Sliding mechanism

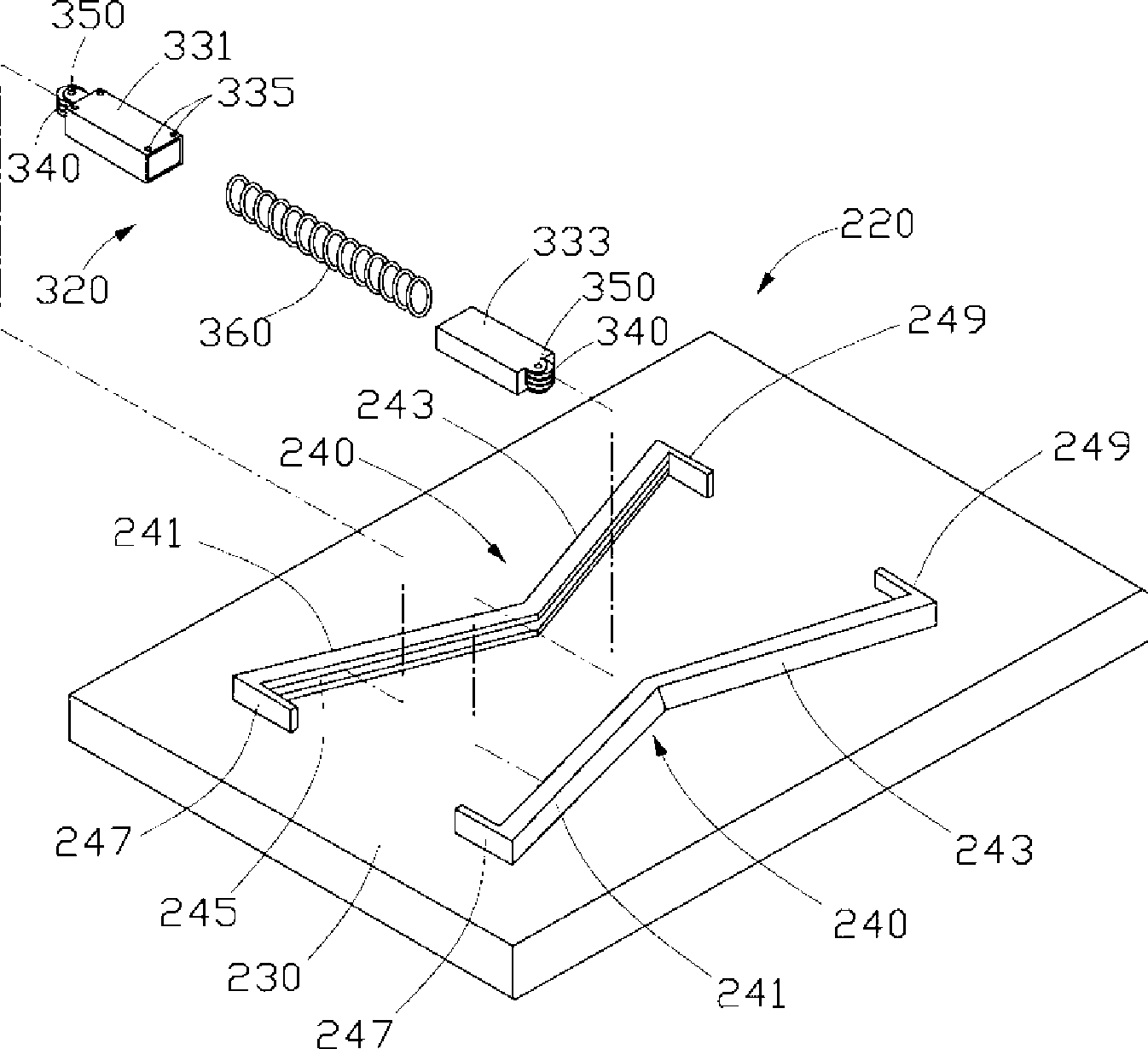

A sliding mechanism and sliding cover technology are applied in the directions of telephone structure, support structure installation, casing/cabinet/drawer parts, etc., which can solve problems such as affecting the service life, wearing of related components, and hindering the sliding of the connecting assembly 320. , to achieve the effect of prolonging the service life and reducing the sliding friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

