Patents

Literature

35results about How to "Efficient and economical operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

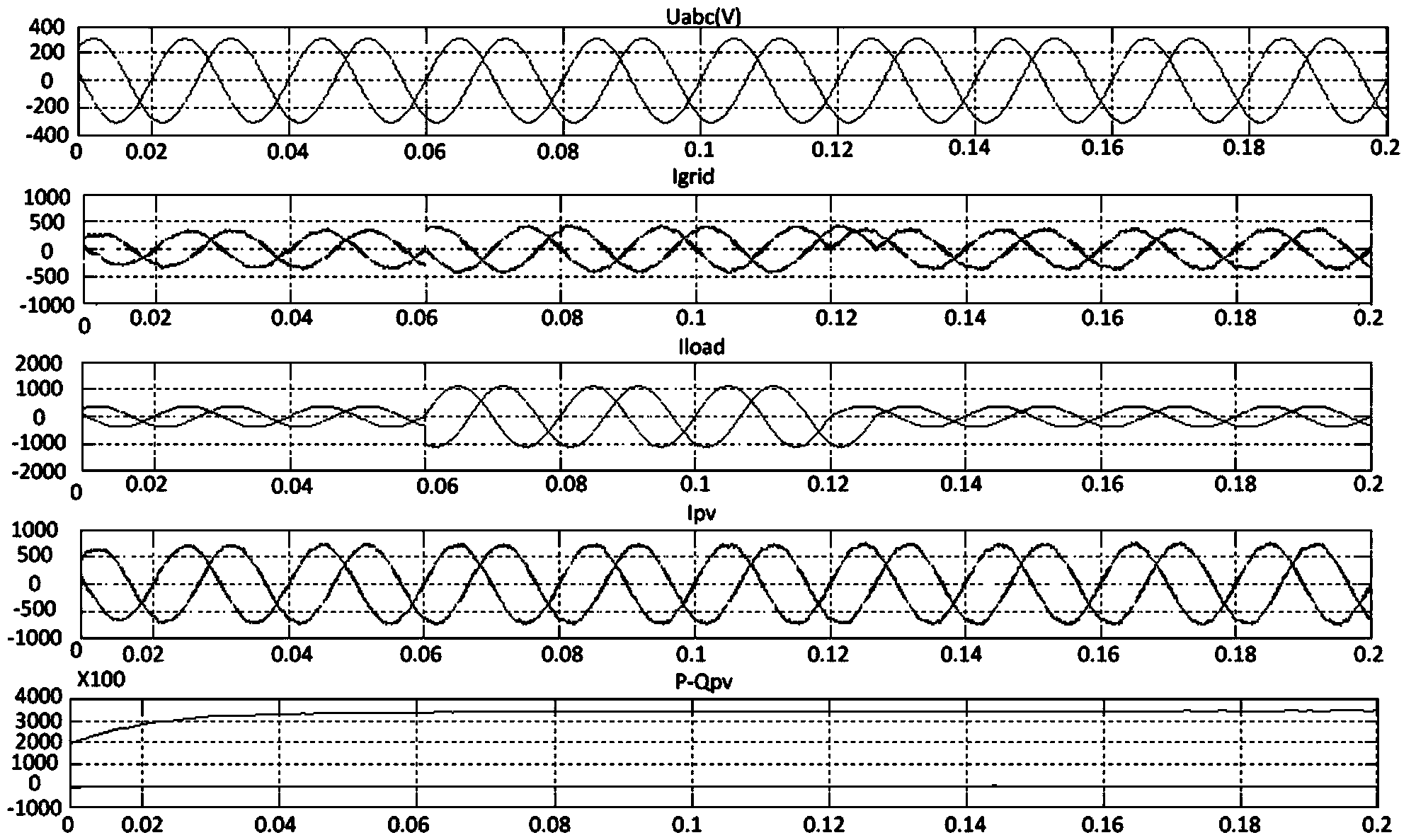

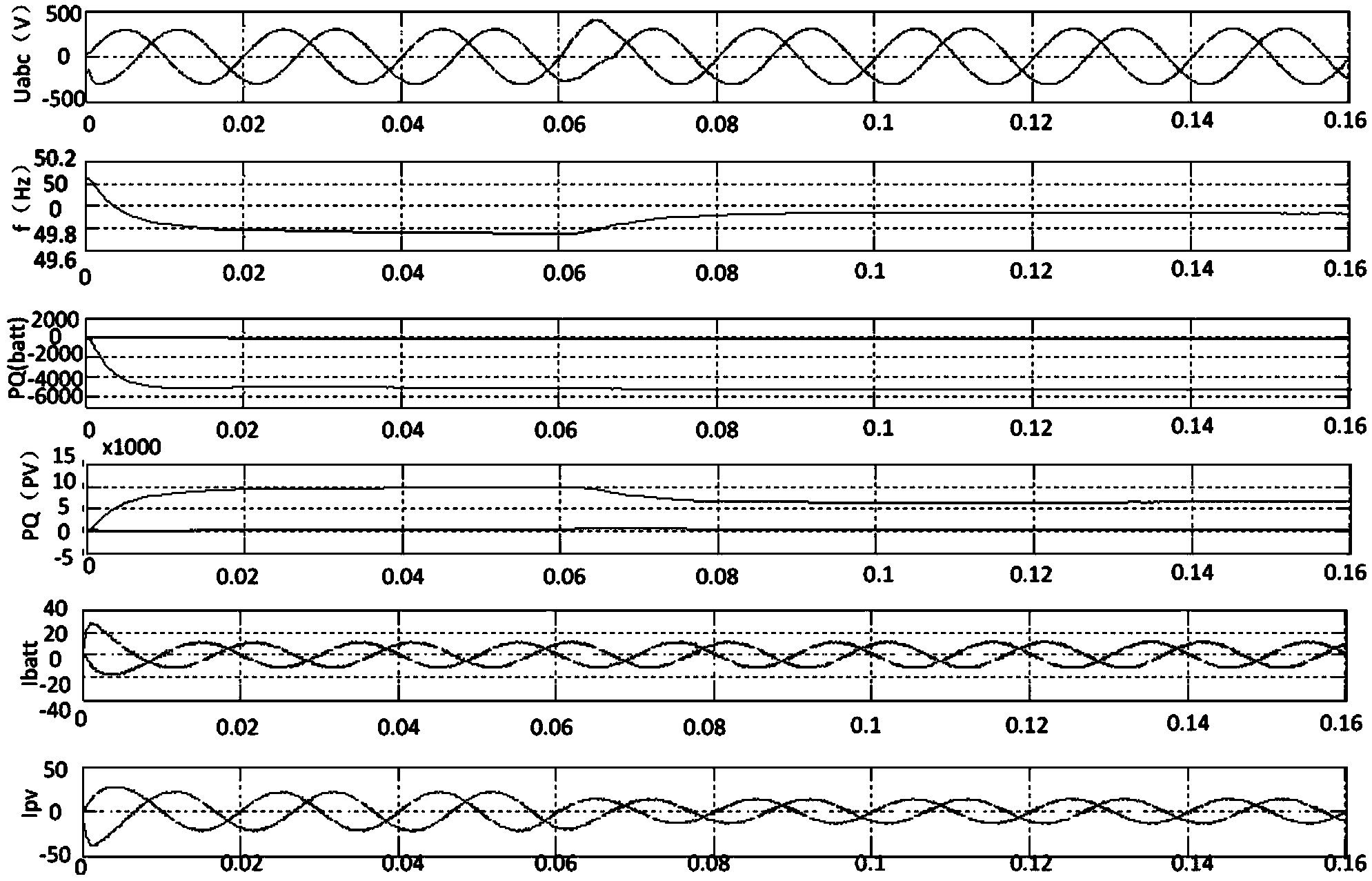

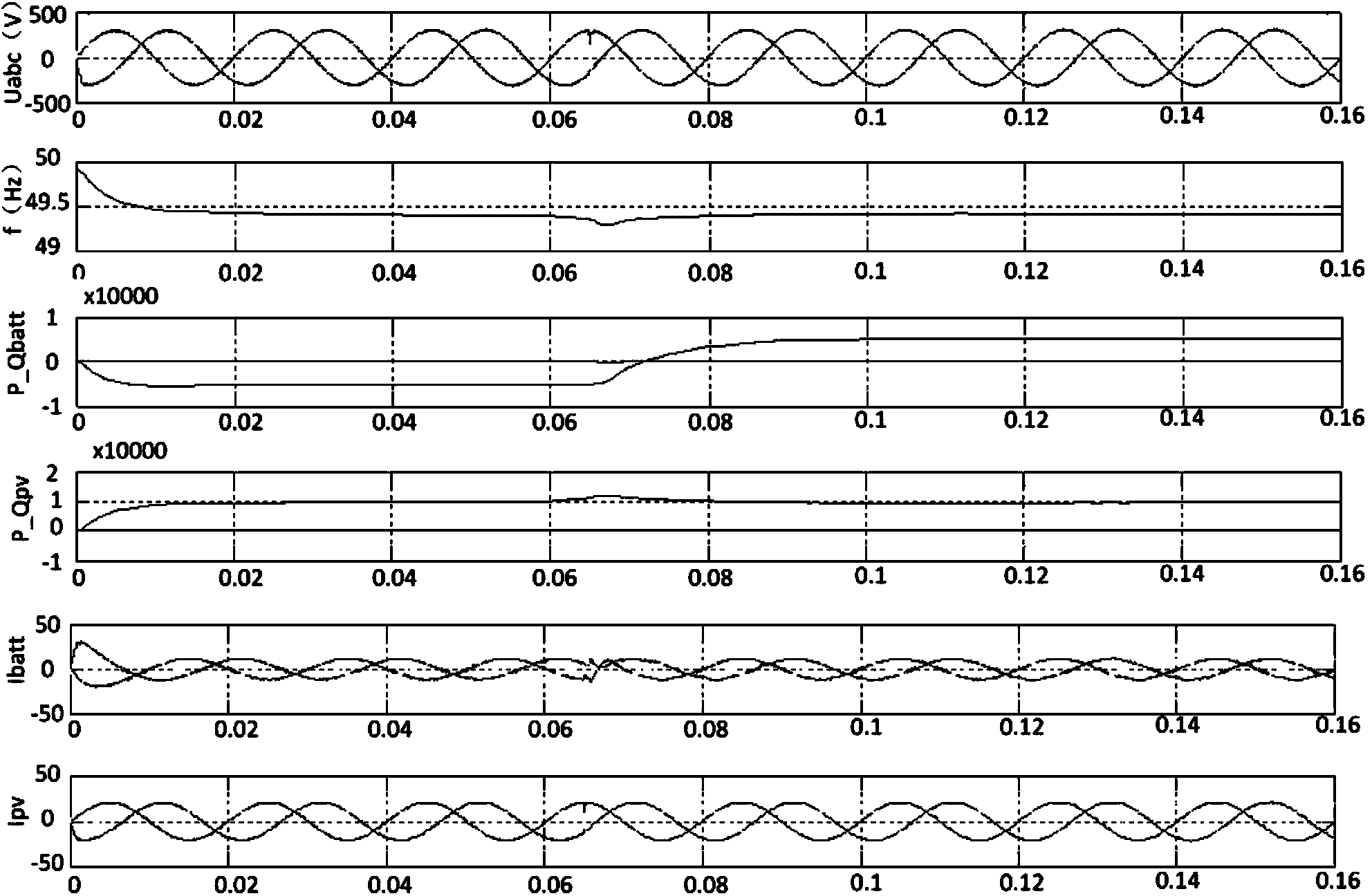

Real-time coordination and control method of photovoltaic micro-grid system

ActiveCN104242337AEfficient and economical operationAchieve Power Optimum MatchingSingle network parallel feeding arrangementsEnergy storageCapacitanceControl layer

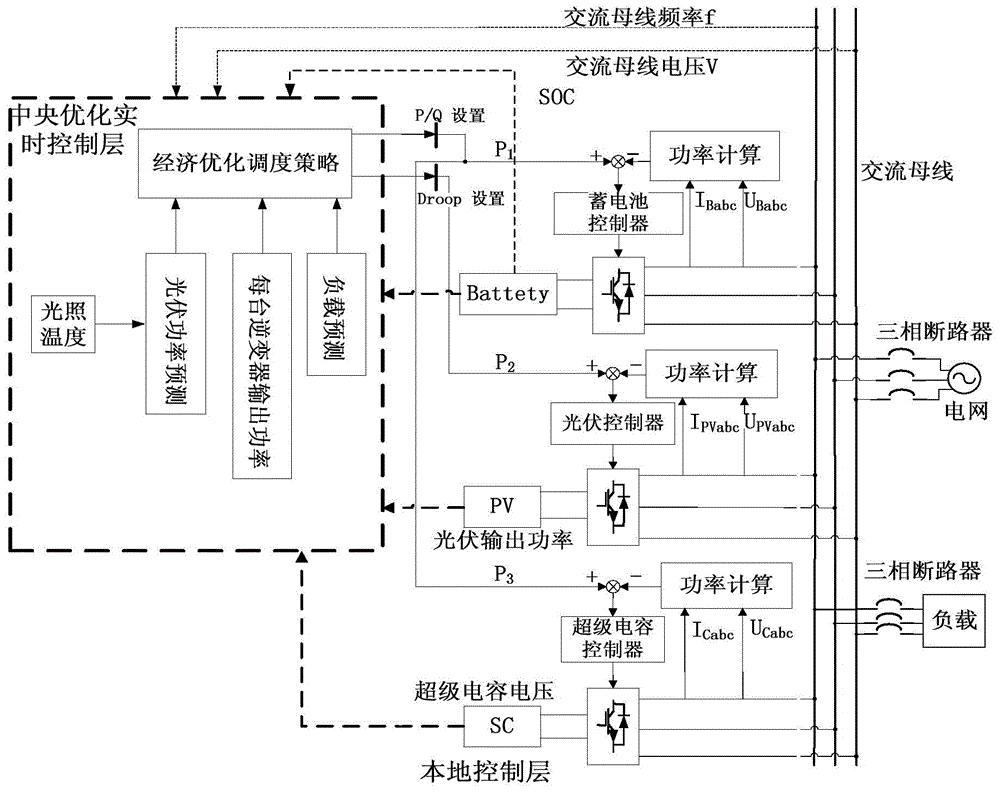

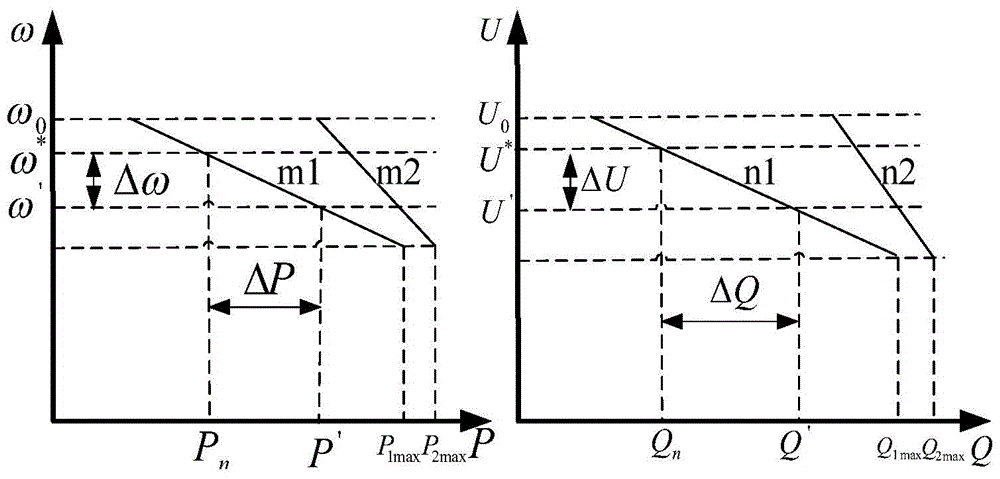

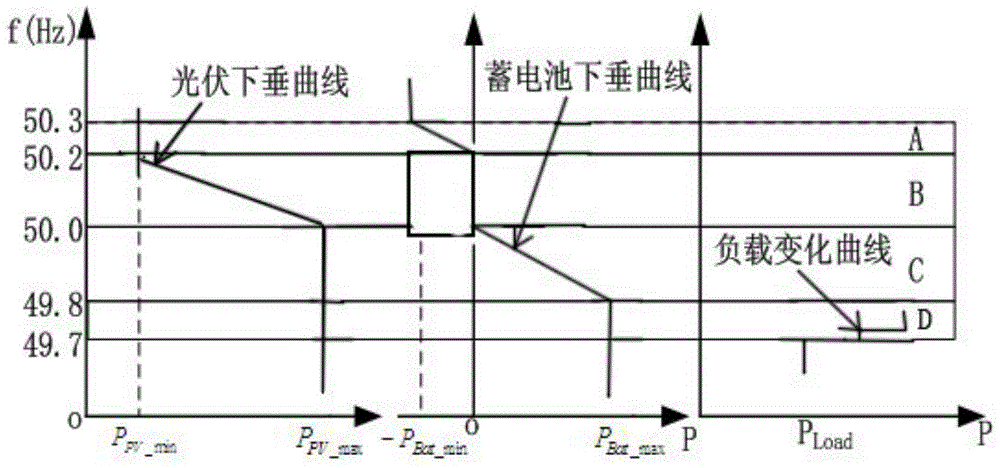

The invention relates to the technical field of photovoltaic micro-grid control, and particularly discloses a real-time coordination and control method of a photovoltaic micro-grid system. A central real-time optimal control layer and a local control layer are involved in the real-time coordination and control method. The central real-time optimal control layer collects the voltage and frequency of an AC bus of the photovoltaic micro-grid system, the charge state of a storage battery pack, the output power of photovoltaic power generation micro-sources, the output power of the storage battery pack, the output power of a super capacitor and the real-time power of a load in real time, generates a real-time coordination and control strategy and a secondary frequency modulation and scheduling plan, and issues the strategy and the plan to all local controllers. The local control layer coordinates and controls all the micro-sources in real time, and particularly achieves the scheduling plan issued by the central real-time optimal control layer. According to the real-time coordination and control method, a micro-grid central optimizing controller can manage, coordinate and control all the local controllers in a unified mode, the micro-grid can efficiently and economically run, the output power of the photovoltaic power generation unit is utilized to the maximum extent, the output power fluctuation and the tracking load change of the photovoltaic power generation unit are restrained, the running method of the micro-grid is reasonably adjusted, and energy balance is achieved.

Owner:EAST GRP CO LTD

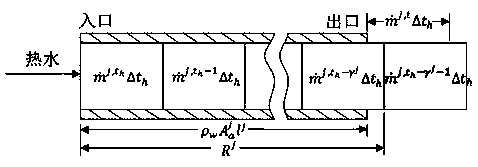

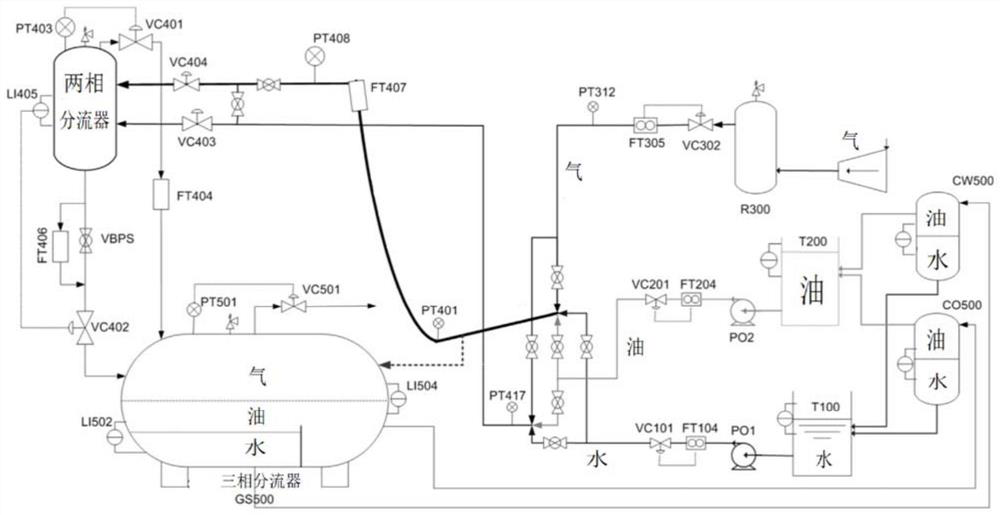

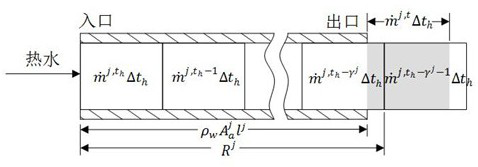

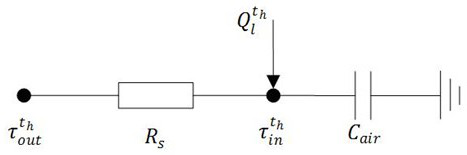

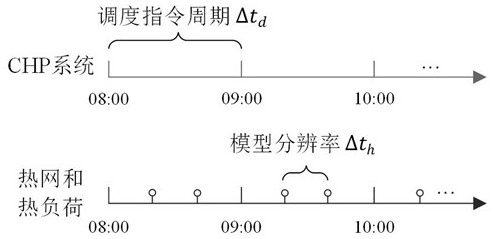

A method for optimizing the operation of an electro-thermal coupling integrate energy system

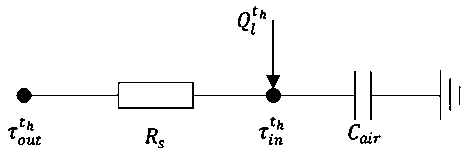

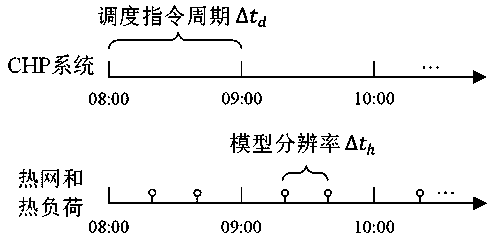

ActiveCN109190785ARun accuratelyGuaranteed comfortForecastingIntegrated energy systemImage resolution

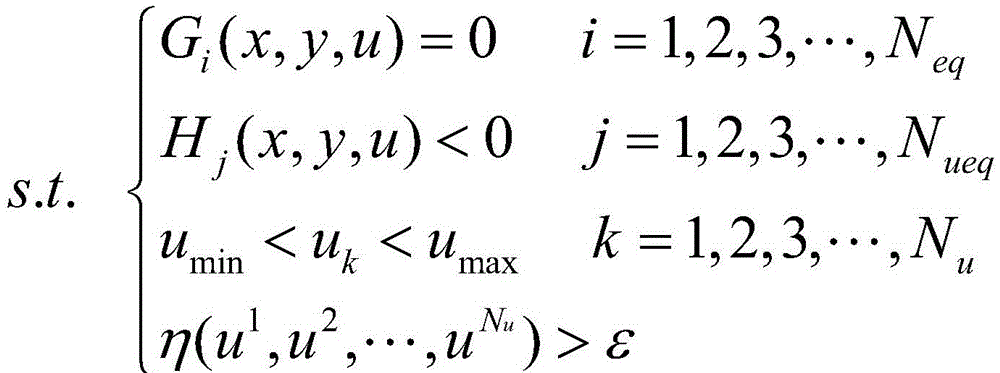

A method for optimizing the operation of an electro-thermal coupling integrate energy system is disclosed. An objective function and constraint conditions of the operation optimization of the electro-thermal coupled integrated energy system are established, so as to establish the operation optimization model of the electro-thermal coupling comprehensive energy system, then the simulation model ofheat network and heat load state is established, taking the temperature of heat medium injected into the heating network in the operation optimization result as the input to calculate the actual stateof the heating network and heat load, at last, the operation optimization flow of the electrothermal couple integrated energy system is established, the results of simulation model are compared withthose of optimization model, and error values are judged. As the error exceeds the allowable range, the resolution of the heating network and the heat load model is reduced and the above steps are repeated, otherwise, the method stops, thereby determining the appropriate resolution of the heat network and the heat load model. The method can fully consider the slow dynamic process of the change ofthe heat network and the heat load state in the dispatching instruction cycle, and effectively ensures the user comfort while realizing the efficient and economical operation of the system.

