Afterheat recovery type evaporation module and double-effect energy-saving evaporation system

A waste heat recovery and evaporation system technology, applied in heat pumps, fluid heaters, lighting and heating equipment, etc., can solve the problems of low cooling water discharge temperature, waste heat energy waste of cooling water, and low temperature, so as to ensure normal operation and stability The effect of economical operation and energy saving maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

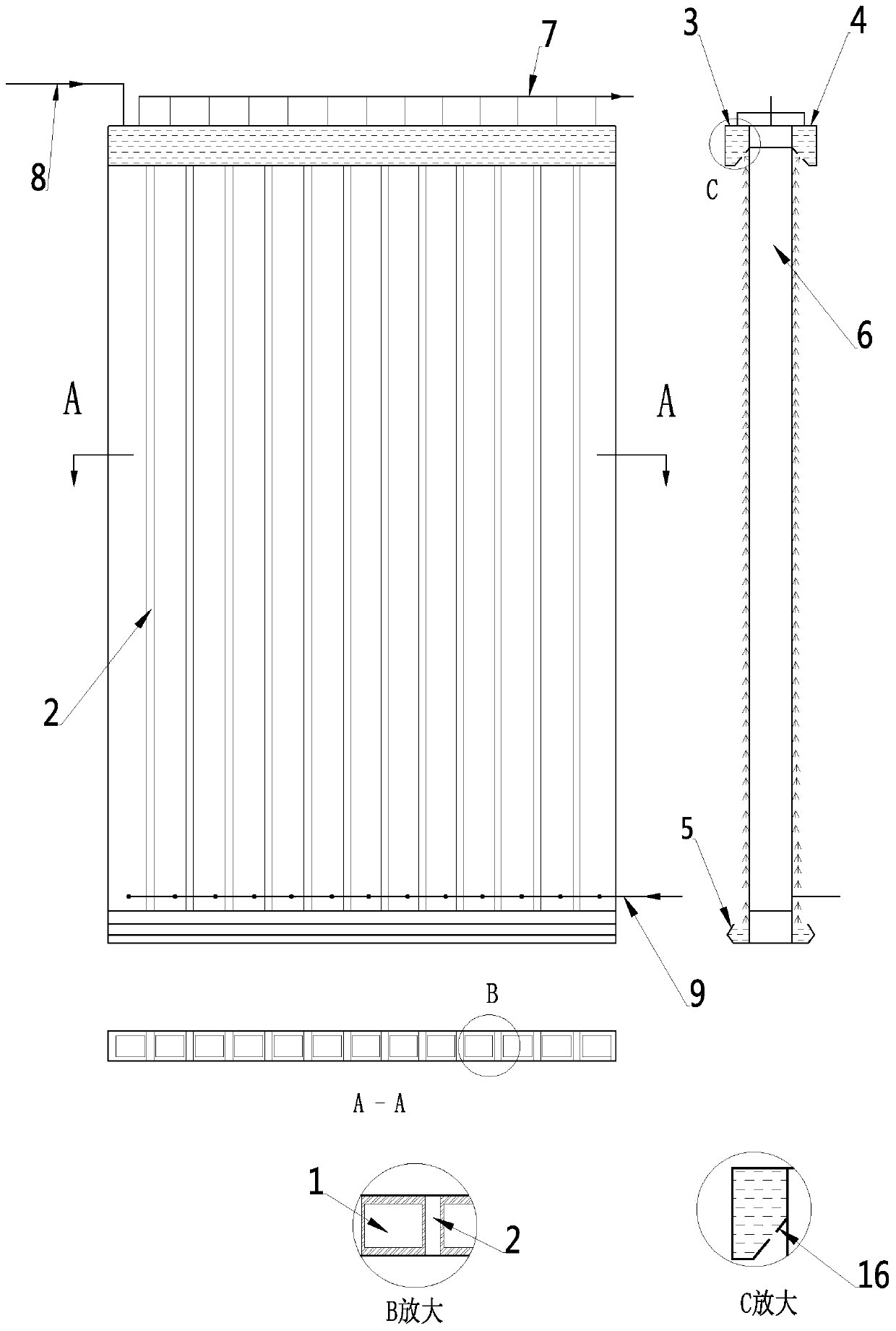

