Method for manufacturing hollowed-out board

A technology of hollowed-out boards and circuit boards, which is applied in the manufacture of printed circuits, printed circuits, electrical components, etc., and can solve problems such as poor punching deviation, uncertain distance between the punched opening 3' and the hollowed-out pattern 9, etc., so as to improve the punching accuracy and avoid Bad offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

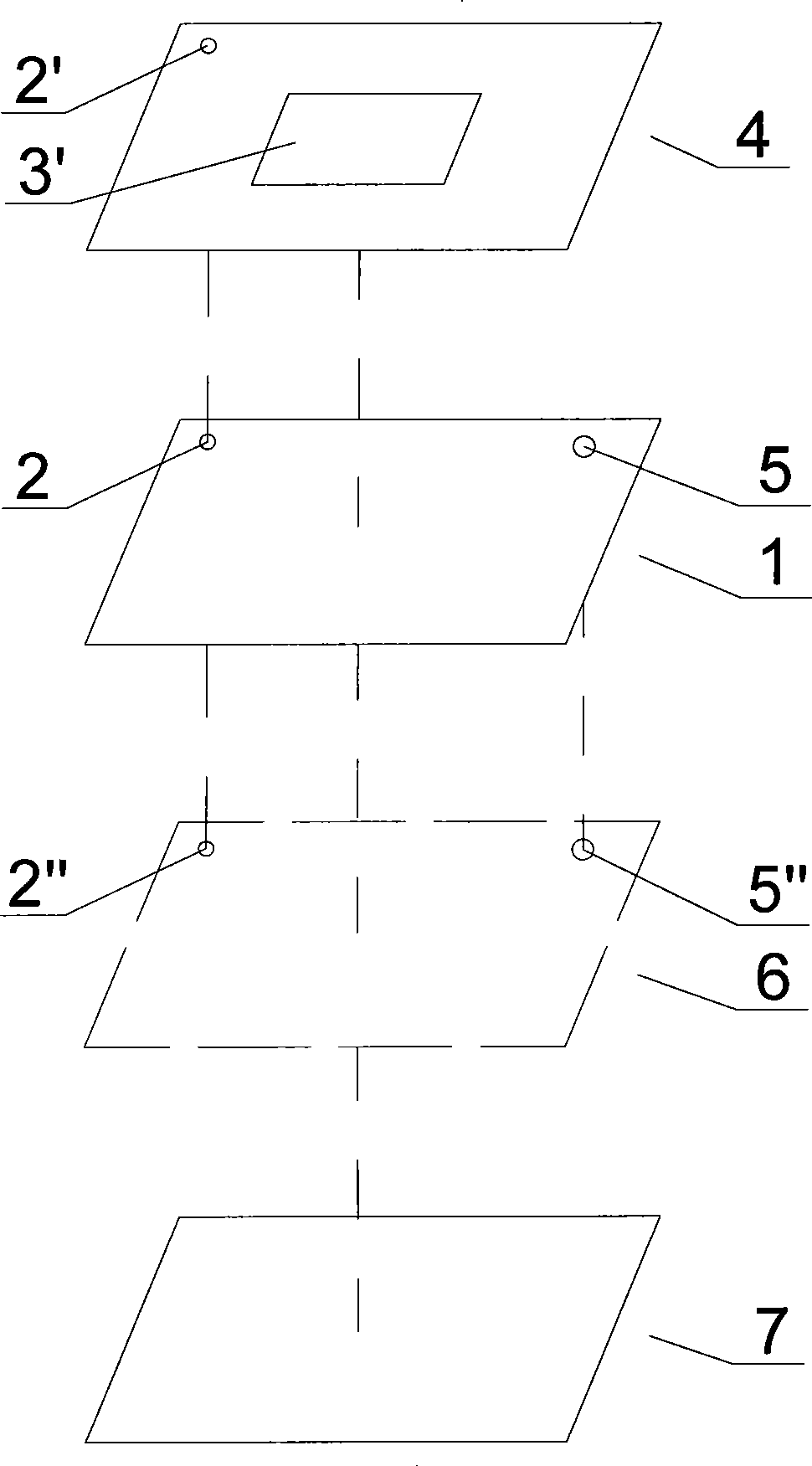

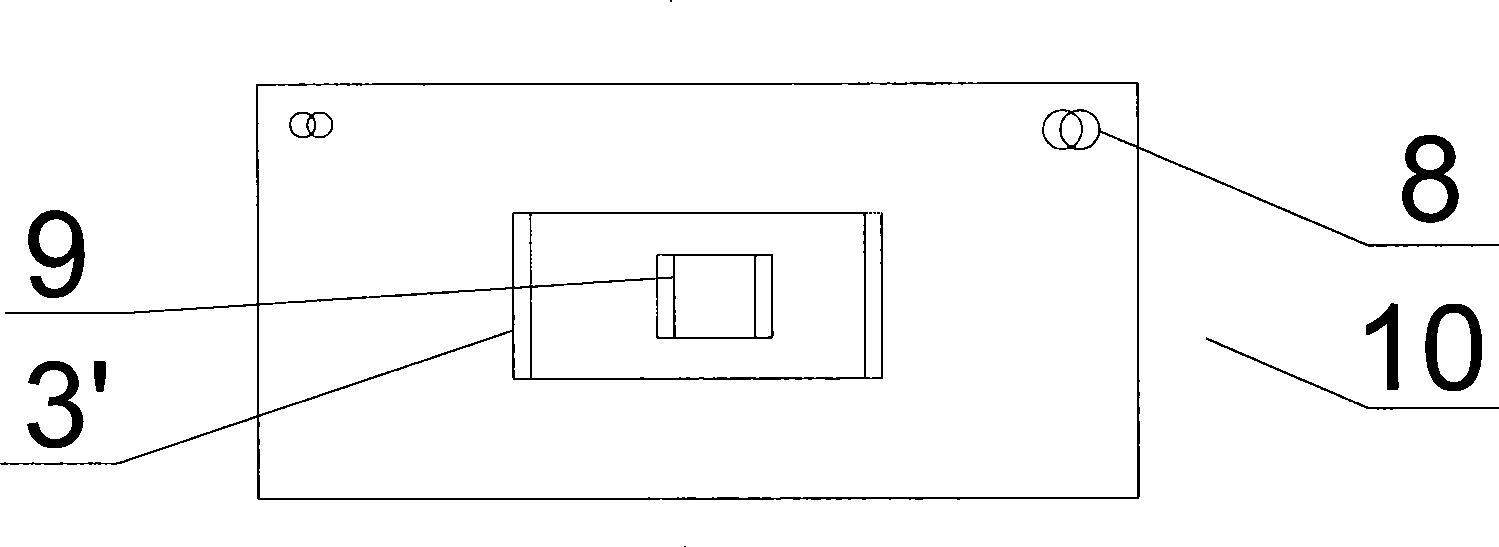

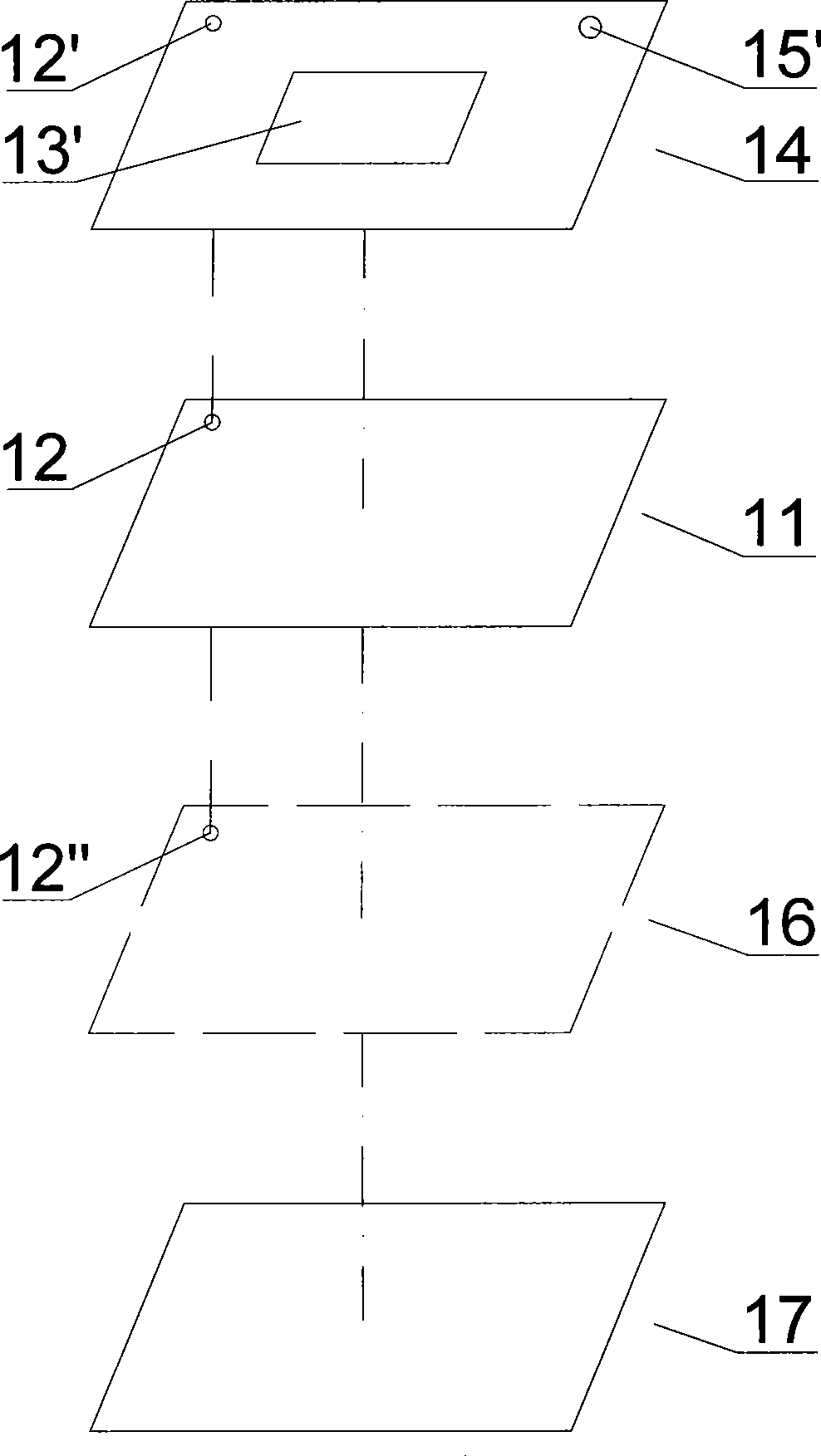

[0011] Below, combine image 3 with Figure 4 , the present invention is described in detail.

[0012] The method for manufacturing a hollow plate provided by the present invention includes: pressing the first covering film 14 formed with punching openings 13' and punching positioning holes 15' onto the first surface of the copper foil 11; After the circuit formation is completed on both sides, the second cover film 17 is pressed on the second surface of the copper foil 11 to obtain the circuit board 100; then punching is performed in alignment with the punching positioning hole 15' on the first cover film 14, Forming punching and positioning through-holes 18 on the circuit board 100; then punching the circuit board 100 based on the punching and positioning through-holes 18, so as to punch out hollow patterns 19 in the area of the punching opening 13' .

[0013] Preferably, a first press-fit alignment hole 12 is formed on the copper foil 11, a second press-fit alignment h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com