Owner:SOUTHEAST UNIV

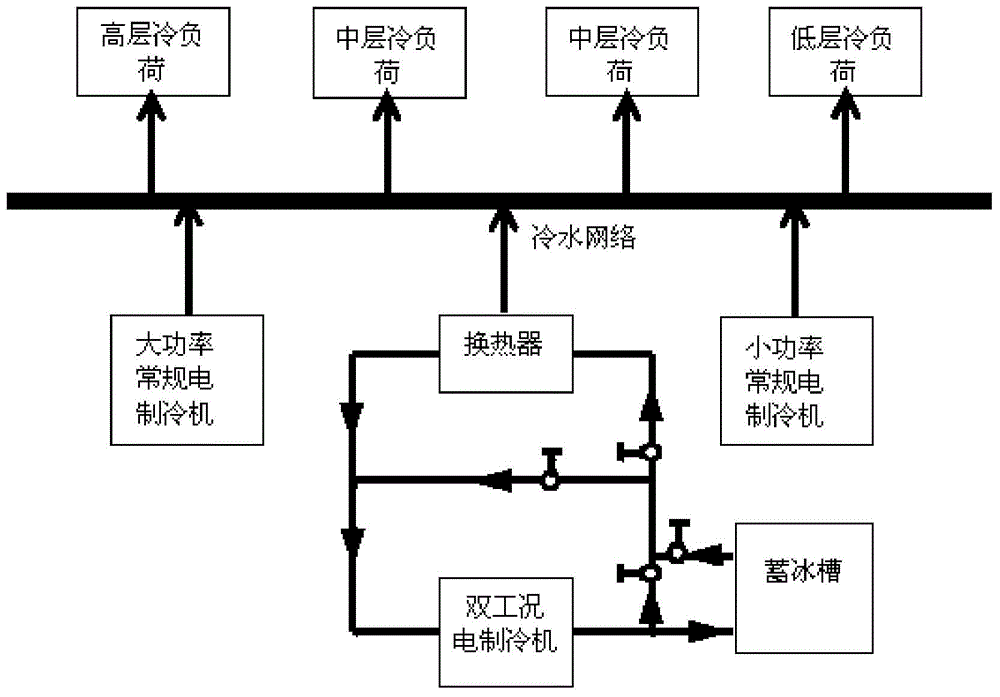

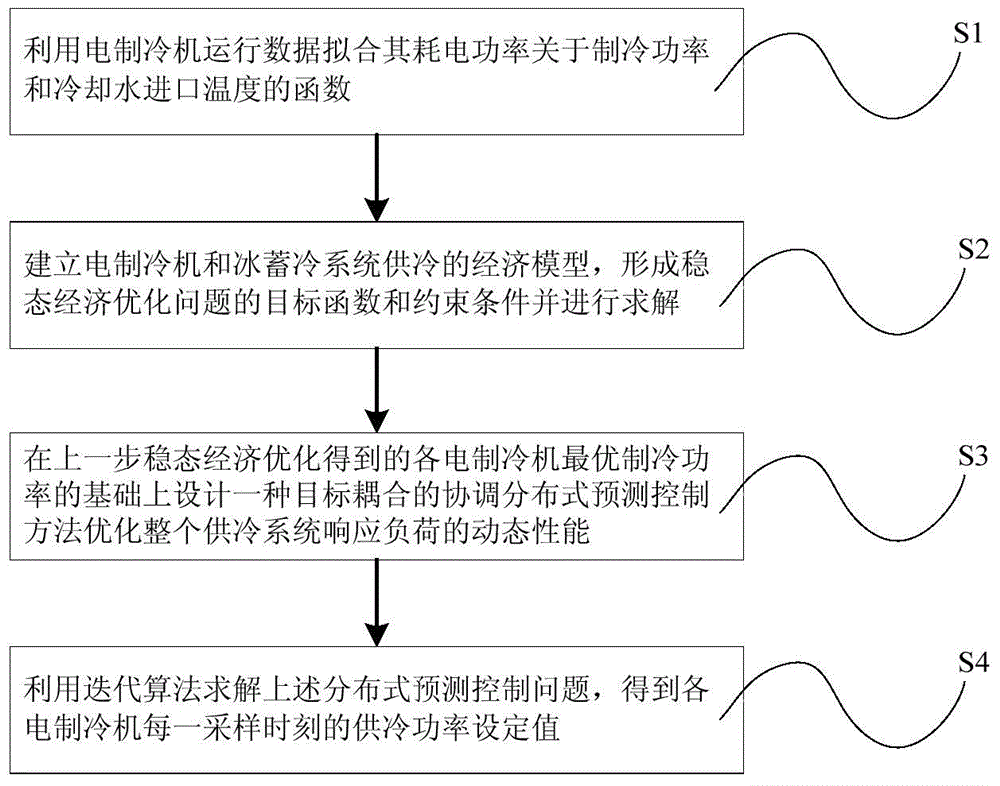

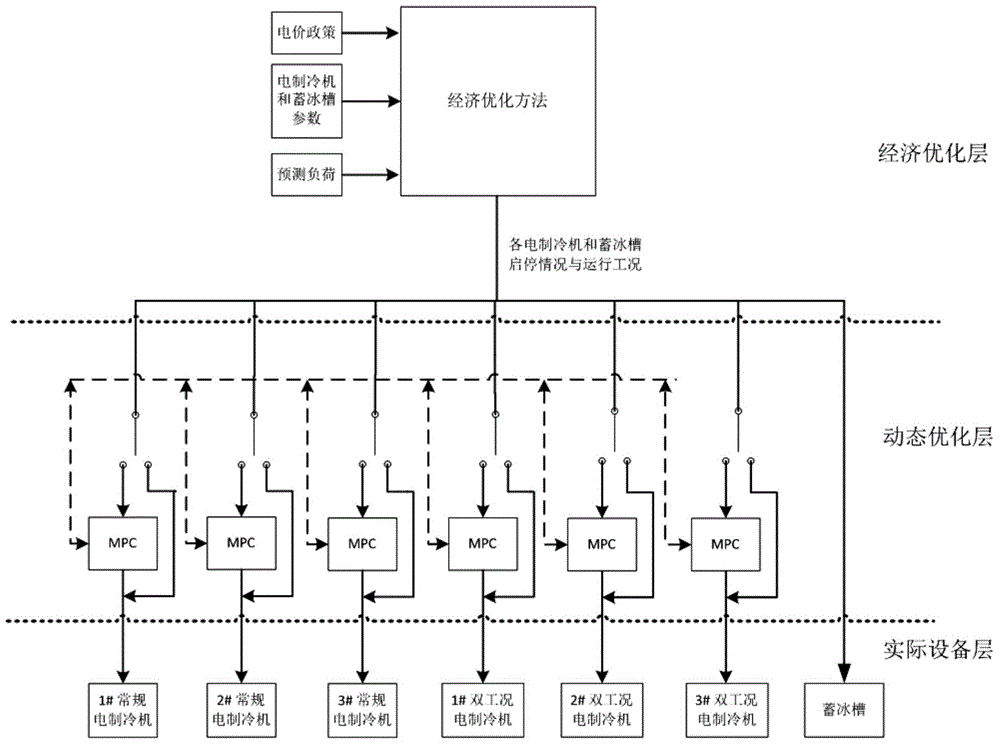

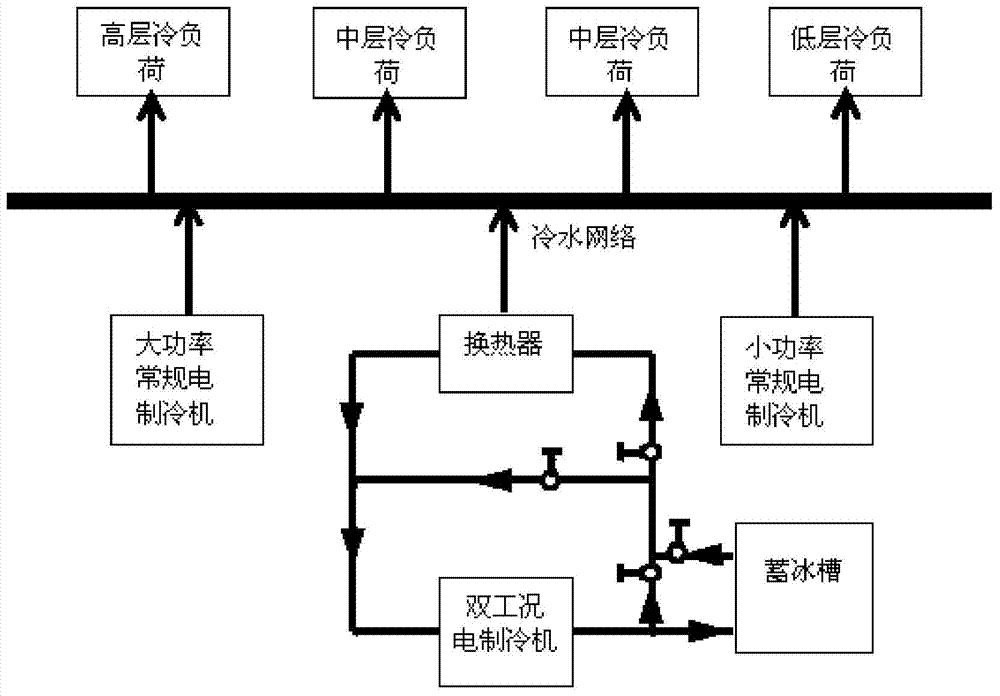

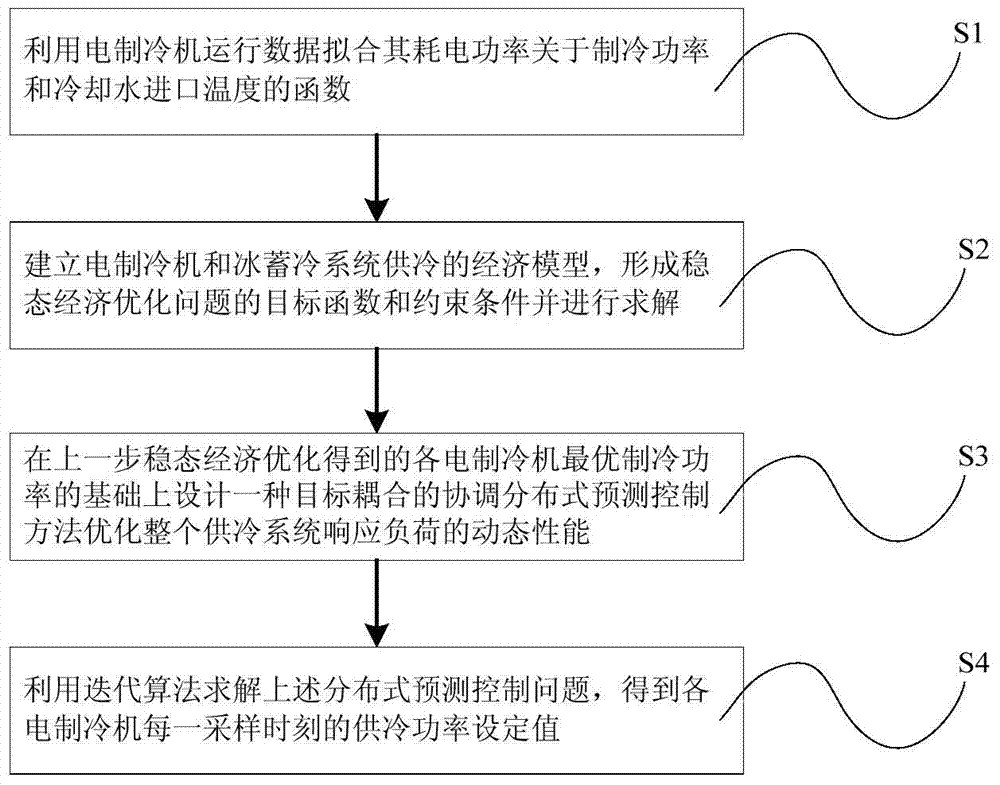

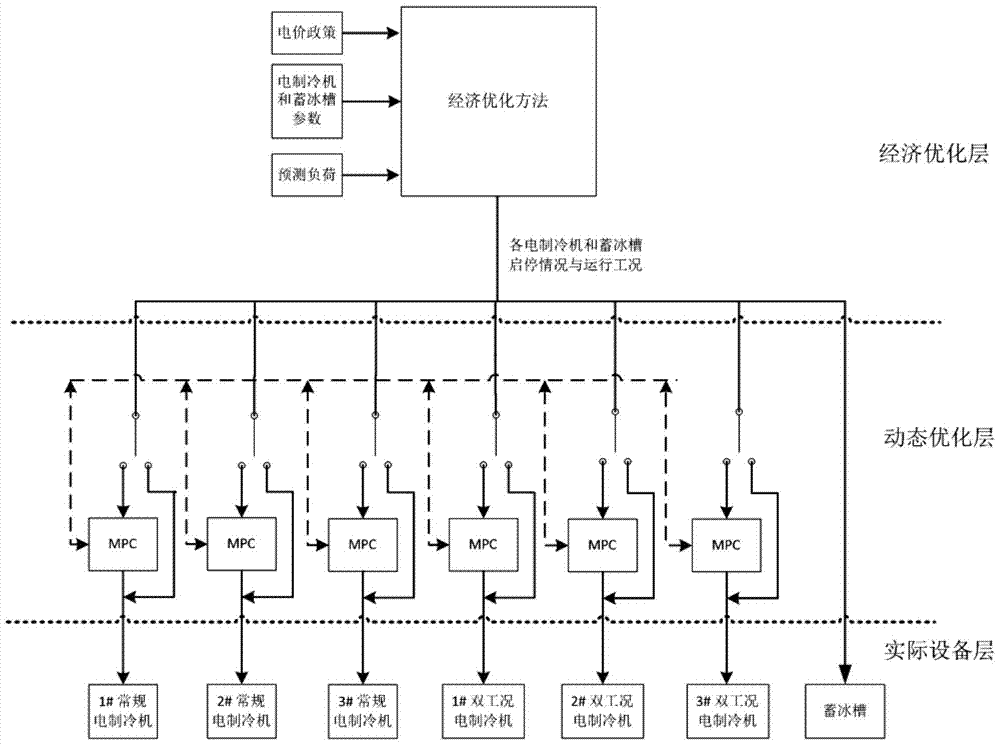

Hierarchical optimization method for united cold supply system

The invention provides a hierarchical optimization method for a united cold supply system consisting of a conventional electric refrigerator and an ice storage system. The method comprises the steps of optimizing the on-state and the optimal power setting value of each cold source by adopting a mixed integer programming method according to the economic model of each cold source and the time-of-use power price policy, designing a target-coupled coordinated distributed prediction control method to better improve the dynamic performance of the system in view of the dynamic adjusting characteristic and physical constraint of each cold source, and newly optimizing the setting value of each cold source under a distributed framework, so that each cold source ensures the total load in the dynamic process and tracks the optimal refrigerating power setting value as much as possible at the same time. The method quantitatively solves the steady and dynamic scheduling problem of the united cold supply system by adopting mixed integer programming and distributed prediction control methods respectively, and provides a rational suggestion for energy management and optimization scheduling of the cold supply system.

