transfer pipe for the raw material mixture. -2 Feed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap