Semiconductor process chamber, semiconductor process equipment and semiconductor process method

A technology of process chamber and process method, which is applied in the field of semiconductor process equipment, can solve problems such as the inability to ensure stable and uniform air flow, irregular flow channels in the internal space, and affect the quality of film formation, so as to improve the effect of pressure control and shorten the film transfer. Time, the effect of improving the film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

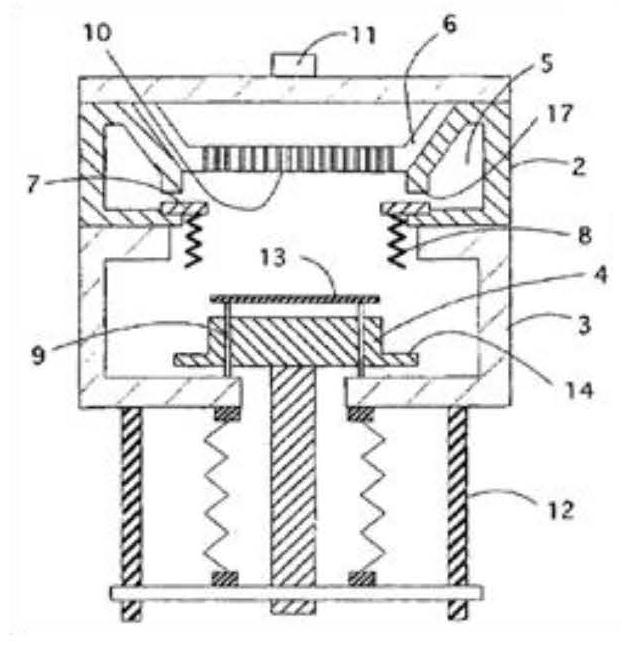

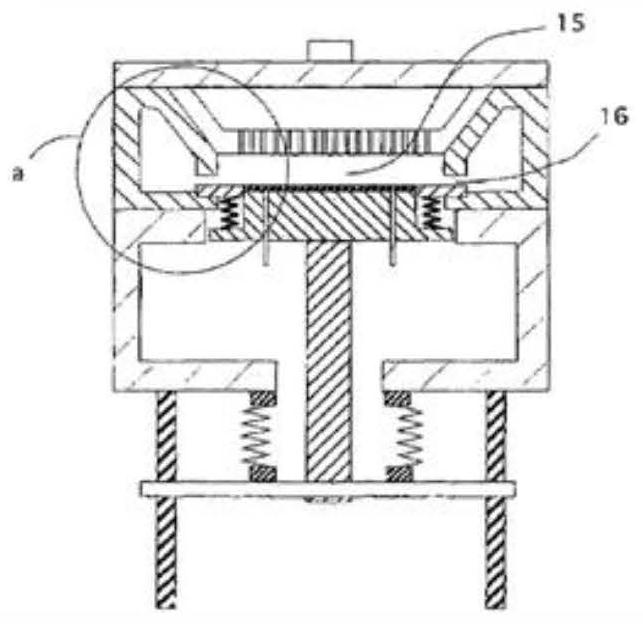

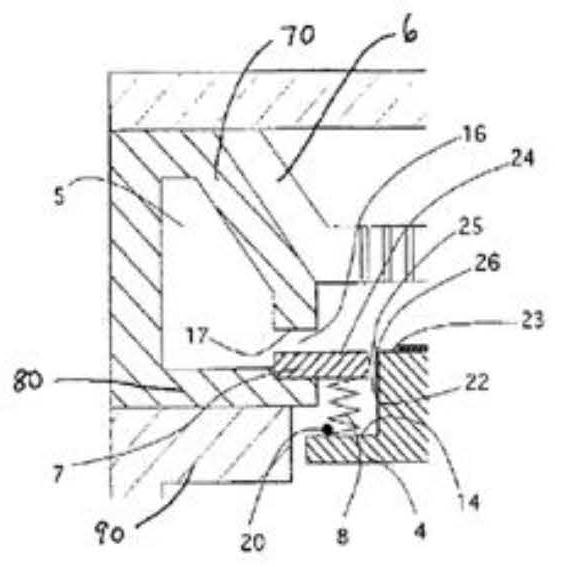

Image

Examples

specific Embodiment

[0102] Before the semiconductor process starts, the four pedestals 300 are all in the low position.

[0103]The wafer 700 is transferred from the outside of the process chamber to the top of the first pedestal 71 and the second pedestal 74 through the transfer port 240, and falls to the plurality of supporting columns 310 corresponding to the first pedestal 71 and the second pedestal 74 respectively. of the upper end. The driving assembly of the transfer manipulator 600 drives the upper flange 62 to rise to a predetermined height and rotate clockwise until the first finger 611 and the second finger 612 respectively rotate under the fourth base 74 and the wafer 700 carried by the first base 71 .

[0104] The driving assembly of the transfer manipulator 600 drives the upper flange 62 to rise again, so that the first finger 611 and the second finger 612 hold up the wafer 700 on the first base 71 and the second base 74 respectively.

[0105] Subsequently, the upper flange 62 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com