Owner:SHANGHAI JIAO TONG UNIV

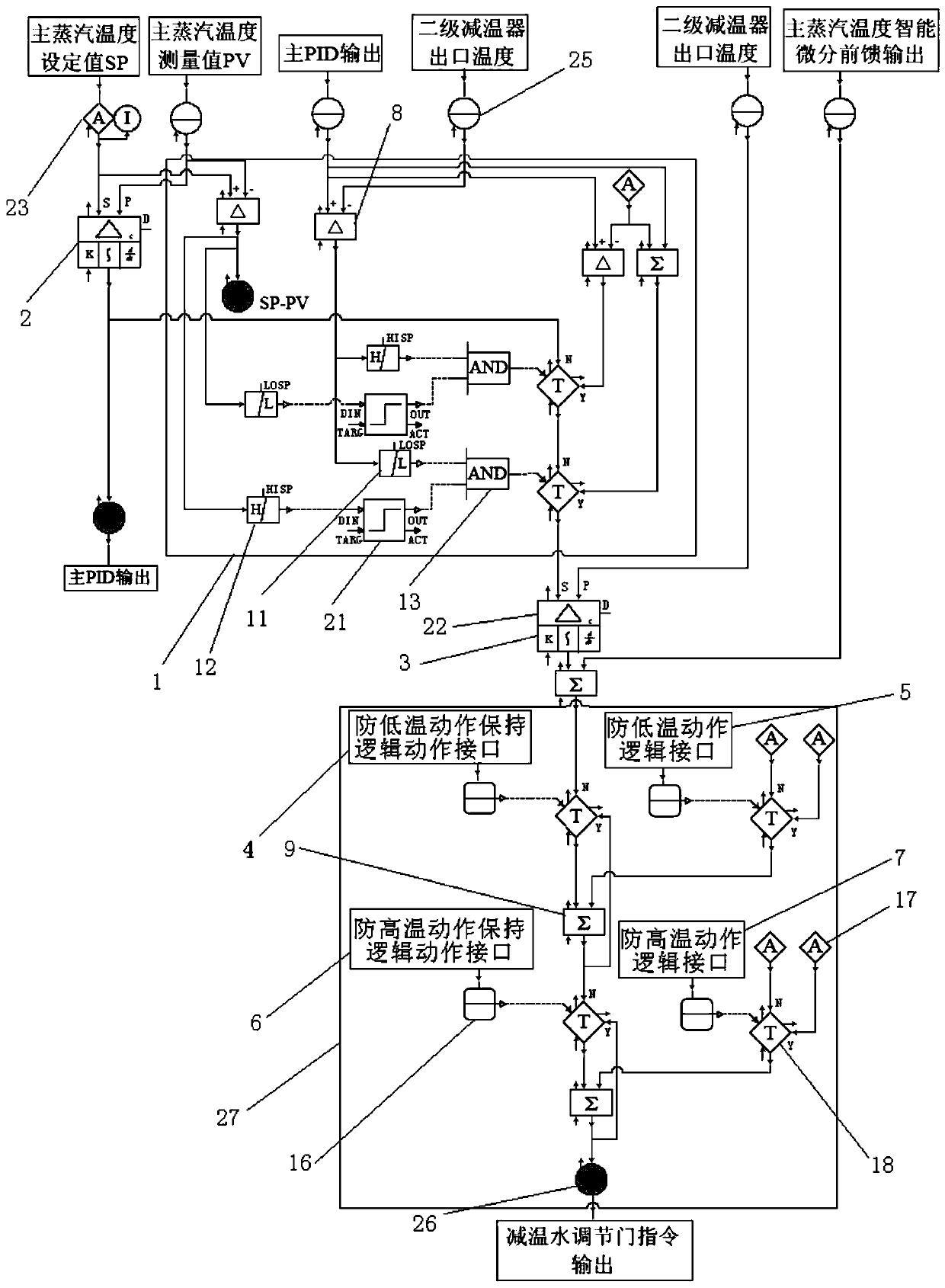

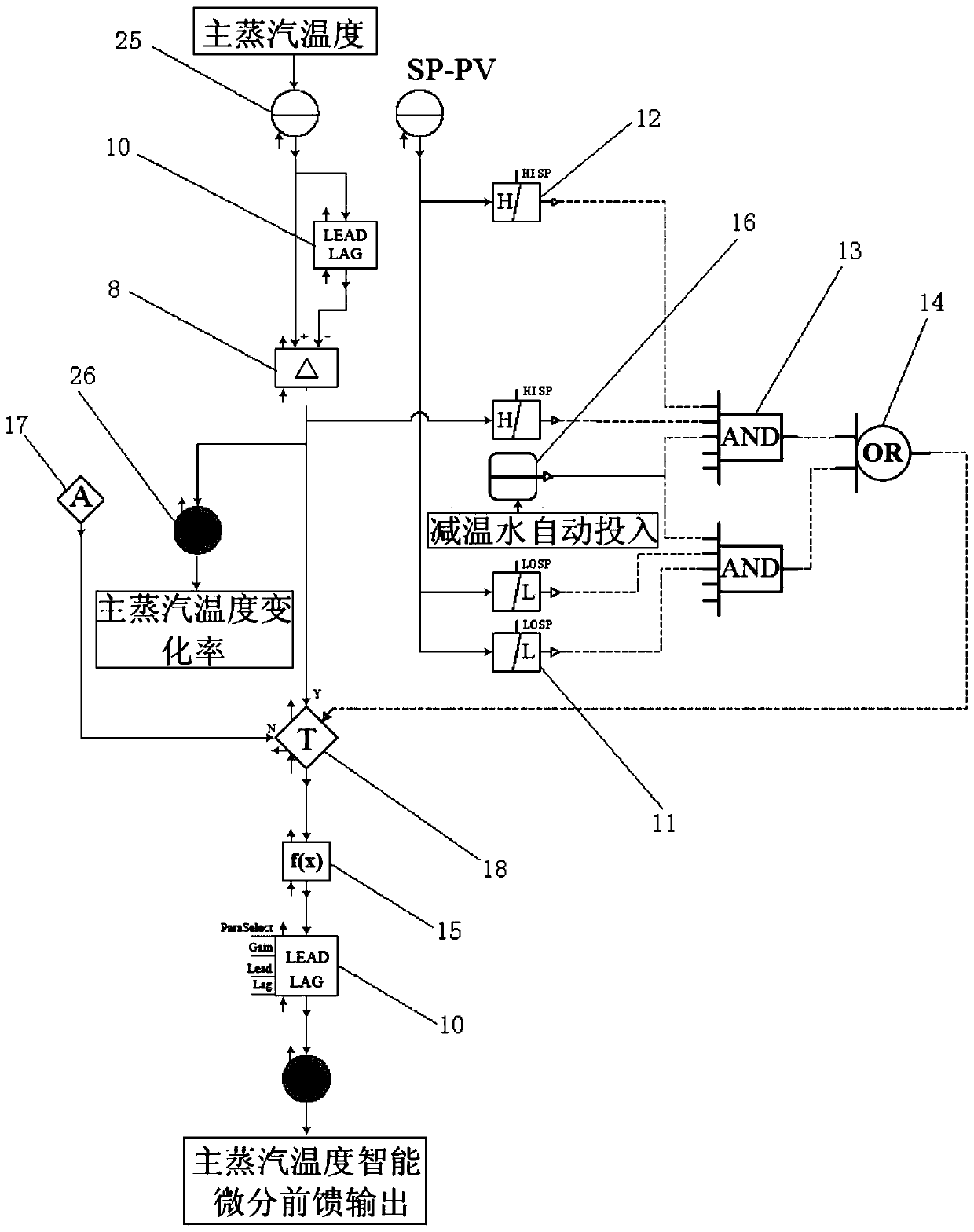

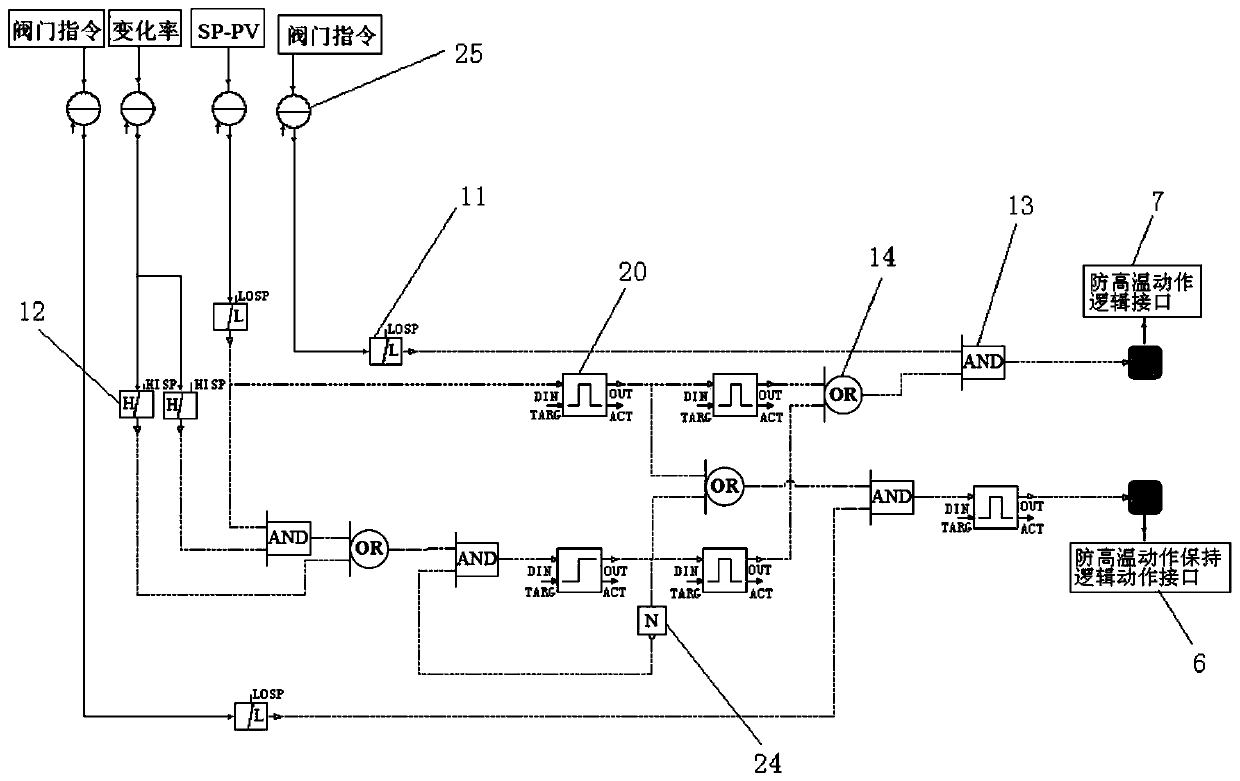

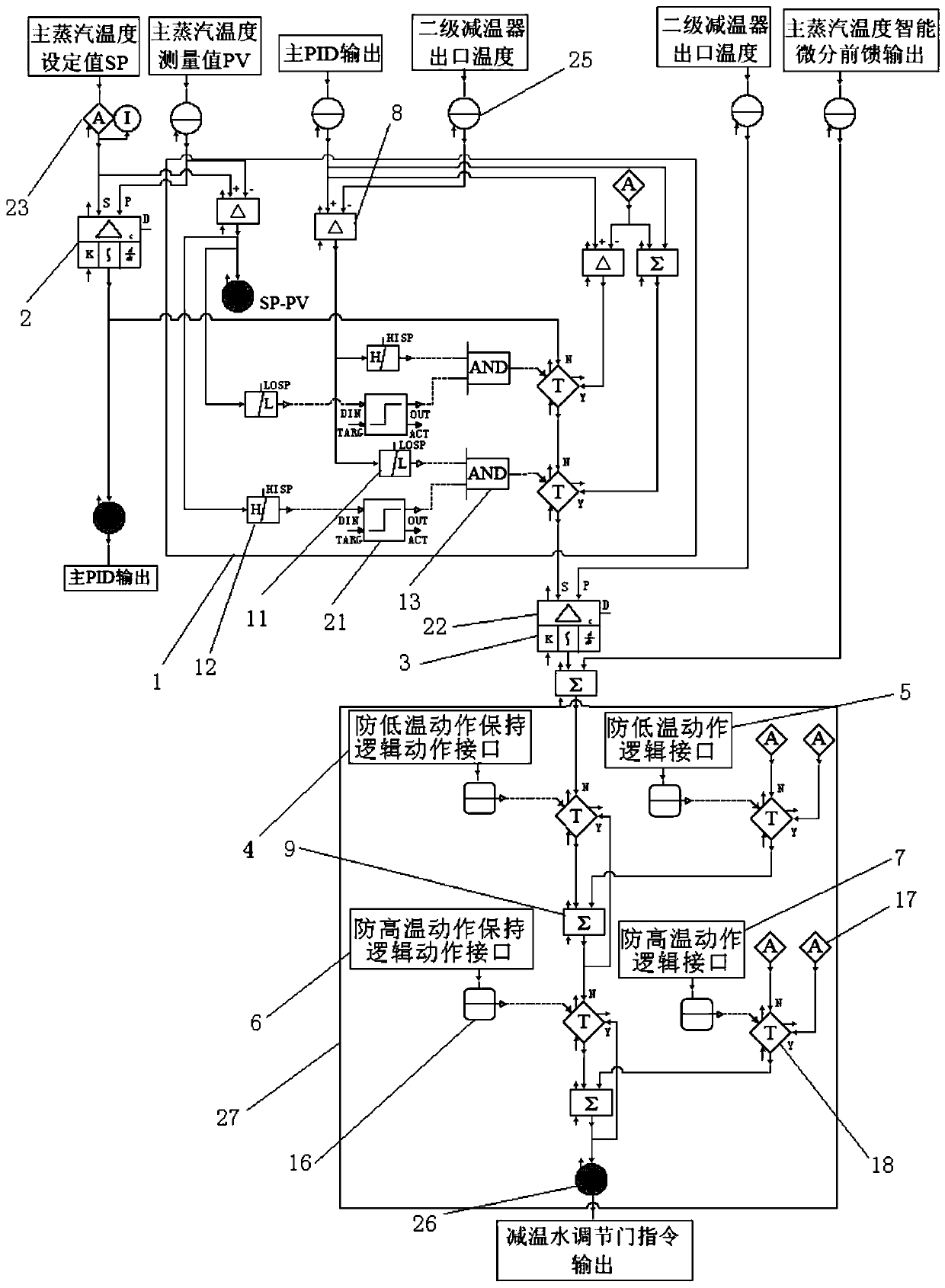

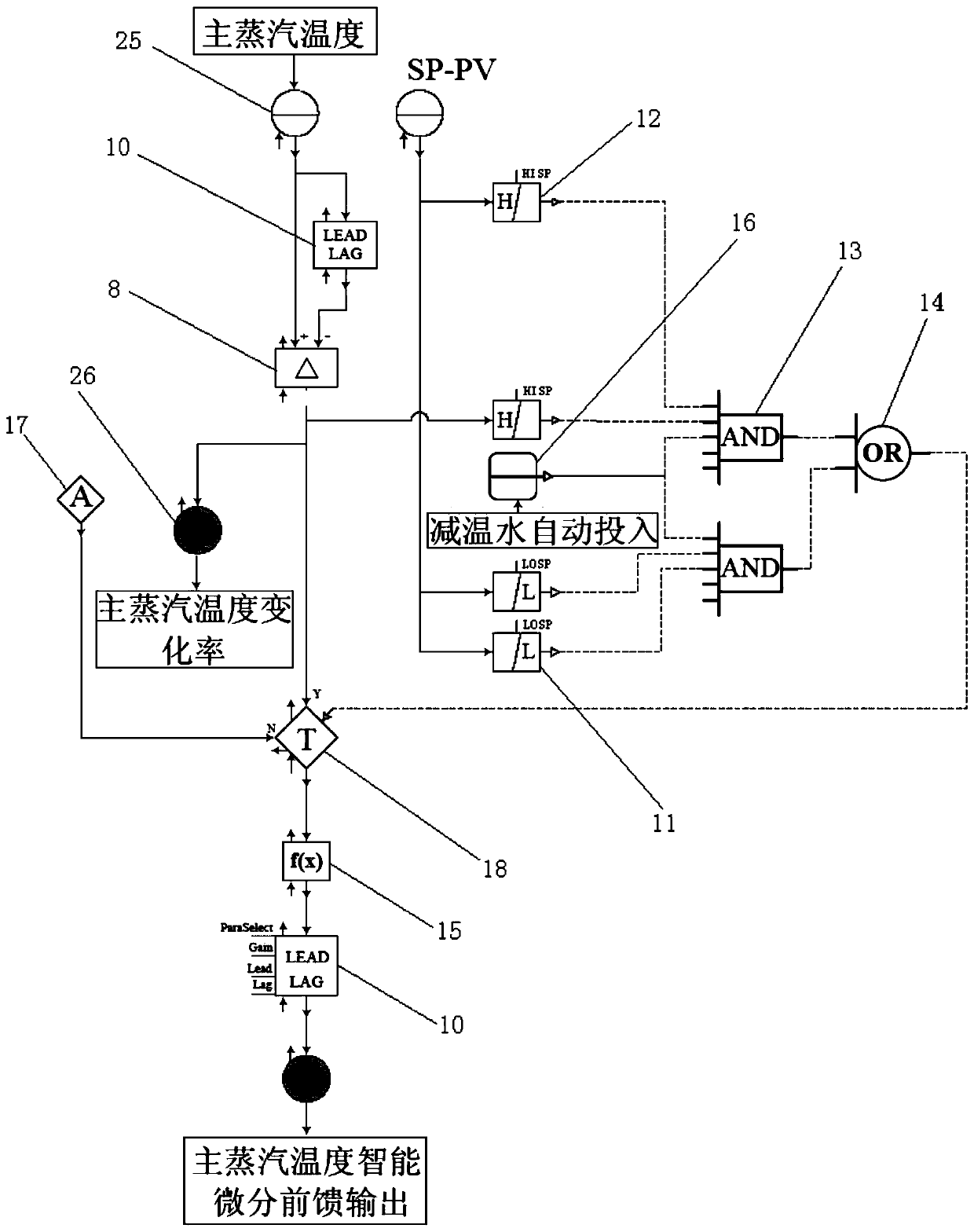

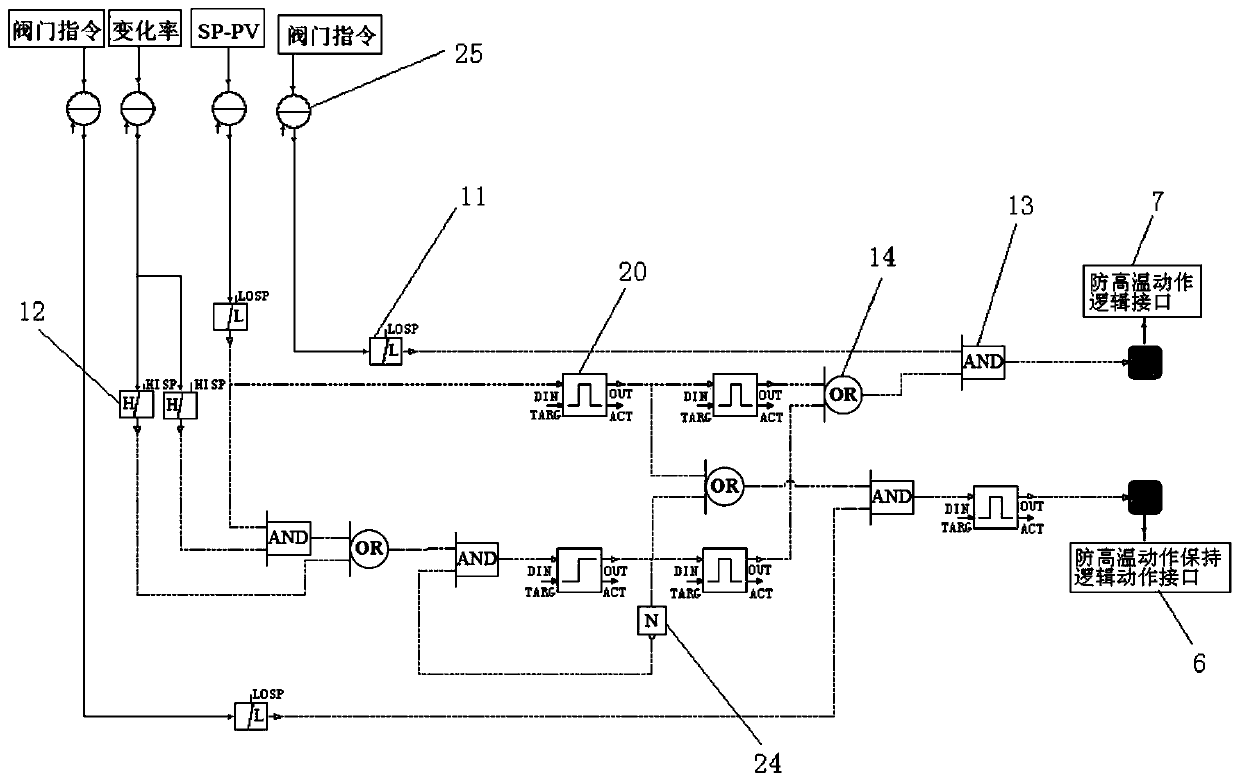

Boiler main steam temperature control method with frequent fluctuation of AGC load instruction of power grid

ActiveCN110360540AImprove adjustment qualityImprove efficiencySuperheating controlBoiler controlLoad instructionPower grid

The invention discloses a boiler main steam temperature control method with frequent fluctuation of an AGC load instruction of a power grid, and belongs to the technical field of boiler main steam temperature control. According to the method, the variation trend of the main steam temperature of a boiler and the difference between the measured value of the main steam temperature of the boiler and the set value of the main steam temperature are comprehensively judged and controlled in advance through a main steam temperature super-differential feedforward control loop; and the desuperheating water jet control logic circuit for preventing the main steam temperature from overshooting is used for working conditions of frequent fluctuation of the AGC load instruction of the power grid, and the main steam temperature is controlled within a set range. According to the method, the main steam temperature regulation quality can be greatly improved, the fluctuation range of the main steam temperature of the boiler is reduced, and the unit efficiency is improved; after using this control scheme, the main steam temperature fluctuation range is reduced by 3-5 DEG C than before; and with the continuous development and maturity of the main steam temperature control technology, the foundation can be laid for improving the safe, stable and efficient economic operation of the unit and achieving the long-term goal of energy-saving optimization.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

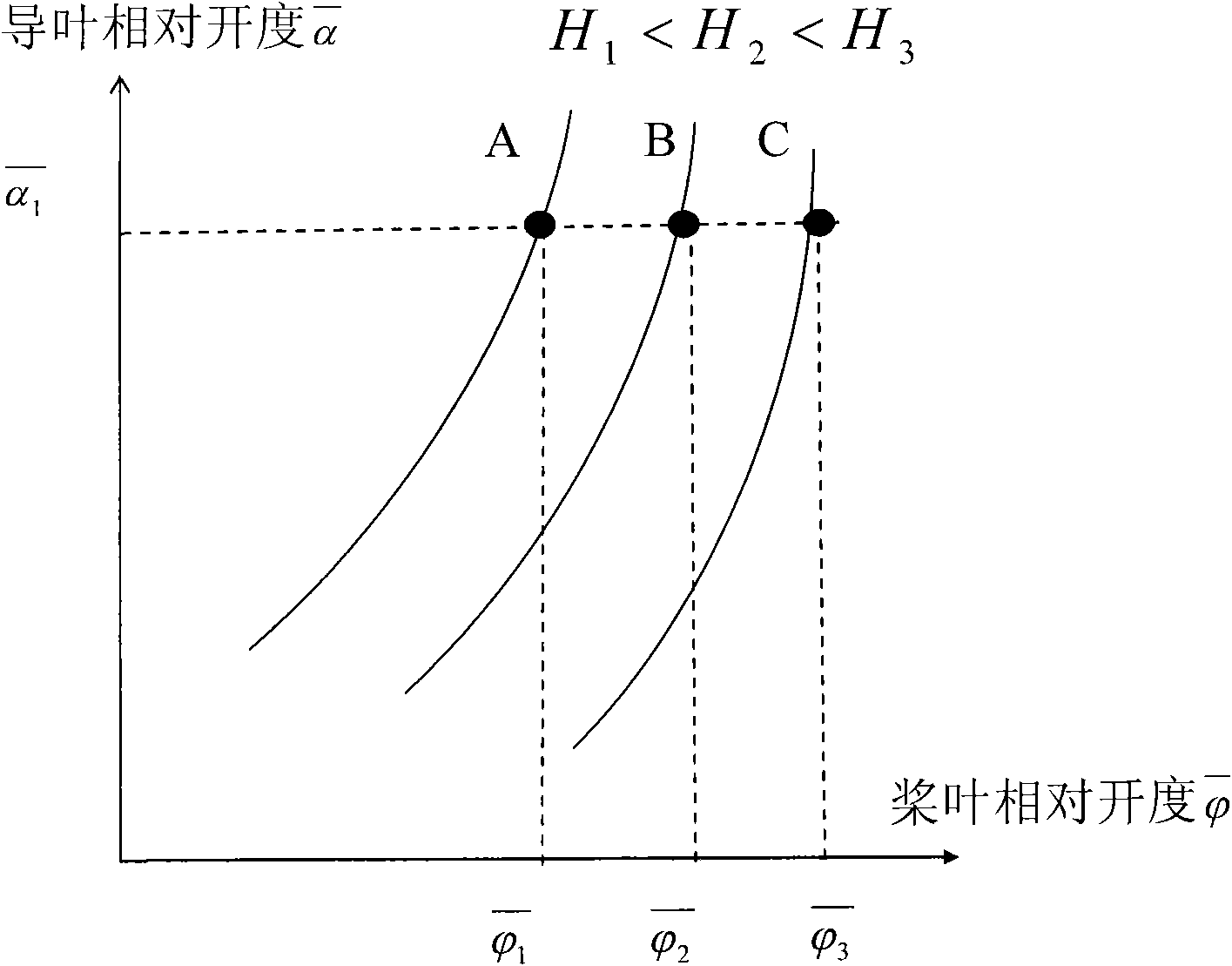

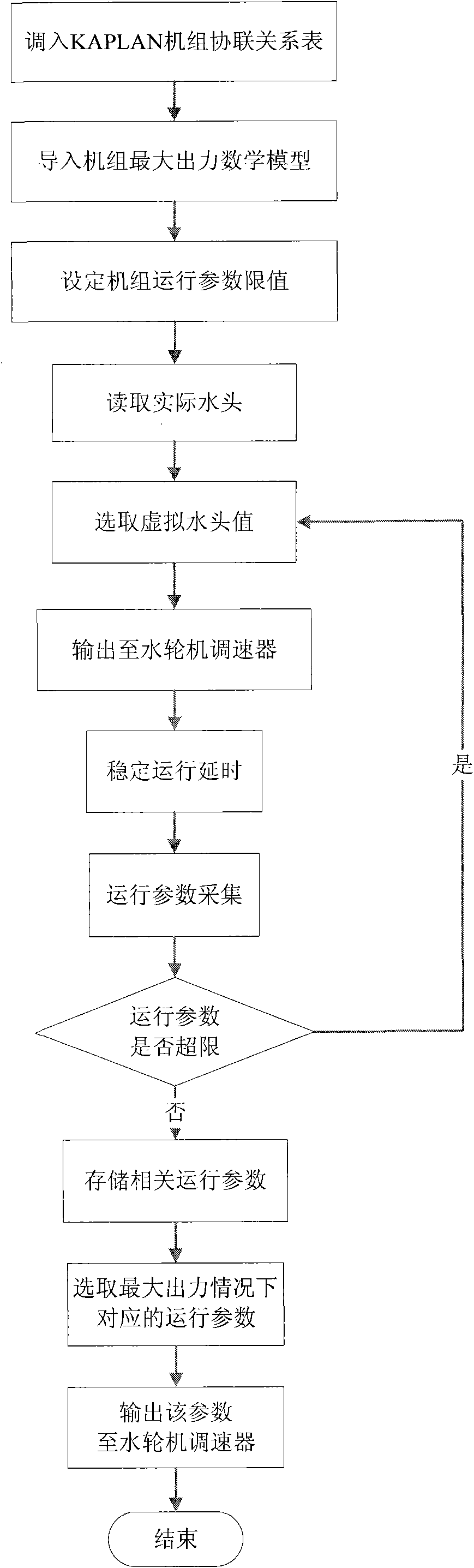

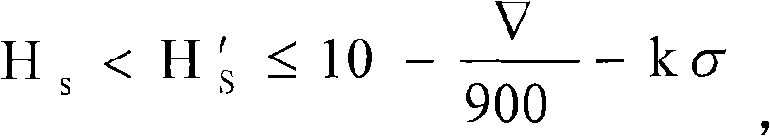

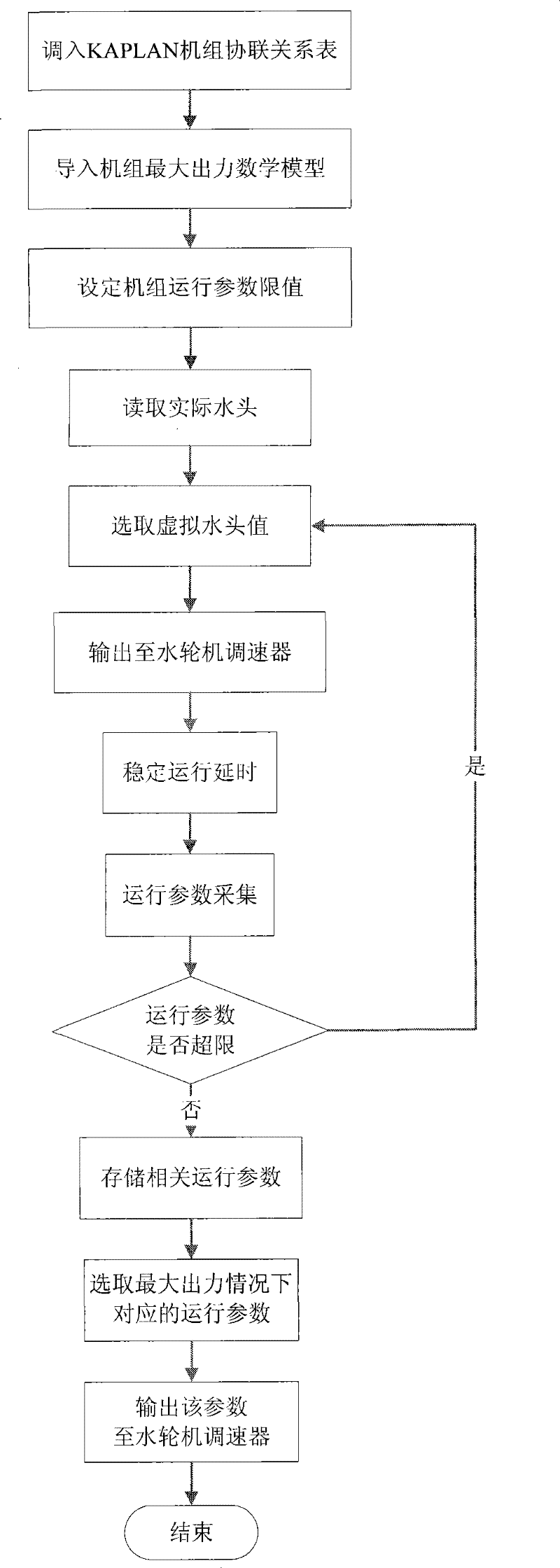

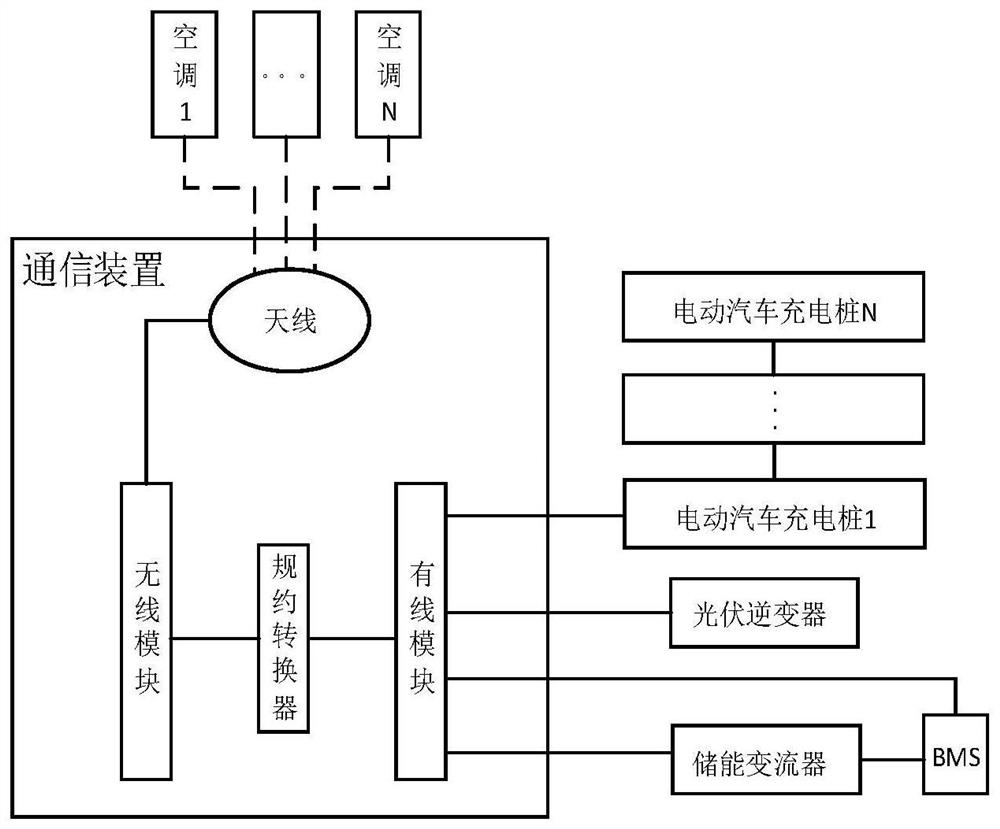

On-line adjustment method for KAPLAN unit

ActiveCN101655063AEfficient and economical operationTo achieve the purpose of regulating flowHydro energy generationMachines/enginesComputer control systemPower station

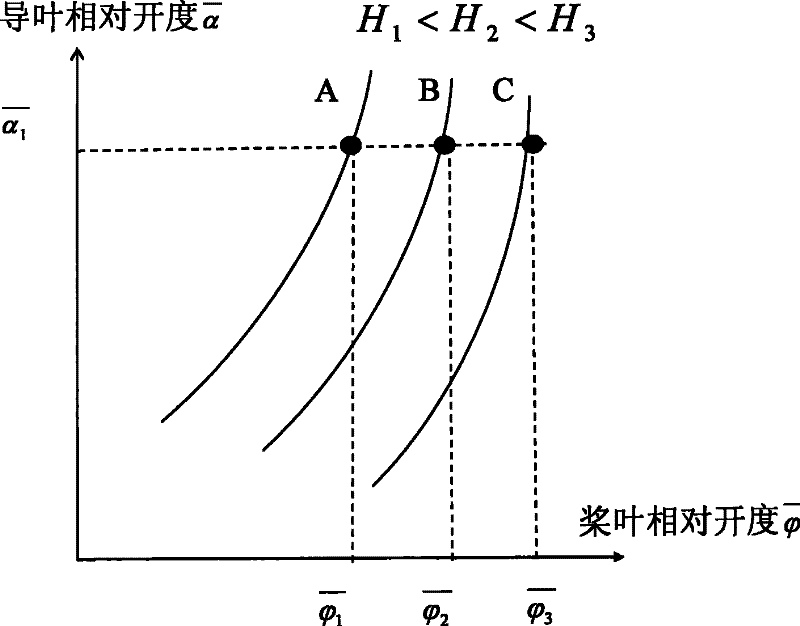

The invention provides an on-line adjustment method for a KAPLAN unit, which has the advantages that: on the basis of not changing the prior KAPLAN computer control system, an actual water head signalwhich is input into the control system is intercepted and shielded based on the prior combination relationship, while a virtual water head signal is input into the control system to form a novel combination relationship between the relative opening degrees of guide blades and blades, and outflow conditions are adjusted to achieve the aim of adjusting the flow. Therefore, the on-line adjustment method can realize the real-time adjustment of a unit system of a hydropower station by means of the prior computer control system, and also can realize various adjustment targets in real time accordingto operation conditions of the hydropower station such as water head, the flow, and the distribution of the flow among units to realize the high-efficiency and economical operation of the hydropowerstation.

