Push-pull type electric transducer with zero voltage switch and its switching method

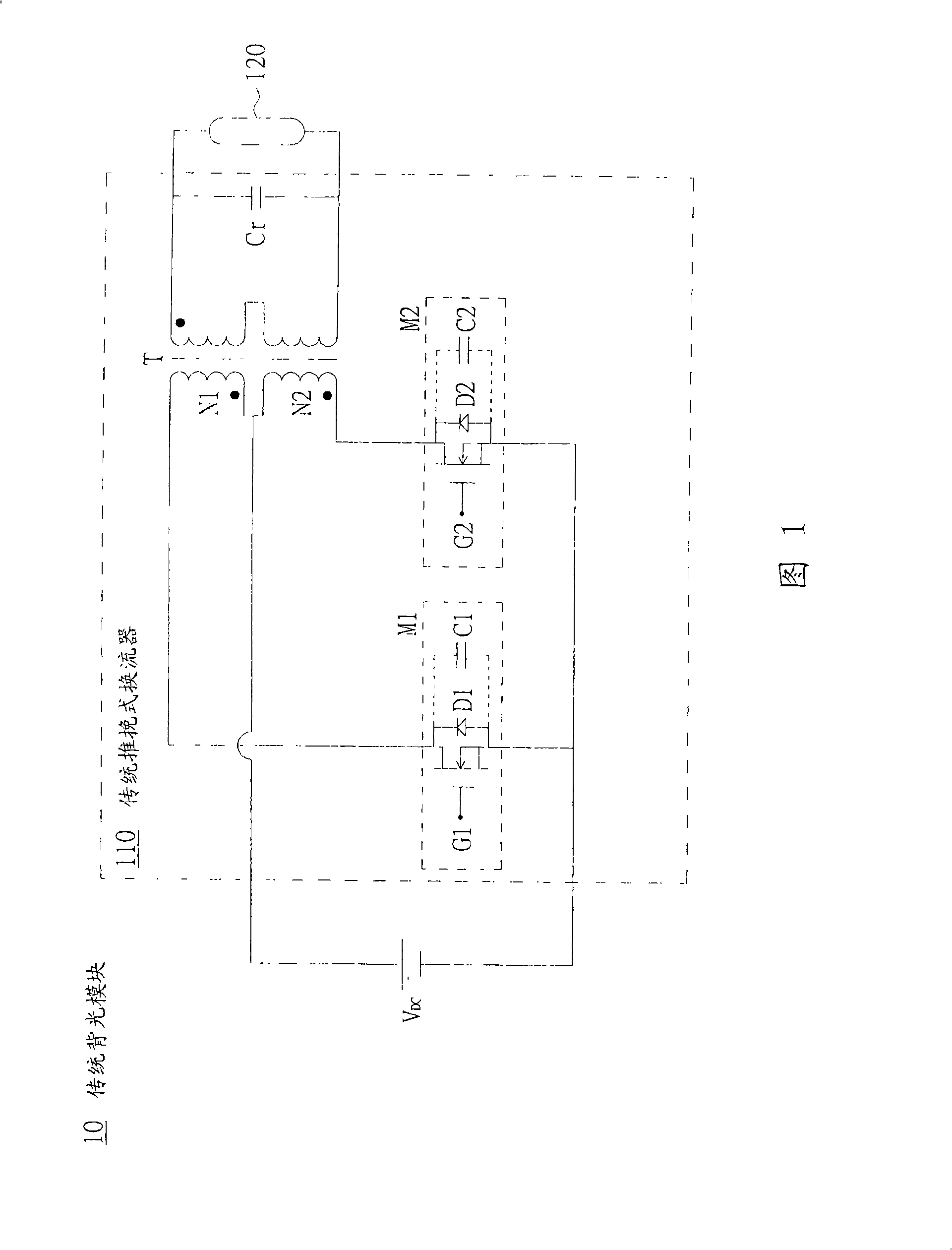

A voltage and transformer technology, applied in the field of push-pull converters, can solve the problem that the conversion efficiency of the push-pull converter 110 cannot be effectively improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