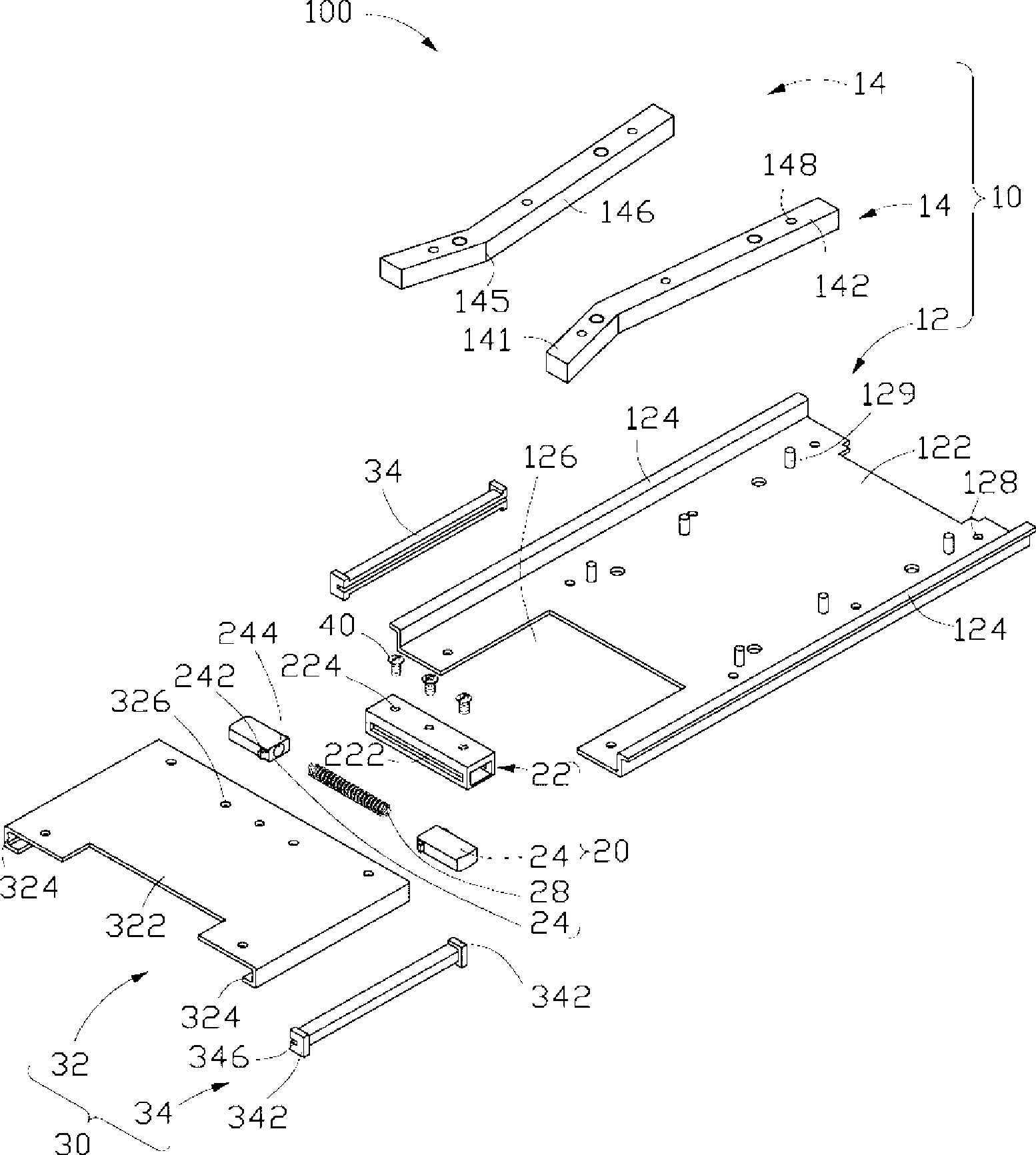

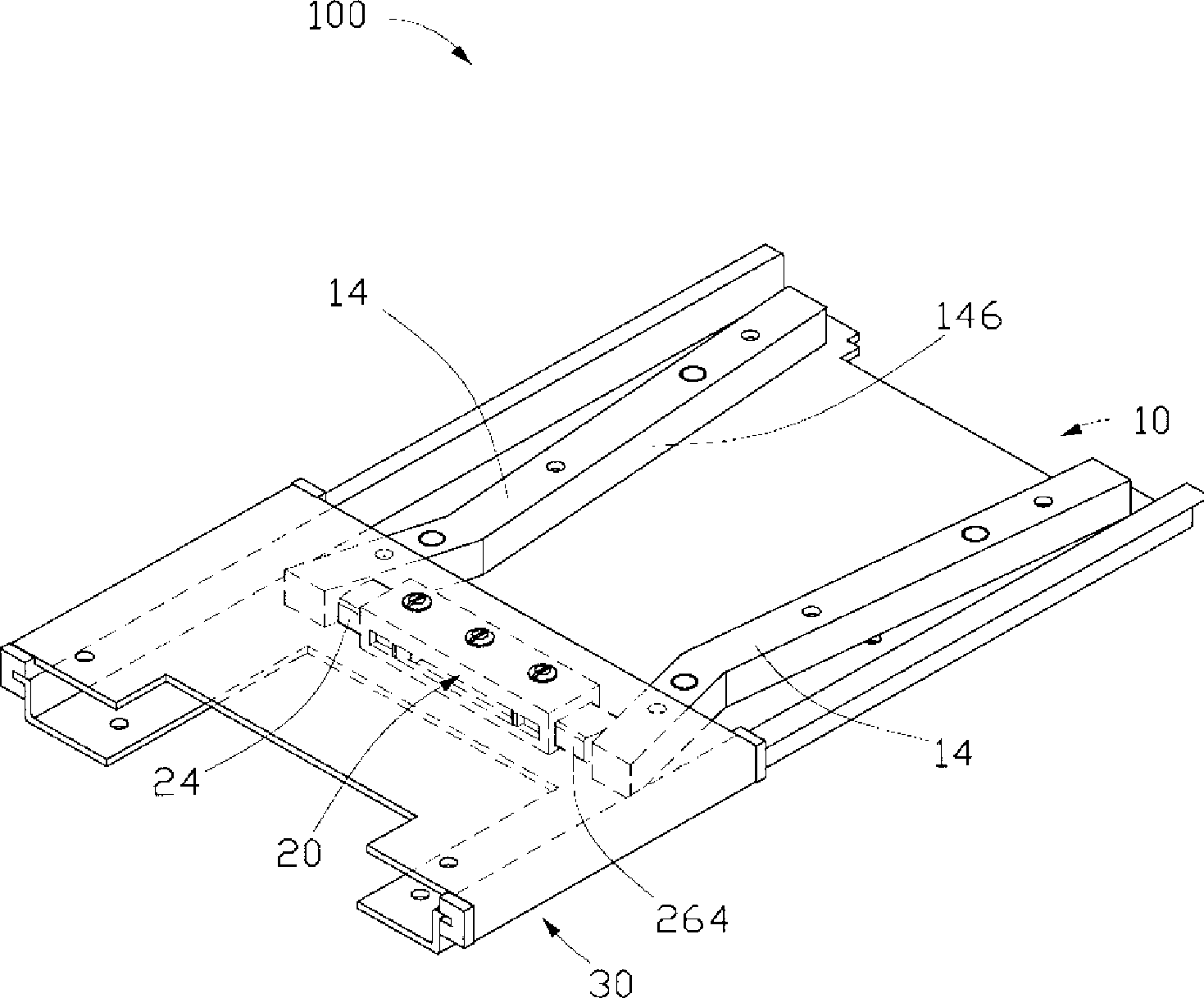

[0017] The sliding mechanism of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0018] see figure 2 , the sliding mechanism 100 of the first preferred embodiment of the present invention includes a back plate assembly 10 , a connecting assembly 20 and a sliding assembly 30 .

[0019] The backplane assembly 10 includes a backplane 12 and two guide rails 14 mounted on the backplane 12 .

[0020] The backboard 12 is substantially a rectangular board, which includes a bottom board 122 and two raised sides 124 . The two protruding sides 124 are formed by bending and protruding slightly from two opposite sides of the bottom plate 122 towards the same side of the bottom plate 122 . One end of the bottom plate 122 is provided with a square gap 126, and the bottom plate 122 is also provided with a number of round holes 128 for connecting the back plate 12 to the body with buttons in the electronic device. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com