Owner:广州市恩莱吉能源科技有限公司

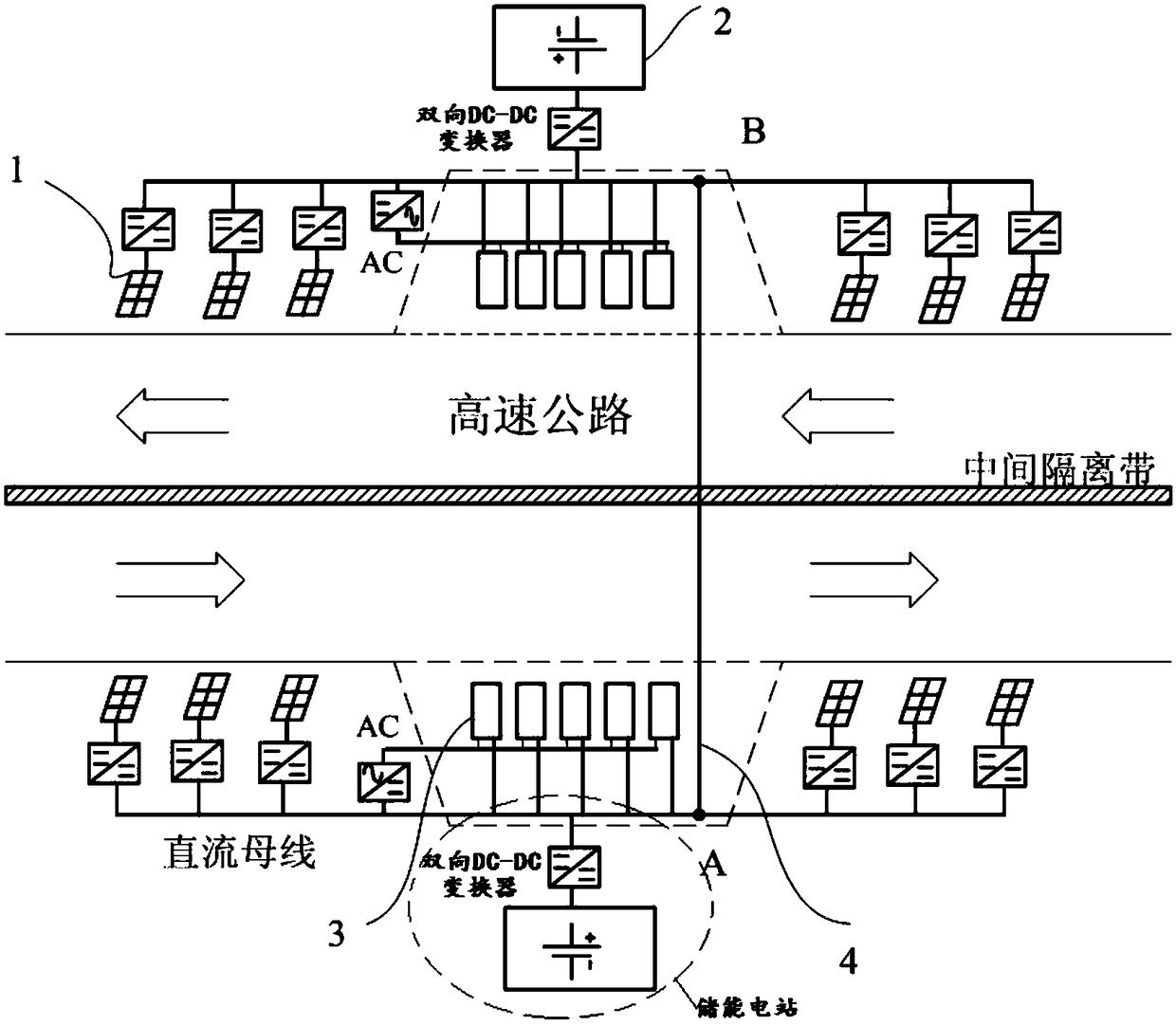

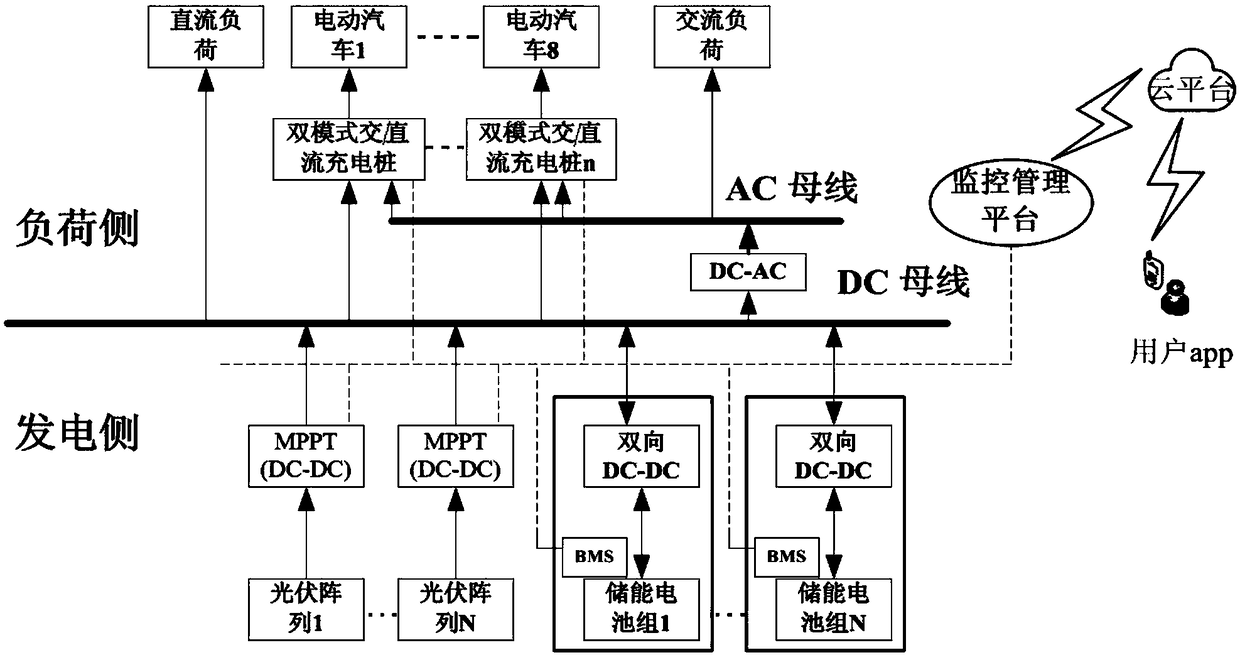

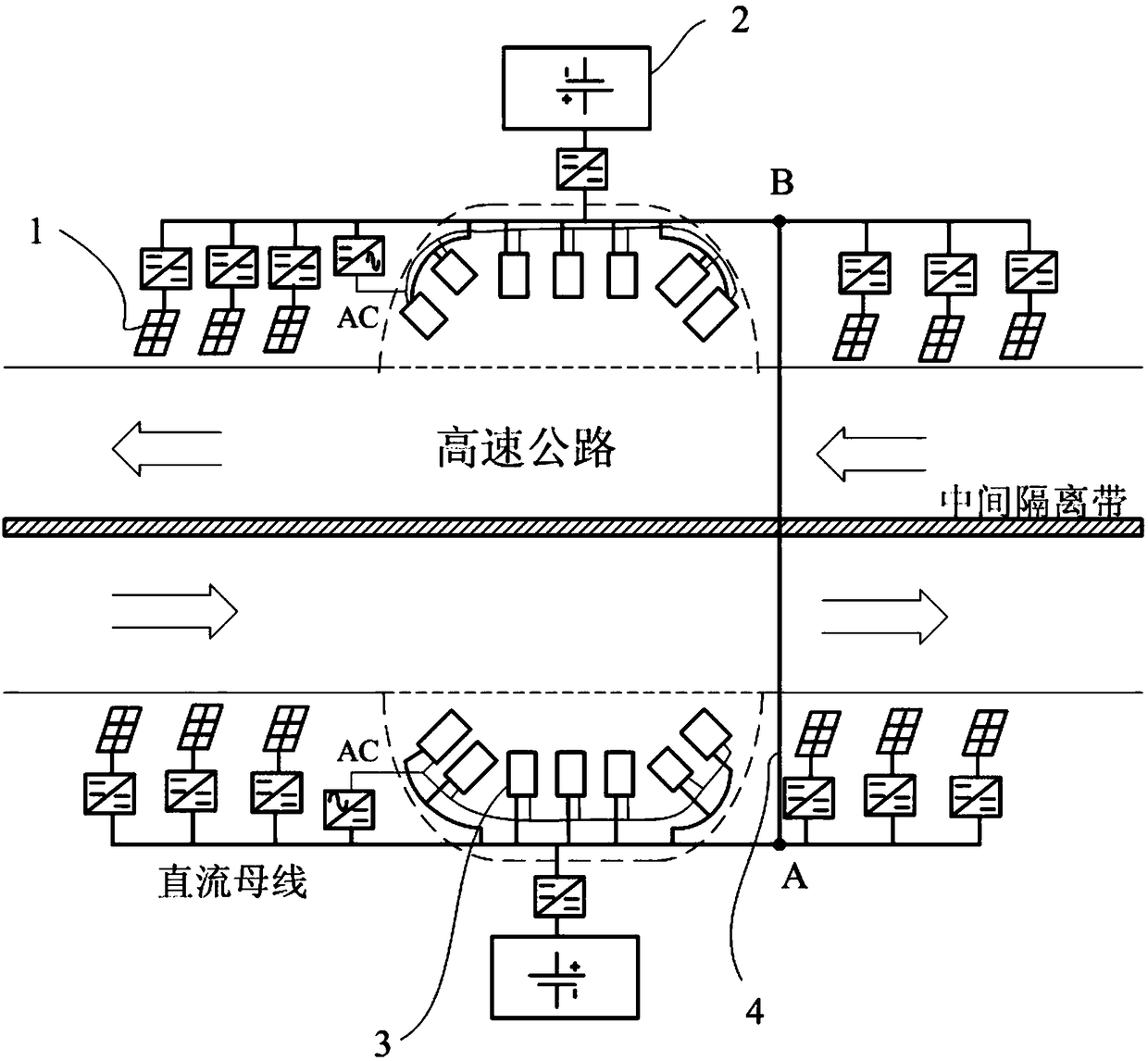

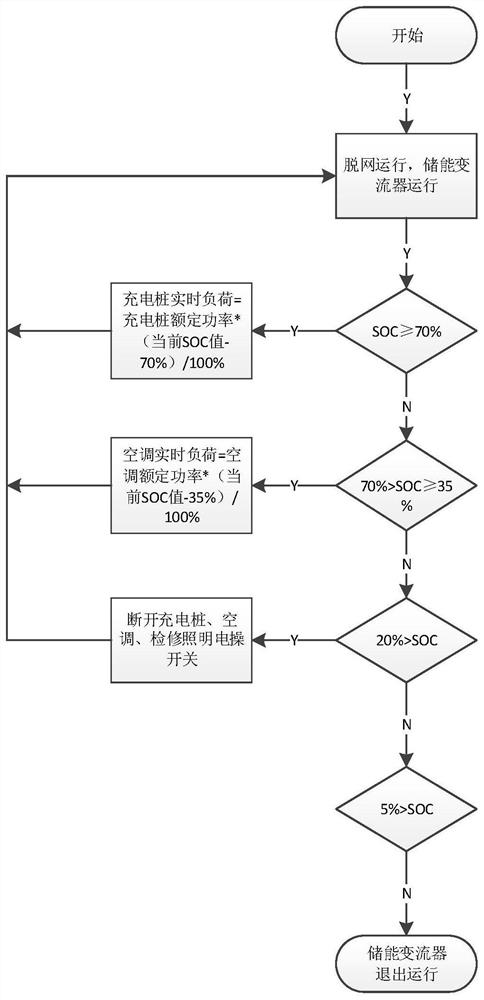

Expressway distributed photovoltaic-storage-charging AC-DC hybrid microgrid self-service charging stations

PendingCN108394298AAvoid dependenceGuaranteed uptimeCharging stationsMobile unit charging stationsMicrogridDual mode

The invention discloses expressway distributed photovoltaic-storage-charging AC-DC hybrid microgrid self-service charging stations which are arranged on two sides of an expressway respectively. Each station mainly includes a power generating side and a load side; the power generating side includes renewable energy generation systems, energy storage stations and a direct-current bus, the output ends of the renewable energy generation systems are connected to the direct-current bus via DC-DC converters having a maximum power tracking function, and the energy storage stations are connected with the direct-current bus via bidirectional DC-DC converters; the load side includes dual-mode AC-DC charging piles and an alternating current bus, the direct-current bus is connected with the alternatingbus via DC-AC converters; the direct-current buses of the stations on opposing side of the expressway are connected via an energy mutual supply line. A photovoltaic-storage-charging distributed AC-DChybrid microgrid is established herein; relay charging is provided for new energy vehicles running on inter-city roads or on expressways for long range; the application problems that new energy vehicles have low storage battery energy density, dependence on grid construction, 'short driving range' and the like are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

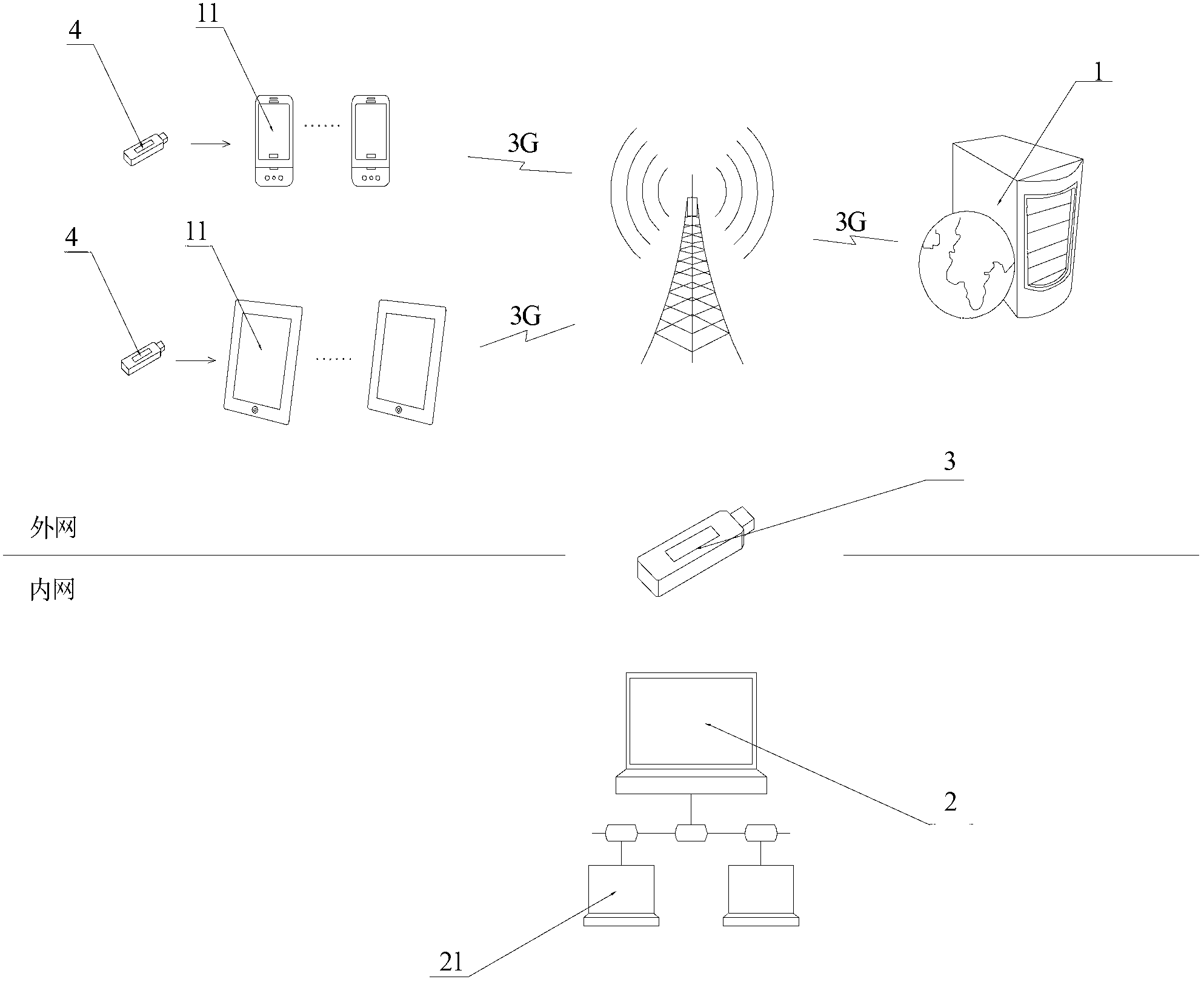

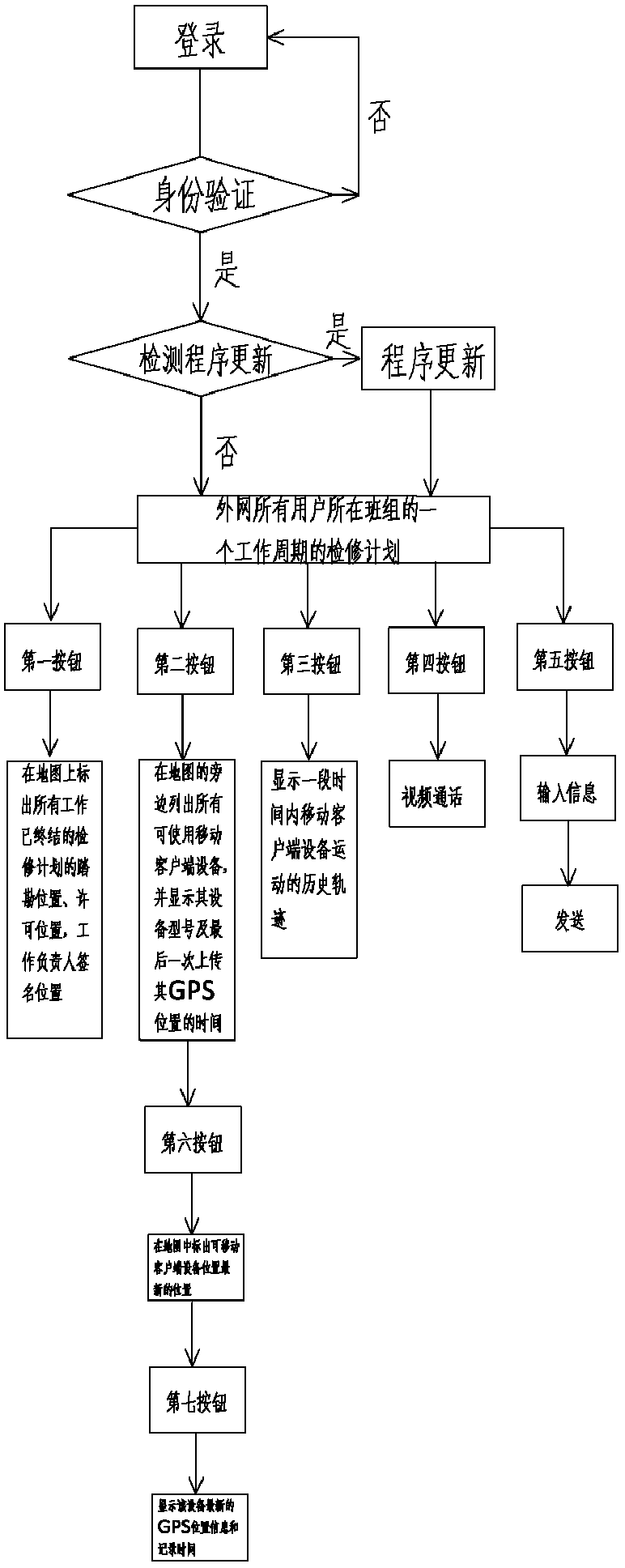

Electric power work management and control method combining motion trail

InactiveCN103226792AEasy maintenanceImprove emergency repair managementData processing applicationsDigital data authenticationDaily operationWork cycle

The invention relates to an electric power work management and control method combining a motion trail. The method comprises the steps as follows: providing a page layout displaying an overhaul plan in a working period of a work group comprising all external network users, marking all completed exploration and permission of the overhaul plan and a work responsible person's signature position on a map; and listing all usable mobile client equipment, types and the time of lastly uploading a GPS position by the map, and further displaying the history trail of the mobile client equipment moving in a period of time. The method carries out comprehensive monitoring and management of electric power overhaul by combining GPS data and the motion trail, provides multifunctional and visual process of the implement, monitoring and maintenance of the electric power overhaul work, improves management level of operation, maintenance, overhaul and urgent maintenance of electric power enterprises, normalize work procedures including daily operation and maintenance, overhaul and fault urgent maintenance, improves fault urgent maintenance efficiency, enhances filed operation dispatch, improves the modern electric grid control ability of the electric power enterprises, and ensures reliable, efficient and economical operation of the power grid.

Owner:STATE GRID ZHEJIANG HANGZHOU CITY FUYANG DISTRICT POWER SUPPLY CO LTD +2

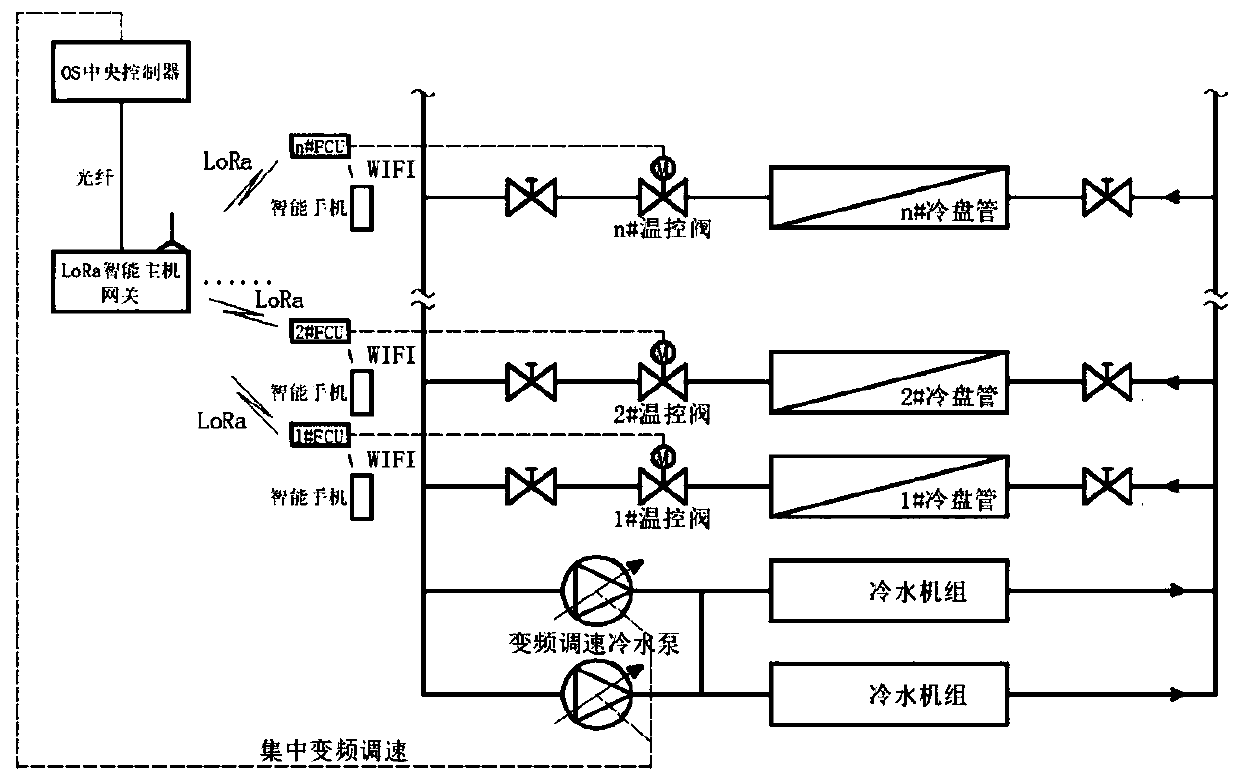

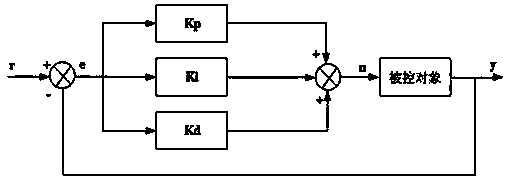

Cold water system control method and device of distributed central air conditioner

ActiveCN110195927AGuaranteed uptimeIncrease speedMechanical apparatusSpace heating and ventilation safety systemsQuality of serviceTemperature control

The invention discloses a cold water system control method and device of a distributed central air conditioner. The control method is based on basic judgment to the essence of things, all tail end branch FCU controllers in the system are formed by intelligent DDC digital controllers or intelligent temperature controllers, distributed control is implemented to tail end FCUs independently, and intelligent PID controllers are arranged in the tail end FCU controllers; the feedback closed-loop automatic control technology is adopted so as to reduce uncertainty; and the actual value of the controlled temperature variable is measured and is compared with a user set value, the deviation of the actual value and the user set value is calculated to correct system responses, and the aim of controllingthe flow q of cold water flowing through a cold coiled pipe is achieved by adjusting and controlling the opening degree of a temperature control adjusting valve. On the premise of meeting the user air conditioner service quality, economic operation management is achieved, energy-saving operation benefits are acquired, meanwhile, the control system is simpler and clearer, operation is rapid and reliable, and the remarkable enegy-saving effect and the actual application meaning are achieved.

Owner:上海润风智能科技有限公司

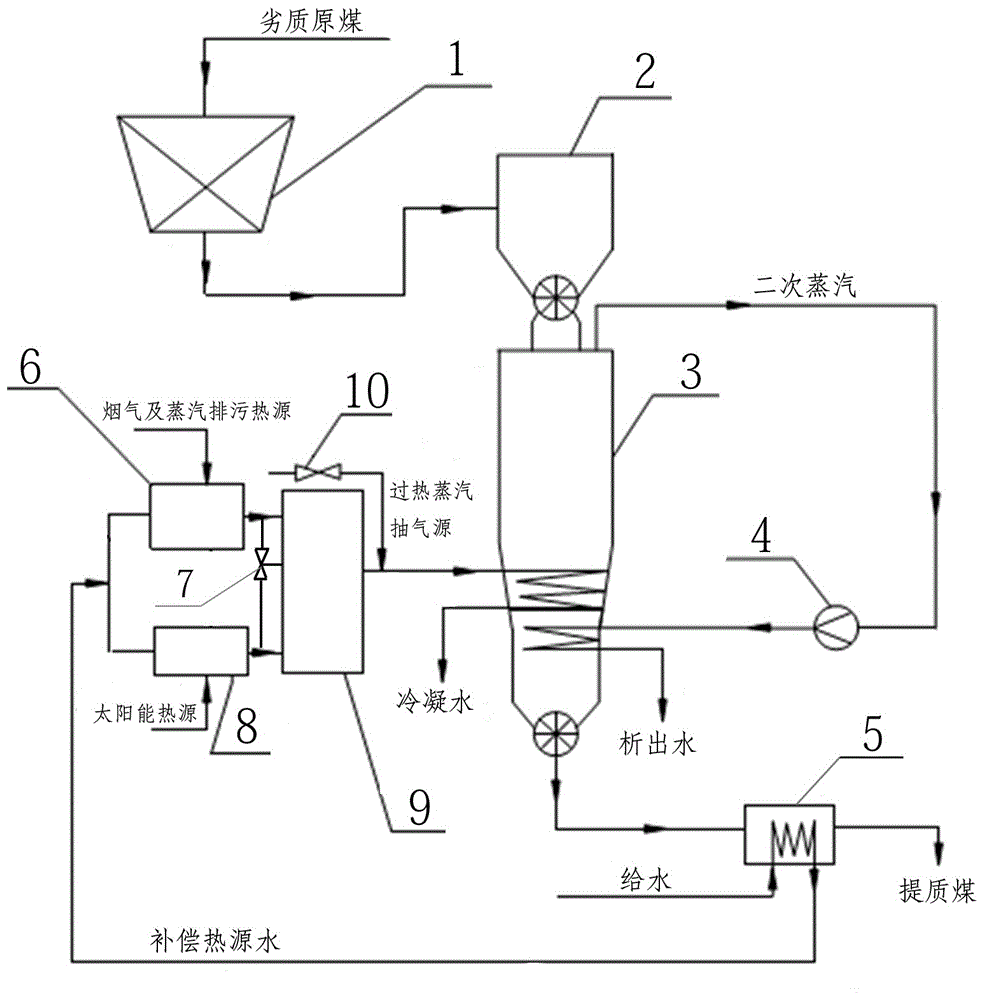

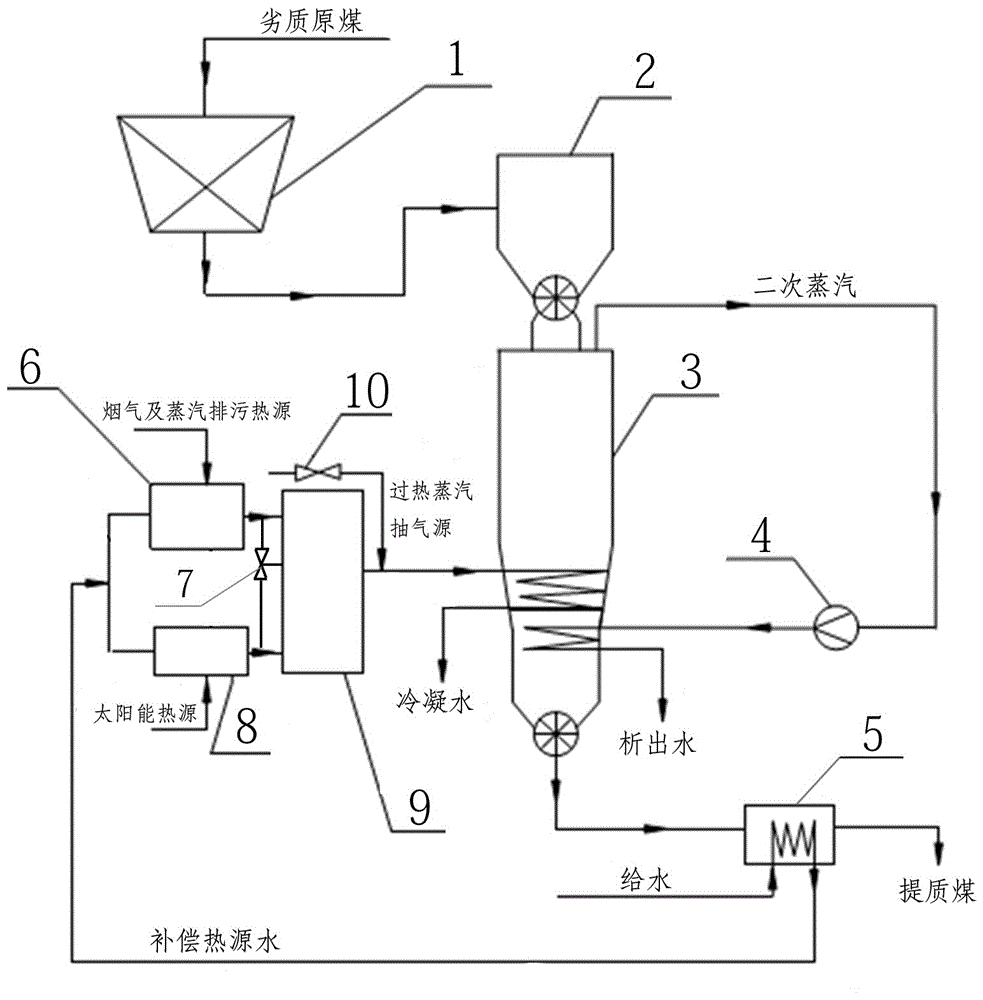

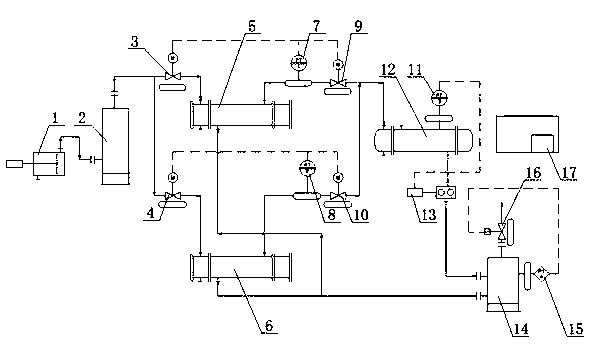

Thermal compensation type superheated steam coal drying system

InactiveCN105716380AReduce energy consumptionReduce superheated steam consumptionDrying solid materials with heatGranular material dryingSuperheaterCoal

The invention discloses a thermal compensation type superheated steam coal drying system. Fault raw coal is broken and screened through a coal breaker, then passes through a coal bunker and then enters a superheated steam fluidized bed, the heat and mass transfer process is carried out inside, then the fault raw coal flows out of the bottom of the superheated steam fluidized bed, and the fault raw coal becomes upgraded coal after passing through a coal cooler. Superheated steam of the superheated steam fluidized bed is from a superheated steam extraction source. Water in the fault raw coal is heated and evaporated in the superheated steam fluidized bed into secondary steam, then the secondary steam is output out of the top of the superheated steam fluidized bed, the secondary steam passes through a circulating fan and then is introduced into the superheated steam fluidized bed to be subjected to heat exchange with the raw coal again, and the secondary steam becomes precipitated water after being condensed. Cooling feedwater introduced into the coal cooler serves as compensation heat source water to be introduced into a waste-heat heat exchanger and a solar heat exchanger through corresponding valves, wherein the waste-heat heat exchanger and the solar heat exchanger are connected in parallel. The waste-heat heat exchanger and the solar heat exchanger are both connected with an electric superheater through valves, and a superheated steam outlet of the electric superheater is connected with the superheated steam extraction source in parallel through a switching valve and then is connected into the superheated steam fluidized bed.