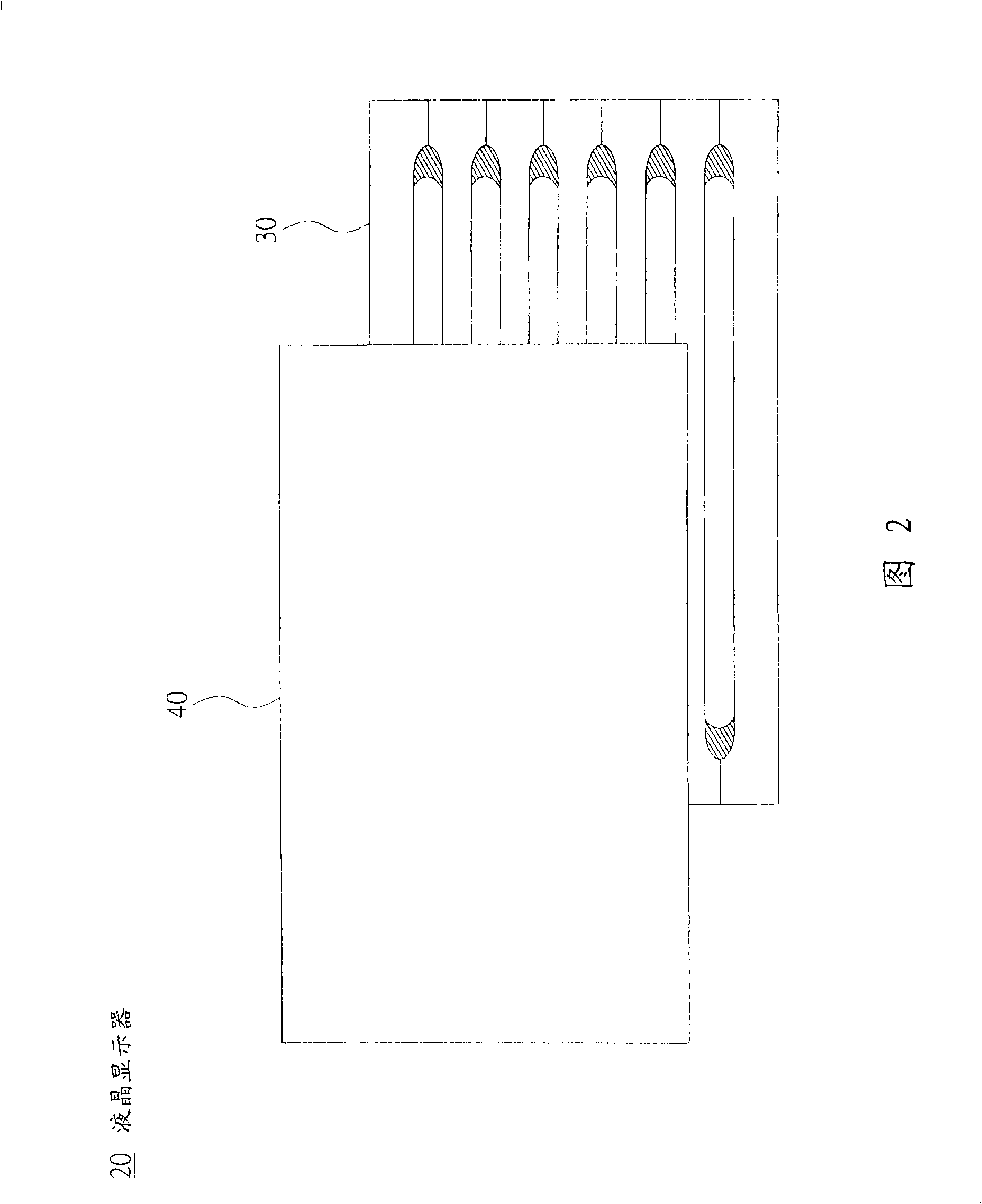

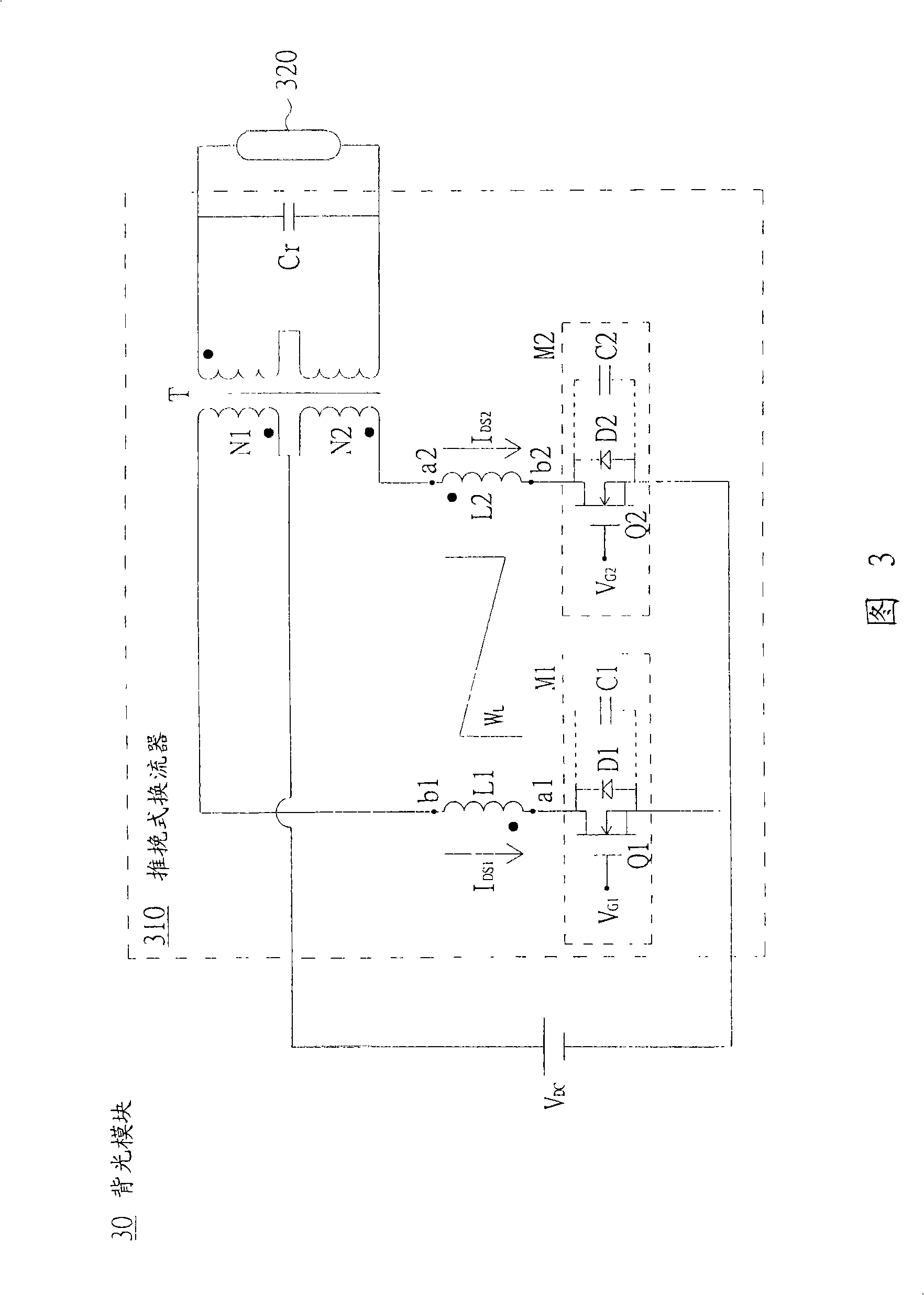

[0044]The push-pull converter alternately switches the first switch and the second switch respectively according to a first control signal and a second control signal, so as to generate an AC voltage to the transformer, so that the transformer drives the light-emitting component according to the AC voltage. In order to improve the switching loss of the traditional push-pull converter, the following embodiments use the charging and discharging characteristics of the inductor and the energy coupling characteristics, so that the first switch and the second switch of the push-pull converter work at zero voltage switching (Zero Voltage Switching) state.

[0045] In other words, the following embodiments utilize the charging and discharging characteristics of the inductor and the characteristics of energy coupling, so that the voltage at both ends of the first switch and the second switch before the first switch and the second switch are turned from off (Off) to on (On) That is, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com