Slurry shielding ordinary-pressure tool changer

A mud-water shield and tool-changing device technology, which is applied to mining devices, mining equipment, earth-moving drilling, etc., can solve the problems of inability to meet the requirements of excavation, inability to meet replacement, and low work efficiency, so as to achieve repeated use and improve construction. Environmental, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

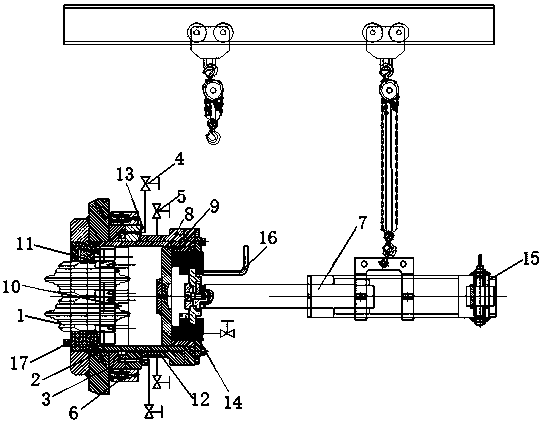

[0023] Embodiment 1: Set a fixed point for the drawing cylinder 7 at the rear end of the cutter head chamber of the slurry shield machine, fix the drawing cylinder 7 through the gourd with the help of a positioning snap ring, connect the hydraulic high-pressure hose, turn on the switch of the hydraulic control unit, and adjust the pulling cylinder 7. Pull the oil cylinder 7 to the F-type pull-push block to cooperate with it, lock the installation lock and remove the bolts on the outer cutter barrel 12 at the same time, keep the additional thrust load of the hydraulic cylinder 7, and further control the retreat of the hydraulic cylinder 7 through the hydraulic control unit switch, and control the retraction amount to The double-opening gate device 3 can be closed to start the double-opening gate device 3. The double-opening gate hydraulic cylinder 6 ensures the rapid closing of the double-opening gate device 3. At the same time, the flushing high-pressure valve 4 and the pressure...

Embodiment 2

[0024] Embodiment 2: The prepared new cutter cylinder and cutter are hoisted by the sling, and the front-end special-shaped lug of the drawing cylinder 7 is used to rotate and cooperate with the F-shaped pull and push block at the end of the cutter cylinder to push and pull the inner cutter cylinder of the hob. 2. Before pushing the outer cutter cylinder 12, apply grease on its outer surface to further reduce the friction force. At the same time, when the inner cutter cylinder 2 of the hob is pushed into the first sealing ring, start the double-opening gate device again. 7 Double-opening gate hydraulic cylinder 6 Ensure that the double-open gate device 7 is opened quickly, and then gradually apply the upper thrust of the hob inner cutter barrel 2, and then lock the bolt after the knife pushing action is successfully completed.

[0025] To sum up, the muddy water shield normal pressure tool changing device, through the design of the oil injection device 13, can realize the rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com