Owner:SHANXI UNIV

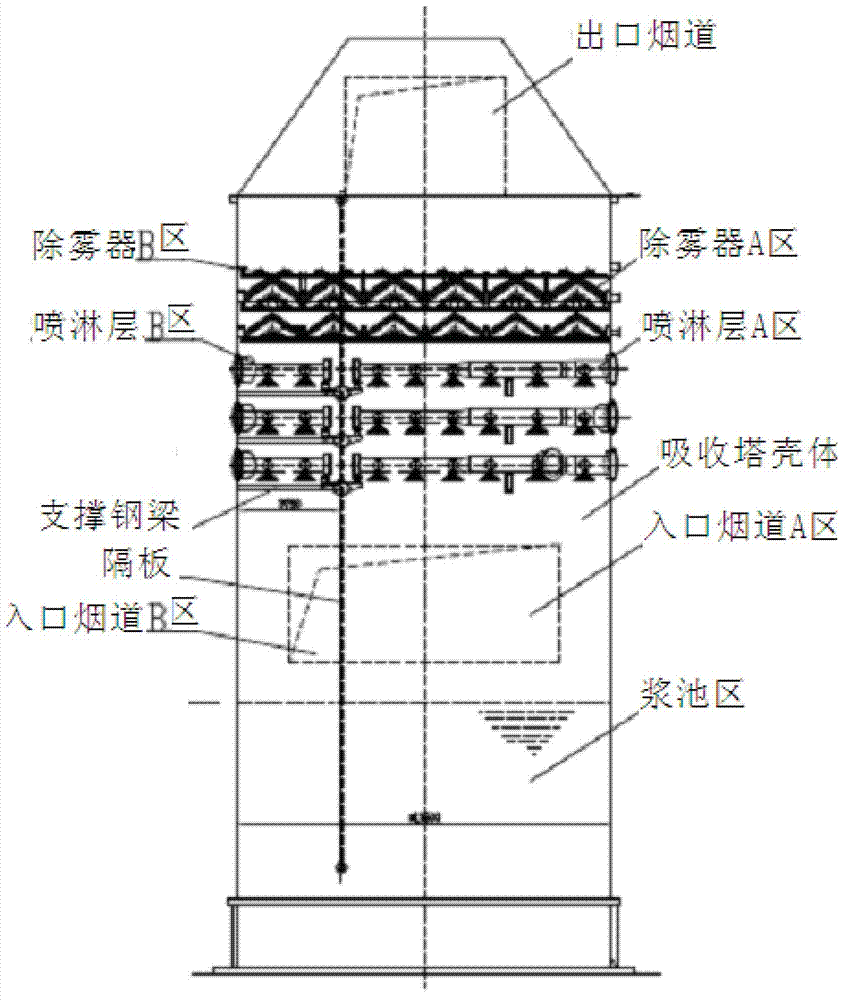

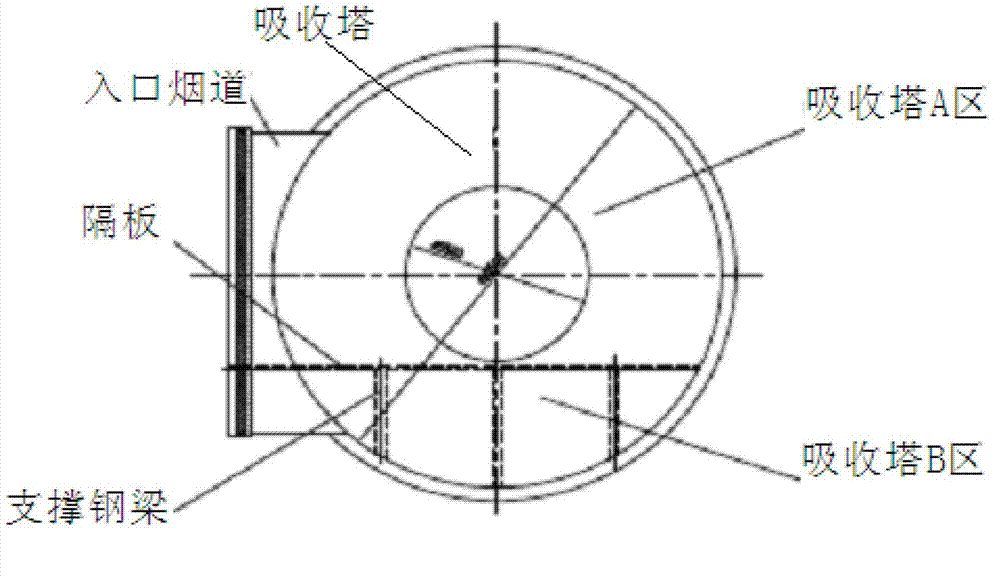

Absorption tower of multi-furnace one-tower desulfurizer

InactiveCN102728187AEfficient and economical operationReduce running power consumptionDispersed particle separationLow loadFlue gas

The invention relates to an absorption tower of a multi-furnace one-tower desulfurizer. The absorption tower comprises an absorption tower shell, and a slurry tank area, an inlet flue, a spraying layer and a demister which are arranged in the absorption tower shell from bottom to top, wherein at least one clapboard is arranged in the absorption tower shell and penetrates through the internal area of the absorption tower shell in which the inlet flue, the spraying layer and the demister are positioned to divide the absorption tower at the section into at least two independent sub-areas, and all independent sub-areas are provided with independent sub-inlet flues, sub-spraying layers and sub-demisters. Each area of the absorption tower can operate independently, so that when flue gas volume changes more violently, each area can be ensured to work in the best flue gas velocity range, and other areas can be shut down so as to ensure efficient economical operation under various working conditions. Therefore, the absorption tower can give consideration to full-load and low-load operation economical efficiency, thereby having obvious energy-saving benefit.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

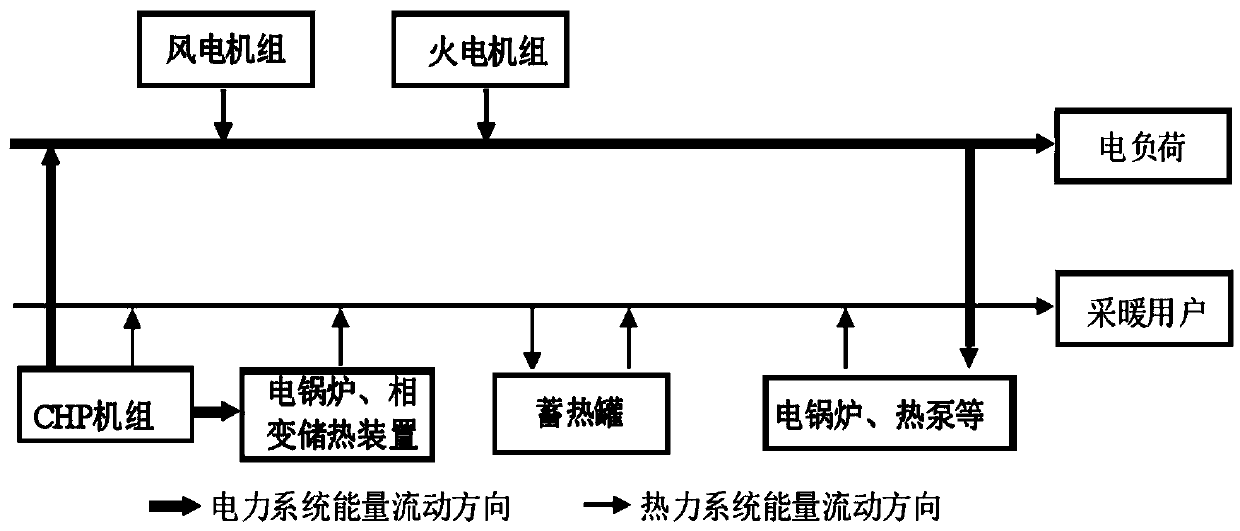

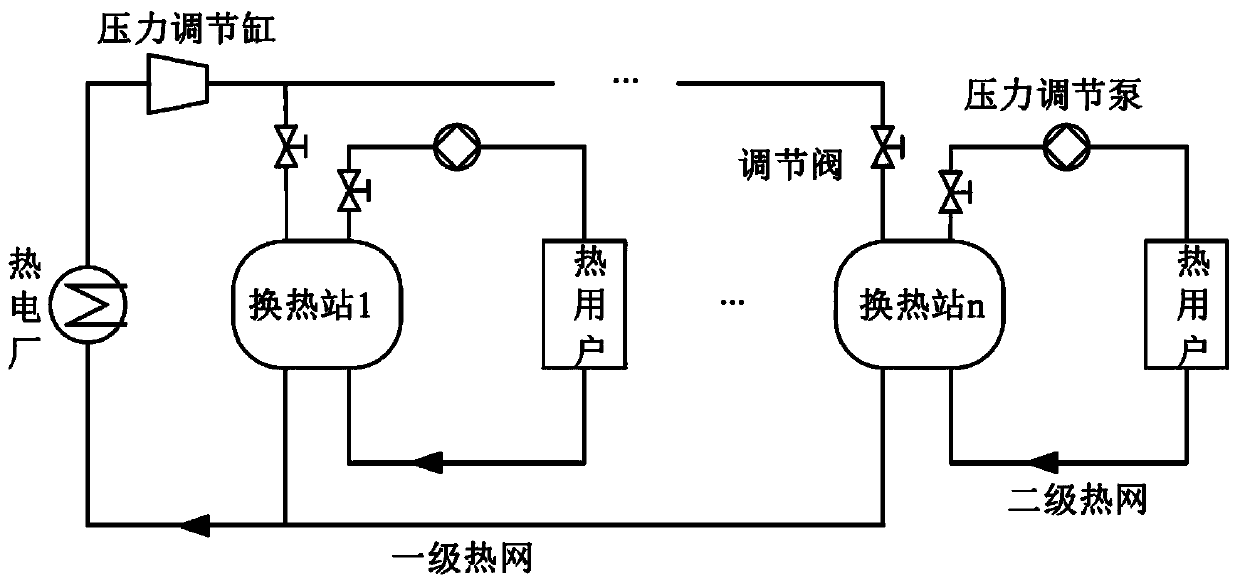

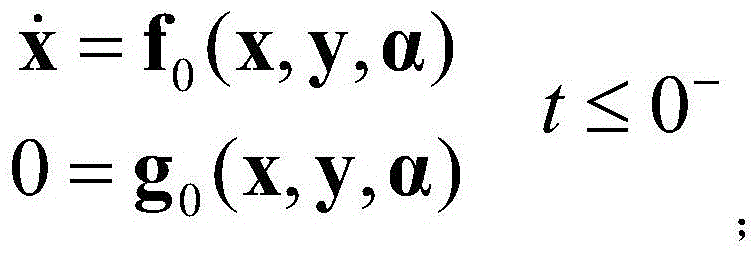

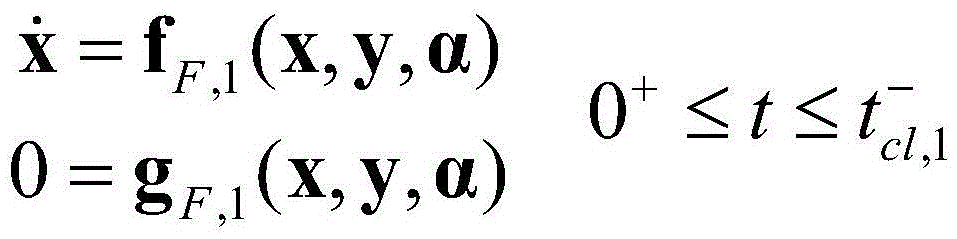

Electricity-heat comprehensive energy system coordinated operation method considering thermal inertia

ActiveCN111191353AEfficient and economical operationGuaranteed uptimeForecastingDesign optimisation/simulationThermodynamicsElectricity system

The invention belongs to the technical field of power system operation and control, and particularly relates to an electricity-heat comprehensive energy system coordinated operation method consideringthermal inertia. The invention aims to improve the operation capability of an electricity-heat comprehensive energy system. The problems that due to the thermal inertia characteristic of an electricity-heat comprehensive energy system, certain heat supply delay exists in the links of heat production, heat supply and the like, and a power grid is difficult to dispatch in the heat supply period aresolved. Thermal inertia analysis is carried out on three units including a CHP unit, an electric boiler and a heat supply pipe network in the electricity-heat comprehensive energy system; an electricity-heat comprehensive energy system optimization operation model considering thermal inertia is established; the normal operation time interval of the thermal load of the electric-thermal integratedenergy system under the thermal inertia is calculated; and finally, an optimal operation model of the electricity-heat comprehensive energy system is established, the coordinated optimal operation capacity of the electricity-heat comprehensive energy system is improved, the problem that scheduling is difficult under the influence of thermal inertia of the electricity-heat comprehensive energy system is solved, and very high actual scheduling operation application value is achieved.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

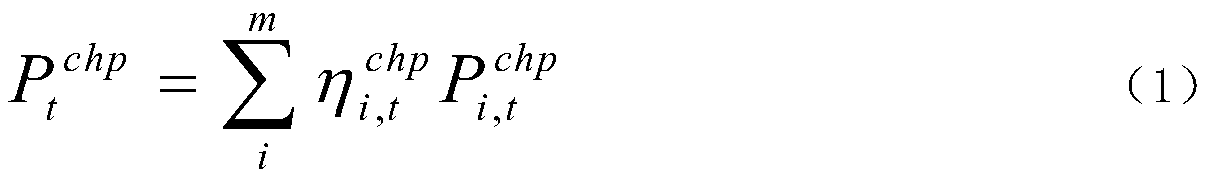

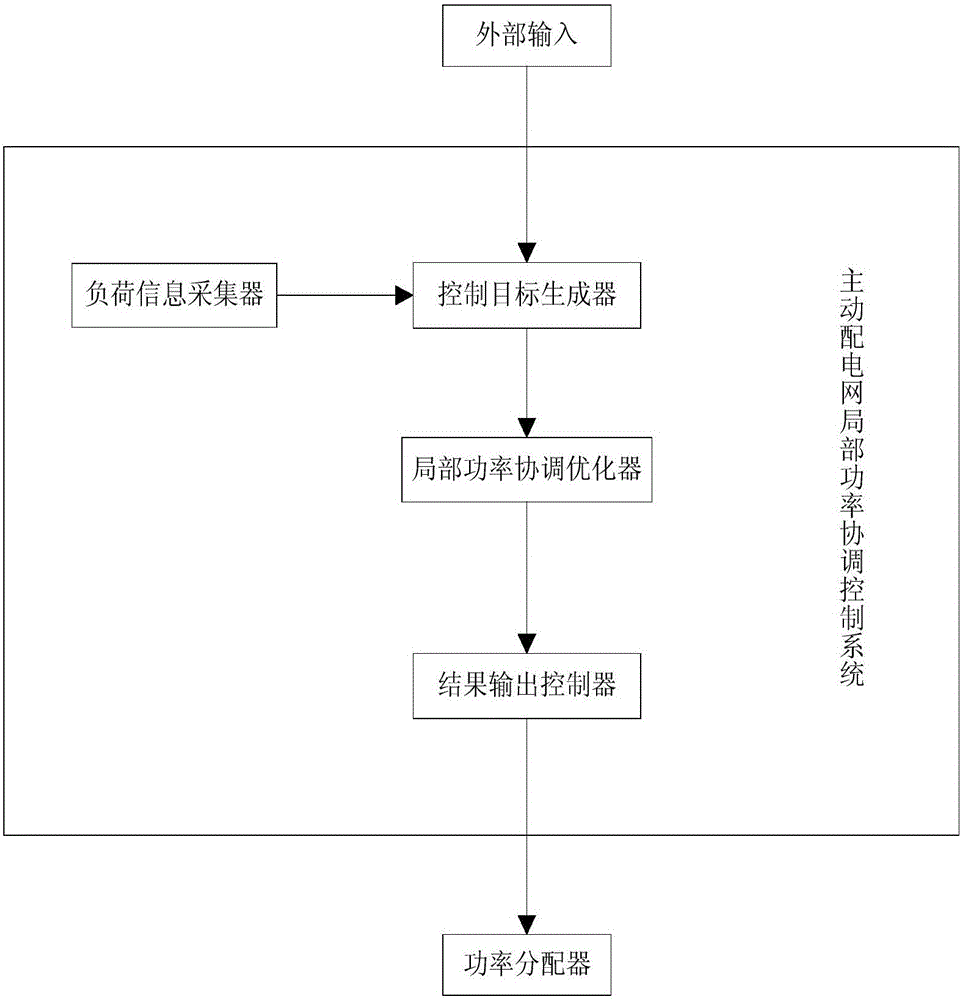

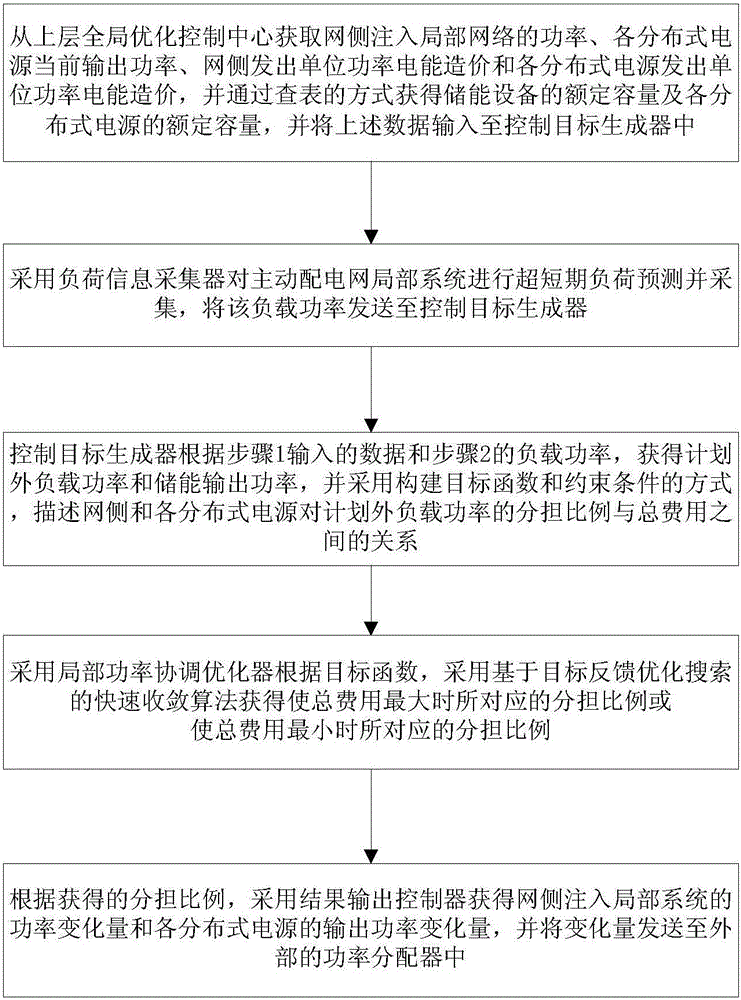

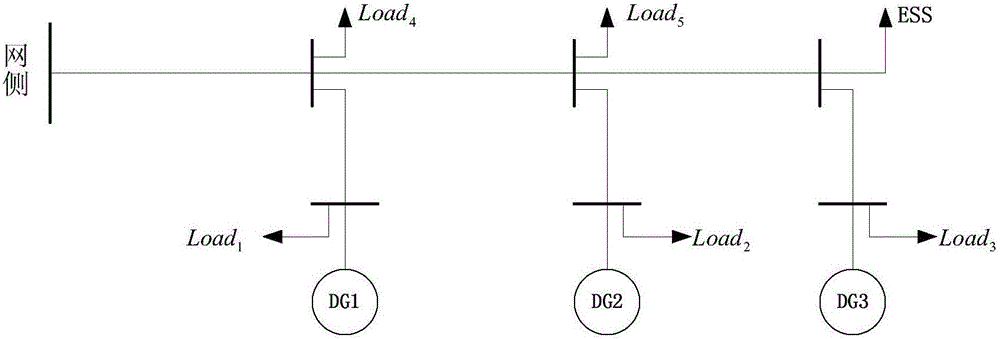

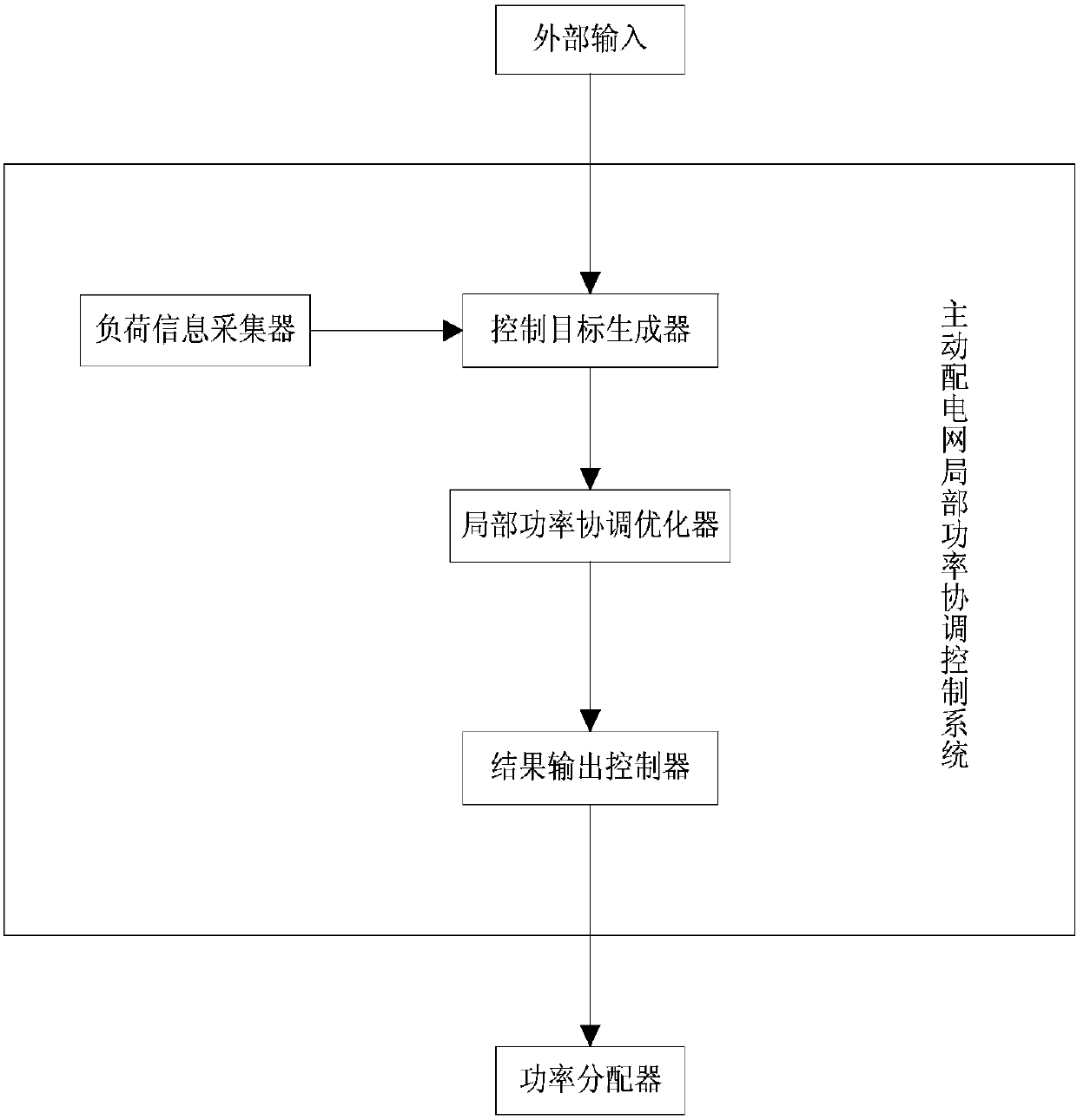

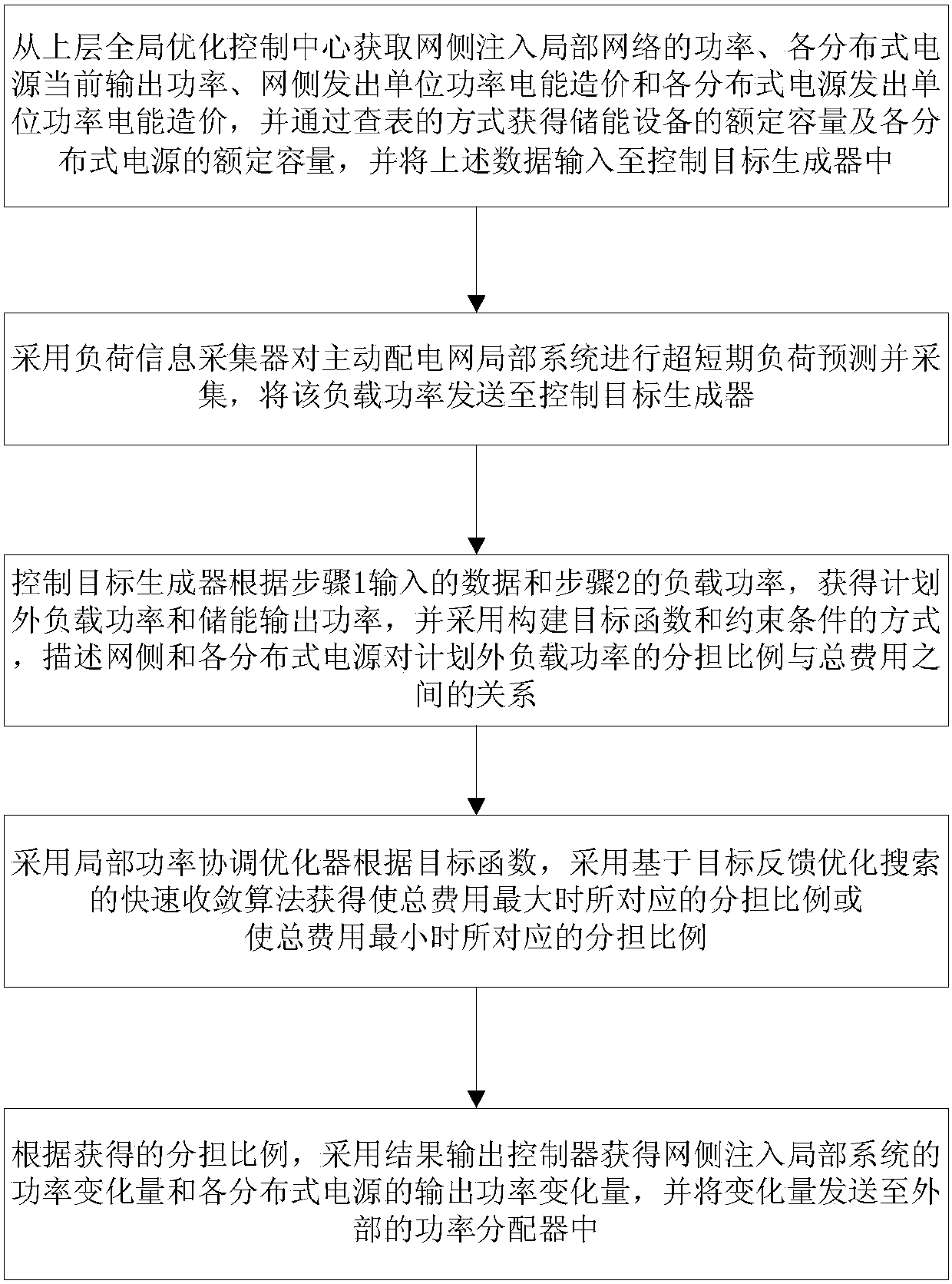

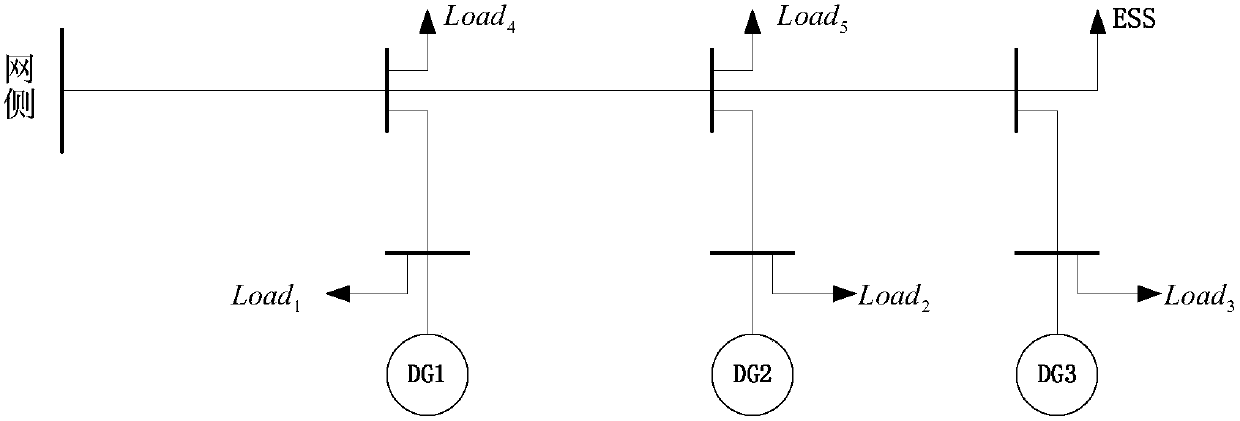

Local power coordinated control system and method of active power distribution network

ActiveCN106099912AAdjustment period is shortEffective Dynamic ResponseSingle network parallel feeding arrangementsAc network with energy trading/transmission rightsEngineeringGlobal optimization

The invention proposes a local power coordinated control system and method of an active power distribution network, and belongs to the technical field of local power coordinated control of the active power distribution network. The local power coordinated control system is based on long-period economic optimized operation of the active power distribution network, the regulation period is short, load change can be effectively and dynamically responded, and the global optimized economic operation of the system also can be satisfied. In the system, a coordinated control strategy for distributed power generation and energy storage of the active power distribution network when a load changes in different situations is fully considered, the output of a distributed power source and a network-side power source can be adaptively adjusted, the active power distribution network can efficiently and economically run by means of power generation capability of the distribution power source, and meanwhile, the residual energy in the system can be reasonably regulated and controlled. By the method, the sharing proportion coefficients of the distributed power source and the network-side power source on the load change can be rapidly and accurately solved, the rapid response of a local system to the load change is achieved, and the safe and economic operation of the system is ensured.

