Automobile front cover decoration

A decorative part and front cover technology, applied in the field of automobile front cover decorative parts, can solve the problems of weather resistance, poor durability, inconvenient disassembly, replacement, and high production cost, and achieve simple manufacturing process, convenient after-sales maintenance and replacement, and production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

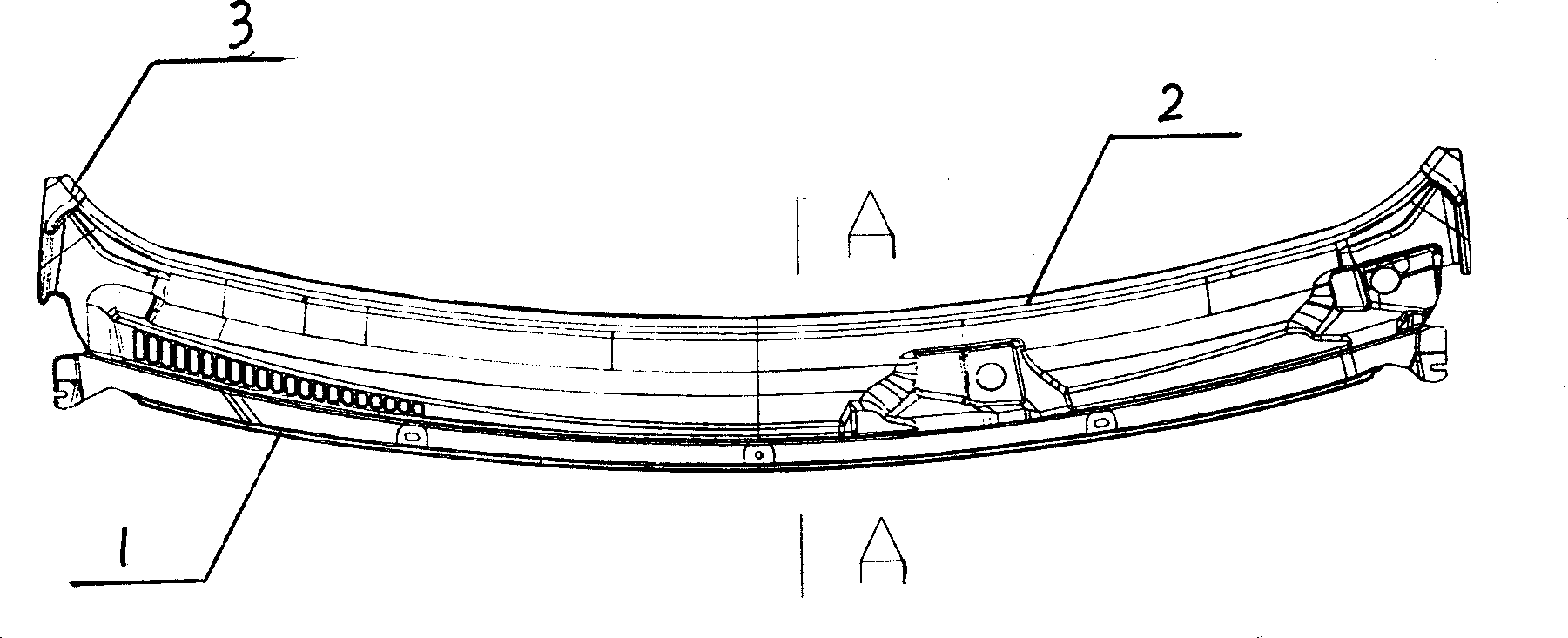

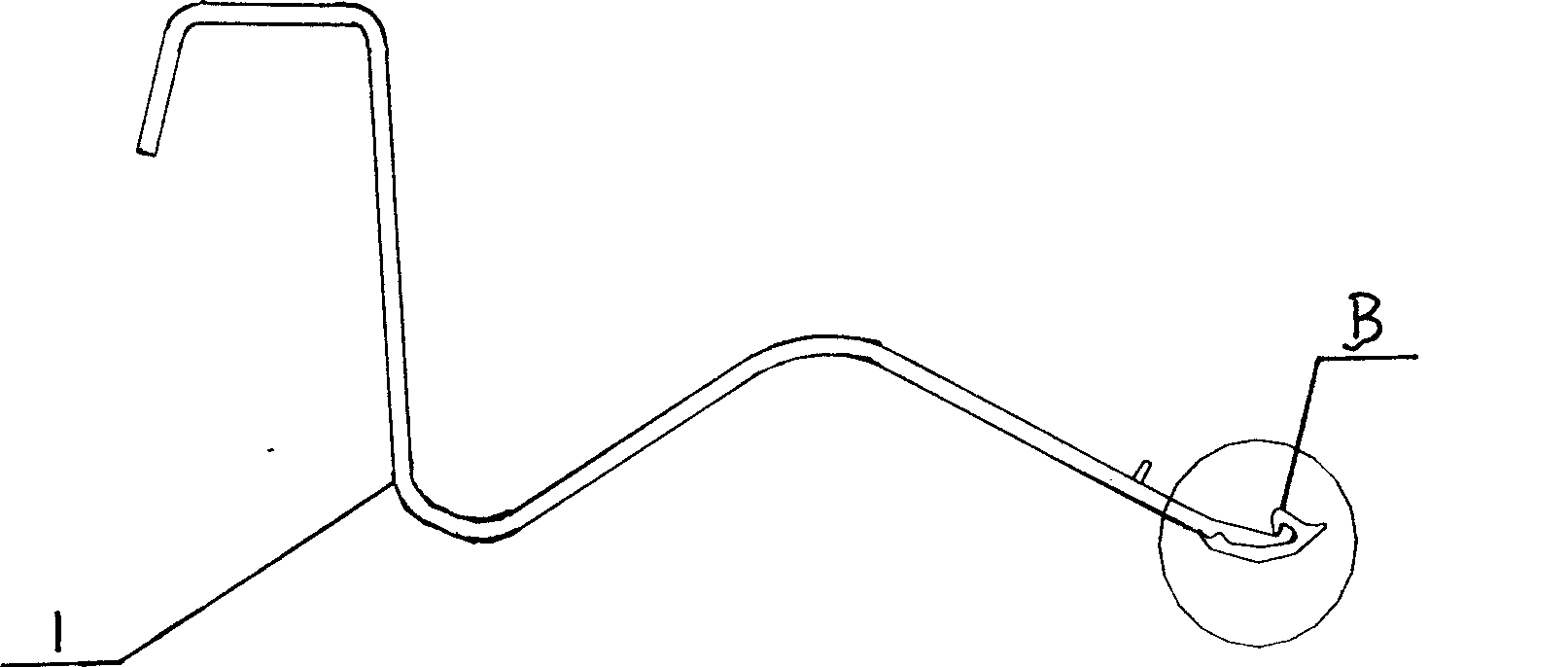

[0012] see figure 1 , The structure of the front cover trim includes a front cover trim body 1, and a sealing strip 2 is connected to the upper edge of the front cover trim body by means of hook pressure.

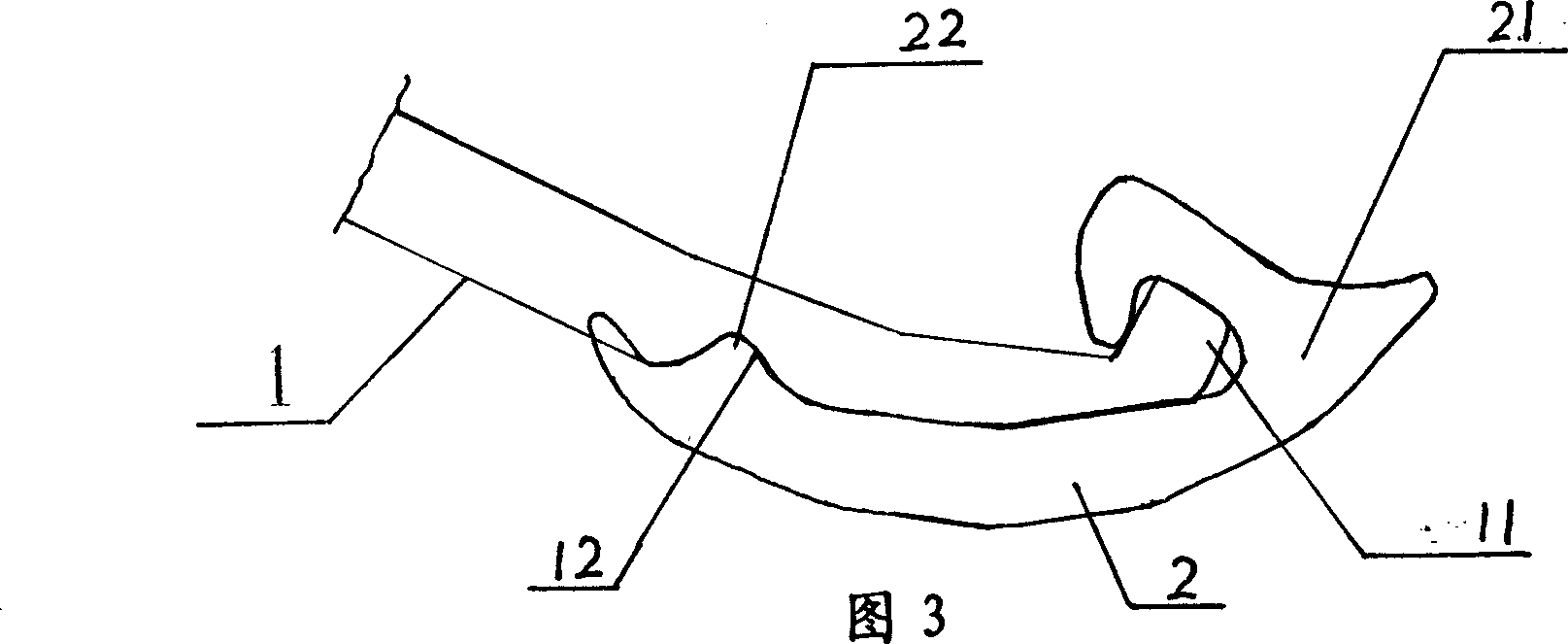

[0013] see figure 2 As shown in FIG. 3 , the mutual hooking structure of the front cover trim body 1 and the weather strip 2 is that the boss 11 is combined with the hook groove 21 , and the groove 12 is combined with the protrusion 22 . An upwardly bent boss 11 is formed on the upper edge of the front cover trim body, and a downwardly bent hook groove 21 is correspondingly formed on the edge of the weather strip 2, and the hook groove 21 and the boss 11 are hooked together, so that The sealing strip is firmly hooked to the front surface of the front cover trim body. A groove 12 is formed on the surface of the front cover trim body close to the upper edge, and a protrusion 22 is formed on the inner side of the sealing strip 2 correspondingly, and the protrusion 22 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com