On-line adjustment method for KAPLAN unit

An adjustment method and unit technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as unmaintainable efficiency, inaccurate association relationship between guide vanes and blades, unbalanced flow distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

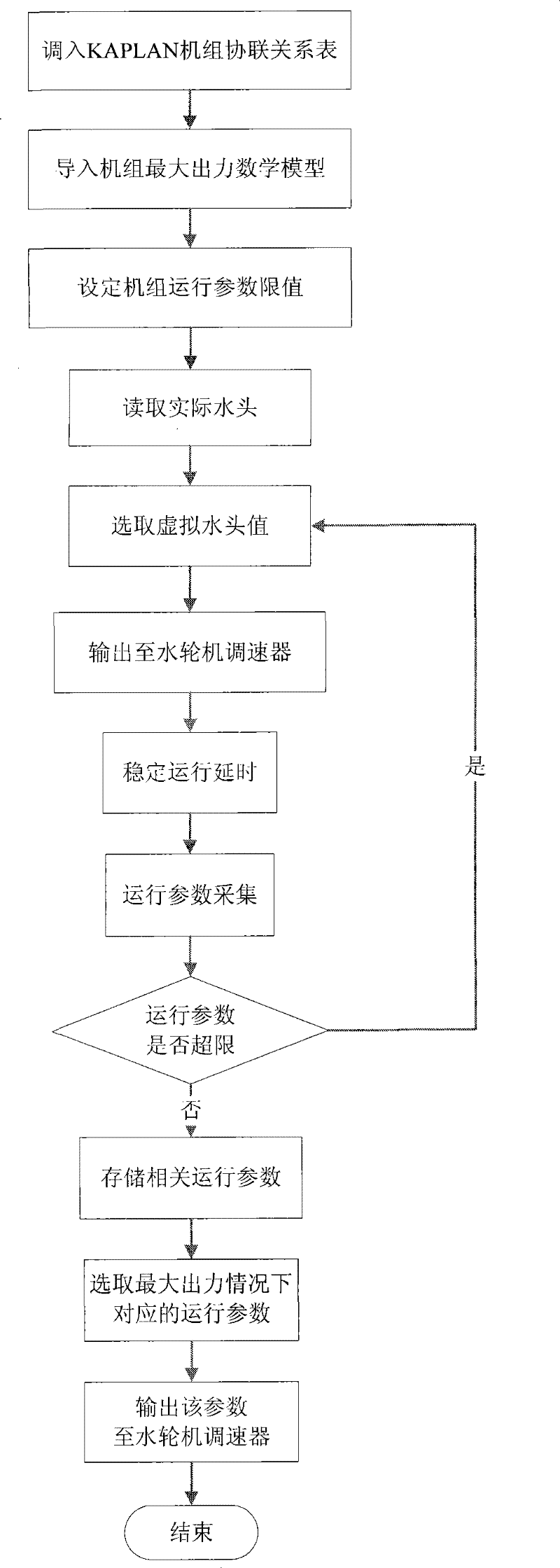

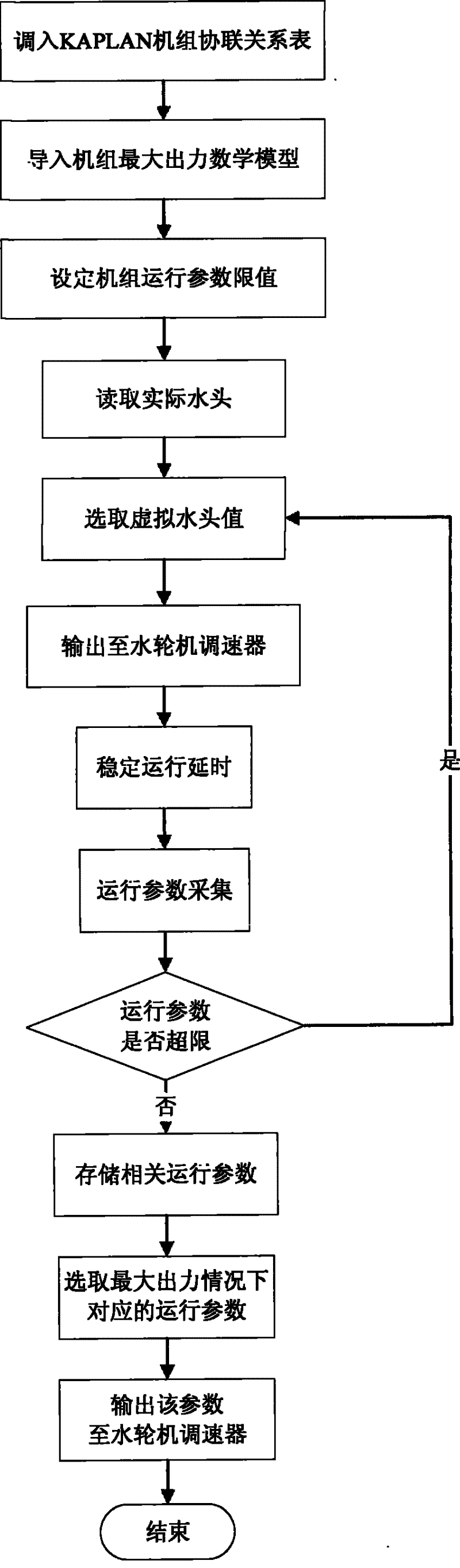

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The invention relates to an online adjustment method that can be based on the original water KAPLAN hydropower station computer adjustment control system.

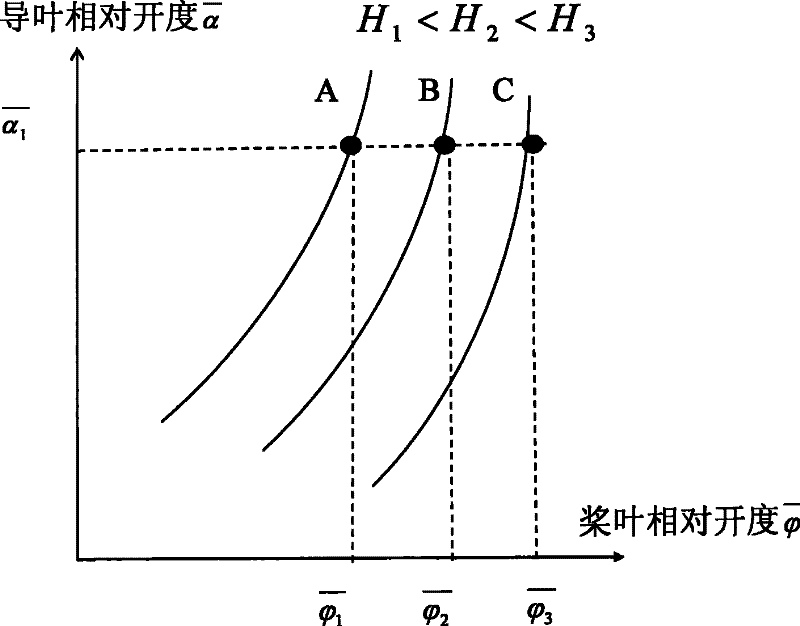

[0029] The advantage of the known KAPLAN unit hydropower station is that the generator set adopts dual regulation of the guide vane / blade. During control, the relative opening of the guide vane can be adjusted while the relative opening of the guide vane is adjusted according to the association relationship between the guide vane and the blade. , also automatically adjust the relative opening of the blades. After the actual water head H is obtained by the testing equipment of the hydropower station, the operator determines the relative opening of the input guide vane according to the actual water flow and operation requirements Then the computer control system will send this value to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com