Owner:NORTHEASTERN UNIV

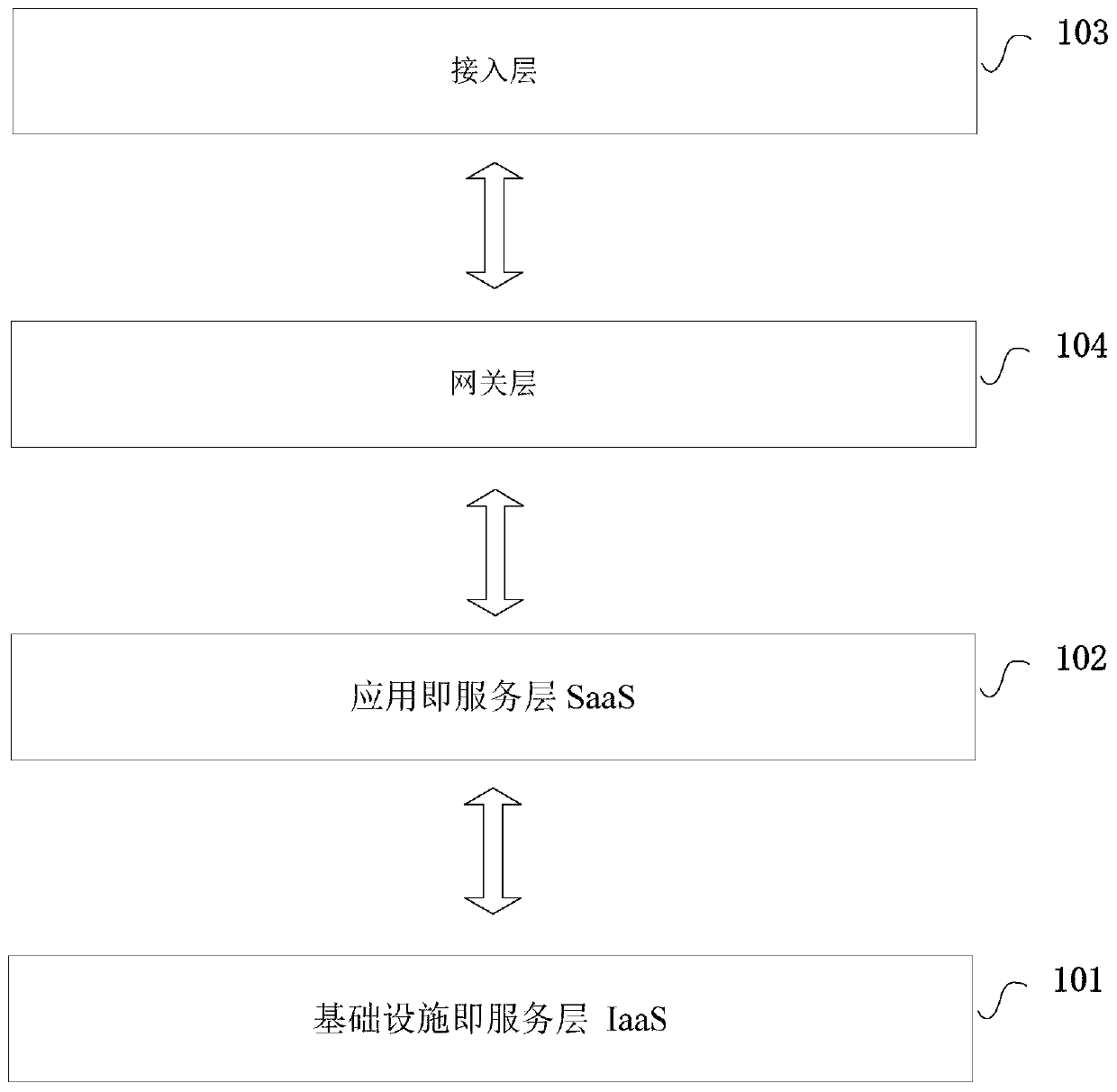

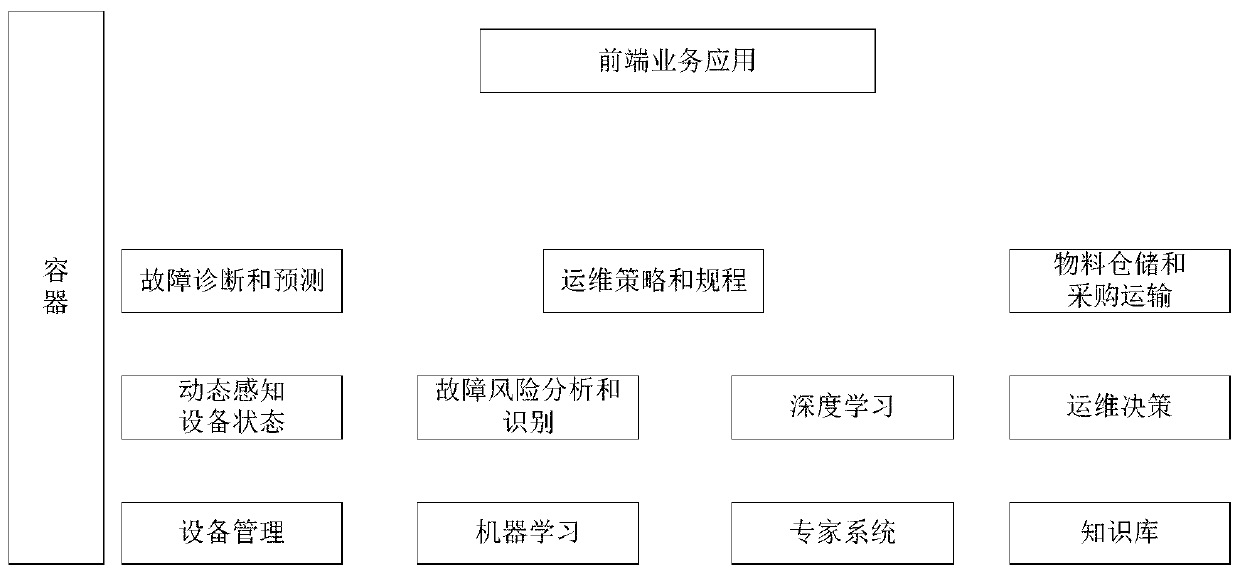

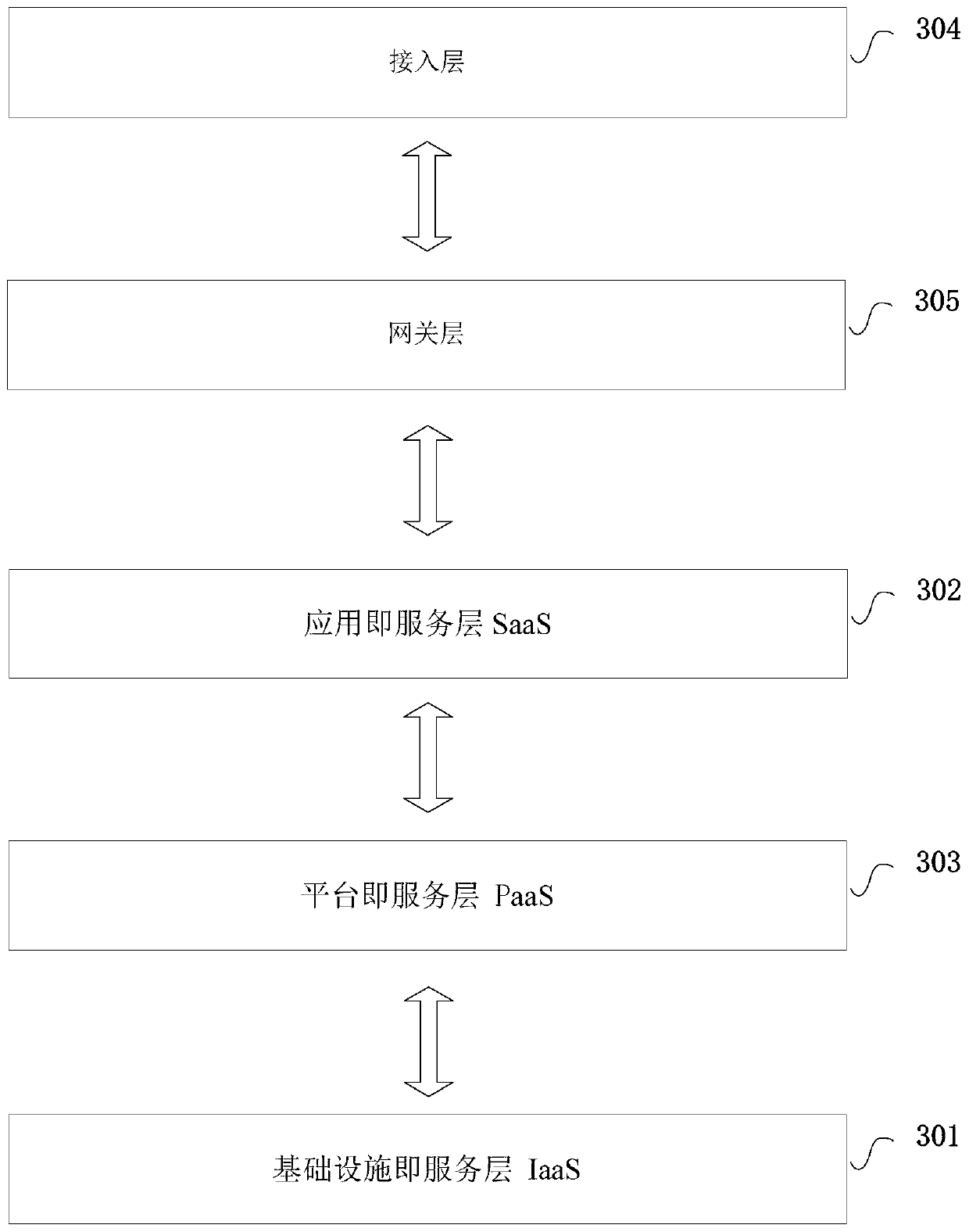

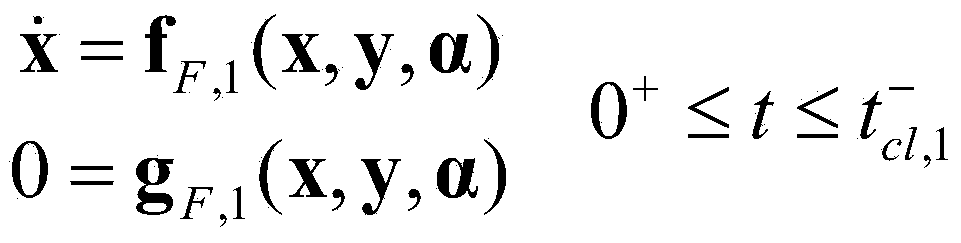

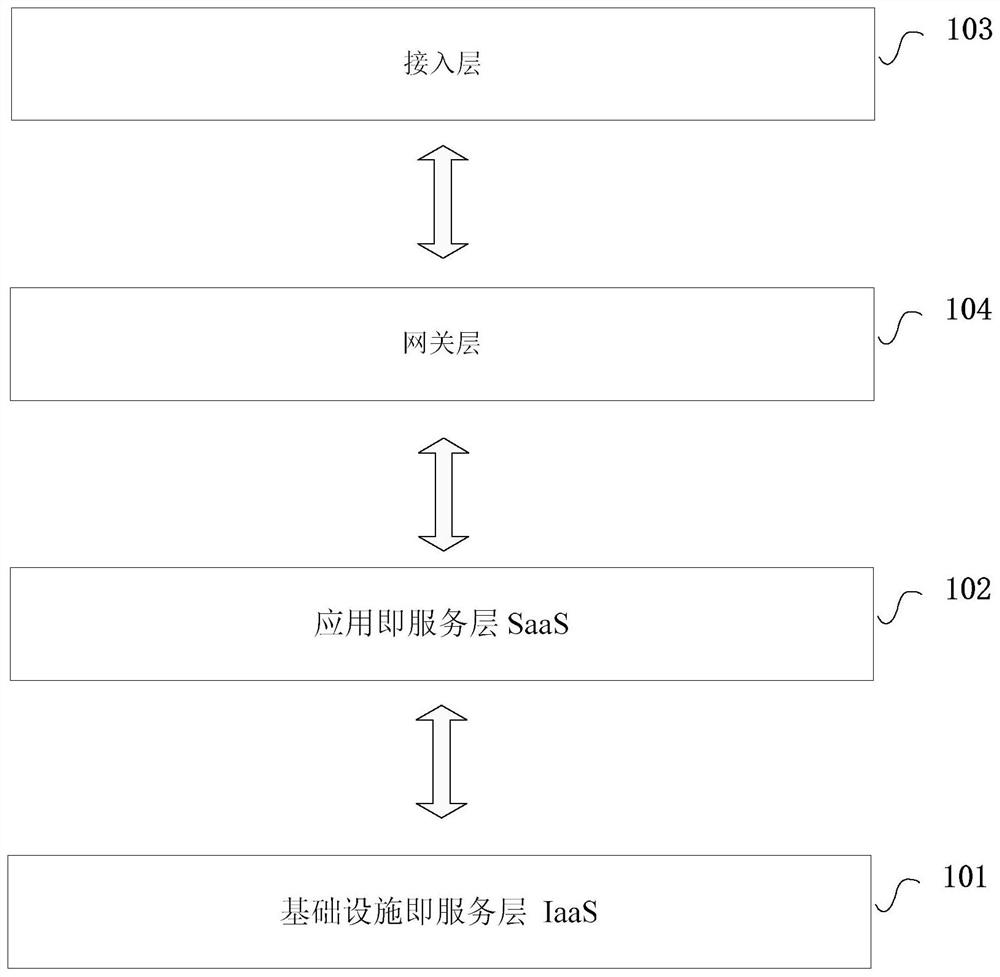

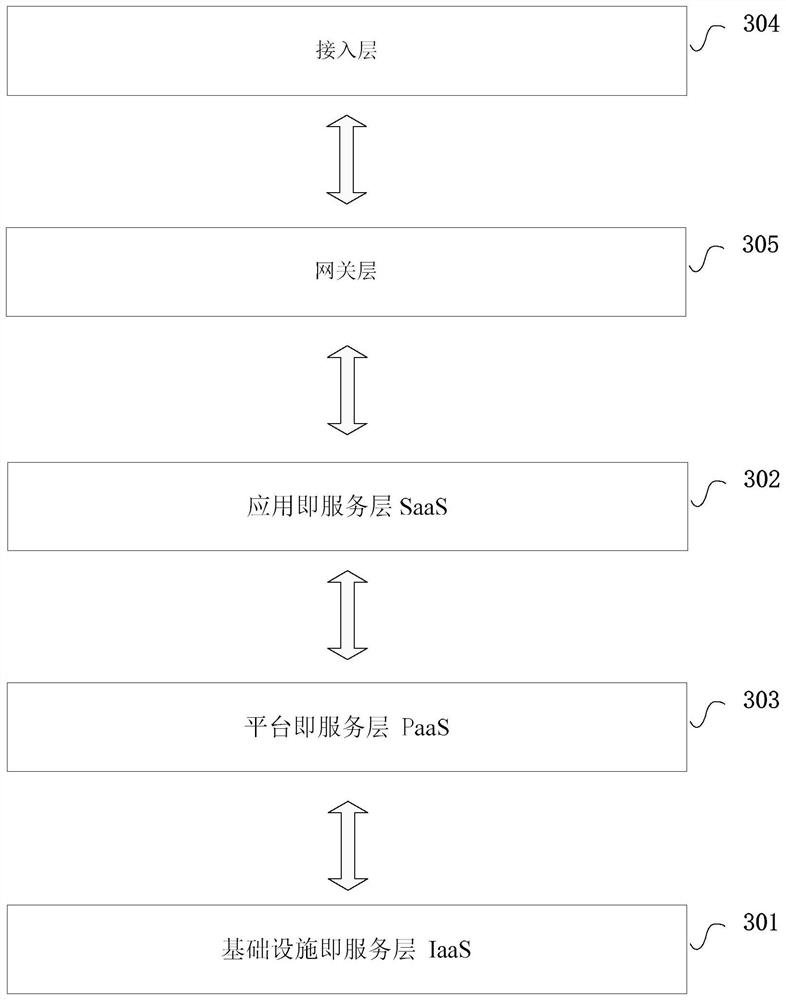

Rail transit operation and maintenance management system based on micro-service architecture

ActiveCN110949458AStable economic operationEfficient and economical operationRailway traffic control systemsMaintenance managementComputer science

The invention provides a rail transit operation and maintenance management system based on a micro-service architecture, and the system comprises an infrastructure-as-service layer, which provides rail transit business data for an application-as-service layer, through a deployed first micro-service, and responds to an operation and maintenance management control instruction; and the application-as-service layer which calls a second micro-service correspondingly deployed by a service module associated with the rail transit service data to perform service processing, provides service processinginformation display and operation and maintenance management control instruction operation prompts for the user through the front-end service application, and returns an operation and maintenance management control instruction to the infrastructure-as- service layer. According to the scheme provided by the embodiment of the invention, by reasonably designing the micro-service architecture, key facilities and equipment in rail transit are subjected to omnibearing whole-process management and control, different operation and maintenance requirements of rail transit operation and maintenance management can be met by deploying different micro-services, the management level of operation and maintenance management is improved, and normal, safe and efficient operation of the facilities and equipment is guaranteed.

Owner:成都交控科技有限公司

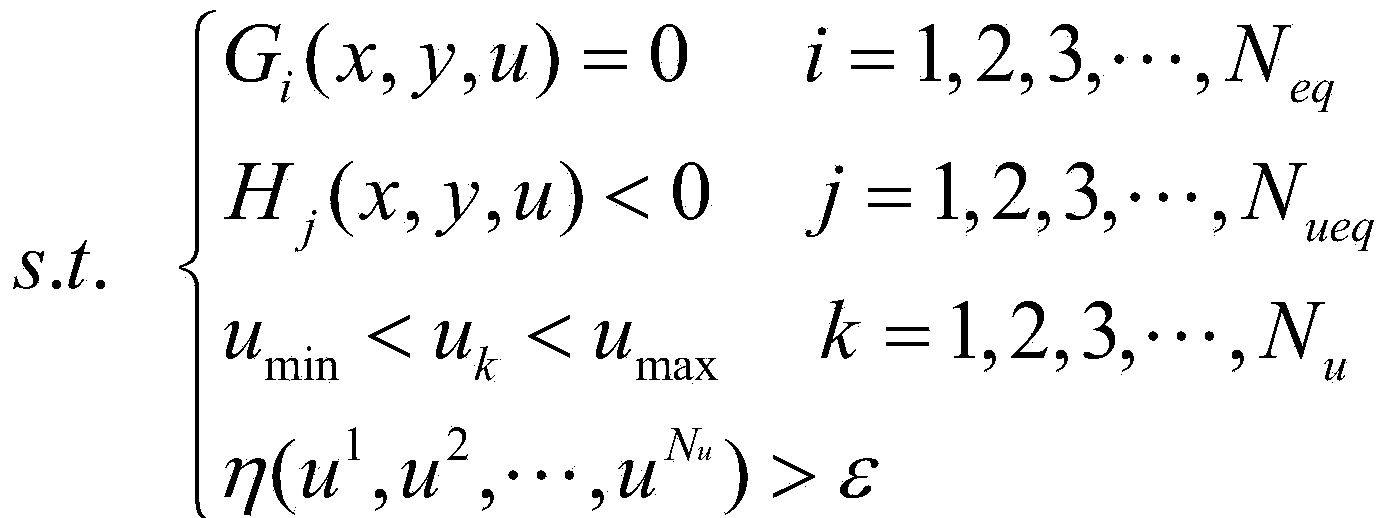

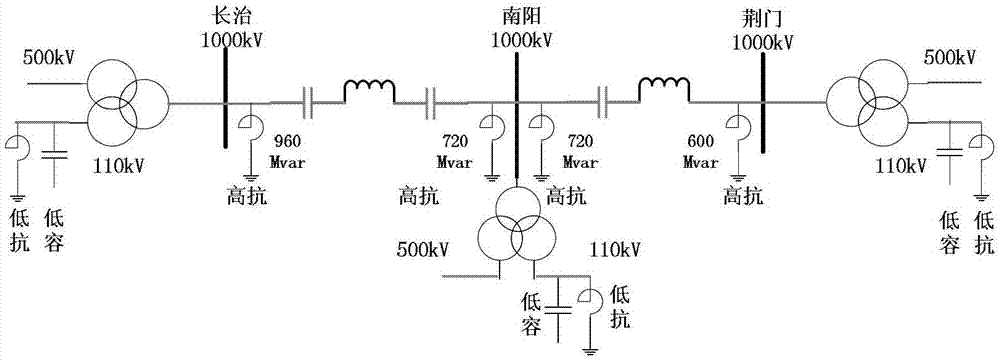

Multi-FACTS (flexible alternating-current transmission system) structure based chain structure high-voltage grid security control method

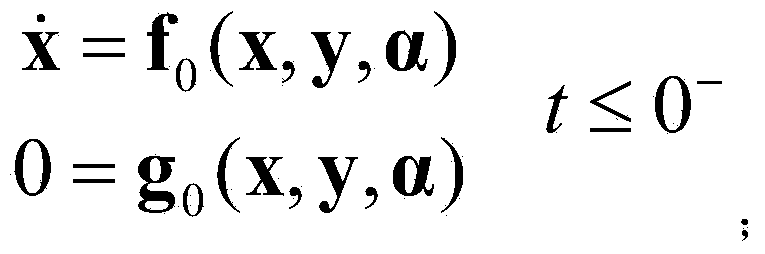

InactiveCN103972881AStable economic operationEfficient and economical operationData processing applicationsAc network circuit arrangementsElement modelElectric power system

The invention discloses a multi-FACTS (flexible alternating-current transmission system) structure based chain structure high-voltage grid security control method. The chain structure high-voltage grid security control method mainly comprises establishing a power system model and a dynamic element model on the basis of transient stability; establishing a coordinated optimization model considering coordination among multiple FACTS for the chain structure high-voltage grid on the basis of the power system model and the dynamic element model; and solving the optimal solution of the coordinated optimization model. The multi-FACTS structure based chain structure high-voltage grid security control method can overcome the defects of low reliability, poor coordination and stability and the like in the prior art and has the advantages of high reliability, good coordination and stability.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP

Rail Transit Operation and Maintenance Management System Based on Microservice Architecture

ActiveCN110949458BStable economic operationEfficient and economical operationRailway traffic control systemsMaintenance managementMicroservices

