Swing valve and plasma processing device and method for controlling pressure in reaction chamber

A technology of reaction chamber and internal pressure, applied in valve device, flow control, non-electric variable control and other directions, can solve problems such as poor pressure control ability of pendulum valve, and achieve the effect of good pressure control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

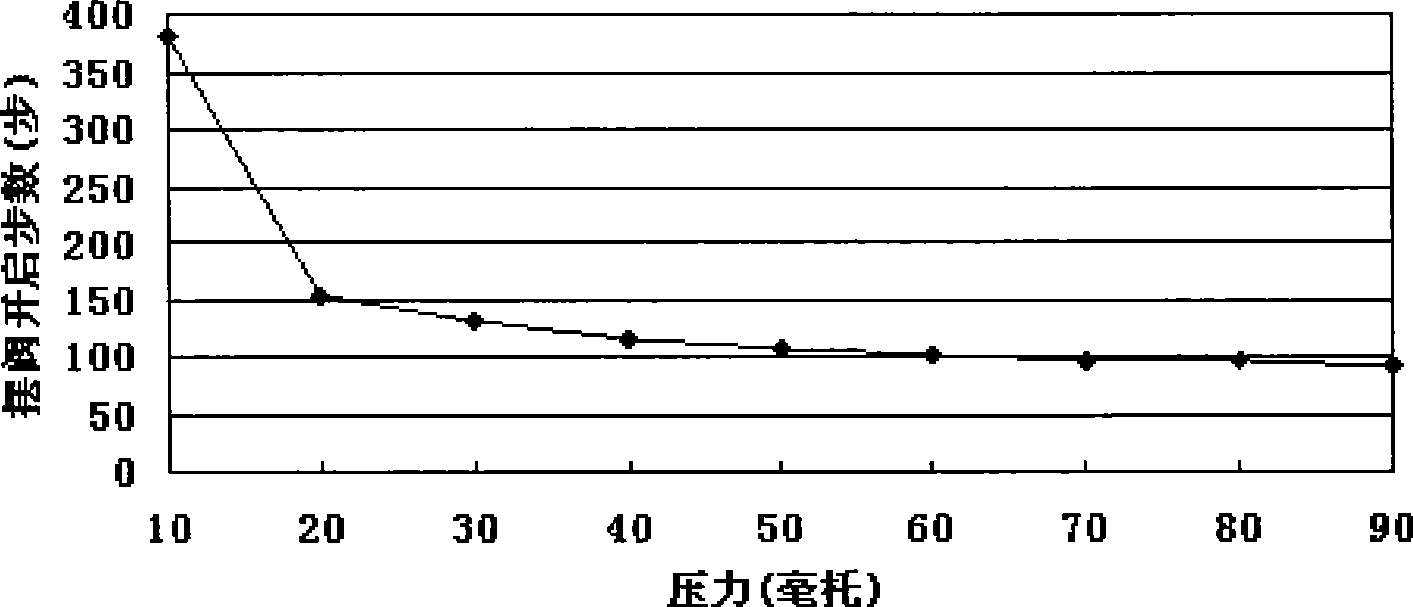

[0033] Assuming that in the process of pressure control, the total number of opening steps of the pendulum valve is 1000 steps, the segmented pressure control can be realized by dividing the number of opening steps of the pendulum valve:

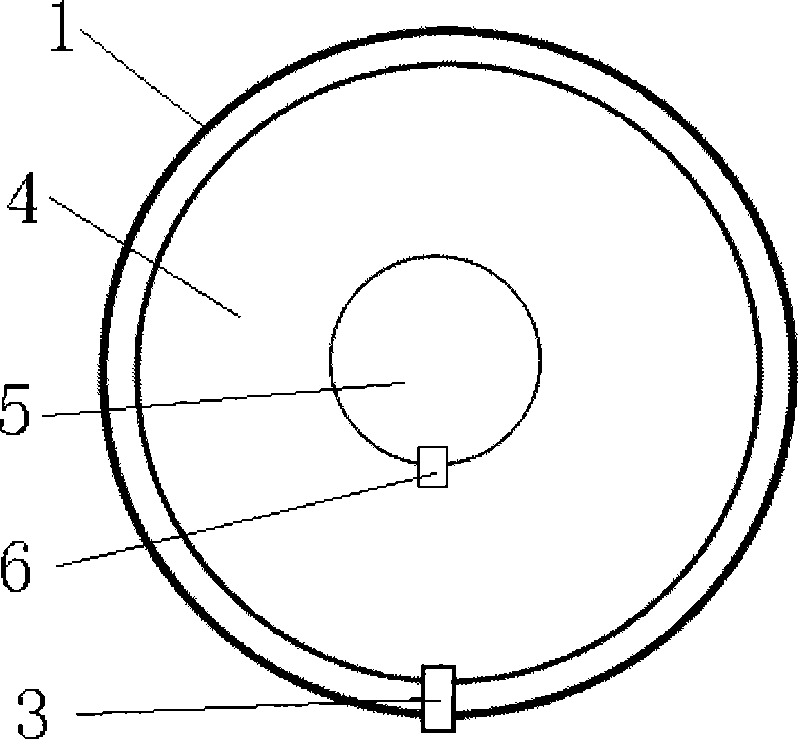

[0034] When the number of opening steps of the pendulum valve is greater than 100 steps, the pressure control is realized through the main valve core 4;

[0035] When the number of opening steps of the swing valve is less than or equal to 100 steps, the pressure control is realized through the auxiliary swing valve.

[0036] Segmented pressure control can also be realized by dividing the pressure in the reaction chamber. During the pressure control process, when the flow rate of the intake air in the reaction chamber is 45-55 sccm, such as 45, 50, 55 sccm:

[0037] When the pressure in the reaction chamber is less than 50mT, the pressure control is realized through the main valve core 4;

[0038] When the pressure in the reaction chamber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com