Thermal compensation type superheated steam coal drying system

A superheated steam and coal drying technology, which is applied in the directions of heating to dry solid materials, drying solid materials, and drying gas arrangement, can solve the problems of reducing system energy consumption and system complexity, so as to improve drying speed, reduce system fluctuations, and stabilize effect of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

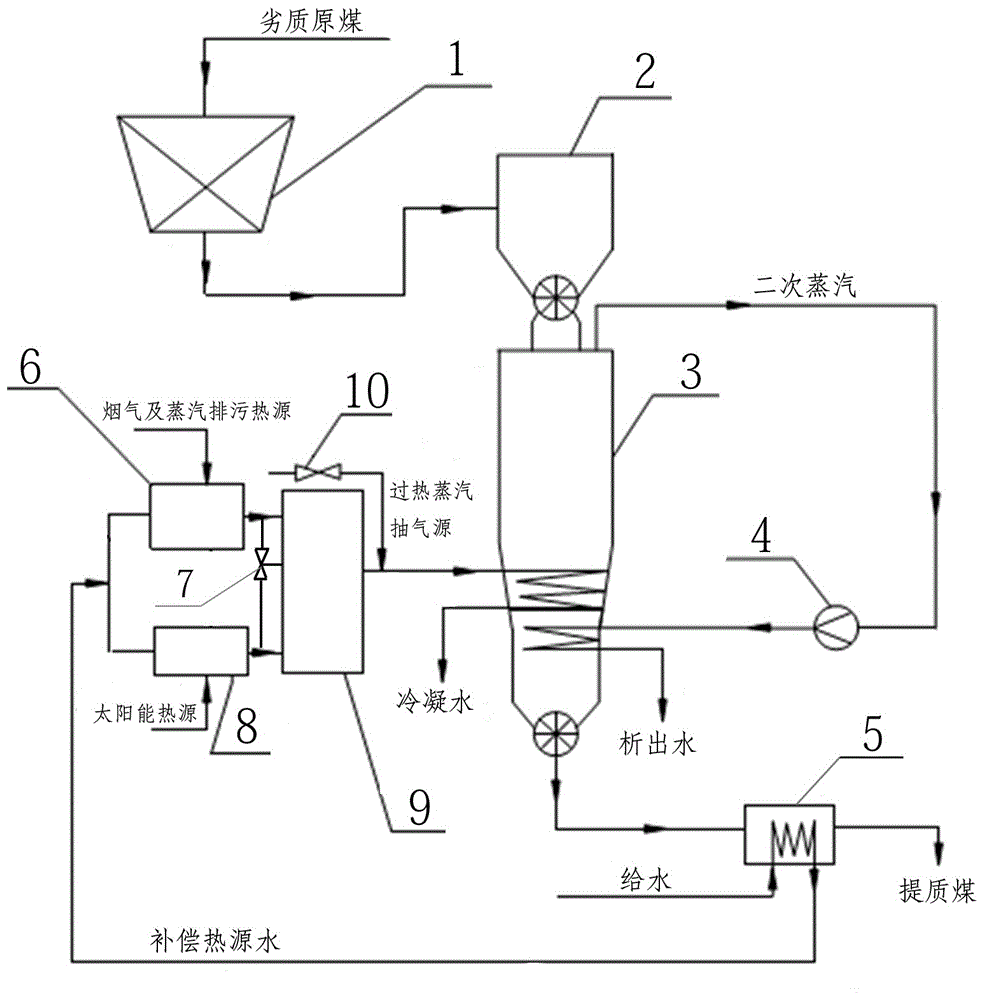

[0022] A heat compensation type superheated steam coal drying system, including a coal crusher 1, a coal bunker 2, a superheated steam fluidized bed 3, a coal cooler 5, a waste heat exchanger 6, a mixing valve 7, a solar heat exchanger 8, an electric Superheater 9, switching valve 10.

[0023] Such as figure 1 As shown, the inferior raw coal is crushed and screened by the coal crusher 1, then passes through the coal bunker 2, and then enters the superheated steam fluidized bed 3 for heat and mass transfer process inside, and then flows out from the bottom of the superheated steam fluidized bed 3, and passes through the coal bunker 2. After the cooler 5, it becomes upgraded coal; the superheated steam of the superheated steam fluidized bed 3 comes from the superheated steam pumping source, and the superheated steam gas source enters the superh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com