Owner:成都交控科技有限公司

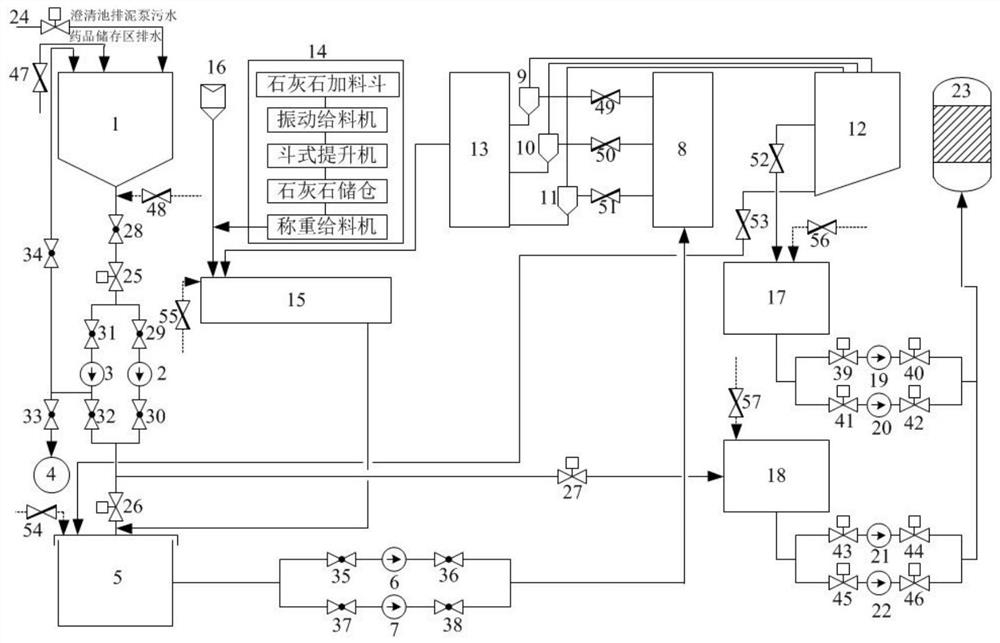

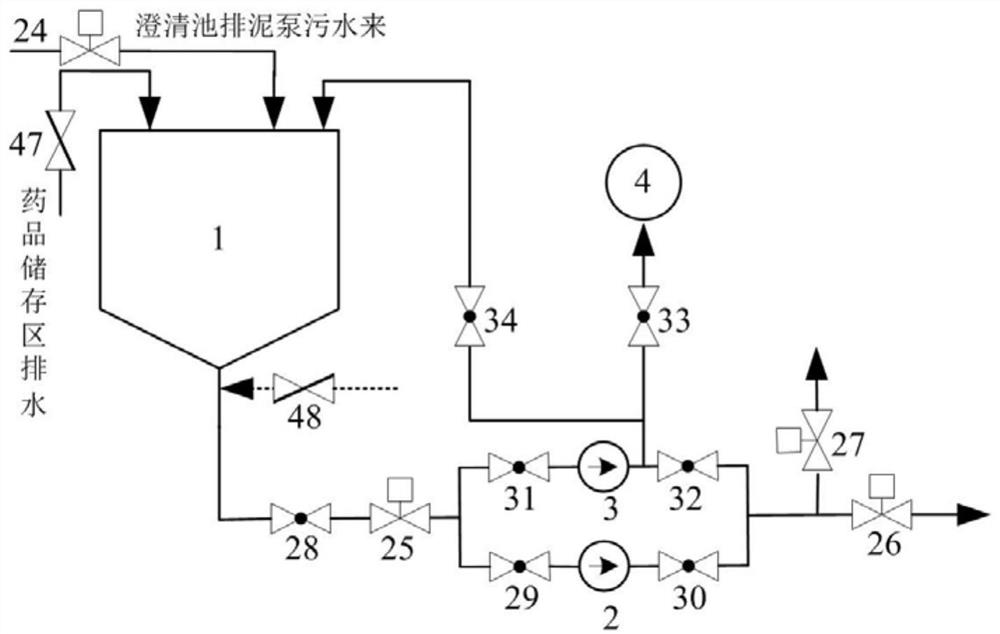

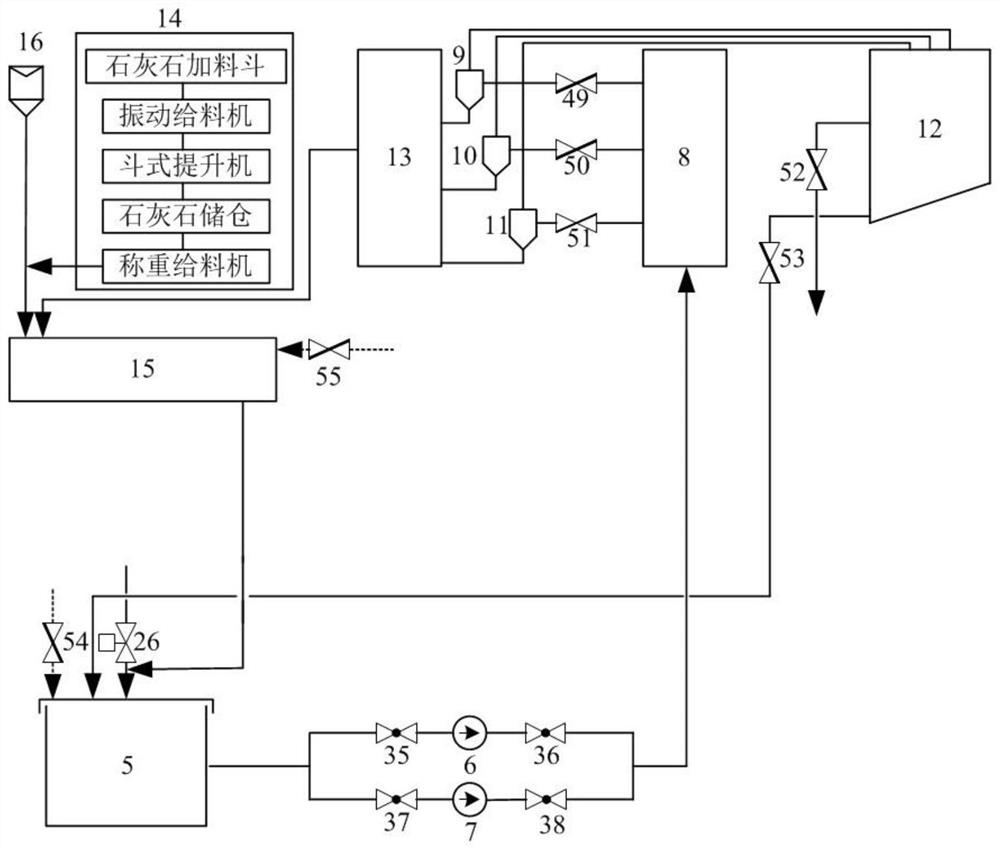

System and method for purifying calcium-containing sludge by recycling water quality of power plant

PendingCN112691523AReduce shipping handling costsReduce consumption costSludge treatmentDispersed particle separationSludgeProcess engineering

The invention provides a system and a method for purifying calcium-containing sludge by recycling water quality of a power plant. The system for purifying the calcium-containing sludge by recycling the water quality of the power plant comprises a sludge concentration tank, a desulfurizing agent grinding unit and a desulfurizing agent slurry supply unit, the sludge concentration tank is used for storing calcium-containing sludge from a power plant clarification tank, and the calcium-containing sludge is sent to the desulfurizing agent grinding unit or the desulfurizing agent slurry supply unit; the desulfurizing agent grinding unit is used for circularly grinding a mixed material of limestone and calcium-containing sludge; the desulfurizing agent slurry supply unit is used for storing the calcium-containing sludge or mixed slurry from the sludge concentration tank and the desulfurizing agent grinding unit and sending the calcium-containing sludge or mixed slurry to the desulfurization system to be used as a desulfurizing agent. Compared with the prior art, the calcium-containing sludge is conveyed into the desulfurization system to be used as the desulfurizing agent, so that the calcium-containing sludge is treated and recycled, the transportation and treatment expenses of polyacrylamide chemicals and sludge during dehydration of the calcium-containing sludge are reduced, and the consumption cost of alkaline limestone serving as the desulfurizing agent in the desulfurization system is reduced.

Owner:国能宿州热电有限公司

Real-time Coordinated Control Method for Photovoltaic Microgrid System

ActiveCN104242337BEfficient and economical operationAchieve Power Optimum MatchingSingle network parallel feeding arrangementsEnergy storageCapacitanceEnergy balancing

The invention relates to the technical field of photovoltaic micro-grid control, and particularly discloses a real-time coordination and control method of a photovoltaic micro-grid system. A central real-time optimal control layer and a local control layer are involved in the real-time coordination and control method. The central real-time optimal control layer collects the voltage and frequency of an AC bus of the photovoltaic micro-grid system, the charge state of a storage battery pack, the output power of photovoltaic power generation micro-sources, the output power of the storage battery pack, the output power of a super capacitor and the real-time power of a load in real time, generates a real-time coordination and control strategy and a secondary frequency modulation and scheduling plan, and issues the strategy and the plan to all local controllers. The local control layer coordinates and controls all the micro-sources in real time, and particularly achieves the scheduling plan issued by the central real-time optimal control layer. According to the real-time coordination and control method, a micro-grid central optimizing controller can manage, coordinate and control all the local controllers in a unified mode, the micro-grid can efficiently and economically run, the output power of the photovoltaic power generation unit is utilized to the maximum extent, the output power fluctuation and the tracking load change of the photovoltaic power generation unit are restrained, the running method of the micro-grid is reasonably adjusted, and energy balance is achieved.

Owner:EAST GRP CO LTD

On-line adjustment method for KAPLAN unit

ActiveCN101655063BEfficient and economical operationTo achieve the purpose of regulating flowHydro energy generationMachines/enginesComputer control systemPower station

The invention provides an on-line adjustment method for a KAPLAN unit, which has the advantages that: on the basis of not changing the prior KAPLAN computer control system, an actual water head signal which is input into the control system is intercepted and shielded based on the prior combination relationship, while a virtual water head signal is input into the control system to form a novel combination relationship between the relative opening degrees of guide blades and blades, and outflow conditions are adjusted to achieve the aim of adjusting the flow. Therefore, the on-line adjustment method can realize the real-time adjustment of a unit system of a hydropower station by means of the prior computer control system, and also can realize various adjustment targets in real time according to operation conditions of the hydropower station such as water head, the flow, and the distribution of the flow among units to realize the high-efficiency and economical operation of the hydropowerstation.

Owner:广州市恩莱吉能源科技有限公司

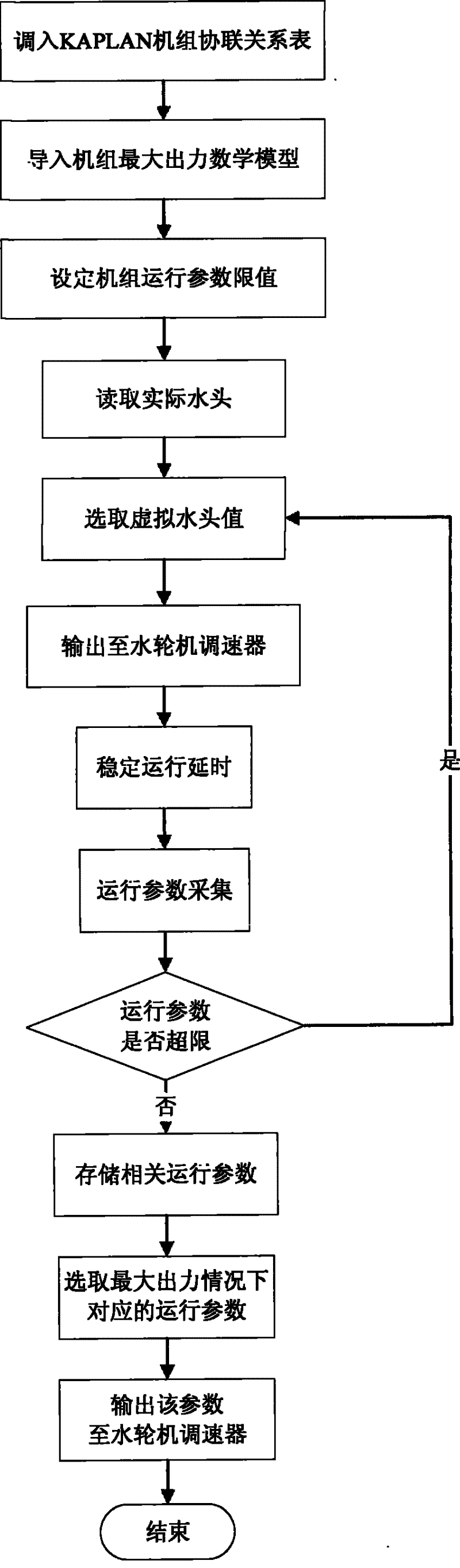

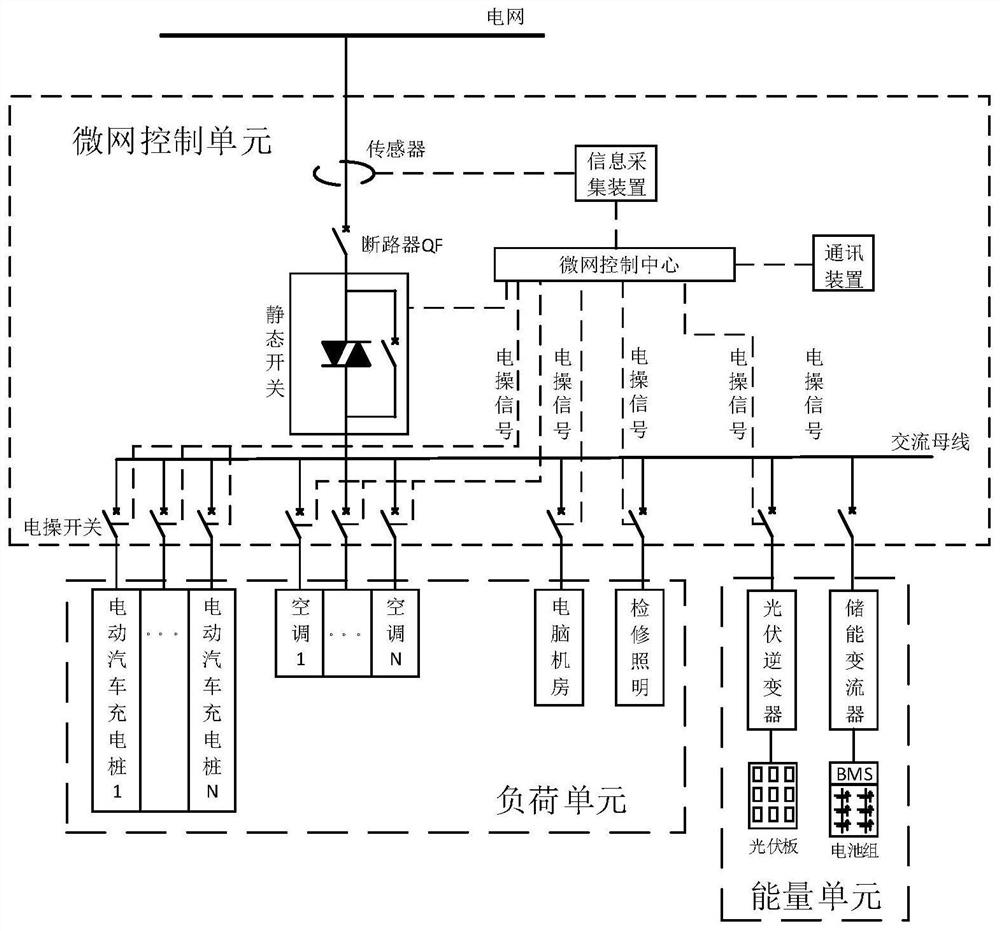

Distributed energy storage aggregation system and control method thereof

PendingCN113162092AReduce capacityReduce peak valley arbitragePower network operation systems integrationSingle network parallel feeding arrangementsPower gridEngineering

The invention discloses a distributed energy storage aggregation system. The system comprises a micro-grid control unit and an energy unit, wherein the micro-grid control unit comprises a micro-grid control center, an information acquisition device, a communication device, a static switch, a plurality of electric operation switches and a circuit breaker; the load unit and the energy unit are connected with an alternating current bus through an electric operation switch, the alternating current bus is connected with a power grid through a static switch and a circuit breaker; and the micro-grid control center is connected with an electric operation switch, a circuit breaker, an information acquisition device, a communication device and an energy unit vector. The system is advantaged in that reasonably planned distributed energy storage can not only reduce the capacity of distribution network and peak valley arbitrage through peak cutting and valley filling, negative influence of the randomness of distributed energy storage on the safety of the power grid can be made up, and the load unit and the energy unit are correspondingly controlled through different connection states with the power grid, so a purpose of efficient, safe and economical operation is achieved.

Owner:南京国电南自新能源科技有限公司

Safety control method of chain structure high voltage power grid based on multi-facts structure

InactiveCN103972881BStable economic operationEfficient and economical operationData processing applicationsAc network circuit arrangementsElement modelElectric power system

The invention discloses a multi-FACTS (flexible alternating-current transmission system) structure based chain structure high-voltage grid security control method. The chain structure high-voltage grid security control method mainly comprises establishing a power system model and a dynamic element model on the basis of transient stability; establishing a coordinated optimization model considering coordination among multiple FACTS for the chain structure high-voltage grid on the basis of the power system model and the dynamic element model; and solving the optimal solution of the coordinated optimization model. The multi-FACTS structure based chain structure high-voltage grid security control method can overcome the defects of low reliability, poor coordination and stability and the like in the prior art and has the advantages of high reliability, good coordination and stability.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP

Thermal Compensation Superheated Steam Coal Drying System

InactiveCN105716380BReduce energy consumptionReduce consumptionDrying solid materials with heatGranular material dryingFluidized bedSuperheater

The invention discloses a thermal compensation type superheated steam coal drying system. Fault raw coal is broken and screened through a coal breaker, then passes through a coal bunker and then enters a superheated steam fluidized bed, the heat and mass transfer process is carried out inside, then the fault raw coal flows out of the bottom of the superheated steam fluidized bed, and the fault raw coal becomes upgraded coal after passing through a coal cooler. Superheated steam of the superheated steam fluidized bed is from a superheated steam extraction source. Water in the fault raw coal is heated and evaporated in the superheated steam fluidized bed into secondary steam, then the secondary steam is output out of the top of the superheated steam fluidized bed, the secondary steam passes through a circulating fan and then is introduced into the superheated steam fluidized bed to be subjected to heat exchange with the raw coal again, and the secondary steam becomes precipitated water after being condensed. Cooling feedwater introduced into the coal cooler serves as compensation heat source water to be introduced into a waste-heat heat exchanger and a solar heat exchanger through corresponding valves, wherein the waste-heat heat exchanger and the solar heat exchanger are connected in parallel. The waste-heat heat exchanger and the solar heat exchanger are both connected with an electric superheater through valves, and a superheated steam outlet of the electric superheater is connected with the superheated steam extraction source in parallel through a switching valve and then is connected into the superheated steam fluidized bed.

Owner:SHANXI UNIV

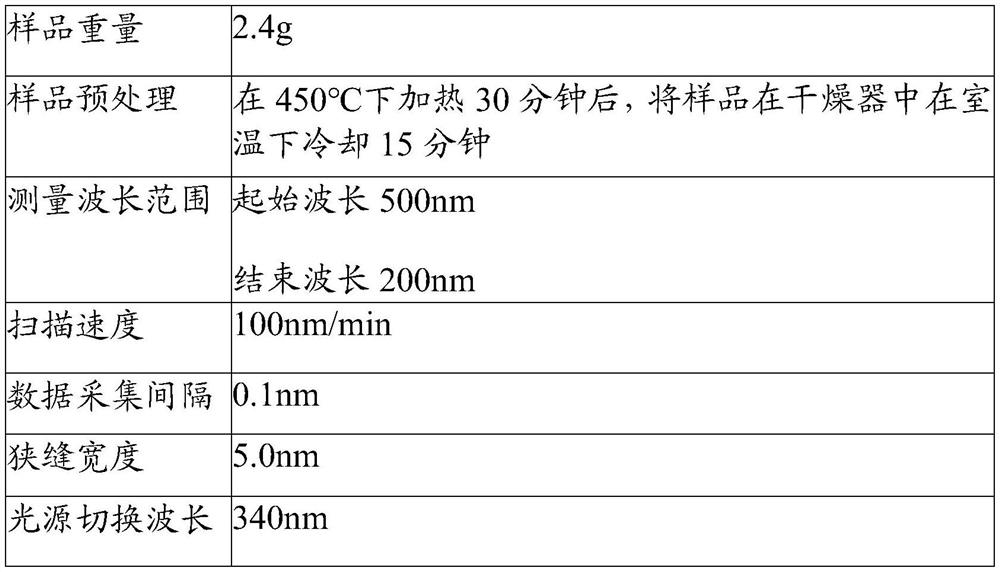

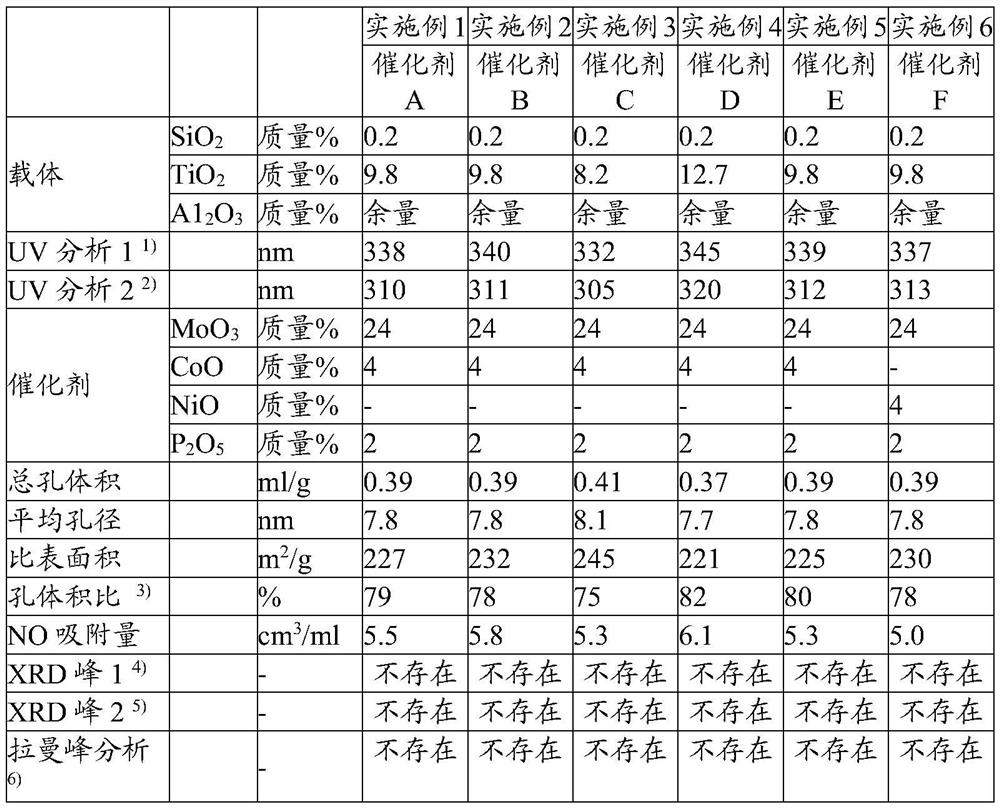

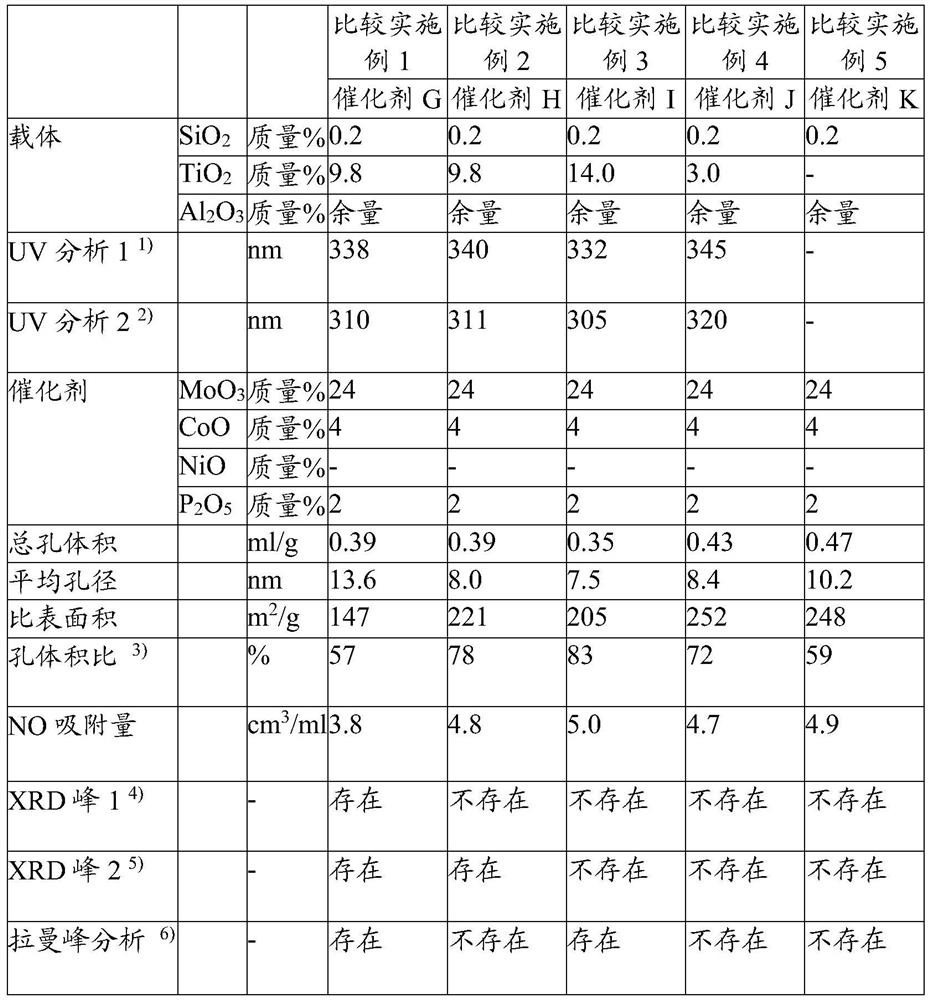

A catalyst for hydrotreating hydrocarbon oil and a method of hydrotreating hydrocarbon oil using the catalyst

PendingCN113825564AEfficient removalEasy to operateHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystHydrogen treatment

To provide a catalyst having hydrotreatment (hydrogenation, desulfurization and denitrogenation) performance that is equal to or superior to the prior art, as a hydrotreating catalyst for hydrocarbon oils, and a hydrotreating process for hydrocarbon oils using the catalyst. A hydrotreating catalyst for hydrocarbon oils comprising, at least one metal selected from the group 6 of the periodic table, at least one metal selected from the groups 8 to 10 of the periodic table, and optionally further phosphorus and / or boron as catalytic active components supported on an inorganic porous support based on alumina, wherein the inorganic porous support comprises, as constituent components thereof, silica in an amount of less than 1% by mass with respect to the mass of the oxide and a metal of the group 4 of the periodic table in an amount of less than 13% by mass as an oxide; wherein the metal of the group 4 of the periodic table is highly dispersed in the inorganic porous support, a degree of dispersion thereof is shown by that no peak is substantially observed in the wave number range of 100 to 200 cm-1 by Raman spectroscopy and that no crystal is substantially observed by X-ray diffraction analysis; wherein the hydrotreating catalyst has a specific surface area of 100 to 300 m2 / g, a pore volume of 0.2 to 0.5 ml / g, an average pore diameter of 6 to 10 nm, and a NO adsorption amount of 4.5 cm3 / ml or more as catalytic characteristics; and wherein no crystals derived from the metal oxide salts of the group 6 of the periodic table are not substantially observed by X-ray diffraction analysis.