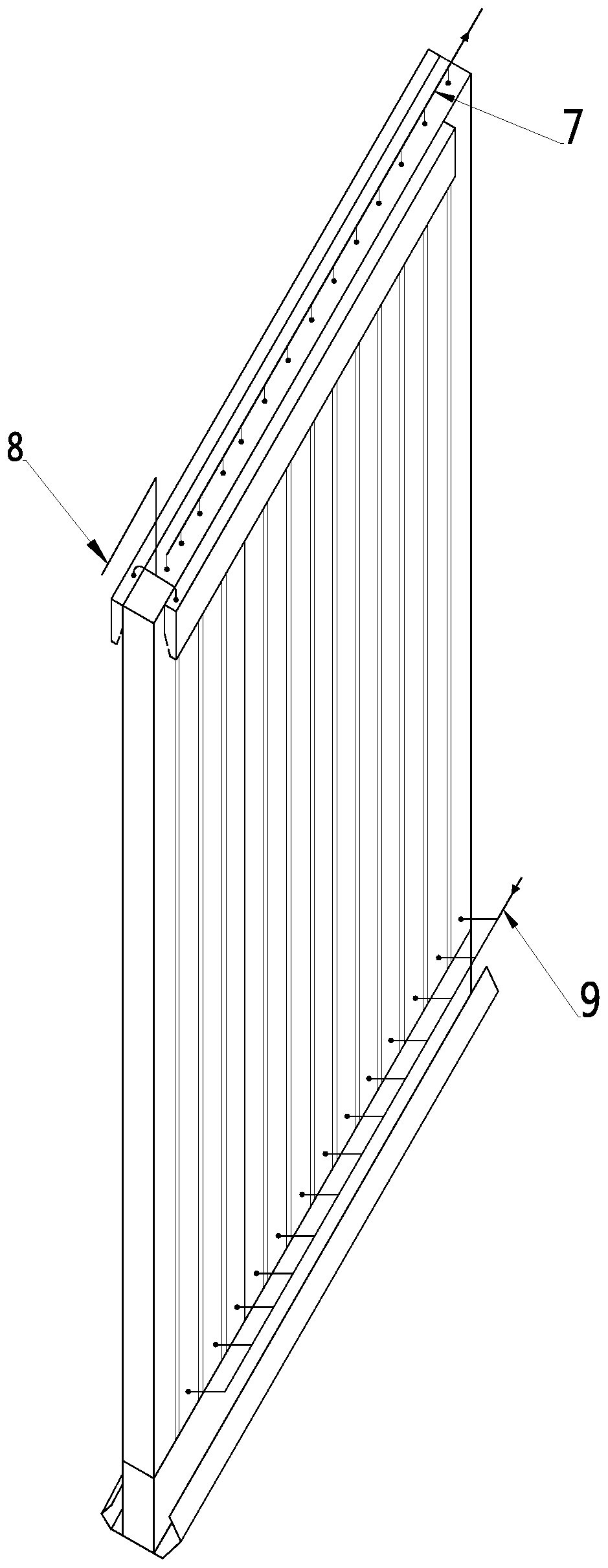

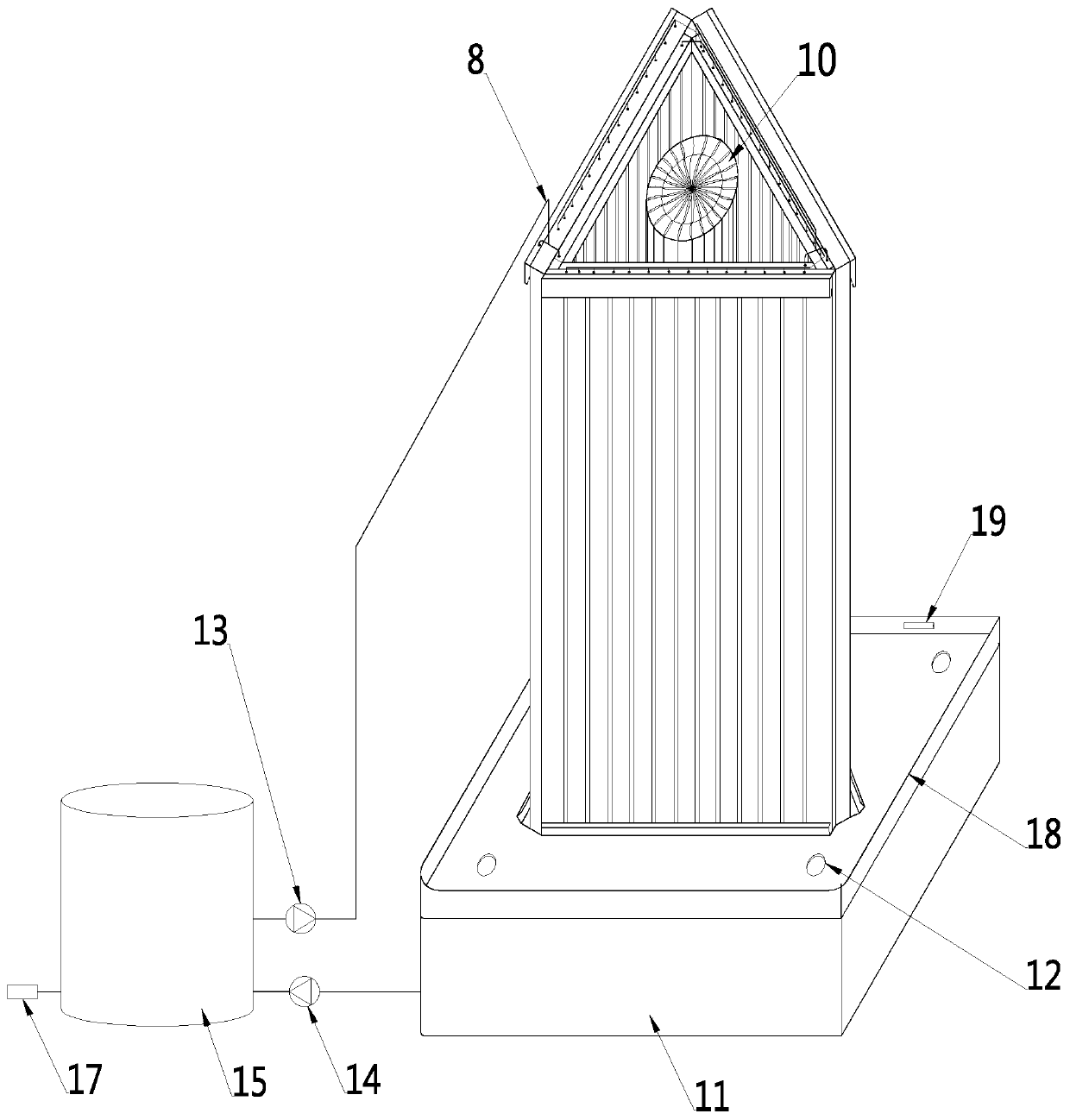

[0017] Such as Figure 1-3 As shown, the waste heat recovery type evaporation module and the double-effect energy-saving evaporation system of this embodiment include a trough-type working medium heat exchange plate 6, a heat exchange air duct 2, a waste heat source water separator I3, a waste heat source water separator II4, and Flow plate 5, cross-flow fan 10 and circulating water tank 11. It specifically includes working medium refrigeration cycle, waste heat source mode working cycle, and air source mode working cycle.

[0018] Refrigeration cycle of refrigerant: the refrigerant refrigerant from the throttling mechanism of the external compression condensing module (this device is general-purpose equipment, not described here) is throttled and depressurized, and enters the trough-type refrigerant heat exchange plate 6 through the refrigerant inlet assembly 9 In the working medium channel 1, evaporation and heat absorption are carried out. Here, the heat absorbed by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com