Rotary working table

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of workbench strength and precision influence, oil and gas pipeline winding, etc., so as to ensure repeat positioning accuracy and eliminate winding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

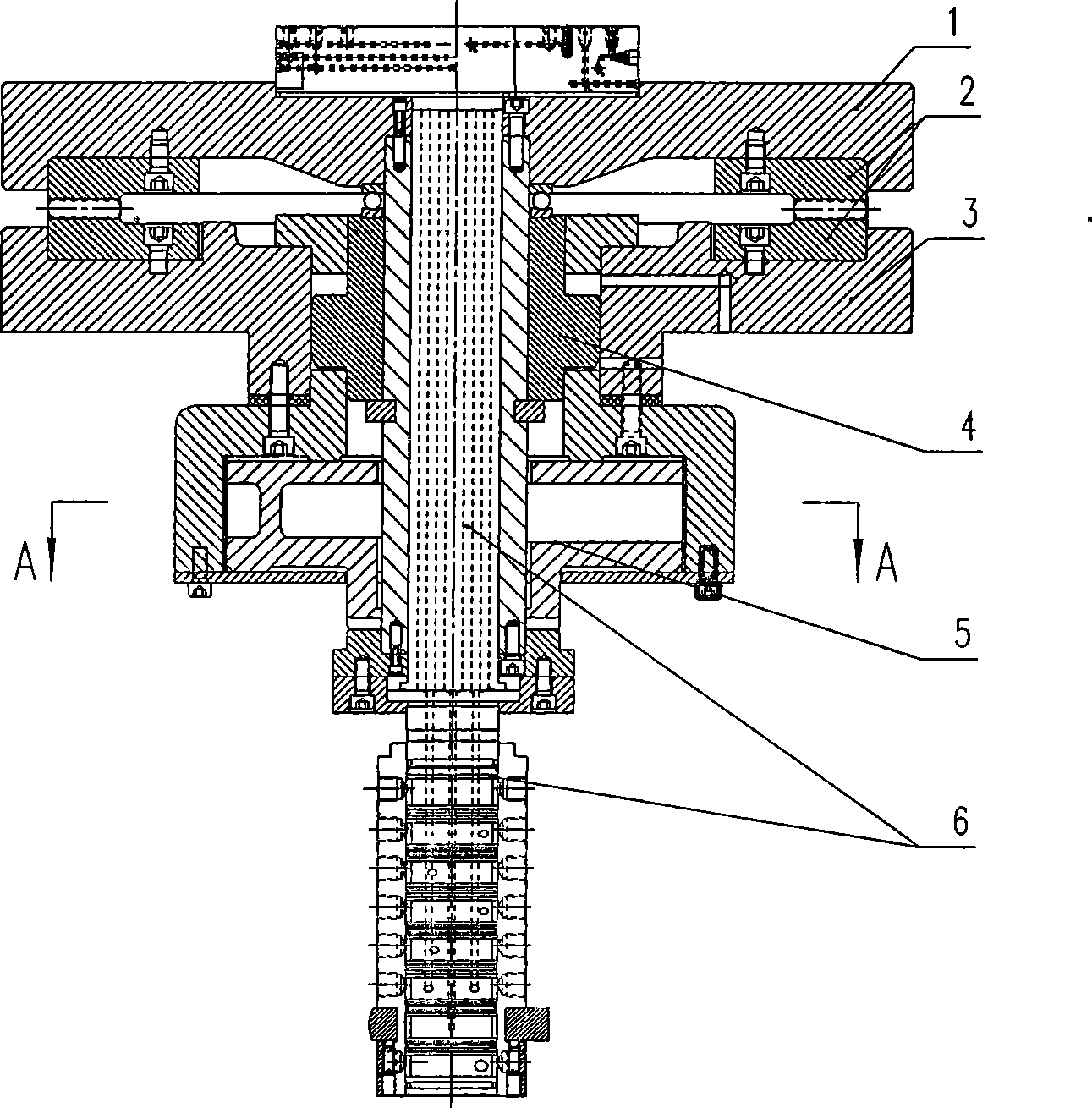

[0010] The rotary table will be further described in detail in conjunction with the accompanying drawings and specific implementation methods:

[0011] figure 1 As shown, the upper part of the end gear plate 2 is installed on the worktable 1, and the lower part is installed on the base. The center of the base 3 is located to form a sealed cavity, and the lifting and locking mechanism 4 is installed in the sealed cavity. Or pneumatic power to lift and lock the table, so that the rotary table can bear the force of heavy load on the side.

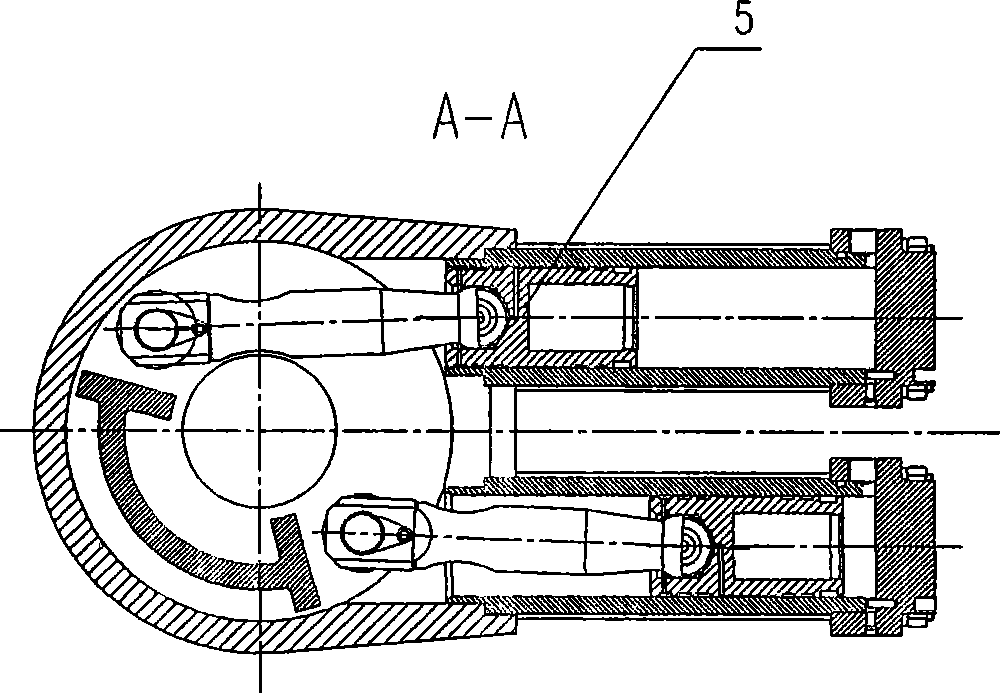

[0012] figure 2 yes figure 1 In the cross-sectional view of the lifting and locking mechanism 4, an intermediate rotating shaft 7 is installed, and the worktable 1 is fixed on the intermediate rotating shaft 7, and the 90-degree indexing drive mechanism 5 drives the intermediate rotating shaft 7 and the working table 2 to make intermittent rotations every 90 degrees. bit.

[0013] The intermediate rotating shaft 7 is a hollow shaft, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com