Owner:NIPPON KETJEN CO LTD

Boiler main steam temperature control method with frequent fluctuations in power grid agc load command

ActiveCN110360540BImprove adjustment qualityImprove efficiencySuperheating controlBoiler controlTemperature controlPower grid

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

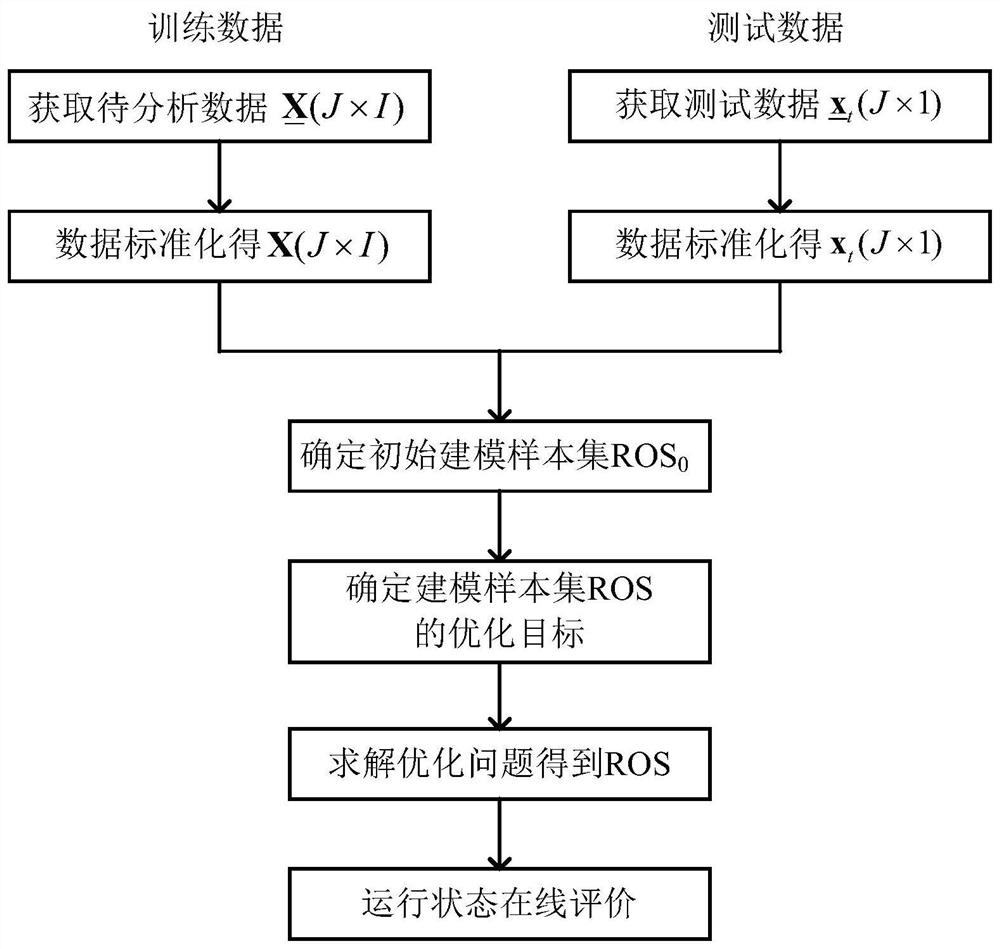

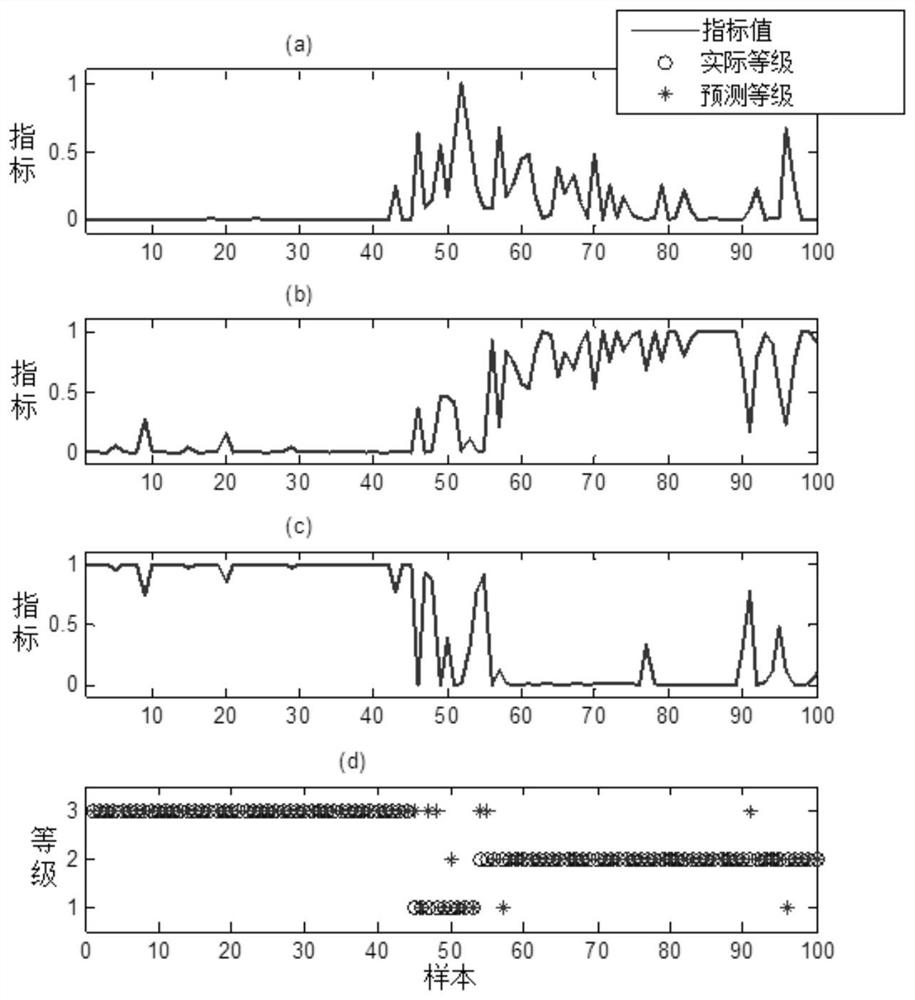

On-line evaluation method of industrial process operation status based on the idea of just-in-time learning

ActiveCN111813064BImprove evaluation accuracyEfficient and economical operationTotal factory controlProgramme total factory controlEvaluation resultData selection

The invention discloses an online evaluation method for the operation state of an industrial process based on the idea of instant learning. The method aims at the evaluation problem of the operation state of the industrial process with dynamic changes in process characteristics and a small amount of modeling data; firstly, according to the online test data, a modeling The optimization objective of the data selection part; then, establish the optimization objective of the state evaluation part; use the evolutionary optimization algorithm to solve the objective function, and obtain the modeling data and evaluation model at the same time; finally, use the established evaluation model and Bayesian posterior probability The evaluation index is used to obtain the evaluation results of the operating status. The invention considers the establishment of modeling data and evaluation model at the same time, and simultaneously solves two parts of optimization objectives in order to obtain the global optimal solution. The present invention improves the accuracy of operating state evaluation by means of more refined modeling, and can finally be applied to actual industrial production sites to ensure high-efficiency and economical operation of industrial processes with dynamic changes and small amount of modeling data.

Owner:ZHEJIANG UNIV

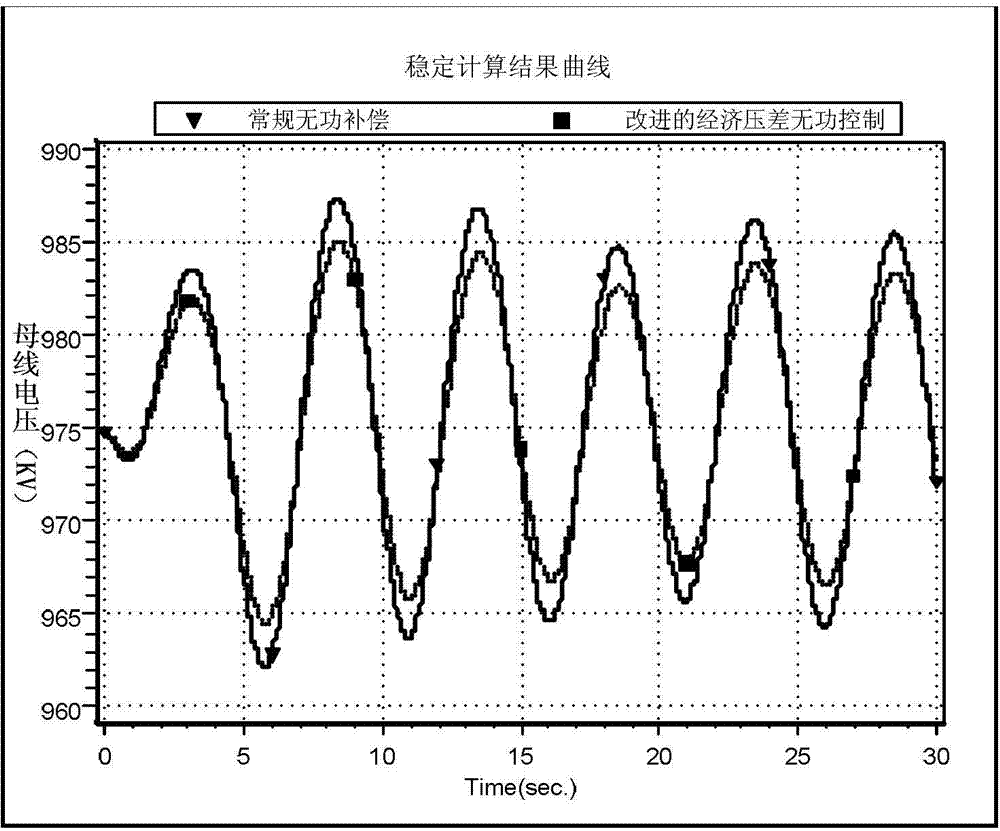

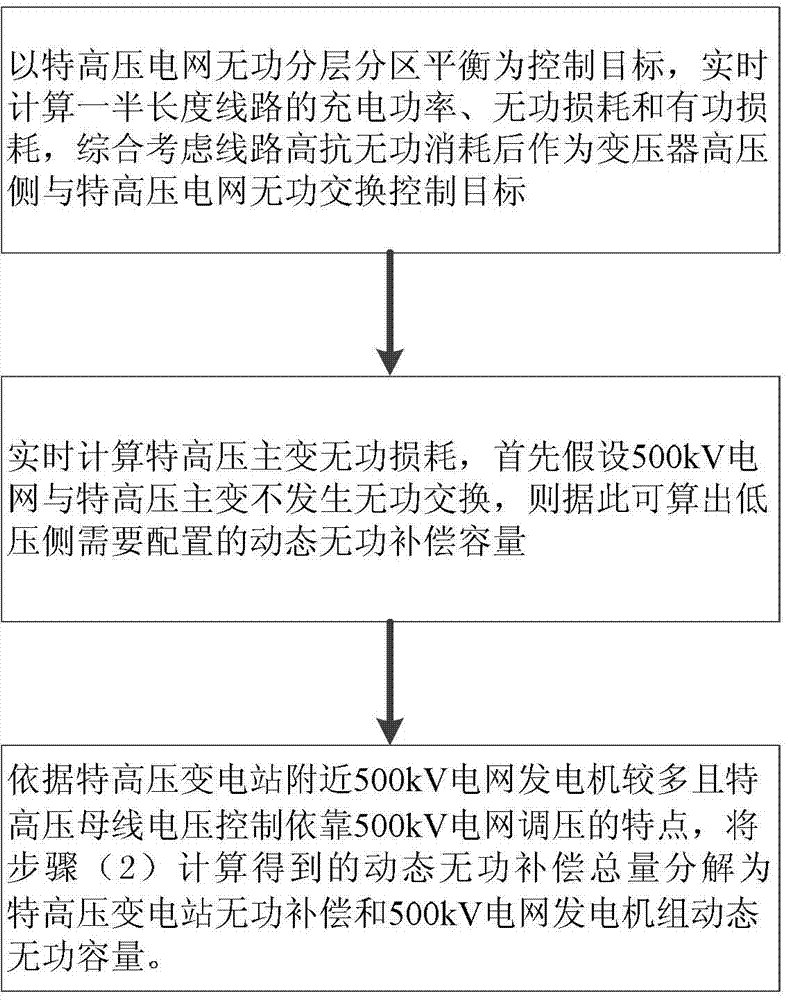

Method for controlling reactive voltage in ultra-high voltage grid on the basis of improved economic voltage difference

ActiveCN103001234BRealize reactive power real-time balanceReduce reactive power lossReactive power adjustment/elimination/compensationReactive power compensationLow voltageUltra high voltage

Owner:CHINA ELECTRIC POWER RES INST +2

An operation optimization method for an electrothermal coupling integrated energy system

Owner:SOUTHEAST UNIV

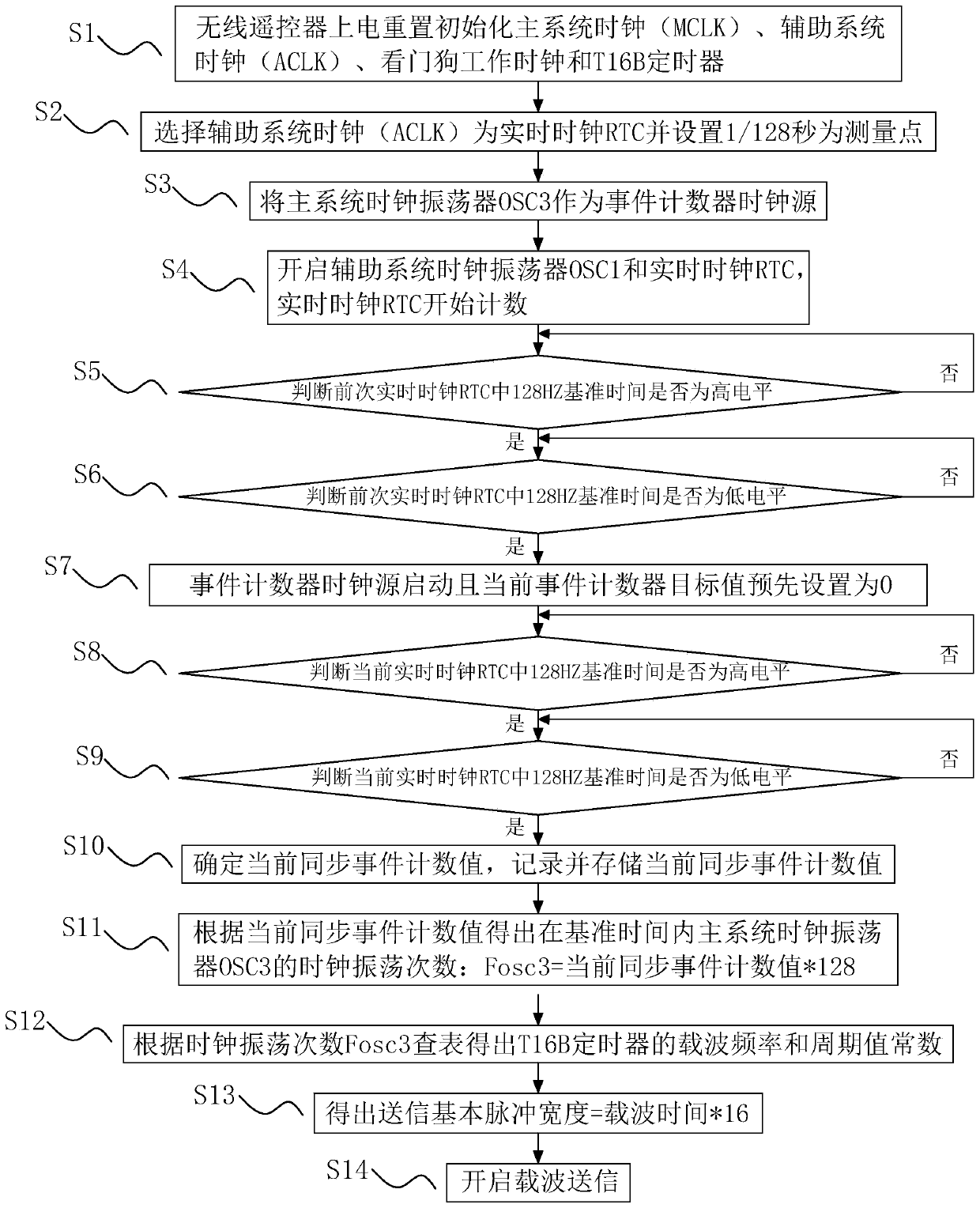

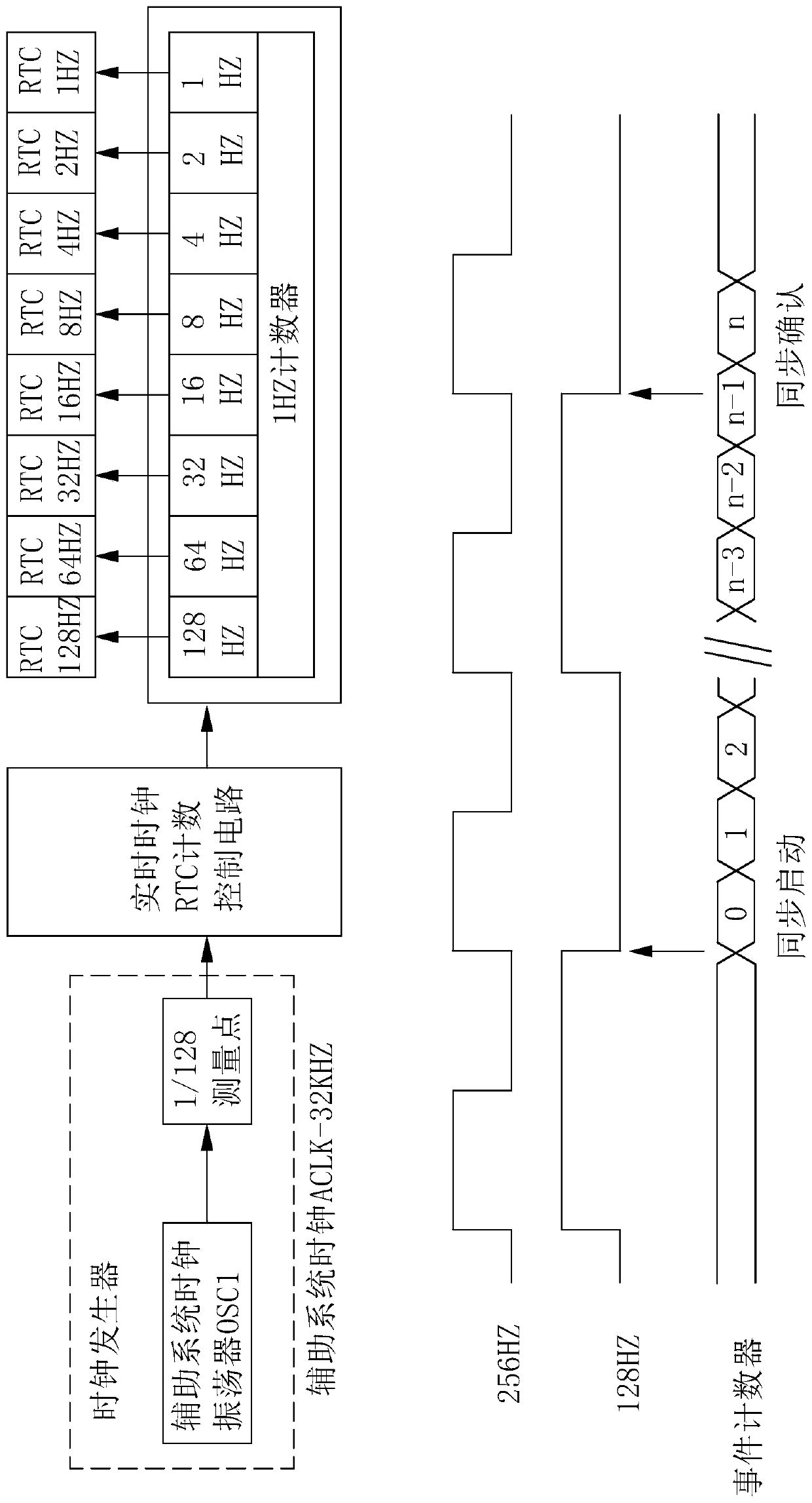

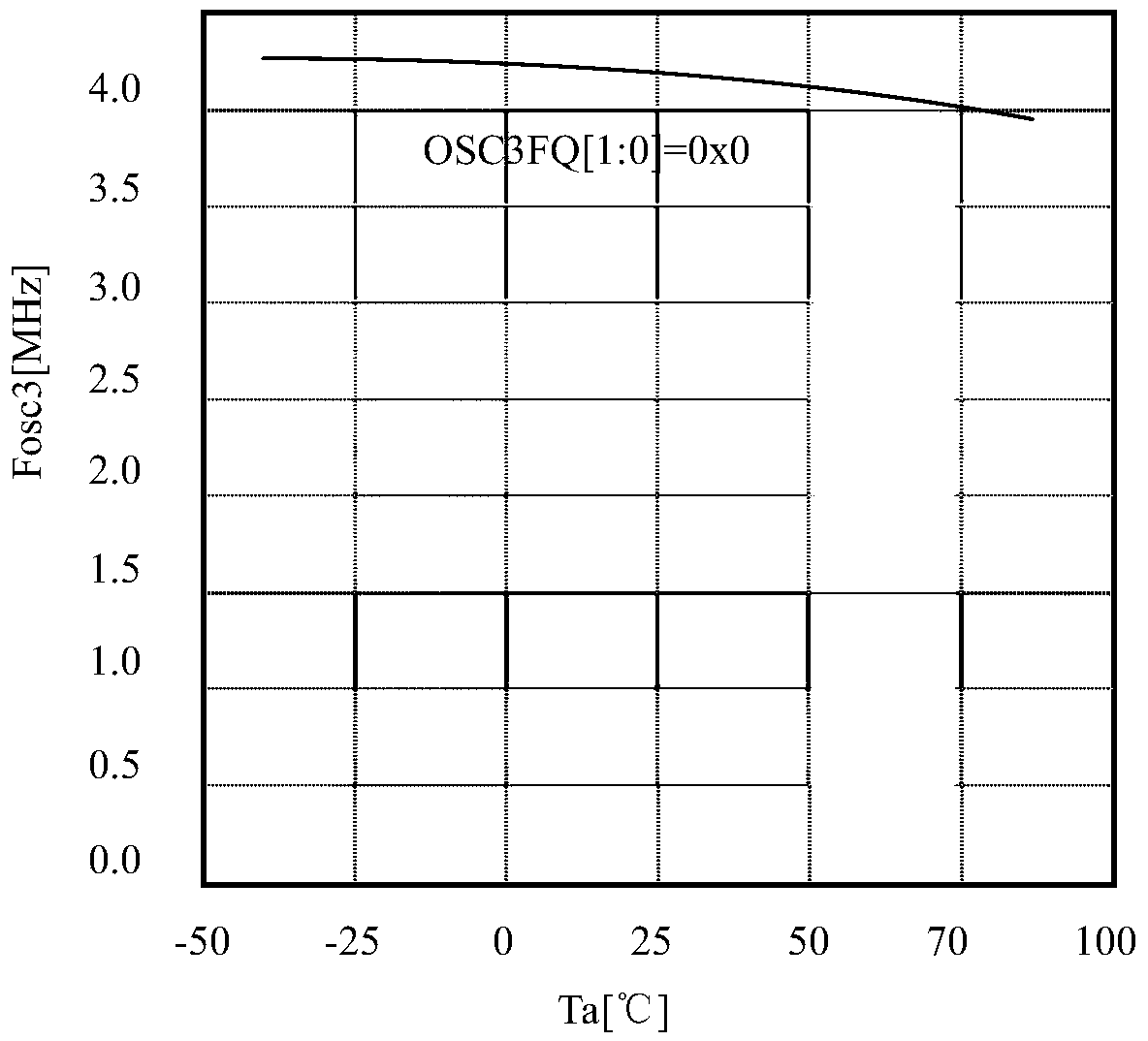

An embedded digital oscillation wireless remote controller control method

ActiveCN108230646BImprove transmission carrier accuracyEasy to operateTransmission systemsCarrier signalCeramic resonator

The invention discloses a control method of an embedded digital oscillation wireless remote controller. The remote controller can work as normal under the severe environment through a way of selectingan internal oscillator; and furthermore, the self-calibration is performed at idle moment according to different time intervals, different working voltages and different temperature differences, thesending carrier precision of the embedded digital ceramic resonator wireless remote controller can be improved as much as possible, and the efficient and economic operation of the embedded digital ceramic resonator wireless remote controller is realized.

Owner:珠海东之尼电子科技有限公司

An active distribution network local power coordination control system and method

ActiveCN106099912BAdjustment period is shortEffective Dynamic ResponseSingle network parallel feeding arrangementsAc network with energy trading/transmission rightsControl systemPower grid

The invention proposes an active distribution network local power coordination control system and method. The invention belongs to the technical field of active distribution network local power coordination control. The invention is based on local power coordination based on the long-term economic optimization operation of the active distribution network. The control system has a short adjustment cycle, which can not only provide effective dynamic response to load changes, but also enable the system to meet the overall optimized economic operation; this invention fully considers the distributed power generation and energy storage in the active distribution network under different load changes. The coordinated control strategy can adaptively adjust the output of distributed power supplies and grid-side power supplies, fully utilize the power generation capacity of distributed power supplies to enable efficient and economical operation, and at the same time reasonably regulate the remaining energy in the system; the method of the present invention can quickly and accurately Solve the proportional coefficient of load changes between distributed power supplies and grid-side power supplies, achieve rapid response of local systems to load changes, and ensure safe and economical operation of the system.

Owner:NORTHEASTERN UNIV LIAONING

A Hierarchical Optimization Method for Combined Cooling System

The invention provides a hierarchical optimization method for a united cold supply system consisting of a conventional electric refrigerator and an ice storage system. The method comprises the steps of optimizing the on-state and the optimal power setting value of each cold source by adopting a mixed integer programming method according to the economic model of each cold source and the time-of-use power price policy, designing a target-coupled coordinated distributed prediction control method to better improve the dynamic performance of the system in view of the dynamic adjusting characteristic and physical constraint of each cold source, and newly optimizing the setting value of each cold source under a distributed framework, so that each cold source ensures the total load in the dynamic process and tracks the optimal refrigerating power setting value as much as possible at the same time. The method quantitatively solves the steady and dynamic scheduling problem of the united cold supply system by adopting mixed integer programming and distributed prediction control methods respectively, and provides a rational suggestion for energy management and optimization scheduling of the cold supply system.

Owner:SHANGHAI JIAO TONG UNIV

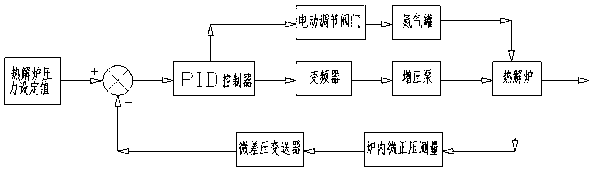

Oil-containing pollutant treatment system capable of realizing energy-saving control by using PID (Proportion Integration Differentiation) to adjust constant pressure

PendingCN108726832AAchieve ultra-clean treatmentReduce energy consumptionCoke ovensSludge treatment by pyrolysisEnvironmental resistanceDifferential pressure

The invention belongs to the technical field of energy-saving and environment-friendly equipment and particularly relates to an oil-containing pollutant treatment system capable of realizing energy-saving control by using PID (Proportion Integration Differentiation) to adjust constant pressure. The oil-containing pollutant treatment system comprises a nitrogen making machine, a nitrogen tank, a first electric adjusting valve, a second electric adjusting valve, a third electric adjusting valve, a fourth electric adjusting valve, a first pyrolyzing furnace, a second pyrolyzing furnace, a first micro-differential-pressure transmitter, a second micro-differential-pressure transmitter, a third micro-differential-pressure transmitter, a fourth micro-differential-pressure transmitter, a bufferingtank group, a boosting pump, a noncondensable-gas buffering tank, an electric switch valve and a PID controller. The oil-containing pollutant treatment system has the beneficial effects that after high-temperature anaerobic reaction of oil-containing pollutant particles, water, oil or organic matters such as polyaromatic hydrocarbon are phase-changed to be vaporized so as to be separated from solids, and solid-phase slags are treated by a closed dry type deslagging technology; gases failed to be condensed by the oil gas are conveyed into the pyrolyzing furnace for environment-friendly reburning after being pressure-stabilized by the boosting pump; the energy consumption can be reduced, the efficiency can be improved, the safety risk can be reduced and the operation is reliable.

Owner:大庆百世环保科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com