Frequency conversion control method of compressor unit for natural gas vehicle refueling mother station

A compressor unit, frequency conversion control technology, applied in the direction of pump control, mechanical equipment, machine/engine, etc., can solve the problems of motor efficiency and performance decline, large load fluctuation range, increase gas filling capacity, etc., to increase the average daily gas supply Full capacity and power utilization, reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The principles and technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

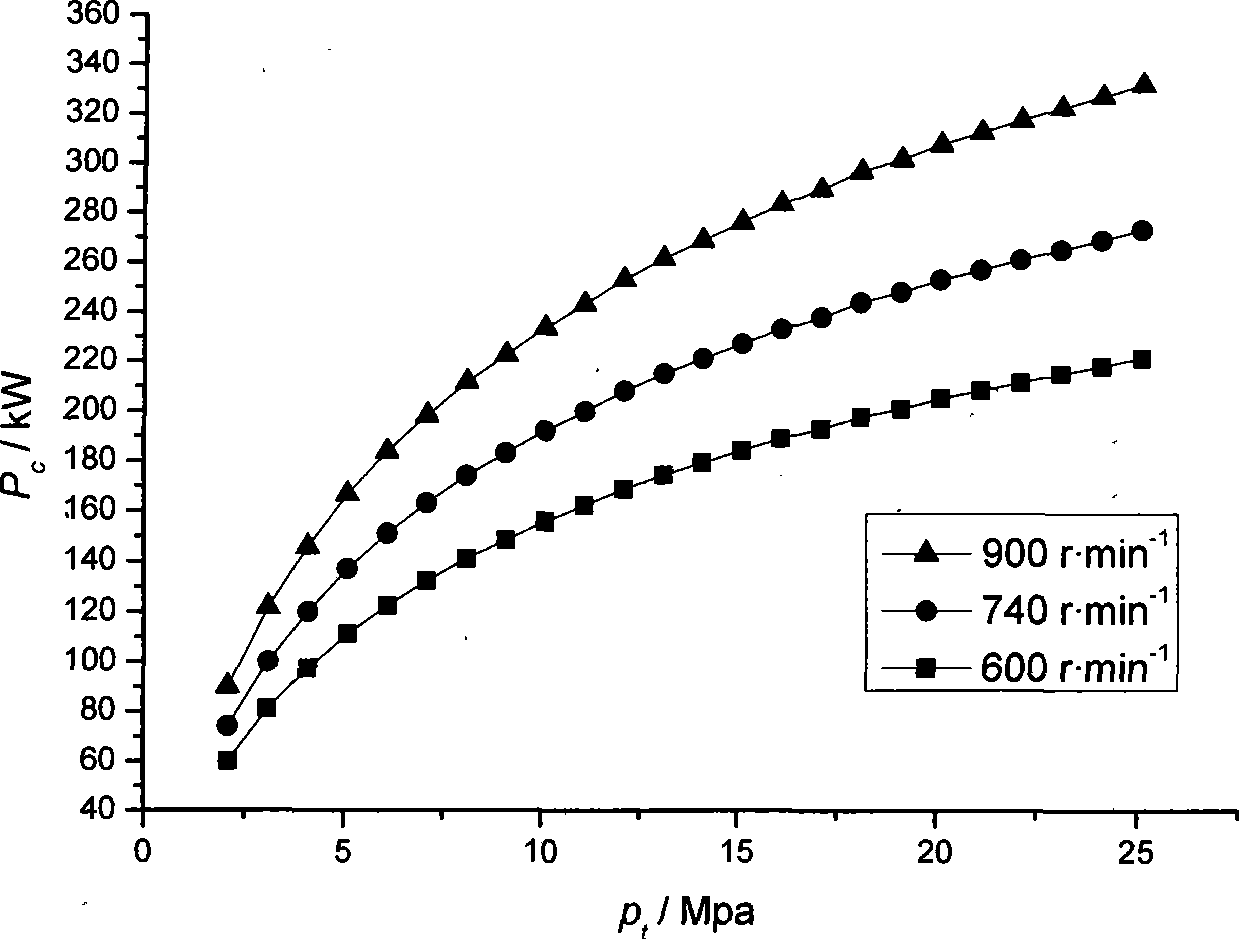

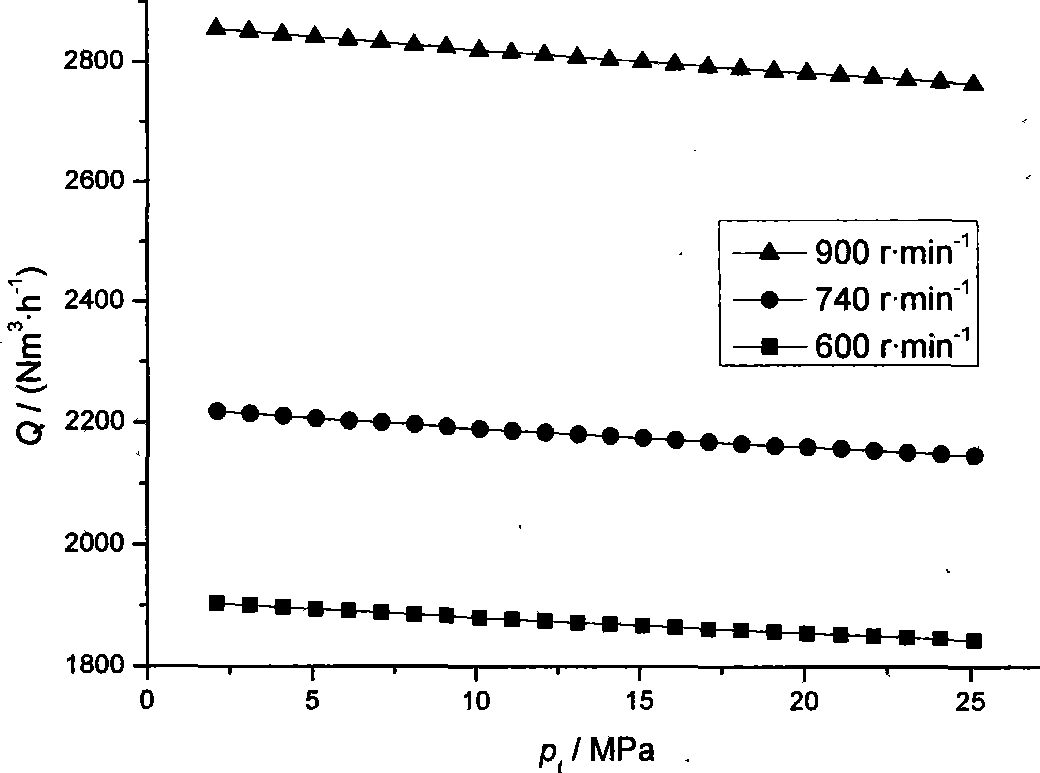

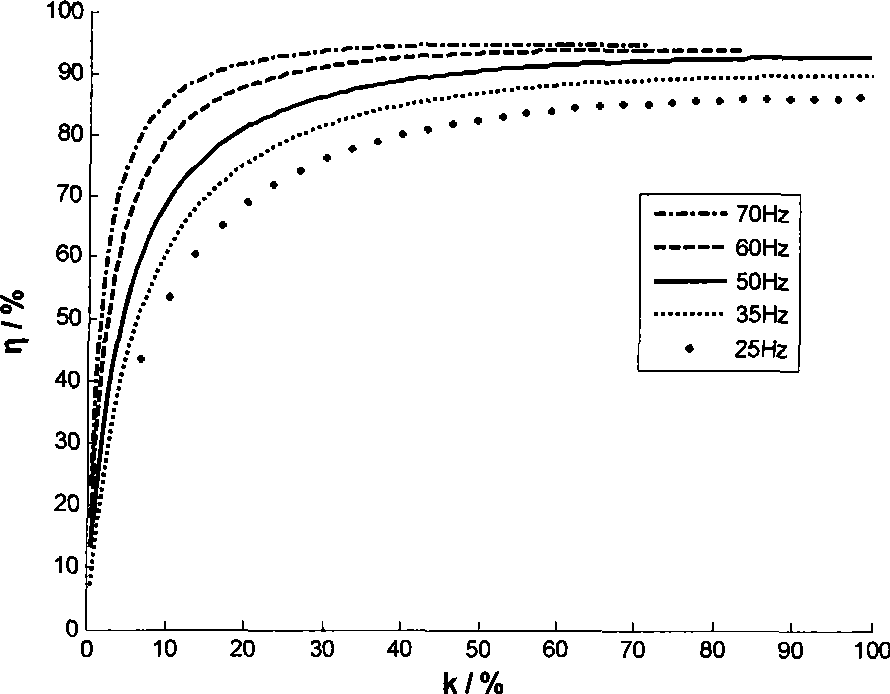

[0056] see figure 1 , figure 2 : According to the working principle of the compressor, the power consumption and air supply volume of the compressor change with the speed, suction pressure and discharge pressure. For the compressor at the mother station, the speed is determined by the driven motor; the suction pressure is close to the gas supply pressure of the natural gas pipeline, and its fluctuation range is generally only a few kPa. Compared with the average gas supply pressure of MPa level, it can be approximated is unchanged; the exhaust pressure is approximately equal to the pressure of the tank car, and the pressure of the tank car gradually increases from 2MPa to 20MPa during the filling process, so the range of exhaust pressure changes is very large. Further research shows that at a constant speed, the higher the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com