Piping-main scheme boiler load coordinating control method

A technology of coordinated control and boiler load, applied in control systems, steam generation, lighting and heating equipment, etc., can solve problems such as unstable pressure of the main pipe, eliminate mutual interference of loads, improve safety and stability, and improve thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

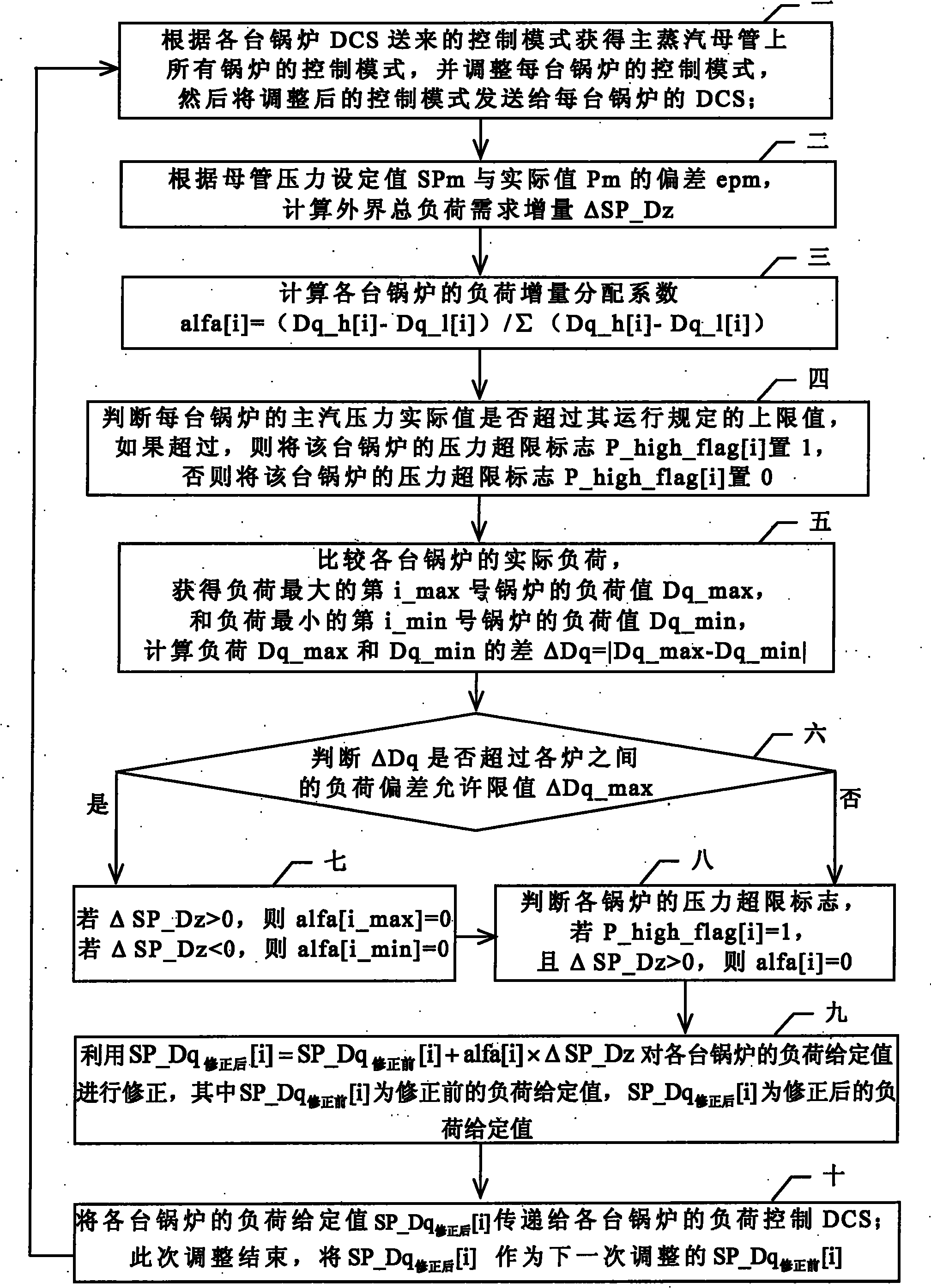

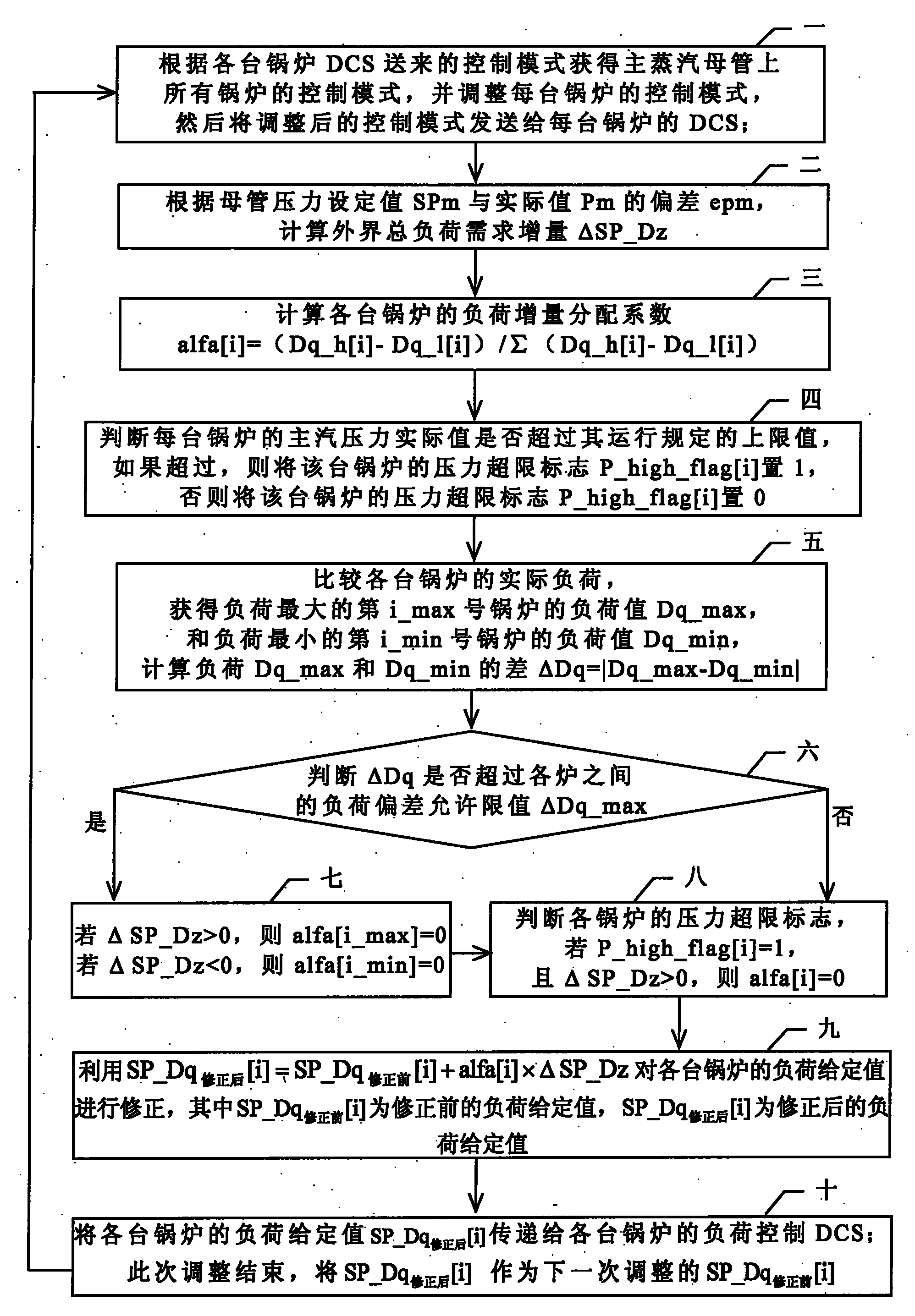

[0028] Embodiment 1: The DCS used in this embodiment is based on the existing DCS of each boiler, and a main pipe pressure load coordination control DCS is added, and the pressure load coordination control DCS of the main pipe is connected with each boiler. DCS connection, the pressure load of the main pipe is coordinated to control the working process of DCS as follows:

[0029] Step 1: Obtain the control modes of all boilers on the main steam main pipe according to the control modes sent by the DCS of each boiler, and adjust the control mode of each boiler, and then send the adjusted control mode to the DCS of each boiler; then Execute step two;

[0030] Step 2: Calculate the external total load demand increment ΔSP_Dz according to the deviation epm=SPm-Pm between the main pipe pressure set value SPm and the actual value Pm, and then perform step 3;

[0031] Step 3: Calculate the incremental load distribution coefficient of each boiler alfa[i]=(Dq_h[i]-Dq_l[i]) / ∑(Dq_h[i]-Dq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com