Overall process under-balance drilling pressure compensation system and method

An underbalanced drilling and pressure compensation technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of wellhead overpressure, increase the difficulty of wellbore pressure control, and increase the difficulty of pressure control, etc., to achieve The effect of avoiding wellhead overpressure, ensuring safe implementation, and enhancing the ability of pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

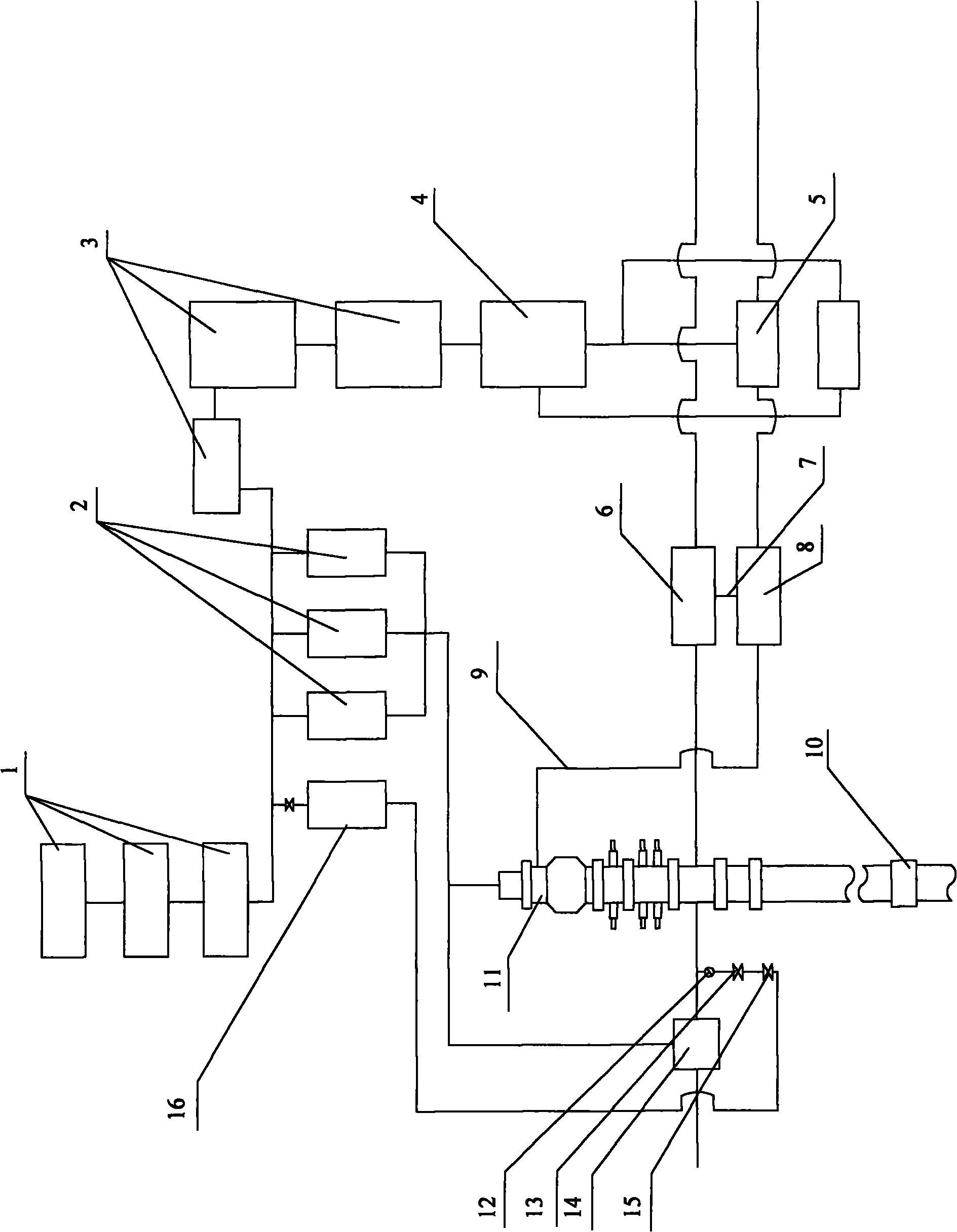

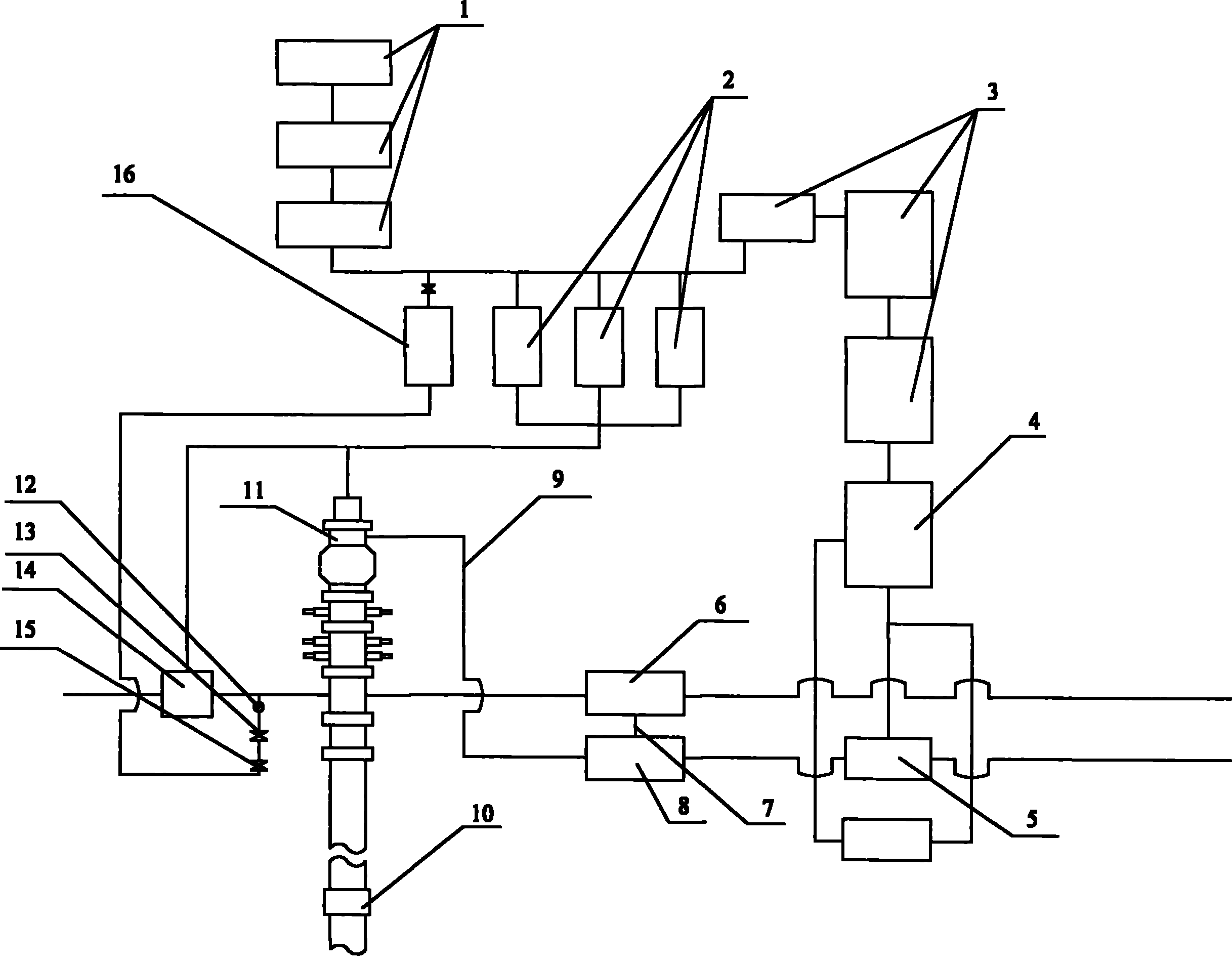

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The present invention is mainly composed of a wellhead rotating blowout preventer 11, an underbalanced choke manifold 8, a drilling fluid continuous perfusion system and a conventional drilling fluid circulation system. The wellhead rotating blowout preventer 11 is placed The injector 11 and the underbalanced choke manifold 8 are connected by a high-pressure hose 9, and the kill manifold 14 connected through the four-way of the conventional wellhead control device is connected in parallel with the drilling fluid continuous injection system through the double-way, and the drilling fluid is continuously injected The outlet of the pressure well ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com